Patents

Literature

41results about How to "Achieve tension control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

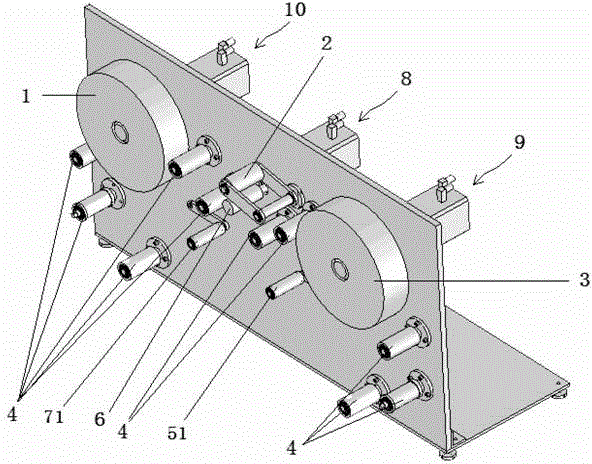

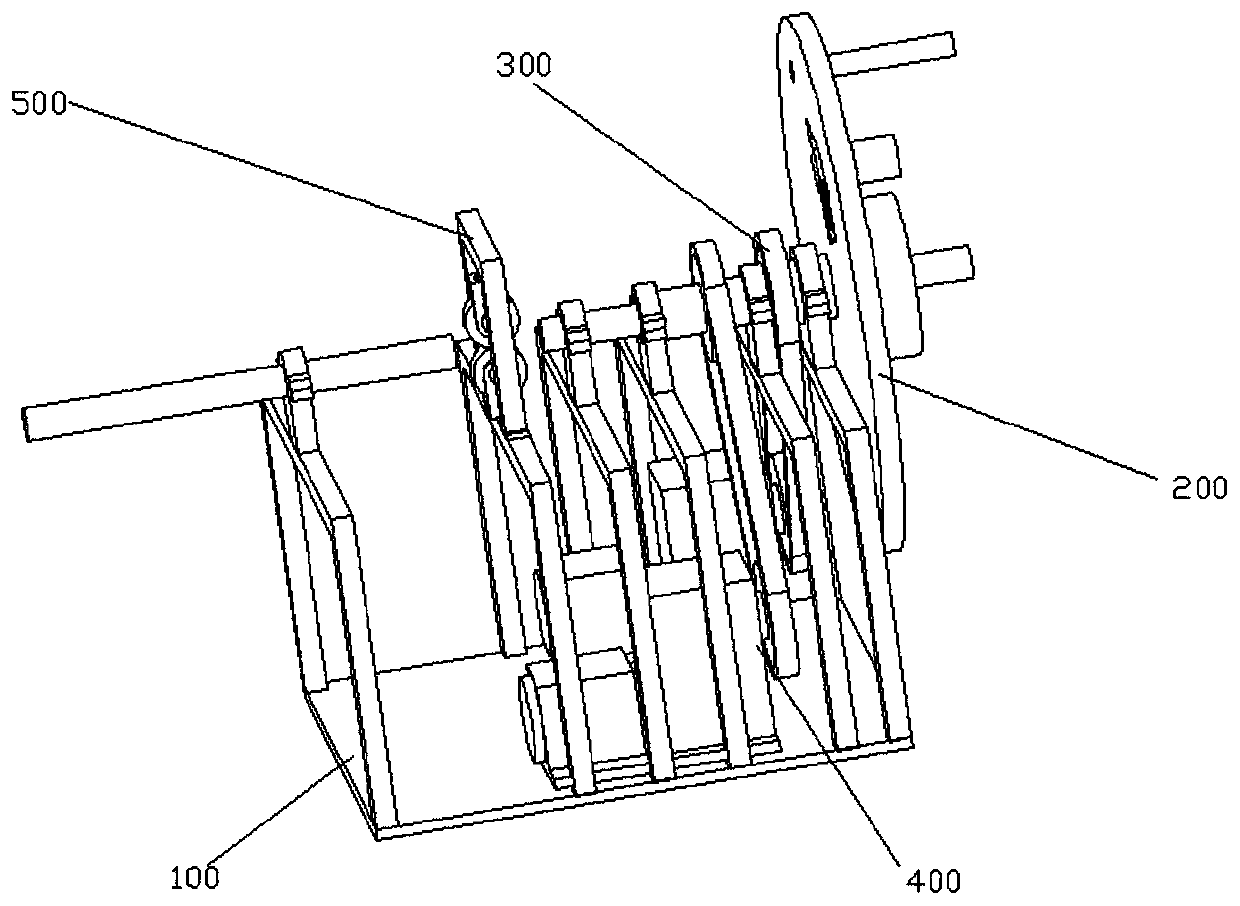

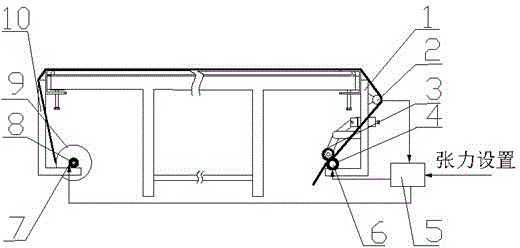

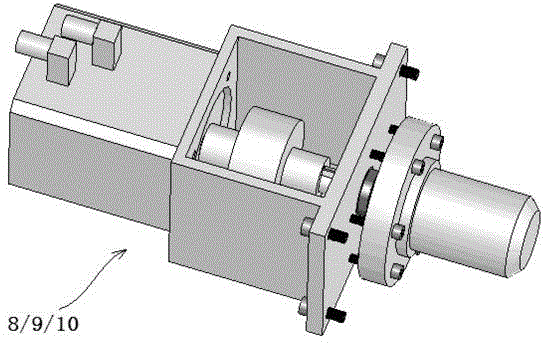

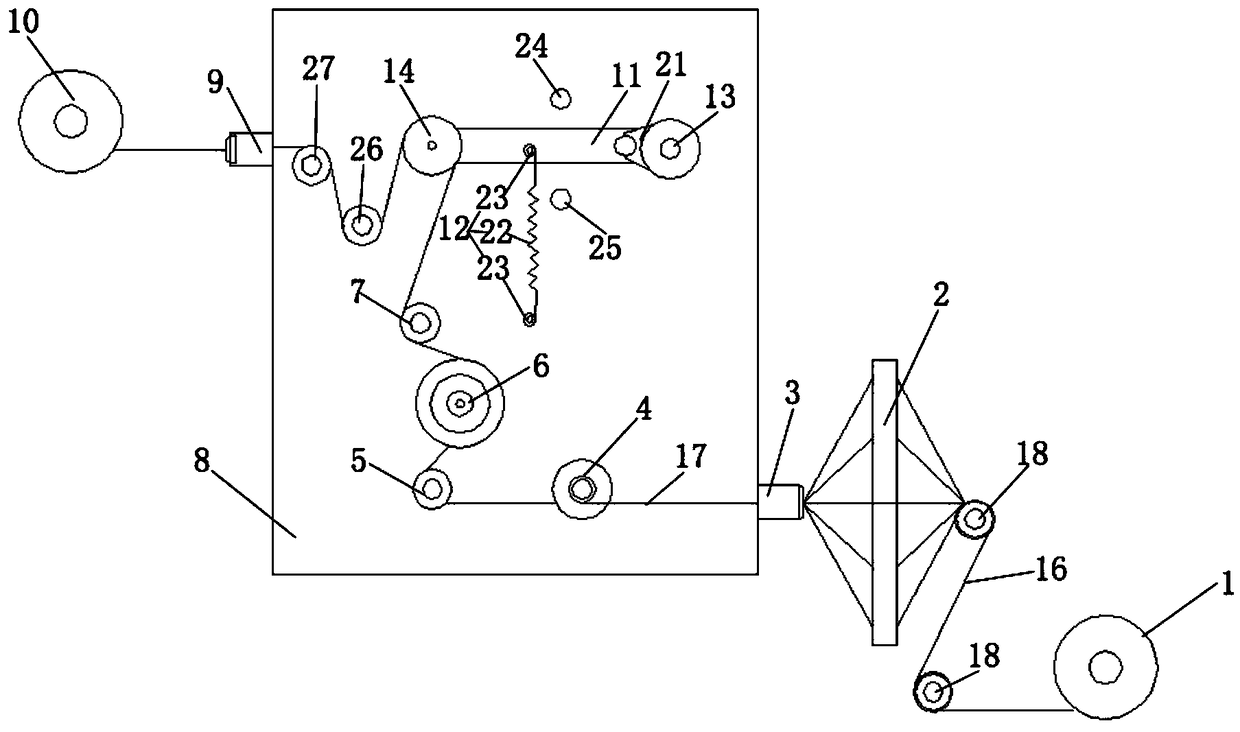

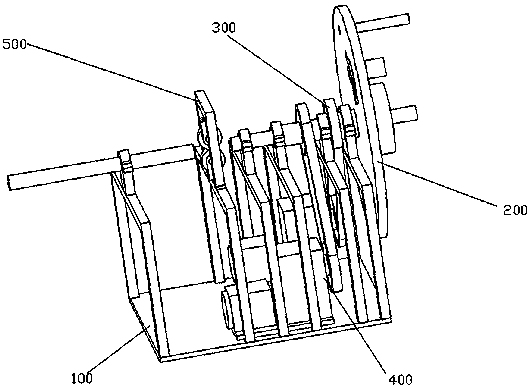

Multi-shaft synchronous control device

ActiveCN102874637ASave adjustment timeThe device takes up little spaceWebs handlingElectric machineryEngineering

The invention discloses a multi-shaft synchronous control device, which comprises an unwinding roller, a transmission roller, a winding roller and a control device, wherein the control device comprises a winding control device for controlling the winding roller, a transmission control device for controlling the transmission roller and a main controller for controlling the running of the parts. By adopting the multi-shaft synchronous control device, when tension control experiment teaching and scientific research are developed, a brake device and a tension controller can be eliminated, and servo synchronous driving and tension control of a plurality of motors are realized; the adjustment time and a space occupied by equipment are saved; and the multi-shaft synchronous control device controls the parts precisely.

