H-shaped steel conveying and jacking mechanism

A technology of conveying mechanism and H-shaped steel, which is applied in the field of steel plate processing, can solve the problems affecting the operation accuracy and product quality of H-shaped steel, the unsafe and stable placement of H-shaped steel, and the inaccurate positioning, so as to improve continuous production efficiency and product quality , Simple structure, precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

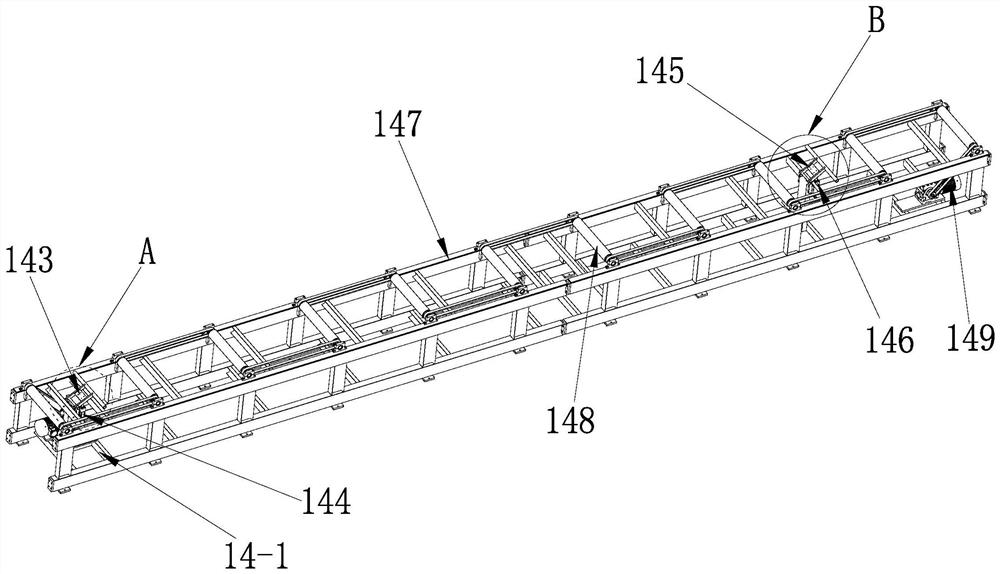

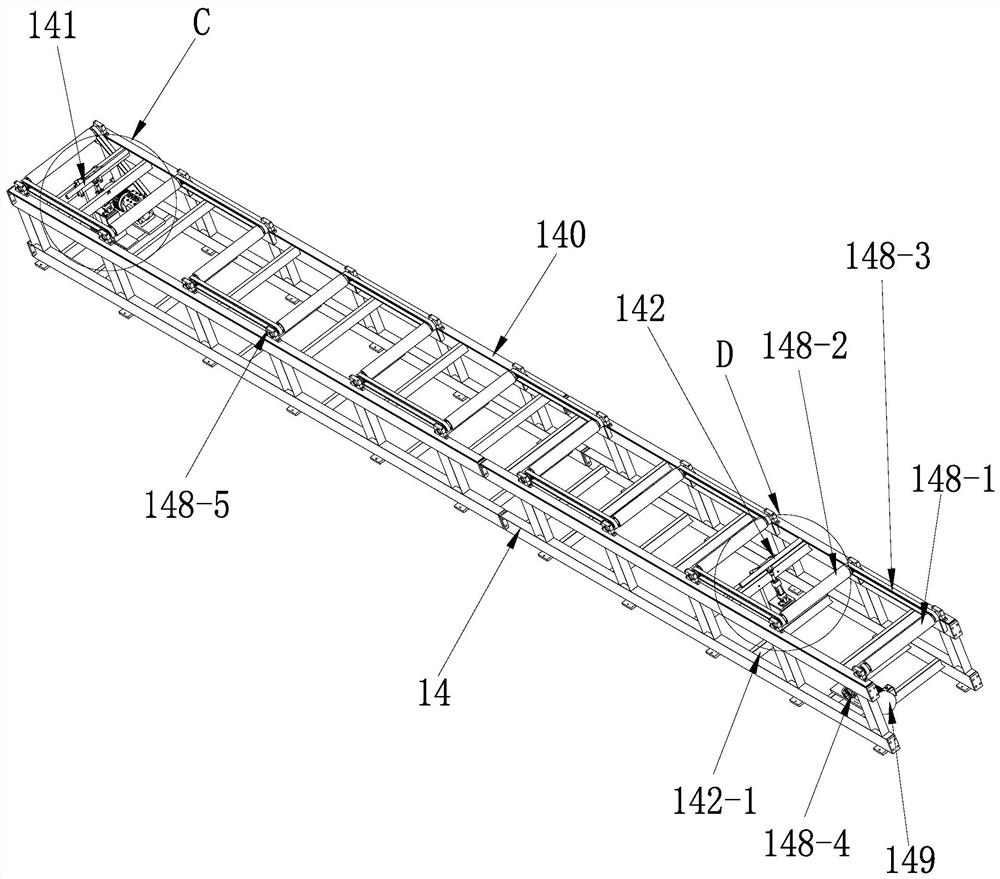

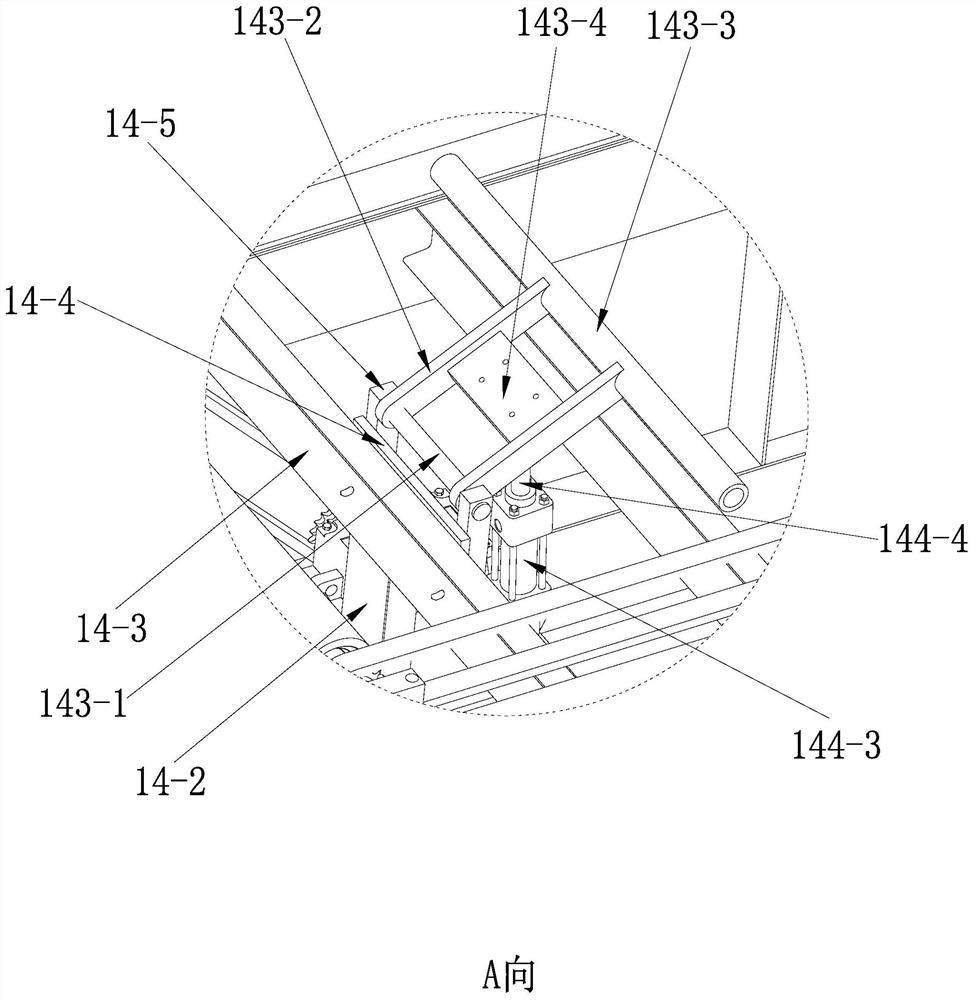

[0033] Example: such as Figure 1-6 As shown, a H-shaped steel conveying and tightening mechanism includes a base 14 and a steel plate conveying mechanism 140 arranged on the base 14; both ends of the base 14 are provided with a front stopper mechanism 141 and a rear stopper mechanism 142 for positioning the H-shaped steel The front retaining mechanism 141 includes a front base plate 14-1 fixed on the base 14, a front support plate 14-2 is vertically fixed on the front base plate 14-1; a front support plate 14-2 is vertically arranged on the front support plate 14-2. The positioning plate 14-3, the front positioning plate 14-3 is assembled on the steel plate conveying mechanism 140, the front positioning plate 14-3 inner side is fixed with the front mounting plate 14-4, and the front mounting plate 14-4 is symmetrically fixed with the front support Seat 14-5, the front support 14-5 is rotatably connected with a front stop bar 143; the front bottom plate 14-1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com