Double-layered speed skating wheel

A pulley and double-layer technology, applied in skating, skating boards, roller skates, etc., can solve the problems of insufficient acceleration, affecting stunt actions, and affecting competition results, etc., to achieve good grip, facilitate exhaust, increase intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

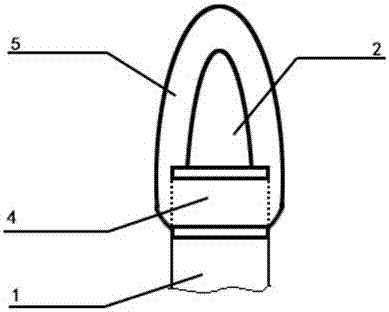

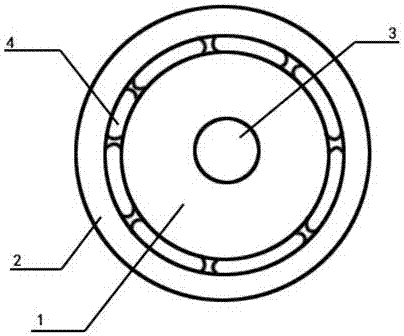

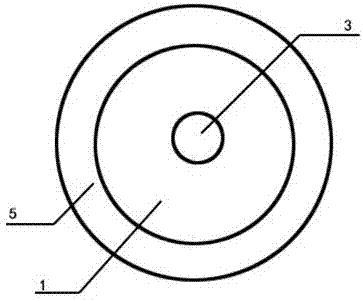

[0014] refer to Figure 1-2 , a double-layer speed pulley, which includes a core 1, an inner tank 2, and an outer tank 5, the core 1 is in a circular shape, and a circle of waist-shaped holes 4 is added to the edge of the core 1, and the center of the core 1 is designed with a shaft hole 3 for For installation, an inner liner 2 is designed on the outer side of the inner liner 1, and the inner liner 2 is in the shape of a ring, and the inner liner 2 is fixedly connected with the outer edge of the inner liner 1 through injection molding, and the outer liner 5 is located on the outer side of the inner liner 2 in a ring shape, and the outer liner 5 is in the shape of a ring. The liner 5 wraps the inner liner 2, and the inner side of the outer liner 5 wraps the waist-shaped hole 4 on the edge of the inner liner 1 by injection molding, and the outer liner 5 is fixedly connected with the inner liner 2 and the inner liner 1.

[0015] The material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com