Owner:海南经济特区中质猎鹰智能勘测科技有限公司

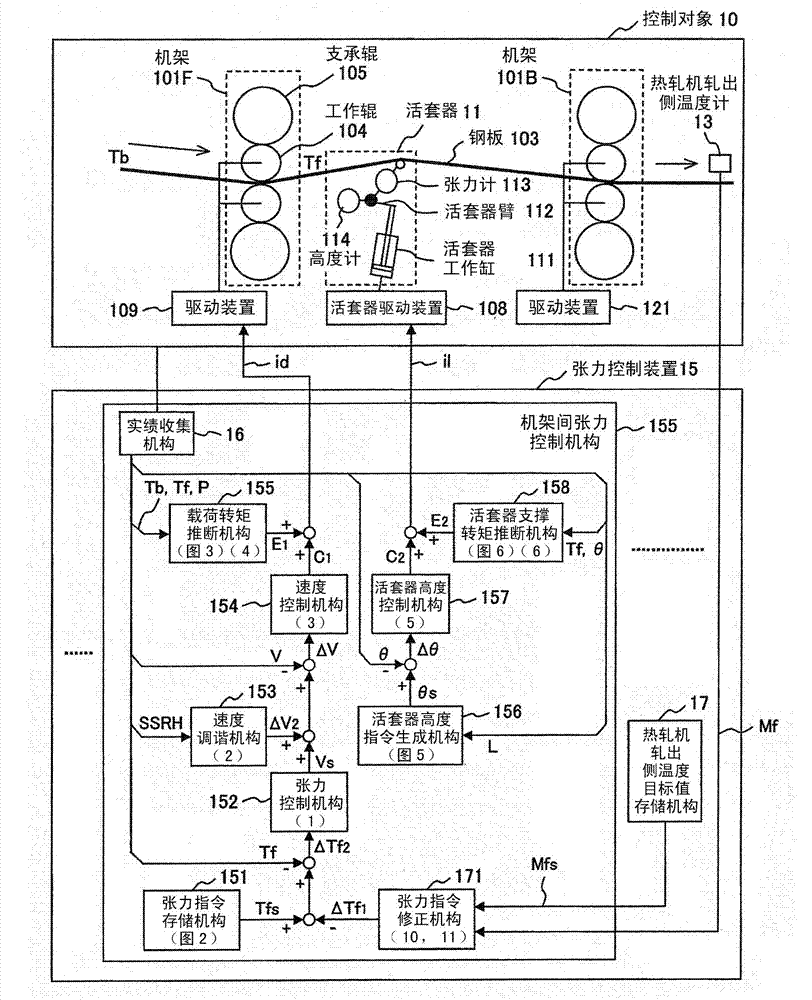

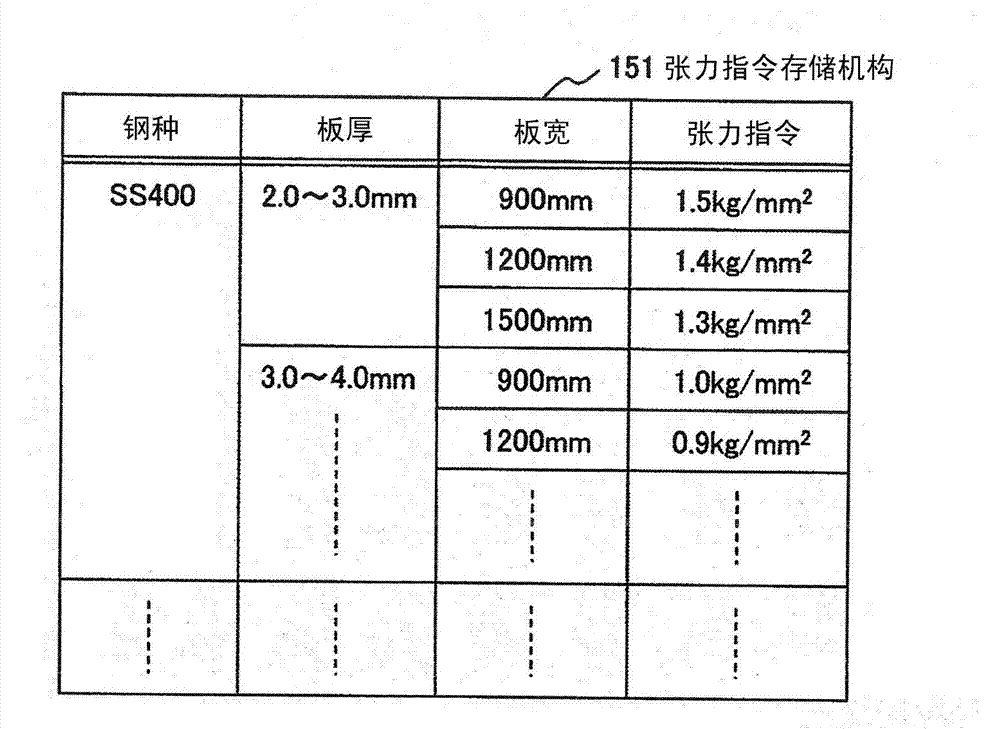

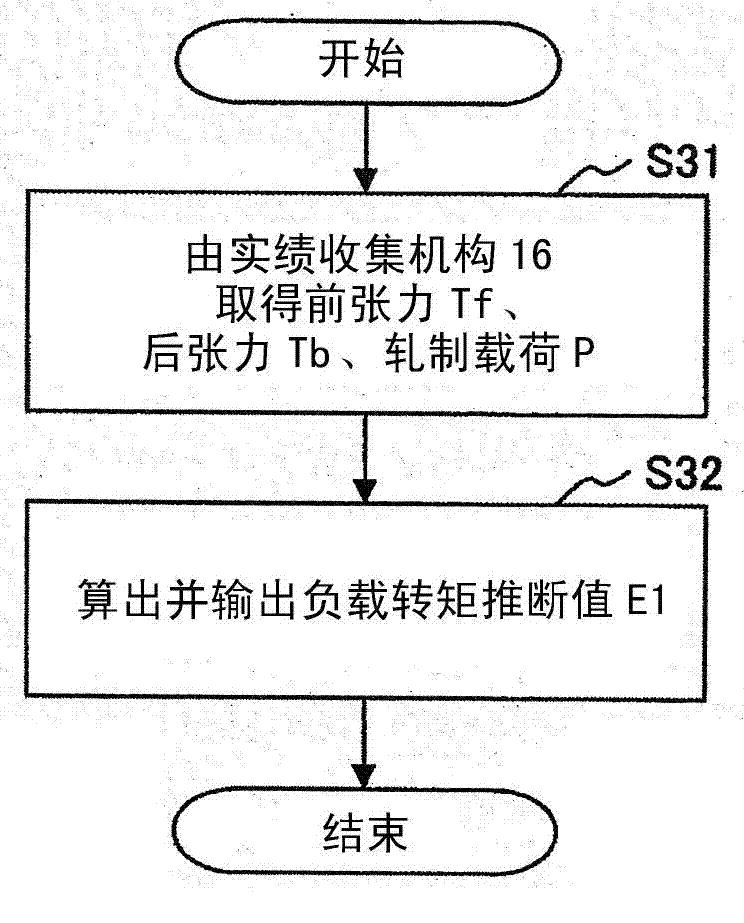

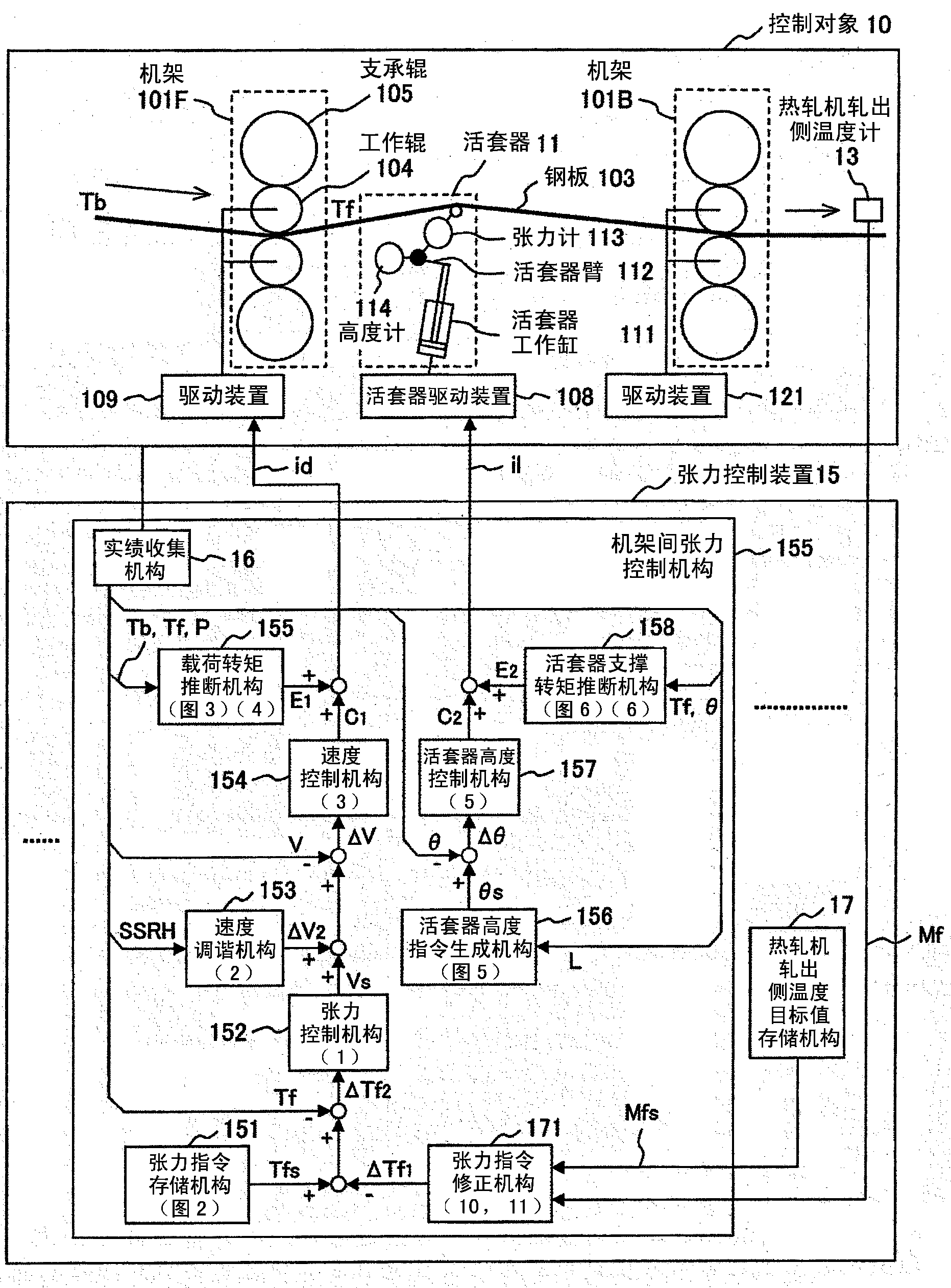

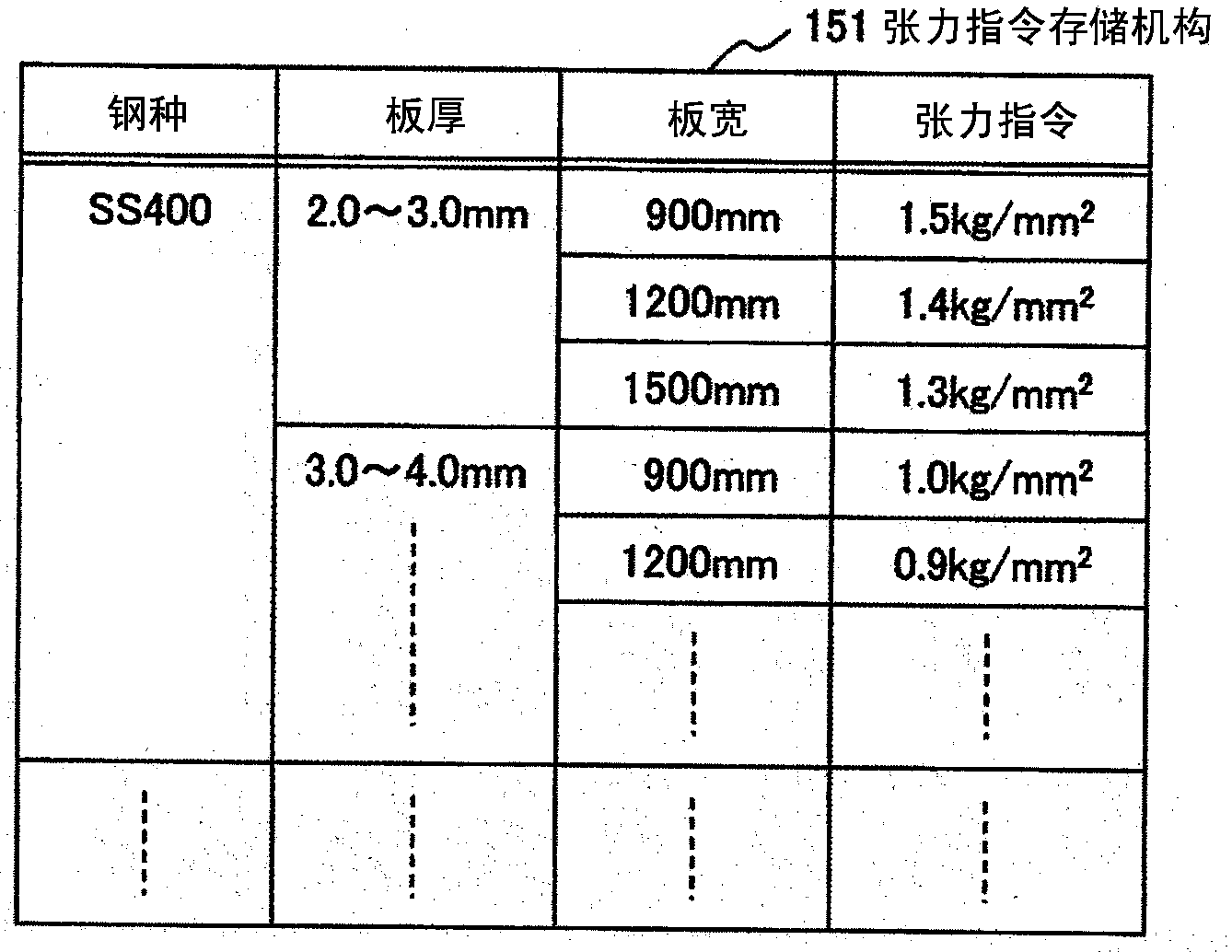

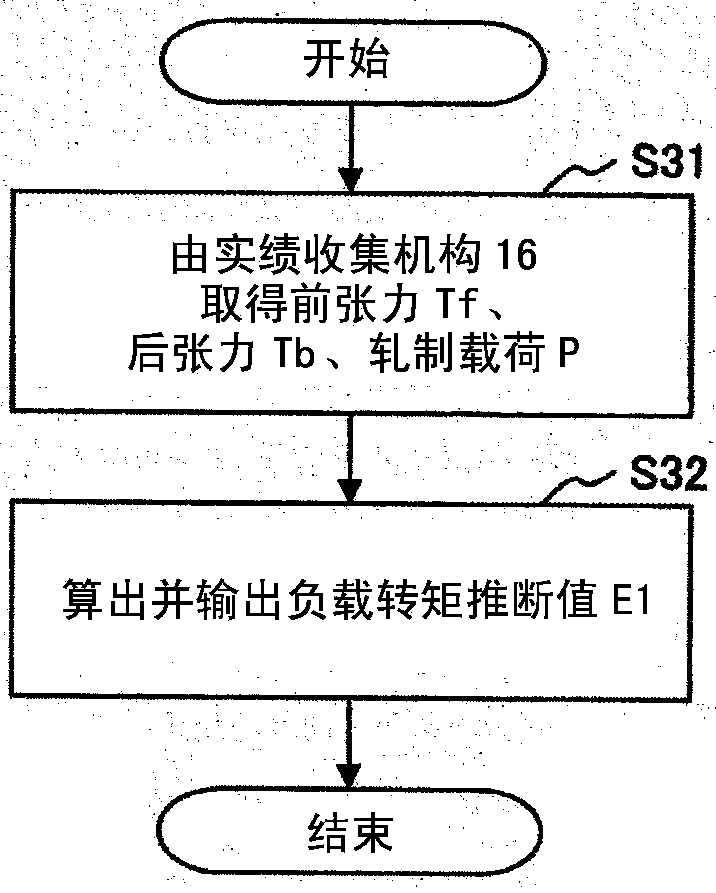

Tension control device of hot mill and control method

ActiveCN102773264AAchieve tension controlTension/compression control deviceEngineeringTension control

