Powder briquetting machine products discharging automatic picking, cleaning and transmitting system

An automatic picking and conveying system technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of a large amount of manual labor and low degree of automation, and achieve the effects of reducing labor intensity, high degree of automation, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

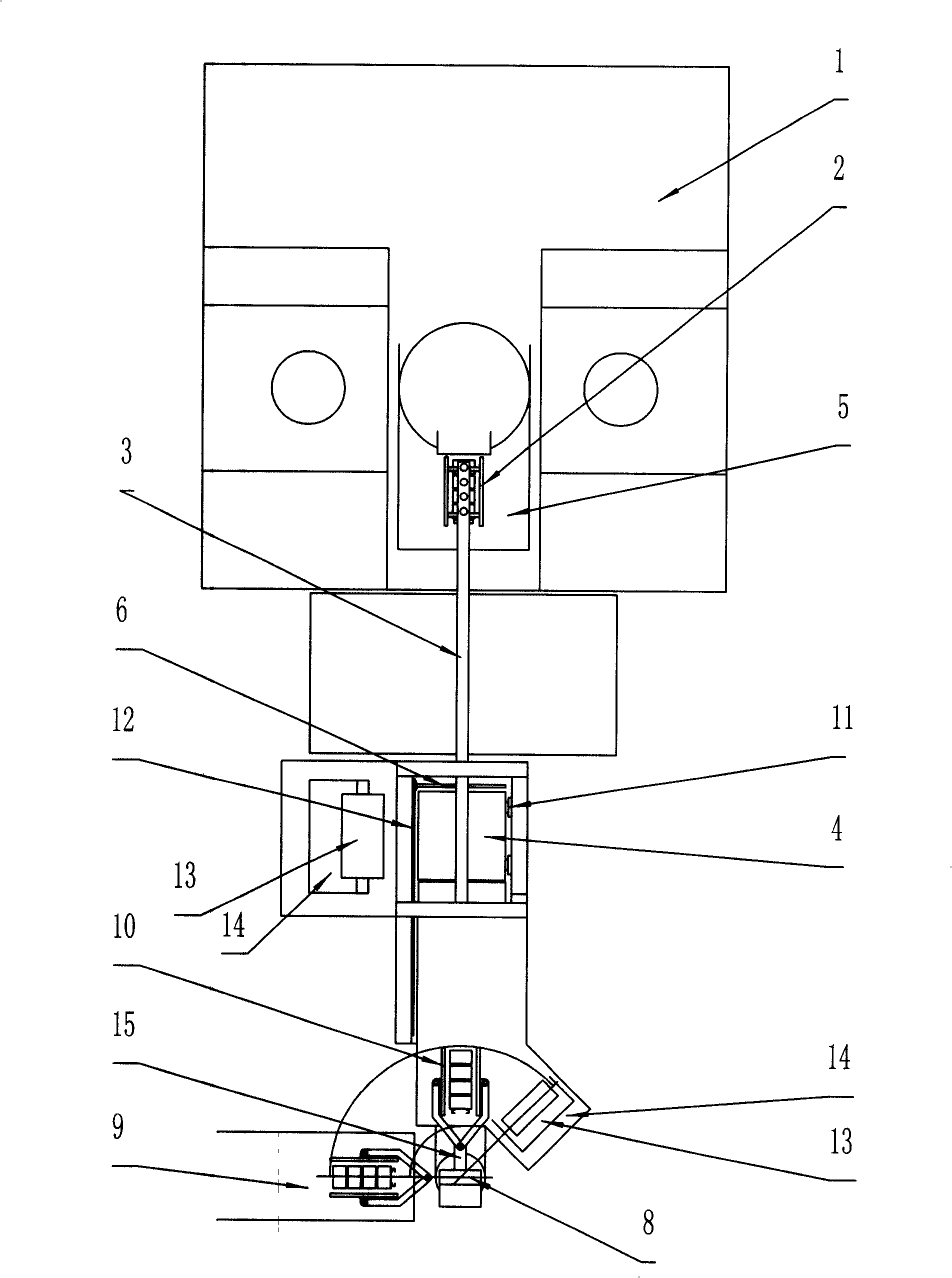

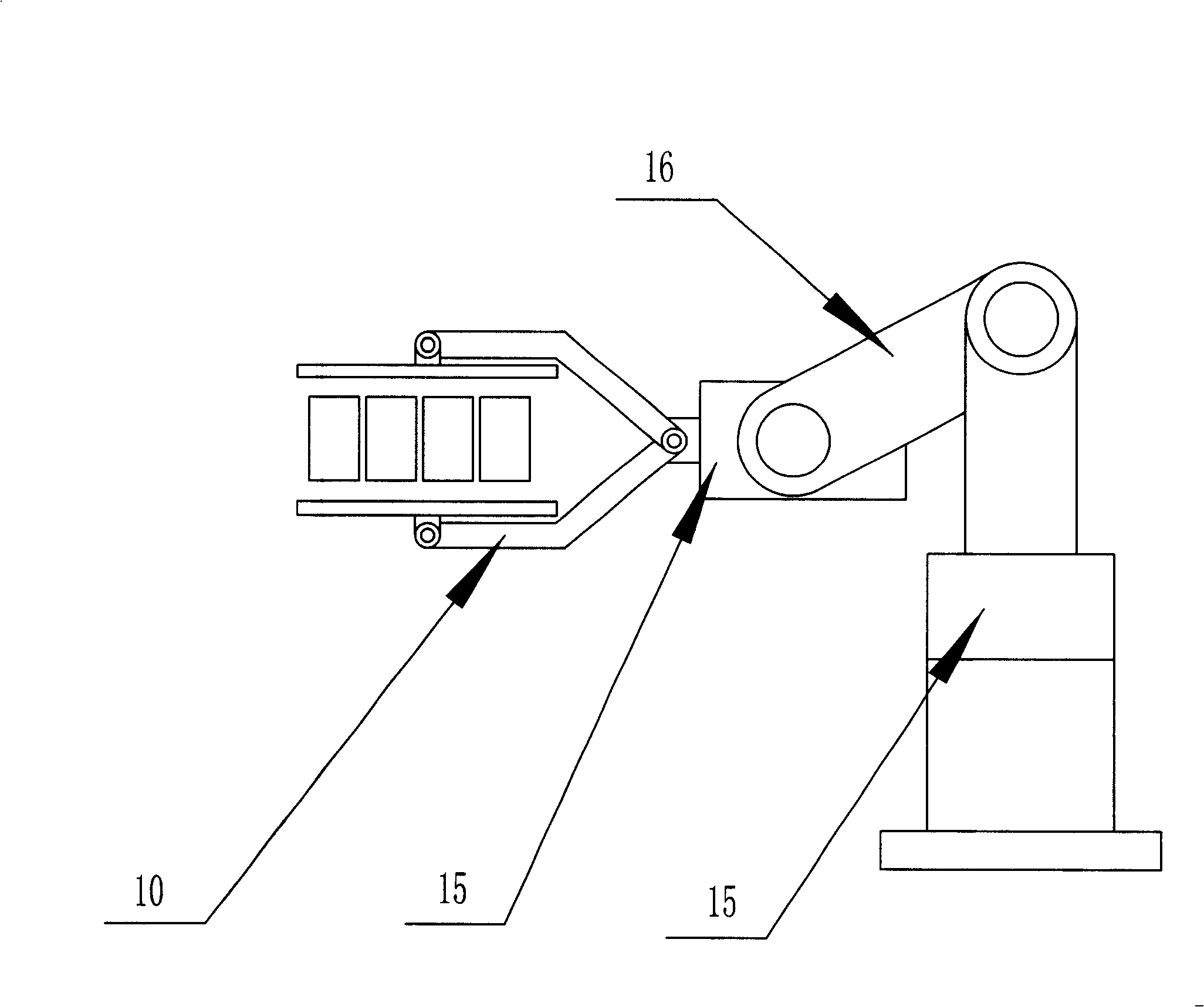

[0027] refer to figure 1 , figure 2 , an automatic pick-up, cleaning, and conveying system for powder press product discharge, including a frame, a pressed product picking mechanism, and a grabbing and conveying mechanism, and the pressed product picking mechanism includes a grabbing manipulator 2 for grabbing pressed products, a beam Guide rail 3, supporting plate 4, the grabbing manipulator 2 is slidably connected with the beam guide rail 3, and the grabbing manipulator 2 is connected with the driving device for controlling the grabbing manipulator to grasp and place and move on the beam guide rail , the support plate 4 is arranged horizontally, the beam guide rail 3 and the support plate 4 are installed on the frame; one end of the beam guide rail 3 is located on the mold base of the powder press 1, and the receiving plate 5 of the pressed product is placed Above, the other end is located at the top of the supporting plate 4; the grasping conveying mechanism includes an o...

