Steel plate lifting and conveying mechanism

A technology of lifting and conveying and steel plates, which is applied to the direction of conveyor objects, transportation and packaging, roller tables, etc., can solve the problems of complex operation process and structure, affecting production and processing efficiency, and inaccurate positioning, so as to improve stability and safety , The lifting process is stable and reliable, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

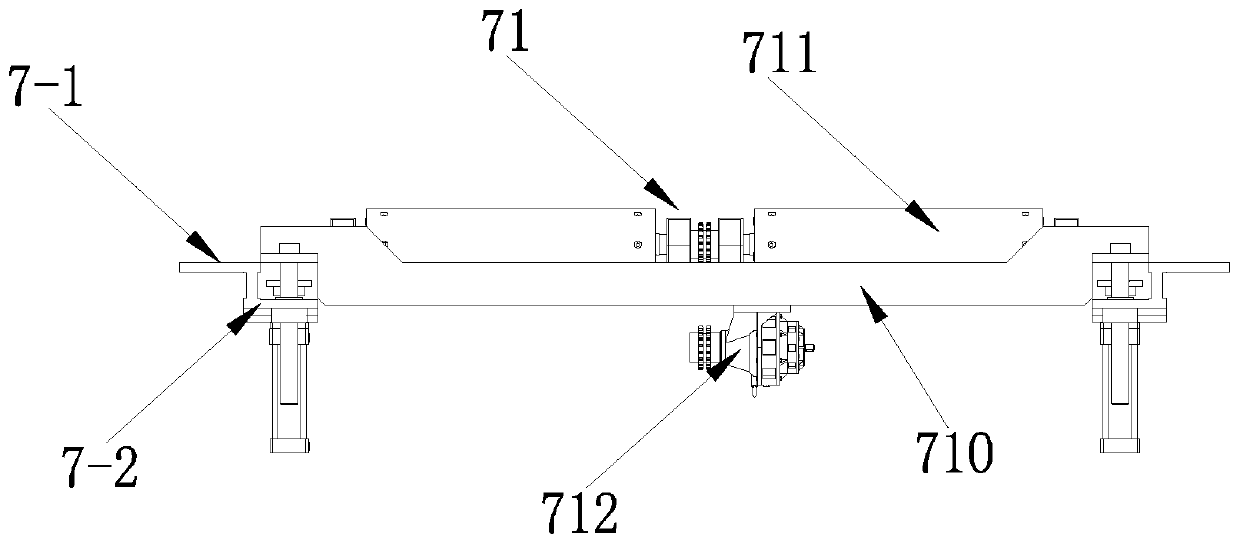

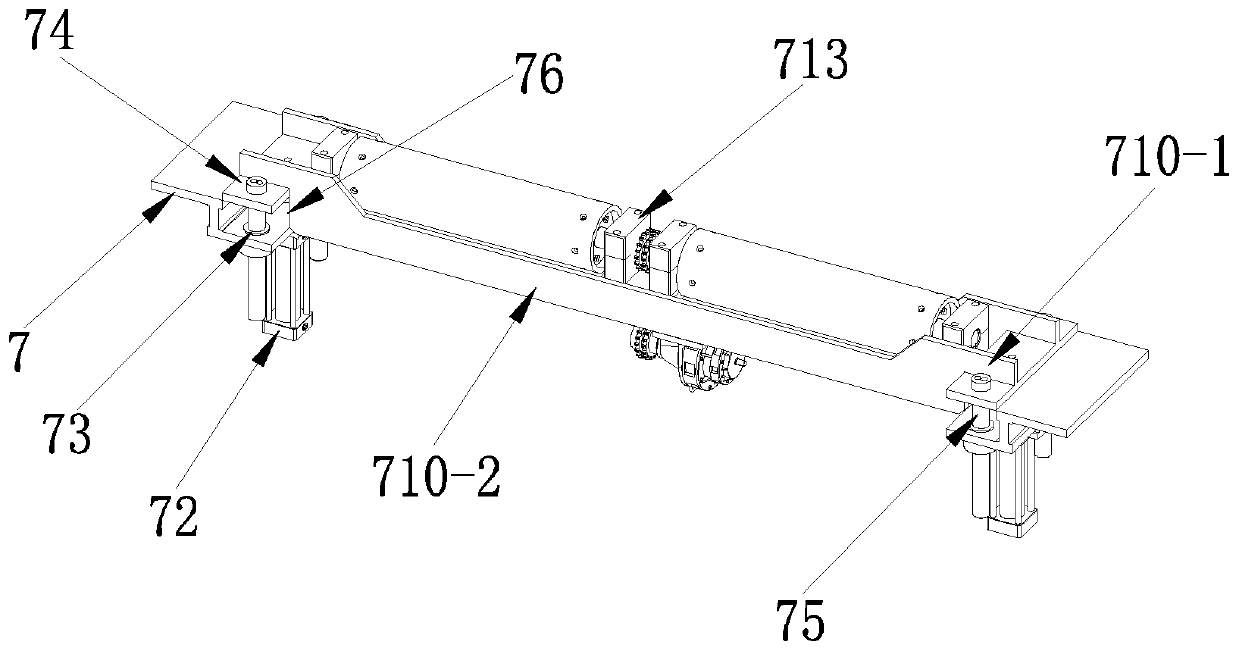

[0025] Embodiment 1: as Figure 1-2 As shown, a steel plate lifting and conveying mechanism includes positioning plates 7 fixed on both sides of the conveying bracket, a conveying device 71 is installed between the positioning plates 7 on both sides, and a driving cylinder 72 is fixed at the bottom of the positioning plate 7, and the driving cylinder The drive shaft of 72 passes through the positioning plate 7 and is opposed to the conveying device 71, which is used to drive the lifting of the conveying device 71; the present invention is simple in structure and easy to operate, and is used to drive the conveying device by driving the cylinder to make the conveying device vertically lift. There is no skewing, which improves the stability and safety of the conveying device for conveying steel plates; the conveying device can be raised and lowered to different heights by driving the cylinder, and can be positioned accurately, and the lifting process is stable and reliable.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com