The invention provides a tension control device of a hot mill and a control method, for reducing the plate width deviation caused by the steel plate temperature effects. By taking a hot mill possessing a plurality of rolling racks and a looper between the racks as a control object, the tension control device of the hot mill for setting the tension of a steel plate passing through the hot mill as a desired value, comprises a tension instruction storing mechanism which stores tension instruction values; a tension instruction correcting mechanism which obtains the detection temperature of a thermometer used for measuring the temperature of the steel plate, and corrects the tension instruction value according to the deviation of the target temperature and the detection temperature of the steel plate; and a tension control mechanism which adjusts the hot mill according to the deviation of the corrected tension instruction value and the detected tension value.

Owner:HITACHI LTD

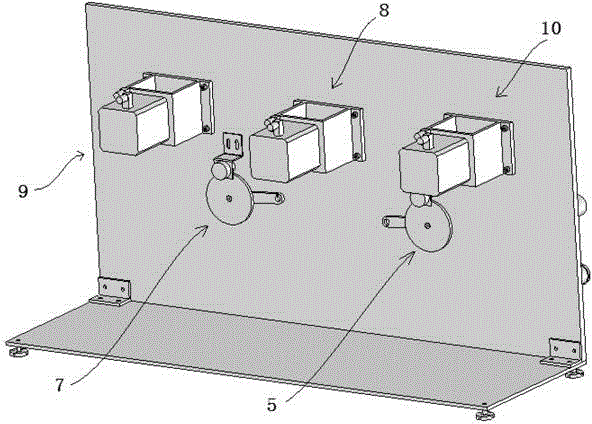

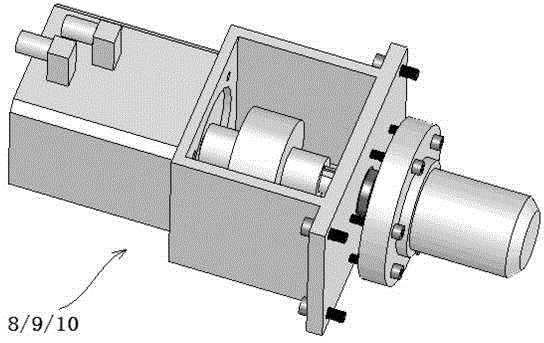

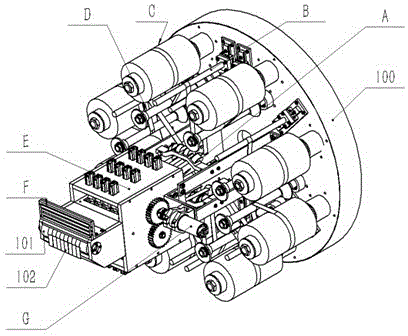

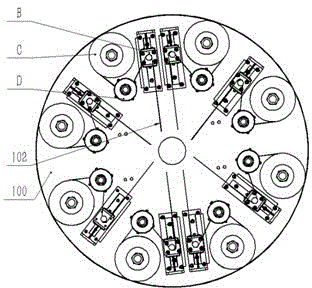

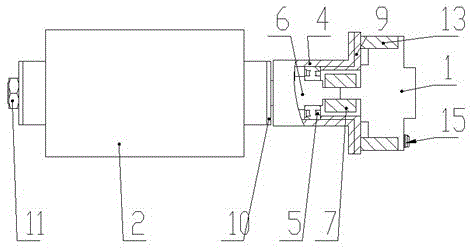

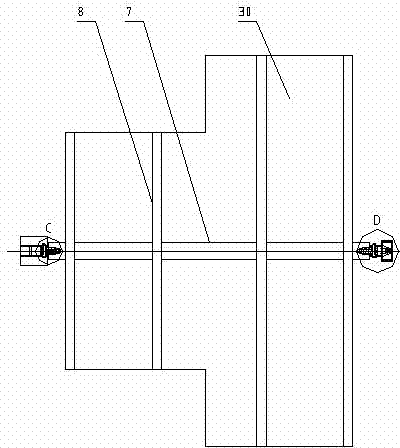

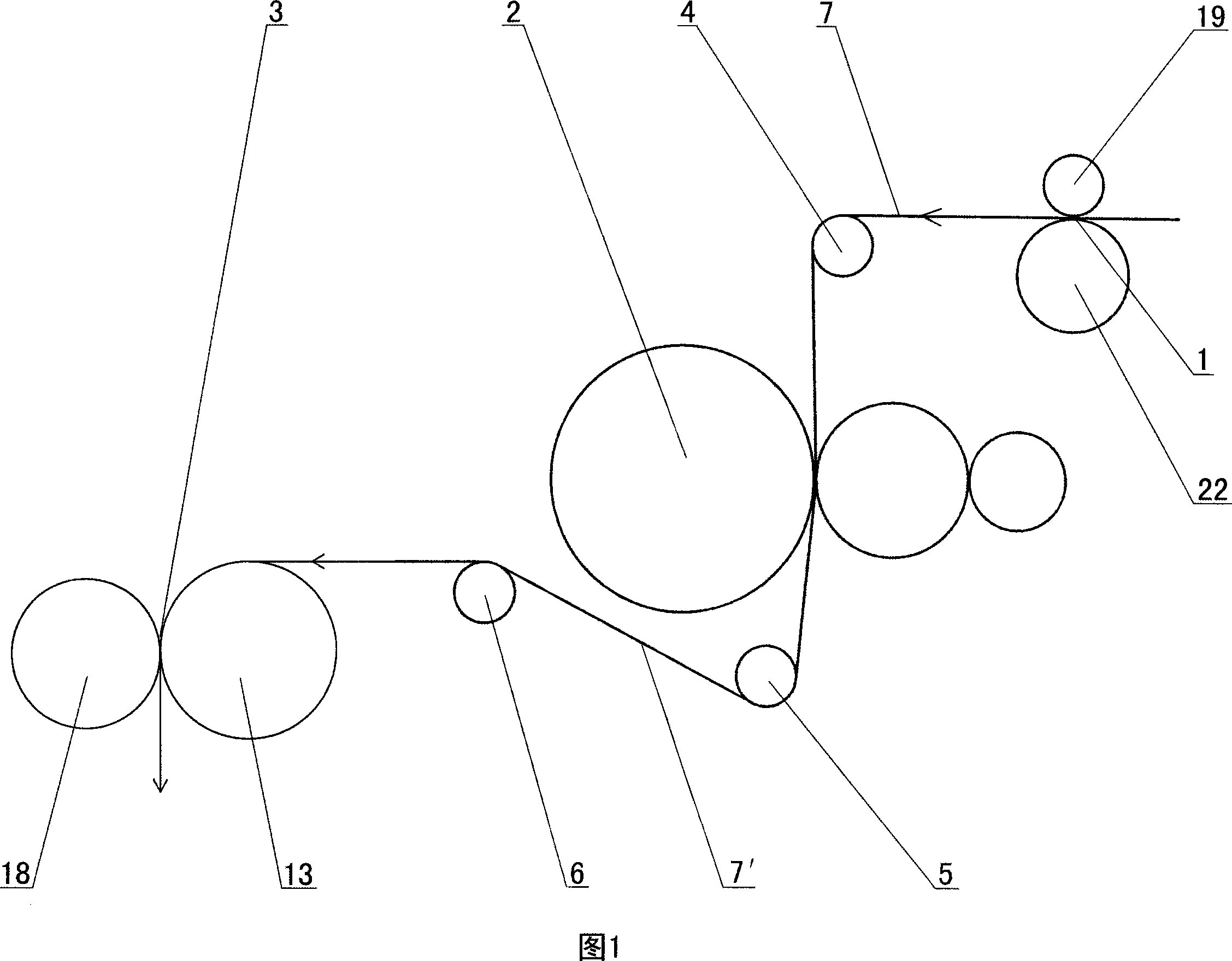

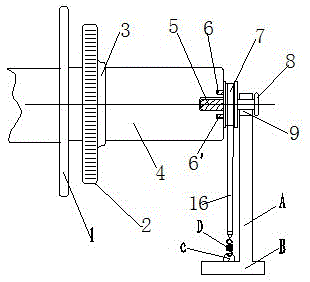

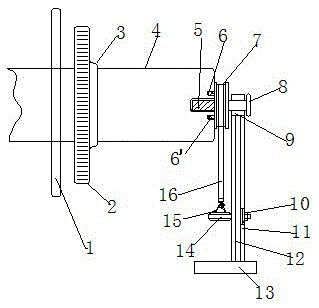

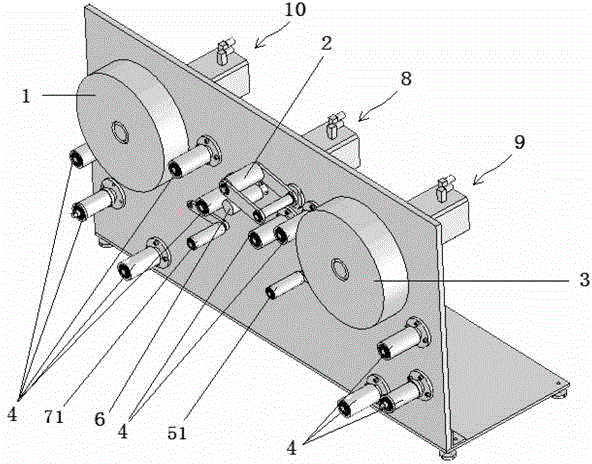

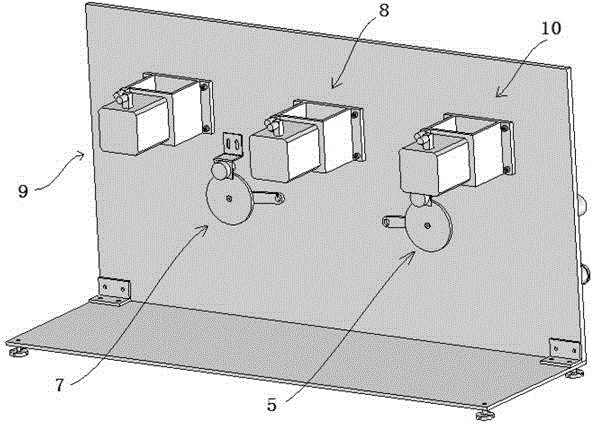

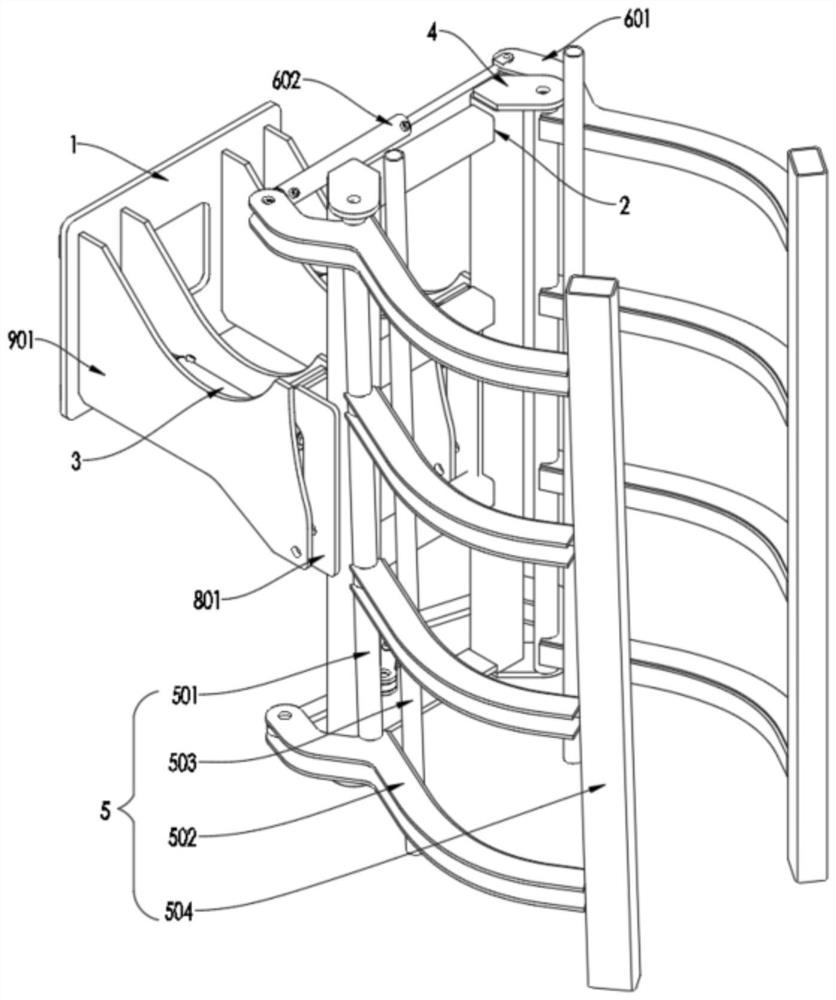

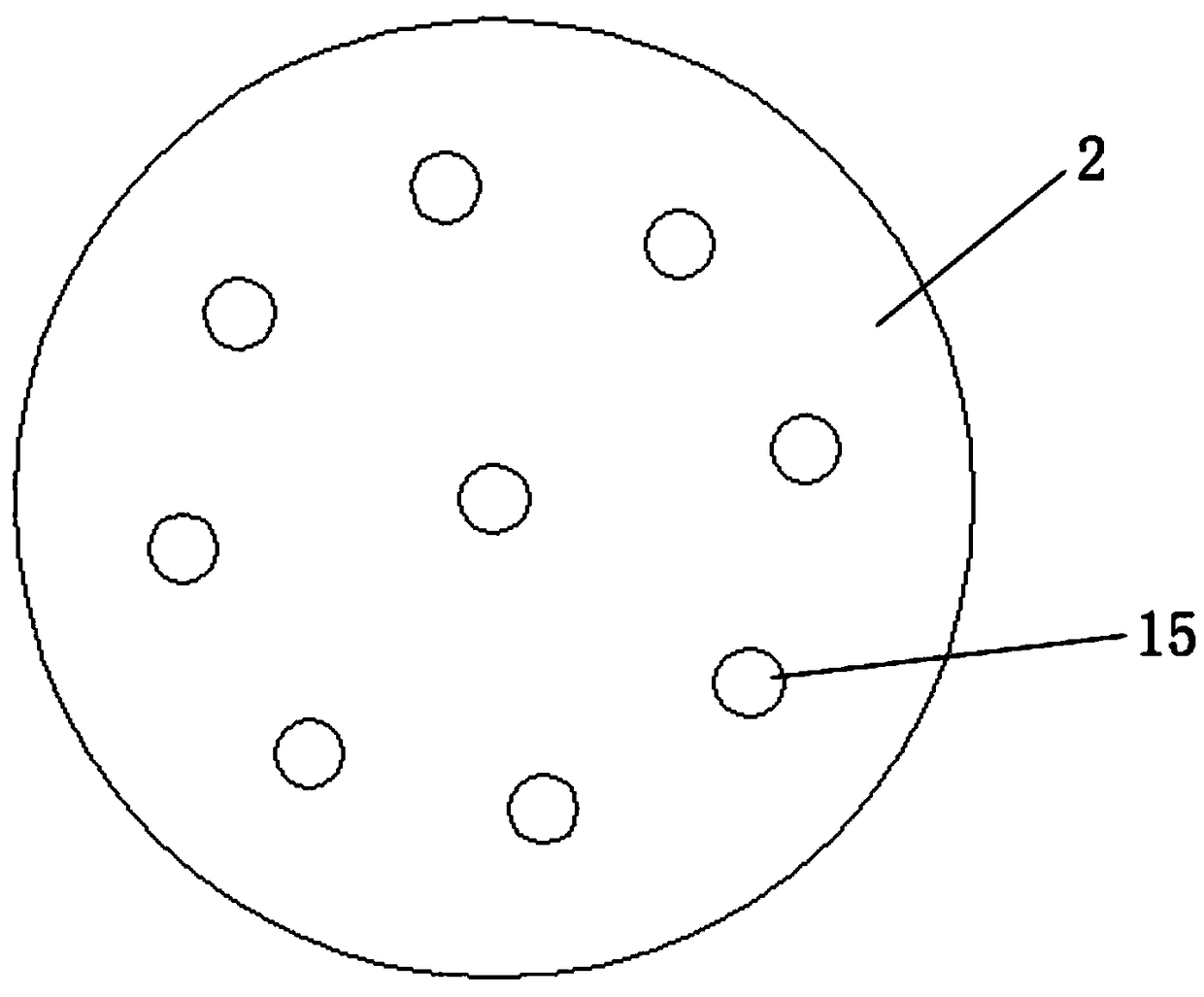

Modularized wire pavement head for automatically paving composite material and method

The invention relates to a modularized wire pavement head for automatically paving a composite material and a method. A six-axial robot-based platform design is used for paving a composite material member. The modularized wire pavement head is mainly characterized in that the wire pavement head is based on a completely modularized design, and comprises a wire coil mounting module (C), a gasket paper collecting module (D), a tension detection module (B), a tow steering module (A), a shearing, clamping and tow-reconveying module (E), a heater (F), a