Feeding roller bed of chamfering machine

A technology of chamfering machine and material roller, applied in the direction of roller table, mechanical equipment, conveyor objects, etc., can solve the problems of low degree of automation, slow operation speed, poor accuracy, etc., to achieve convenient operation, improve conveying speed, reduce The effect of waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

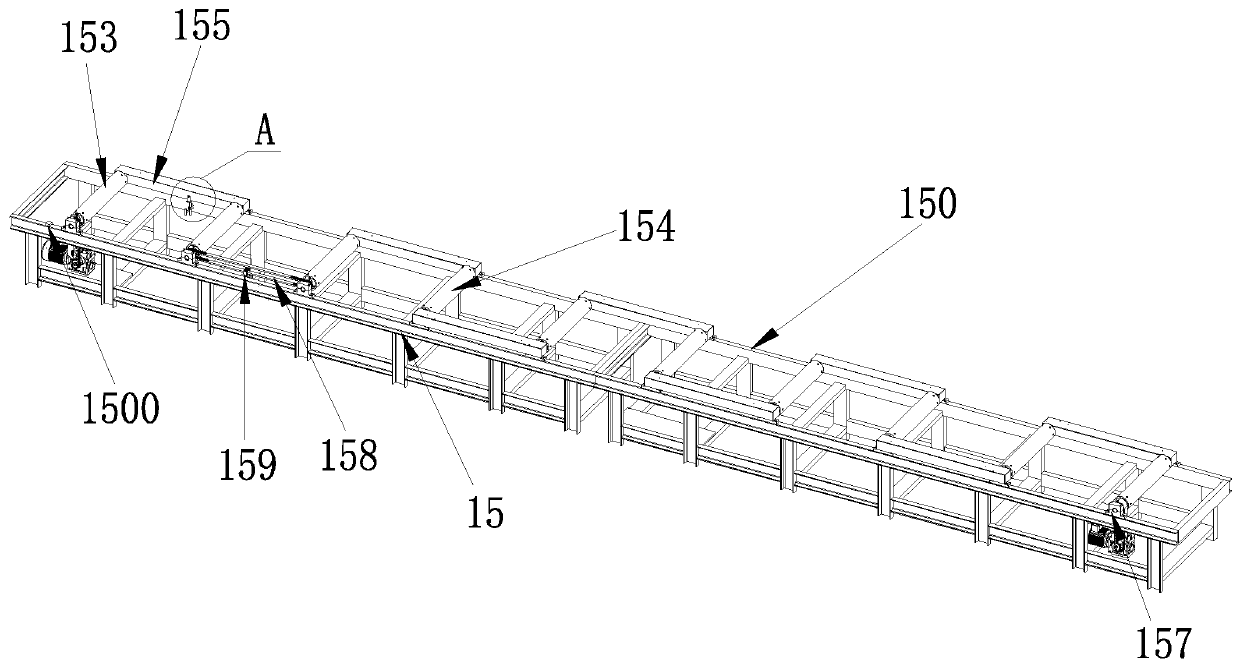

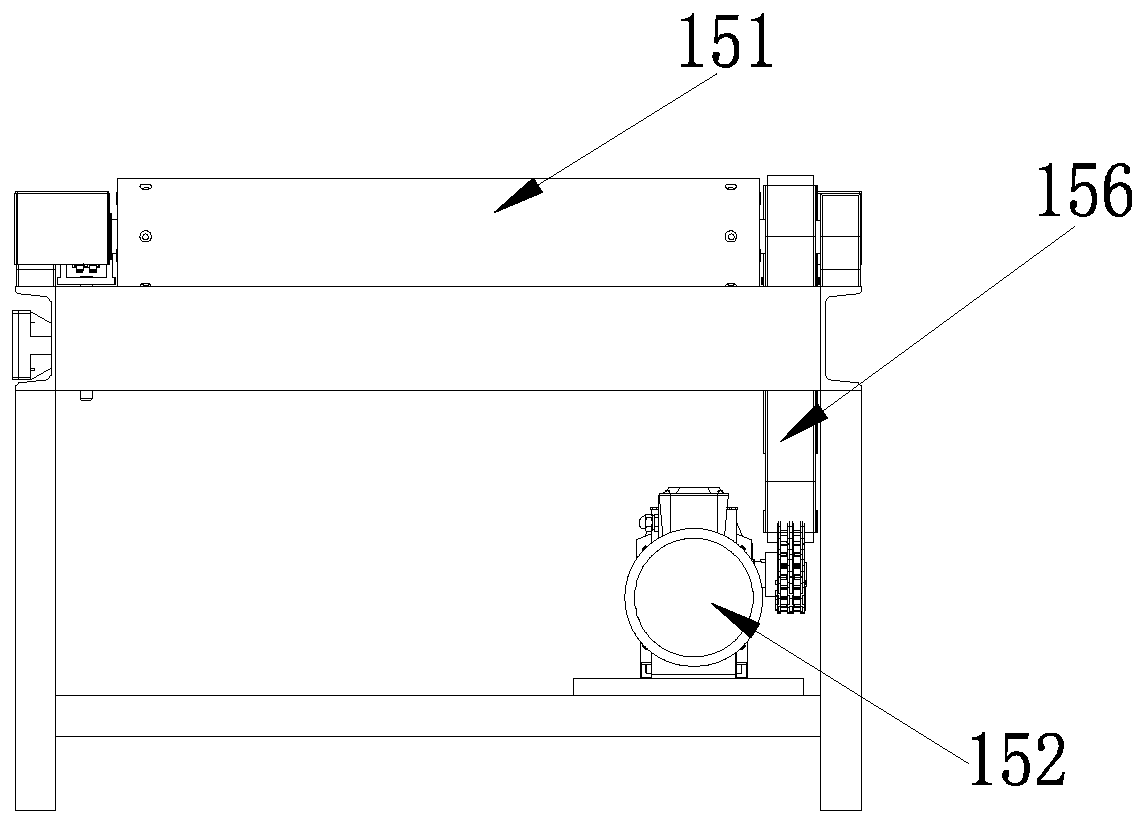

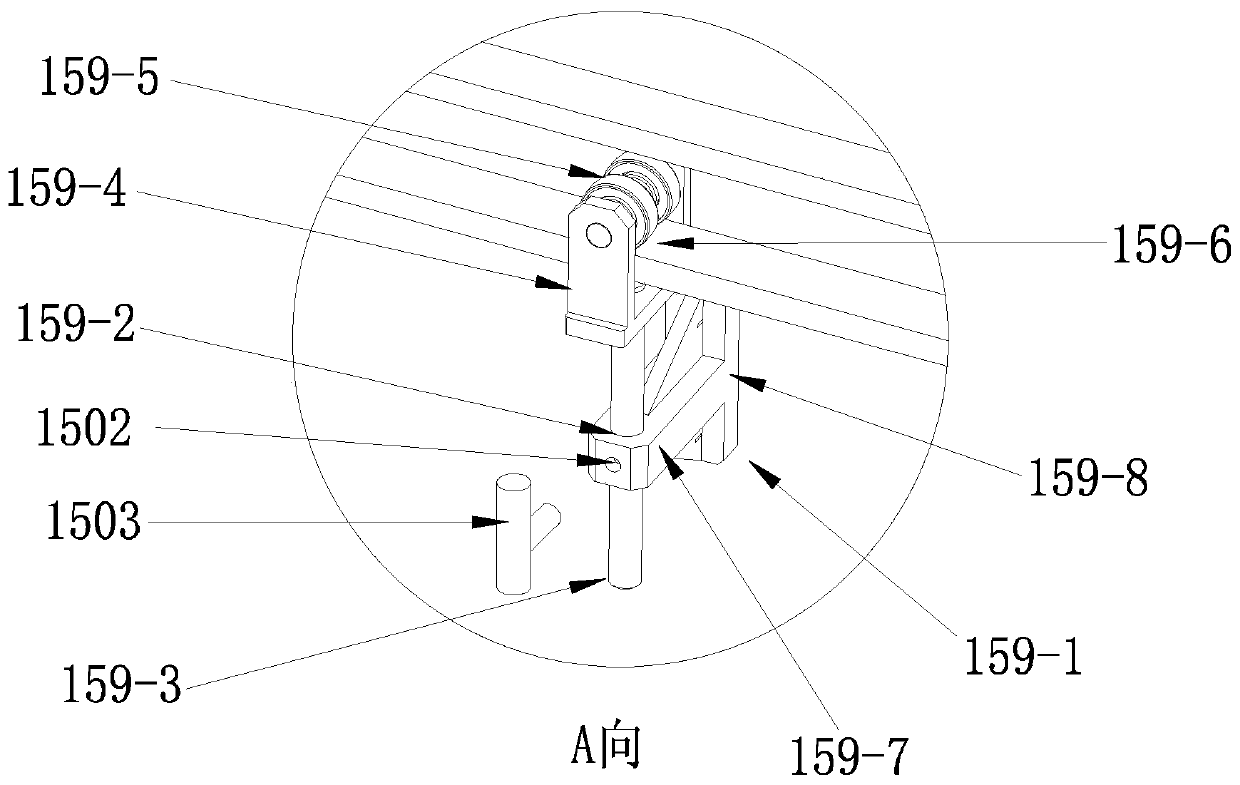

[0030] Embodiment 1: as Figure 1-3 As shown, a feeding roller table of a chamfering machine includes a platform 15 arranged horizontally, on which a linear guide rail 150, a buffer assembly 151 and a drive motor 152 for placing steel plates are installed; the buffer assembly 151 includes at least one receiving material Roller 153 and conveying roller 154; Feeding roller 153 and conveying roller 154 end-to-end are installed on the linear guide rail 150; Feeding roller 153 and conveying roller 154 are connected by connecting chain 155; The end of feeding roller 153 is connected by connecting chain 156 is connected with the driving motor 152; the driving motor 152 is fixedly located at the bottom of the platform 15; the present invention is simple in structure and easy to operate, by setting the material receiving roller and some driving rollers, and then realizing the active transmission between the conveying rollers through the chain, greatly improving Improve the transportati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com