Embodiment 2

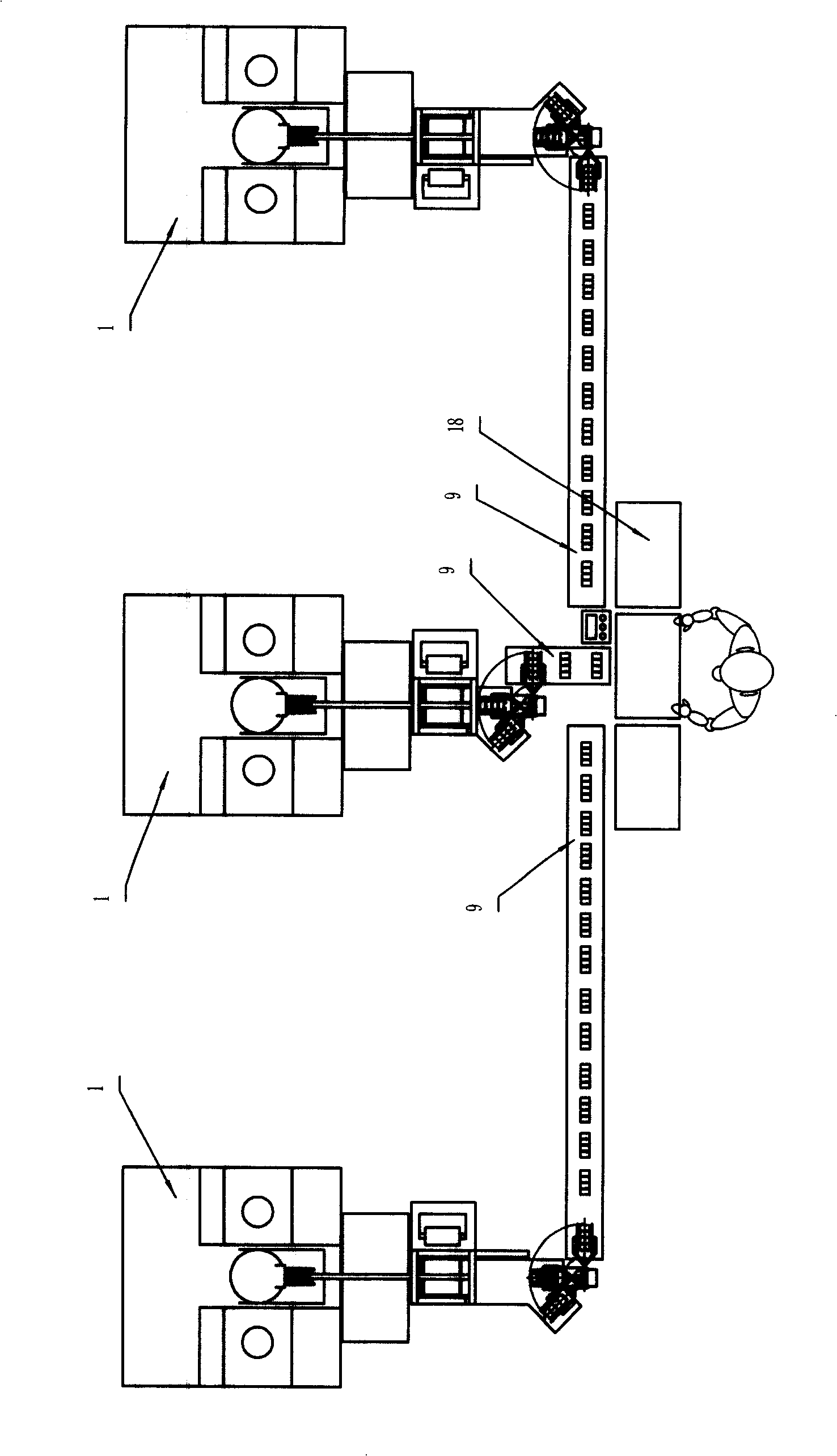

[0036] refer to figure 1 , figure 2 as well as image 3 , this embodiment includes at least two sets of pressed product picking mechanisms and grabbing and conveying mechanisms connected to at least two presses; each of the pressed product picking mechanisms and grabbing and conveying mechanisms is arranged on the discharge side of the corresponding powder press, The inlet end of the conveying equipment 9 of each grabbing and conveying mechanism is connected to the industrial robot 8 corresponding to the pressed product picking mechanism, and the outlet end is connected to the same packing station. Realize the operation mode of one person with multiple machines: such as one person with two machines, one person with three machines, and one person with four machines; the structure and working process of the pressed product picking mechanism, lifting mechanism, pushing mechanism, and grabbing and conveying mechanism in this embodiment are consistent with the embodiment 1 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com