compression roller and the like. The modularized wire pavement head has the capability of simultaneously paving 8 bundles of composite material presoaking yarns; each tow is independently controlled; shearing of the tows and reconveying after shearing can be independently carried out; on the basis of rapid-exchange structure design, mounting and dismantling of the wire pavement head and mounting and exchanging of the tows can be conveniently carried out; on the basis of bared yarn duct design, cleaning of the wire pavement head can be conveniently carried out; and the widths of the used composite material presoaking yarns are 3.17mm, 6.35mm and 12.7mm.

Owner:WUHAN UNIV

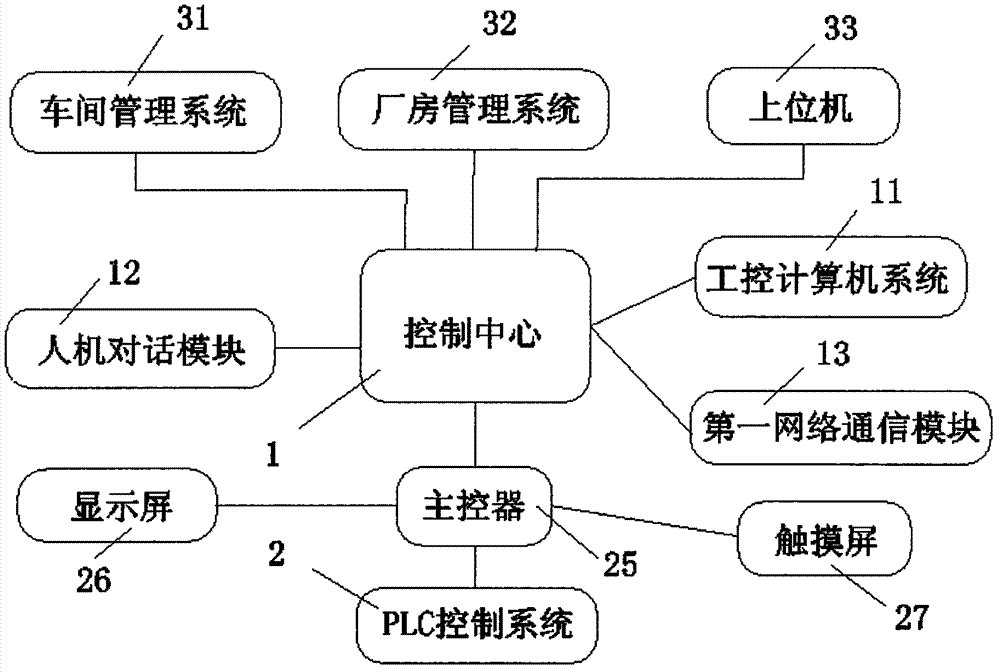

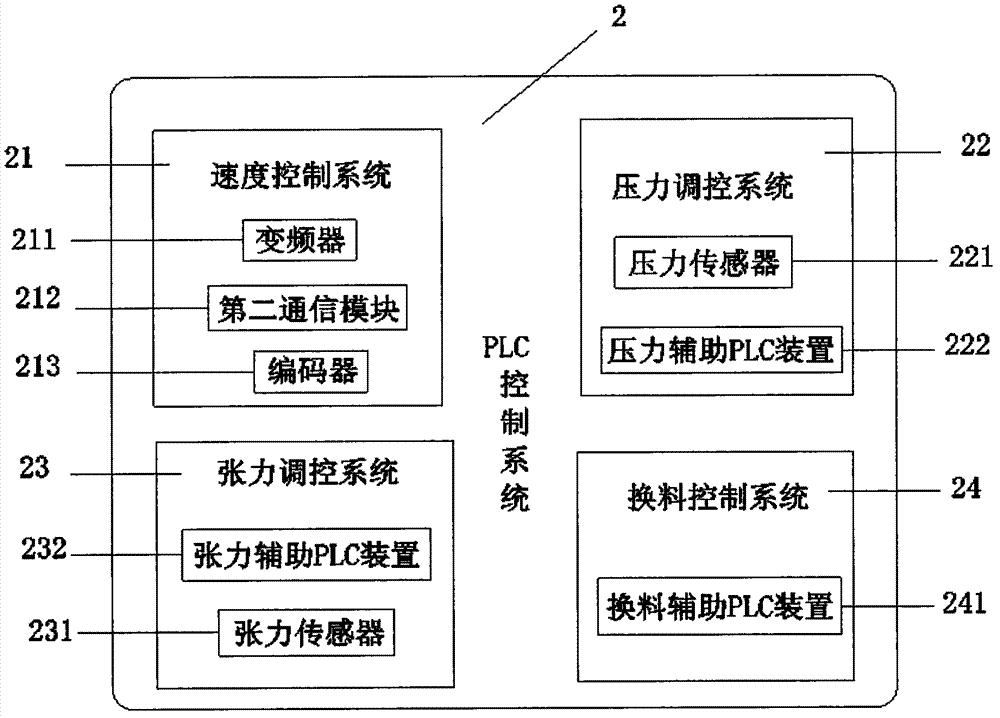

Corrugated paper production line control system

InactiveCN104765343AImprove production efficiency and production qualityImprove effectiveness and convenienceTotal factory controlProgramme total factory controlPaper productionSpeed control system

The invention discloses a corrugated paper production line control system. The corrugated paper production control system comprises a plurality of management systems for conducting operation management on corrugated paper production lines, a control center connected with the management systems through Ethernet and a PLC control system in communicating connection with the control center. The PLC control system comprises a speed control system, a tension regulation and control system, a pressure regulation and control system and a material change control system, wherein the speed control system achieves regulation and control on the operation speeds of the production lines, tension control of paper of the production lines is achieved through the tension regulation and control system, regulation and control on thermal pressures of corrugation rolls are achieved through the pressure regulation and control system, and corrugating base paper change is achieved through the material change control system. The corrugated paper production line control system achieves management and control integration, and production efficiency and production quality are improved.

