Rotary cross beam workbench

A technology for rotating worktables and worktables, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. It can solve the problems of high speed, low precision, and many internal bearing structures of rotary worktables, and achieve the reduction of moving space requirements , high-efficiency and high-precision processing, and the effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Combine below Figures 1~7 The embodiments of the present invention will be described in detail.

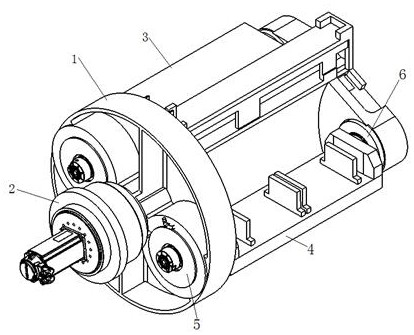

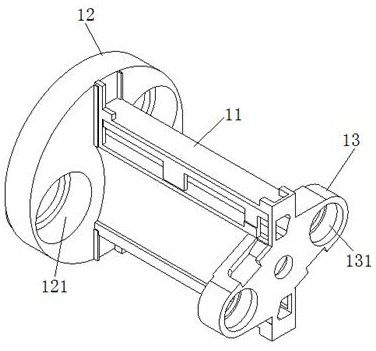

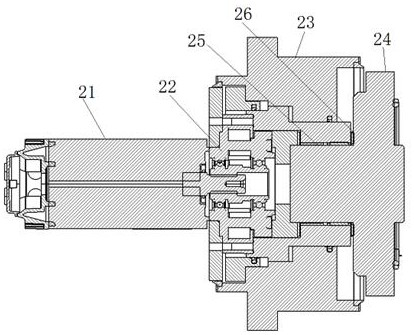

[0032]The rotary beam table includes a beam rotary table 1 and a rotary power assembly 2 that drives the beam rotary table 1 to rotate. 1. Parallel and multiple, multiple rotating worktables 3 are evenly distributed in the circumferential direction of the beam turntable 1, the workpiece is clamped on the rotating worktable 3, and the rotary power assembly 2 and the rotating worktable 3 are controlled by the control system.

[0033] In the above-mentioned rotary beam table, the rotary table 3 is mounted on the beam rotary table 1 and evenly distributed in the circumferential direction of the beam rotary table 1. The rotary power assembly 2 drives the beam rotary table 1 to rotate, so that the plurality of rotary table 3 are synchronized. Rotating to different stations, the workpieces on each rotating table 3 complete the corresponding processing procedures at their respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com