Owner:SHENZHEN TIANTIANSHENG PAPER PROD

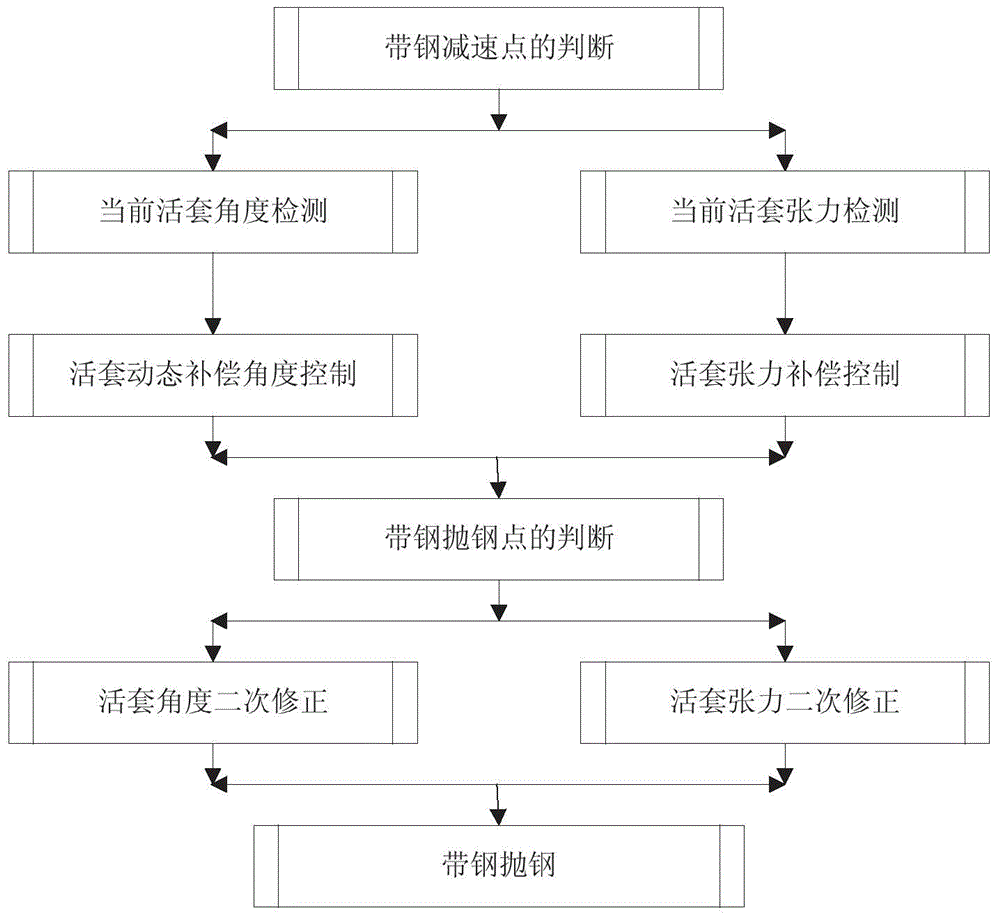

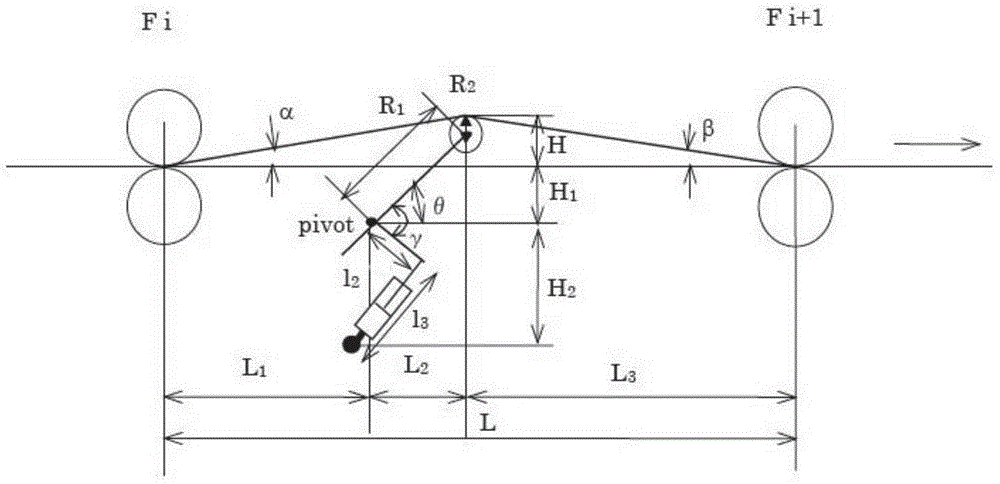

Method for dynamically controlling loop angle of hot continuous rolling mill

ActiveCN104801547AImplementation angleAchieve tension controlRoll mill control devicesFlexible work arrangmentsEngineeringDynamic Tension

A method for dynamically controlling a loop angle of a hot continuous rolling mill adopts a strip steel rolling force detector, a strip steel speed detector, a loop angle detector, a strip steel tension detector, a basic automatic level control machine and a process control machine to conduct dynamic control on angles of six loops among seven continuous rolling mills according to the set process requirements, accordingly the stability of the loops during strip steel throwing is improved, specifically variable-angle control before strip steel throwing and a unary function loop angle compensation method are adopted to achieve continuous dynamic control in the control process according to change of angle and tension control, meanwhile synchronous and dynamic tension control is achieved in the tension control process according to angle change, and the stability of the loops in the strip steel throwing process is improved greatly.

Owner:BAOSHAN IRON & STEEL CO LTD

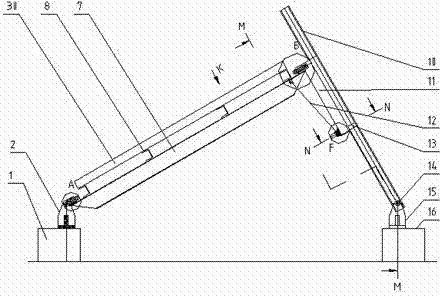

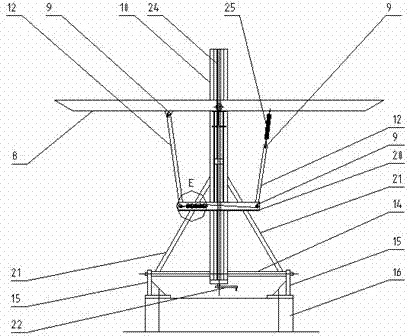

Solar energy tracking device

InactiveCN103246294AAchieve tension controlLow costControl using feedbackEngineeringMechanical engineering

The invention discloses a solar energy tracking device which is characterized by comprising a first base, a first hinged support, a primary beam , an secondary beam, a slide rail column, a second hinged support, a second base, inclined struts, a screw rod, a lead screw nut, a C-shaped slide block and a photovoltaic panel, wherein the secondary beam is welded on the primary beam; the photovoltaic panel is mounted on an upper plane of the secondary beam; the primary beam is hinged with the first hinged support and the C-shaped slide block through a T-shaped shaft; the C-shaped slide block in in clearance fit with an inner slideway of the slide rail column; the lead screw nut is fixed in the C-shaped slide block; the screw rod is screwed into the lead screw nut; two ends of the screw rod are mounted in the slide rail column through a slide bearing; a shaft and the inclined struts are welded at the lower part of the slide rail column; and the side rail column is hinged with the second hinged support through the shaft. According to the solar energy tracking device, the automatic tracking for solar azimuths and the manual tracking for slowly-changing solar azimuths are achieved at low cost.

Owner:MAANSHAN JUBAO NEW ENERGY EQUIP TECH

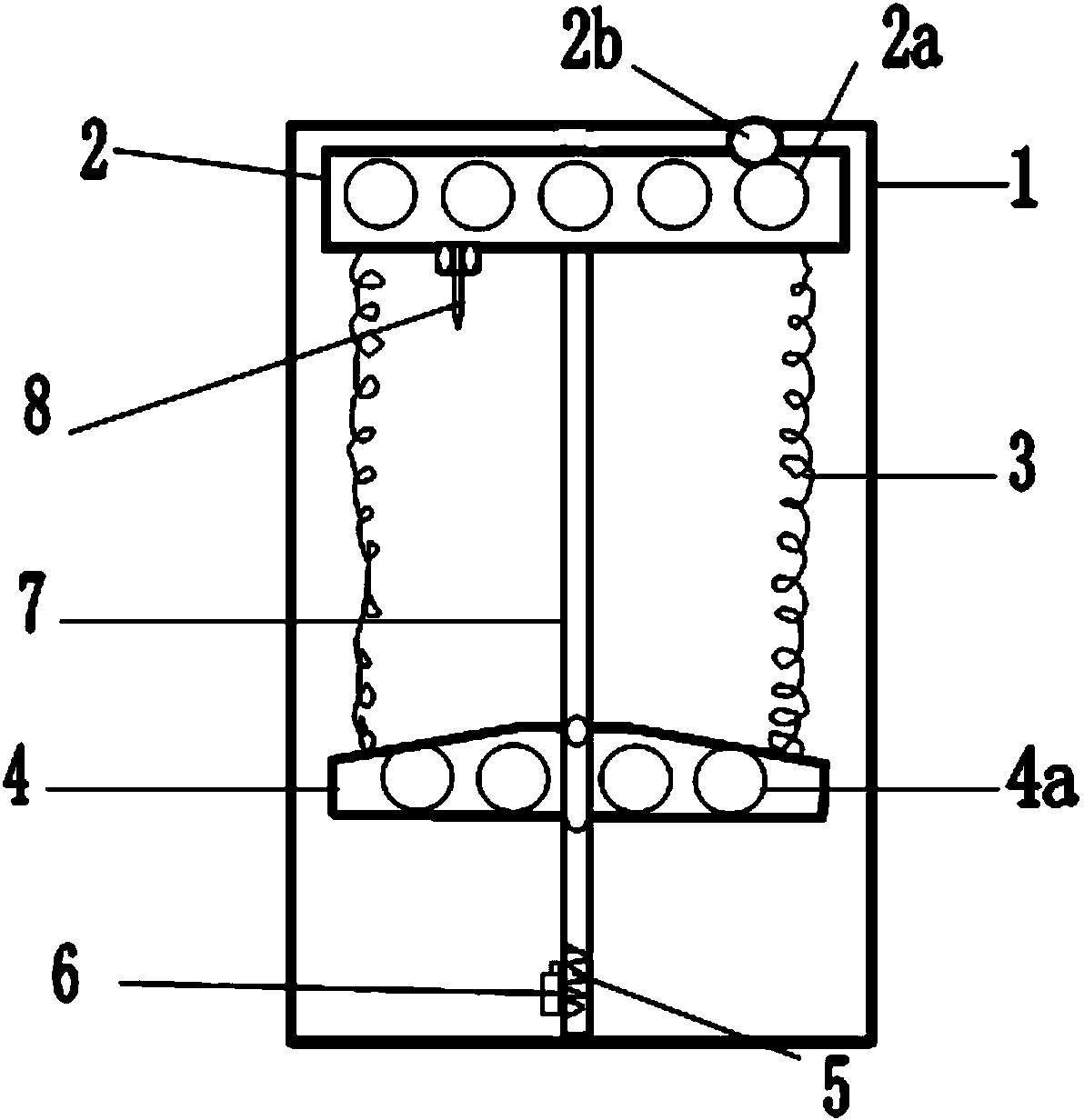

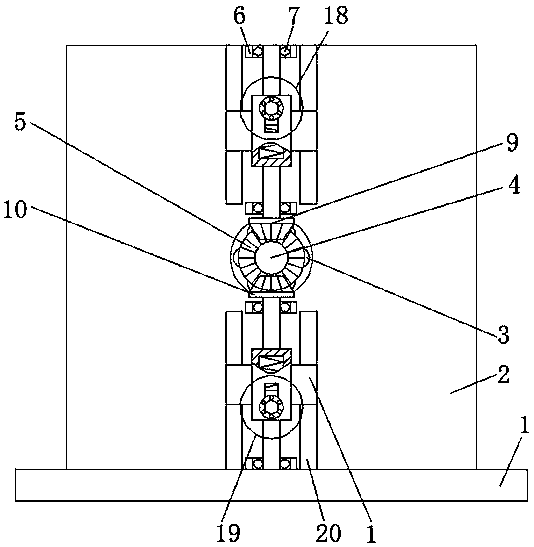

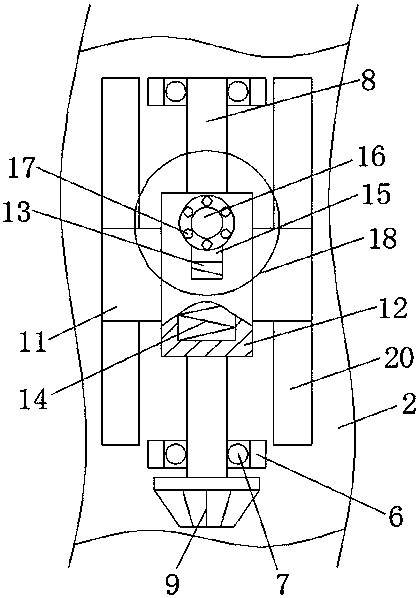

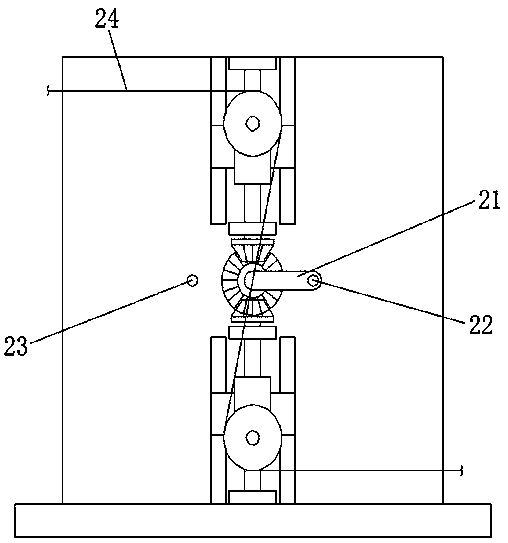

Constant-tension cloth containing device

The invention relates to a cloth containing device, in particular to a constant-tension cloth containing device which mainly comprises a shell, a track, a displacement sensor, a fixed lateral plate, a movable lateral plate and a travel switch. A group of fixed guide rollers which are installed side by side are installed on the fixed lateral plate and located on the upper portion of the inner portion of the shell, a group of movable guide rollers which are installed side by side are arranged on the movable lateral plate and located on the upper portion of the inner portion of the shell, the track is arranged between the center of the fixed lateral plate and the center of the movable lateral plate, the two ends of the track are welded to the fixed lateral plate and the bottom of the shell respectively, the movable lateral plate is in sliding connection with the track, and the fixed lateral plate is connected with the movable lateral plate through a spring. The constant-tension cloth containing device is simple in structure and convenient to install, can effectively achieve tension control over cloth or films, provides enough end connecting time and enough seam connecting time for a prior process, and therefore the phenomena that the cloth or the films are wrinkled and the films are thinned through tension or snapped due to the fact that tension control is unstable are avoided.

Owner:大连恒大高新材料开发有限公司

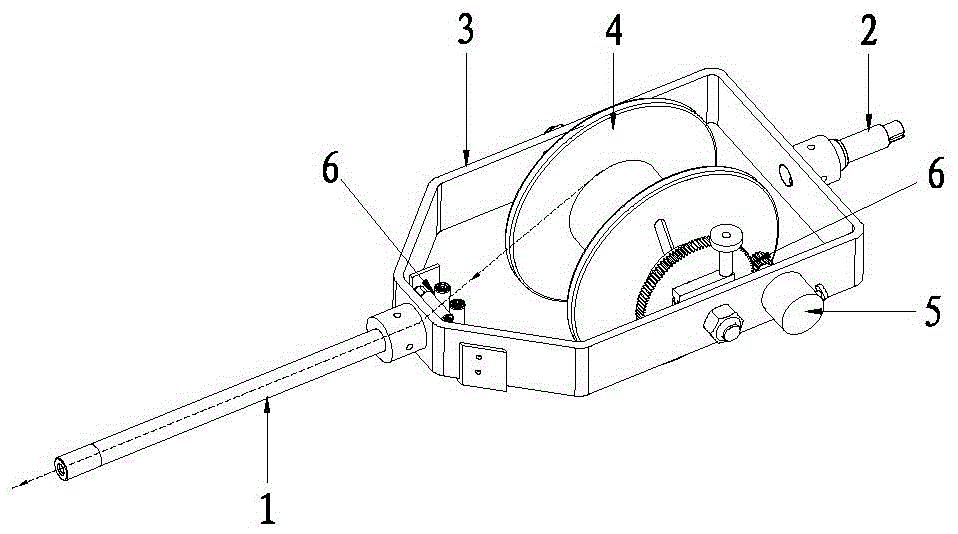

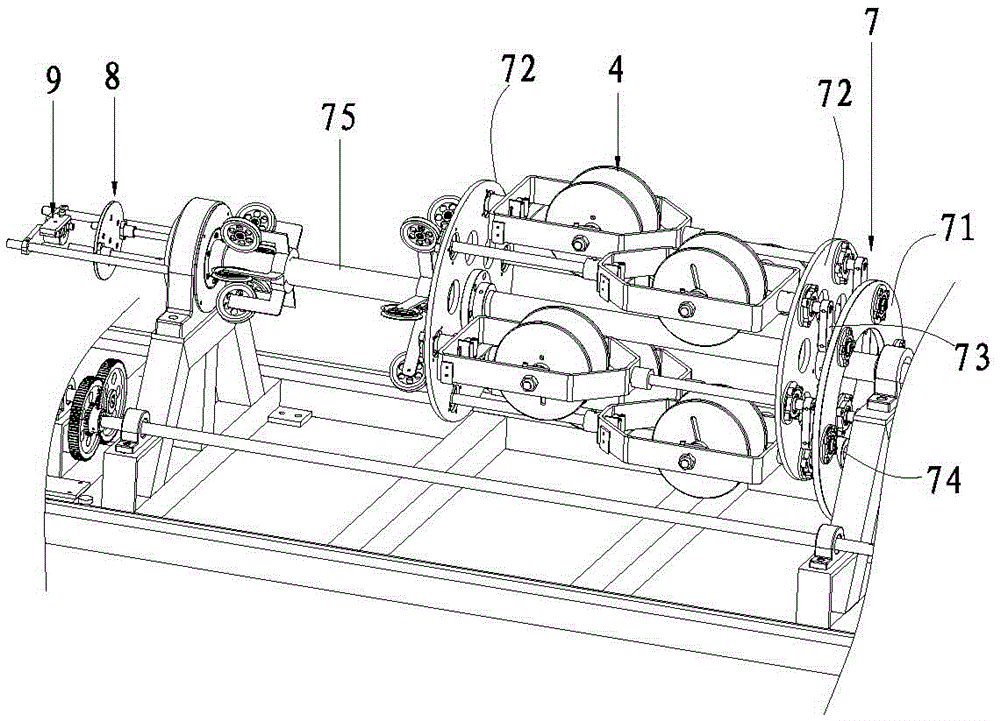

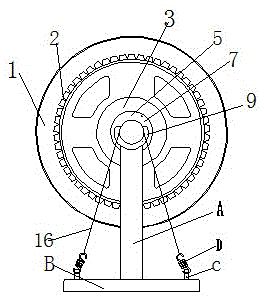

Cradle type tension pay-off device

ActiveCN106448938AIngenious designUnwinding action is naturalCable/conductor manufactureWire twisterMagnet

A cradle type tension pay-off device disclosed by the present invention comprises a threading shaft, a rotating shaft, a cradle frame, a pay-off shaft, a permanent magnet damping regulator and a transmission gear set. The pay-off shaft is connected with and arranged in the cradle frame, the permanent magnet damping regulator is arranged on the cradle frame and is connected with the pay-off shaft via the transmission gear set, and the threading shaft and the rotating shaft are arranged at the two ends of the cradle frame symmetrically. The cradle type tension pay-off device of the present invention is ingenious and reasonable in design, adopts the passive pay-off, can regulate the pay-off speed via the permanent magnet damping regulator, thereby realizing the tension control. Moreover, the cradle type tension pay-off device is arranged on the cradle frame of a stranding machine via the rotating shaft, can swing freely, realizes the back twist pay-off, enables the pay-off actions to be more natural and smooth, a pay-off effect and the working efficiency to be improved substantially and the production cost to be reduced, is good in stranding effect, can guarantee the product quality effectively, is simple, easy and convenient to operate, effectively saves a lot of time and labor, and facilitates the wide popularization and utilization.

Owner:DONGGUAN NEW ENSHIANG MACHINERY ENTERPRISE

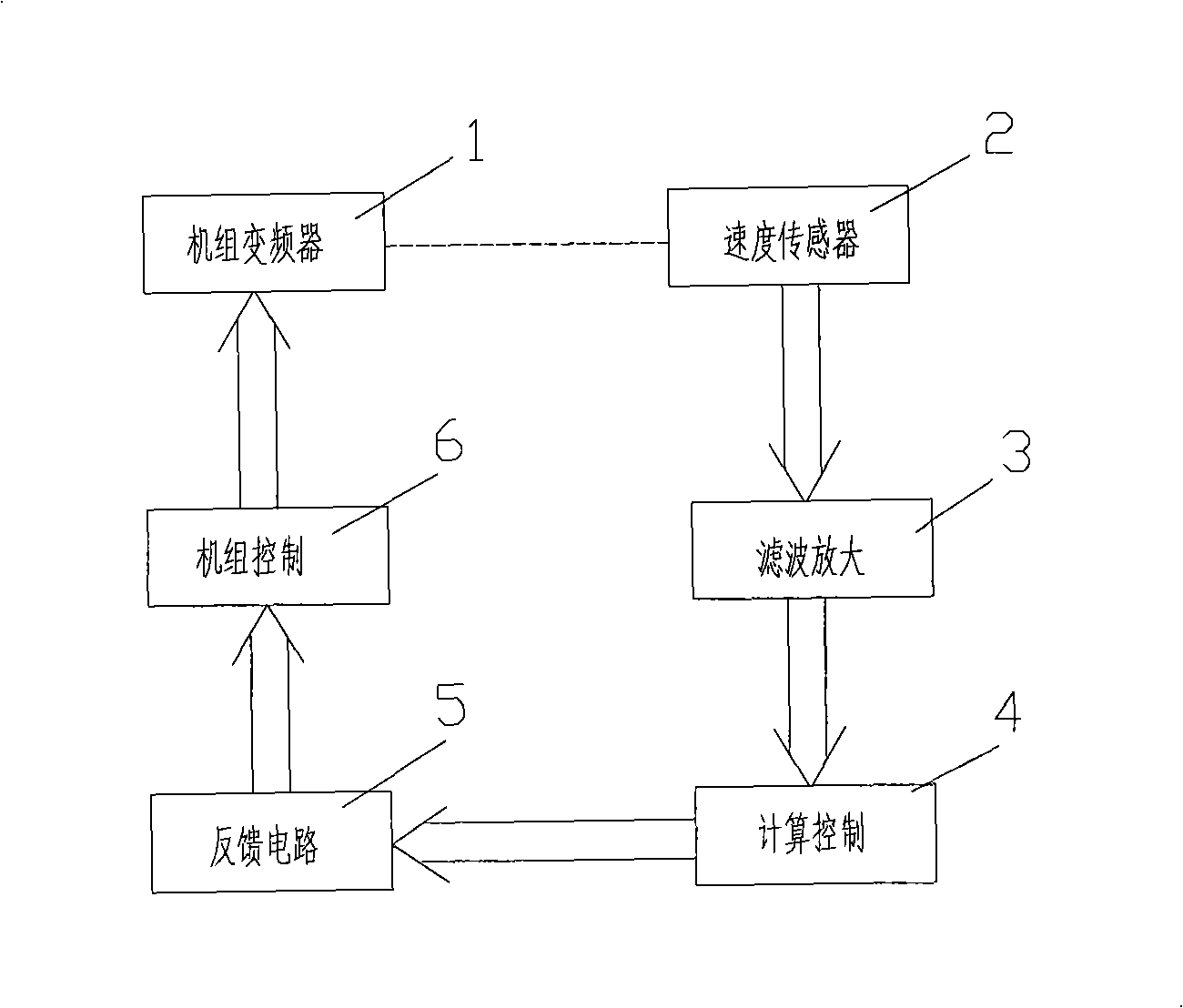

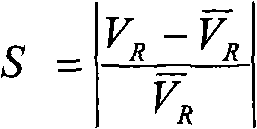

Early warning device and method for slip of strip steel tension roller units

InactiveCN101271321AAchieve tension controlRealize automatic controlProgramme controlComputer controlMetal stripsFrequency changer

The invention relates to a monitoring device with a strip steel tight roll machine set and a monitoring method. The device comprises the tight roll machine set with a transducer (1) and a revolution speed transducer (2) which is connected with the transducer, and the output end of the revolution speed transducer is connected with a preposed processing circuit (3) which is connected with a calculation control module (4), the output end of the calculation control module is connected with a feedback circuit (5) which is connected with the control system (6) of the tight roll machine set. The control method of the system comprises that the revolution speed transducer is used for receiving the linear speed VR of the tight roll and the translational speed V of the metal strip, and the linear speed VR and the translational speed V are output by the transducer; the signal of the revolution speed transducer is conveyed to the calculation control module after the filtering method of the preposed processing circuit; the calculation control module works out the average linear speed VR of the whole tight roll machine set so as to calculate a slippage proportionality factor S according to a formula, the slippage proportionality factor S and a preset value are judged comparatively; a judgment result is conveyed to the control system of the tight roll machine set by the feedback circuit, so as to warn the occurrence of slippage in advance.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

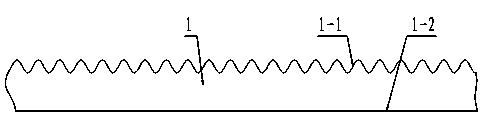

PVC membrane dividing and cutting machine

ActiveCN104176553AImprove cut qualitySimplify production stepsArticle deliveryWebs handlingDrive shaftDrive motor

The invention discloses a PVC membrane dividing and cutting machine which comprises a feeding mechanism, a dividing and cutting actuating mechanism, a material collecting mechanism, a drive motor, a transmission shaft, a transmission mechanism, a rack and a control cabinet, wherein the feeding mechanism, the dividing and cutting actuating mechanism and the material collecting mechanism are mounted on the rack; the drive motor is mounted on the frame on one side of the rack; the transmission mechanism is mounted on the frame on the other side of the rack; the drive motor is connected with the transmission mechanism through the transmission shaft; power is transmitted to the feeding mechanism, the dividing and cutting actuating mechanism and the material collecting mechanism by the transmission mechanism. The PVC membrane dividing and cutting machine has the characteristics as follows: the dividing and cutting actuating mechanism is provided with a group of direct cutters and a group of disc cutters, which are distributed at intervals; the direct cutters are fixed on the cross beam of the rack, and the disc cutters are mounted on the top cross beam of the rack through a drive air cylinder; and besides, the PVC membranes are cut into strips simultaneously with rickracks left on the edges, so that the labor intensity of operators is reduced, and the working efficiency is improved.

Owner:HEBEI JINDA PLASTIC

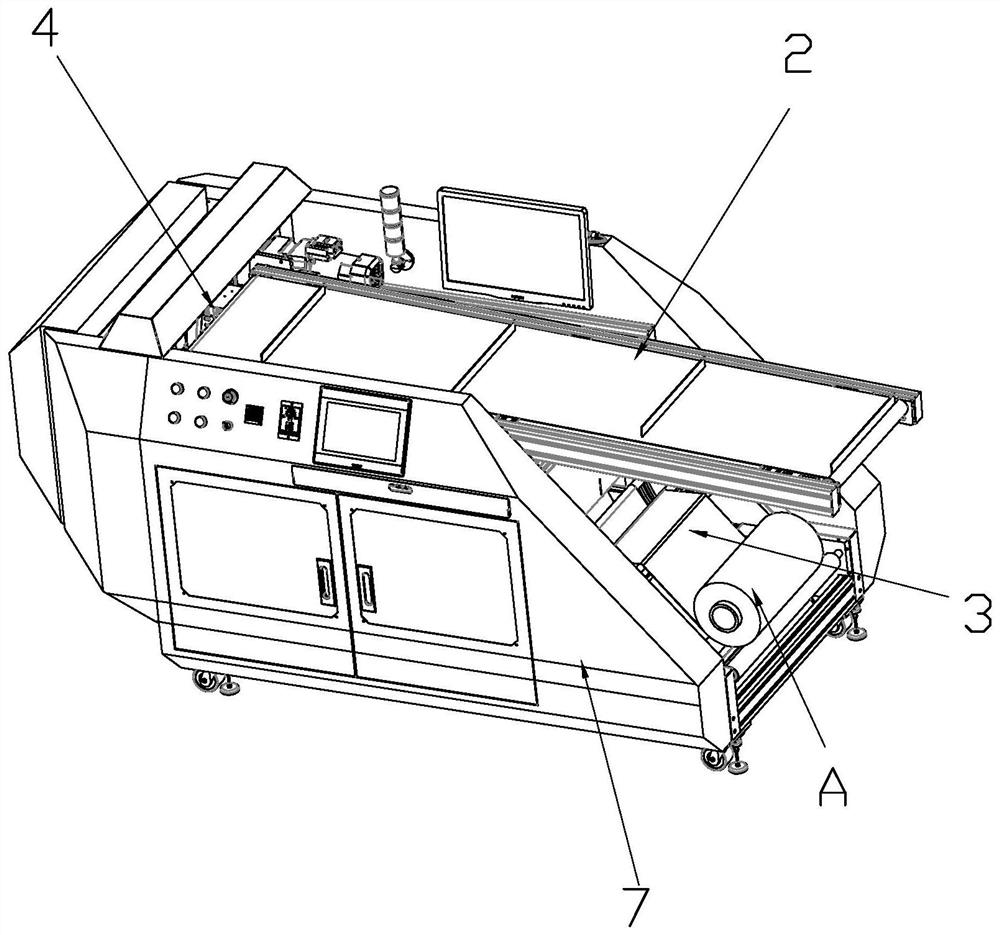

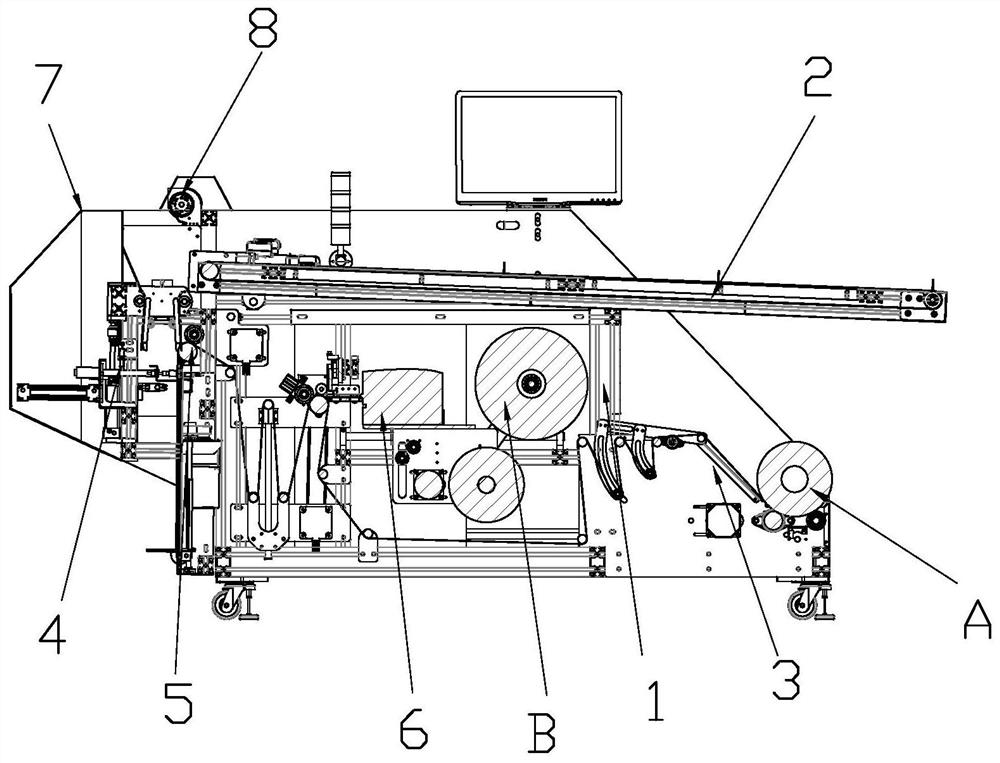

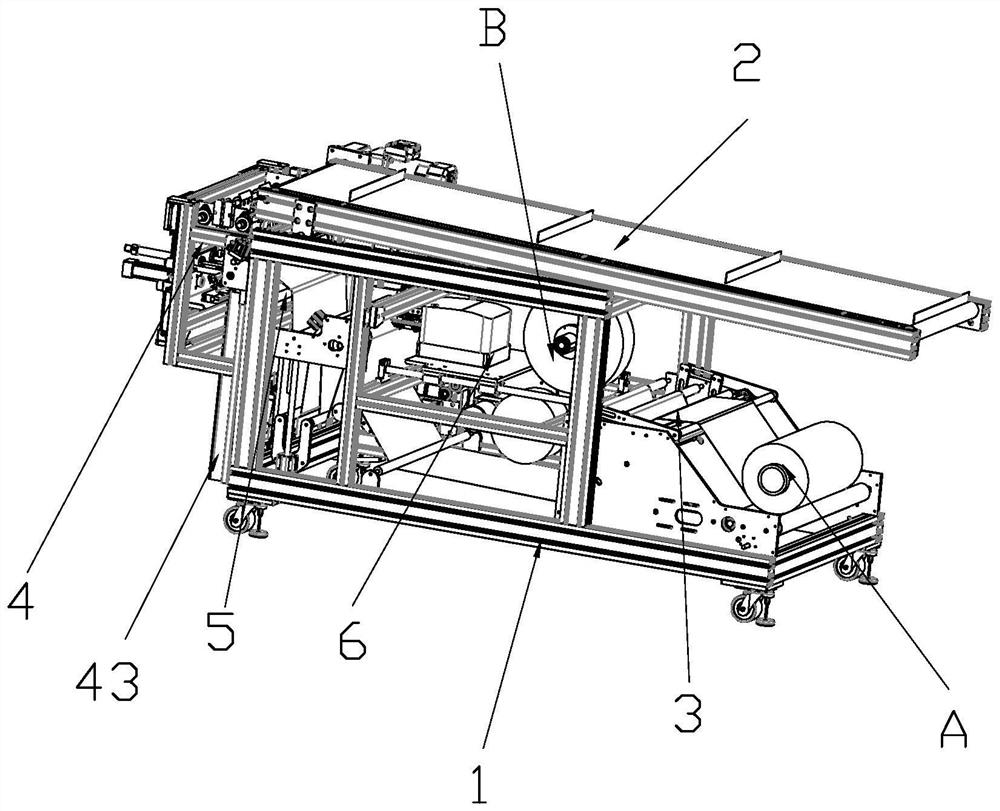

Full-automatic bag falling type express packaging machine

PendingCN112849539AGuaranteed stabilityReduce labor costsWrapper twisting/gatheringPackaging automatic controlFilm materialWaste material

The invention relates to a full-automatic bag falling type express packaging machine. The machine is characterized in that a conveying belt is used for conveying commodities into a packaging film material after a bag is opened, a film material traction mechanism conveys the packaging film material to a bag sucking, sealing and cutting mechanism, an automatic bag opening mechanism opens the packaging film material, a bag opening driving mechanism is arranged to control a bag opening assembly to move axially, a next set of packaging film materials can conveniently enter the bag opening area, an electric bag supporting mechanism is used for preventing goods from being damaged due to falling of expresses and preventing the expresses from being detained on a supporting plate through a bag supporting buffering assembly, full-automatic labeling is achieved through a labeling mechanism, and generated waste materials are recycled through a waste collecting assembly. A waste collecting tensioning shaft is arranged to adjust the tension of the waste collecting assembly, an automatic temporary storage mechanism is arranged, the phenomena that feeding of an unwinding temporary storage device is not timely, and a material roll deforms and even is torn and broken are avoided, and the transmission stability of a whole machine is improved.

Owner:浙江科仓智能科技有限公司

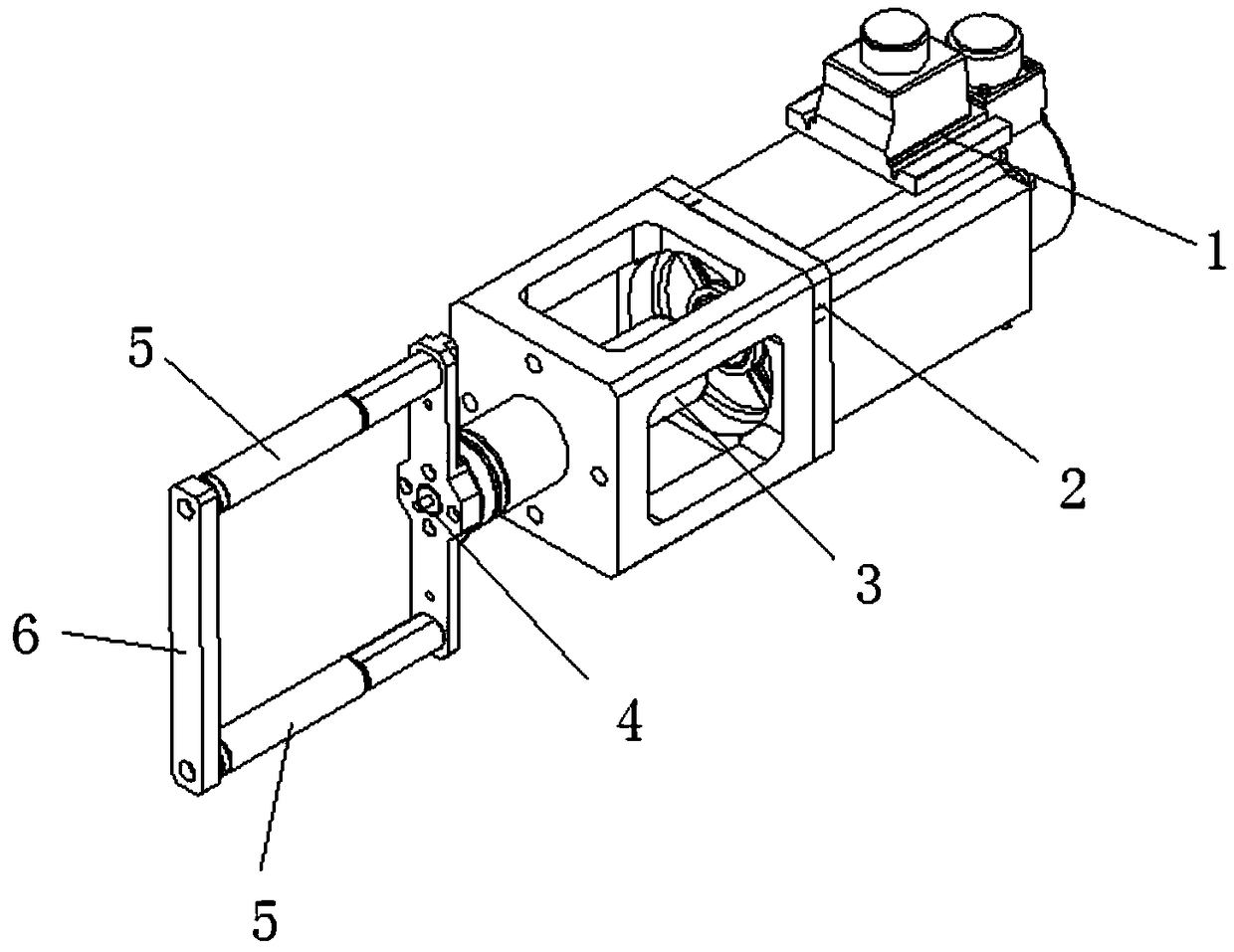

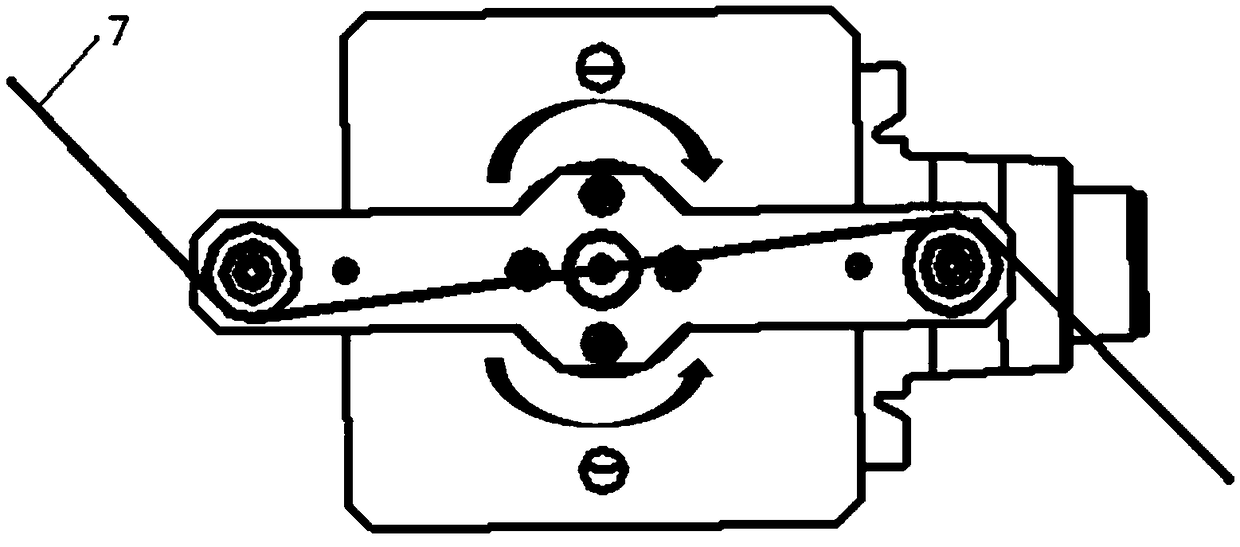

Cell pole piece tension swing arm mechanism and swing arm tension control method

The invention relates to a cell pole piece tension swing arm mechanism and a swing arm tension control method. A servo motor is arranged on a motor seat. A spindle of the servo motor is connected witha tension swing arm through a coupling. Two sets of pole piece passing rollers are symmetrically mounted on the tension swing arm, the ends of the two sets of pole piece passing rollers are connectedthrough a passing roller connecting plate, and a pole piece passes through the position between the two sets of pole piece passing rollers. The tension swing arm is pre-provided with a balance position, an upper limit position and a lower limit position. During passing, passing tension can enable the tension swing arm to generate the magnitude-changing twisting force. Tension generated by passingfeeds back signals to the servo motor in time through a tension sensor, the servo motor carries out fast responding to control output torque, and the tension swing arm can deflect by a certain anglewithin a preset angle range to control the passing tension with high precision. According to the cell pole piece tension swing arm mechanism and the swing arm tension control method, the servo motor controls the tension swing arm to carry out tension real-time control within a certain rotating angle according to pole piece tension negative feedback information.

Owner:BOZHON PRECISION IND TECH CO LTD

Tension control device of hot mill and control method

ActiveCN102773264BAchieve tension controlTension/compression control deviceEngineeringTension control

The invention provides a tension control device of a hot mill and a control method, for reducing the plate width deviation caused by the steel plate temperature effects. By taking a hot mill possessing a plurality of rolling racks and a looper between the racks as a control object, the tension control device of the hot mill for setting the tension of a steel plate passing through the hot mill as a desired value, comprises a tension instruction storing mechanism which stores tension instruction values; a tension instruction correcting mechanism which obtains the detection temperature of a thermometer used for measuring the temperature of the steel plate, and corrects the tension instruction value according to the deviation of the target temperature and the detection temperature of the steel plate; and a tension control mechanism which adjusts the hot mill according to the deviation of the corrected tension instruction value and the detected tension value.

Owner:HITACHI LTD

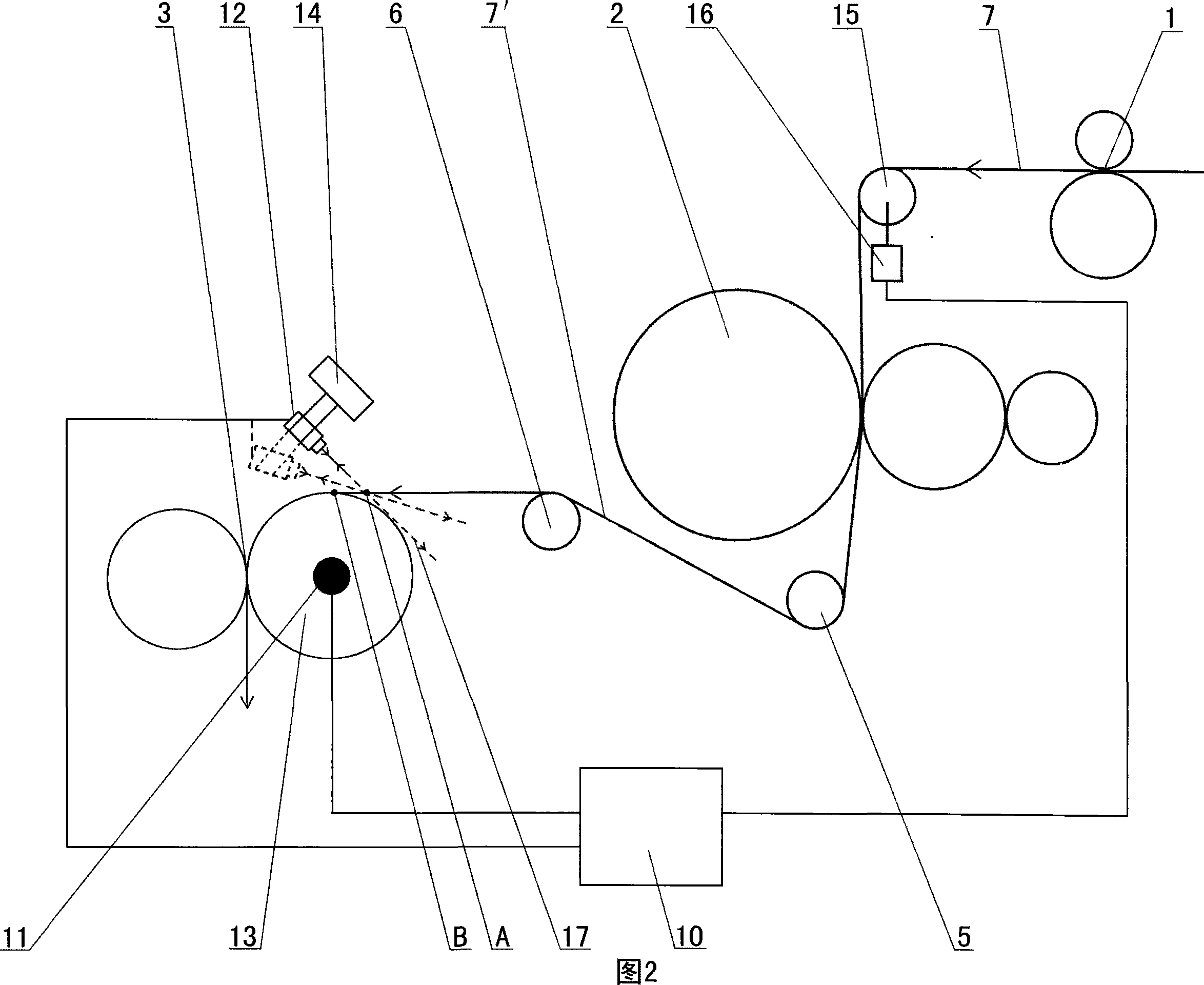

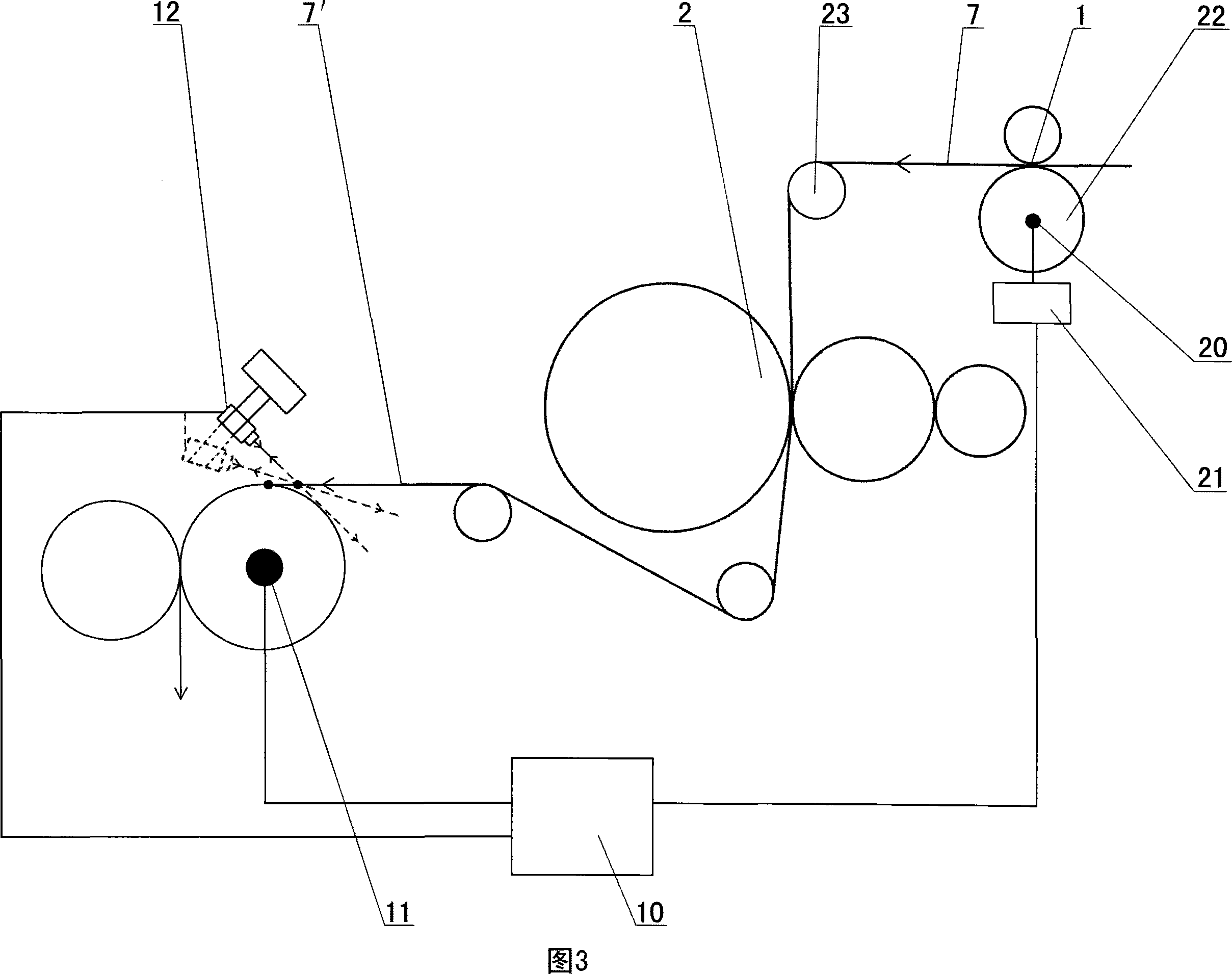

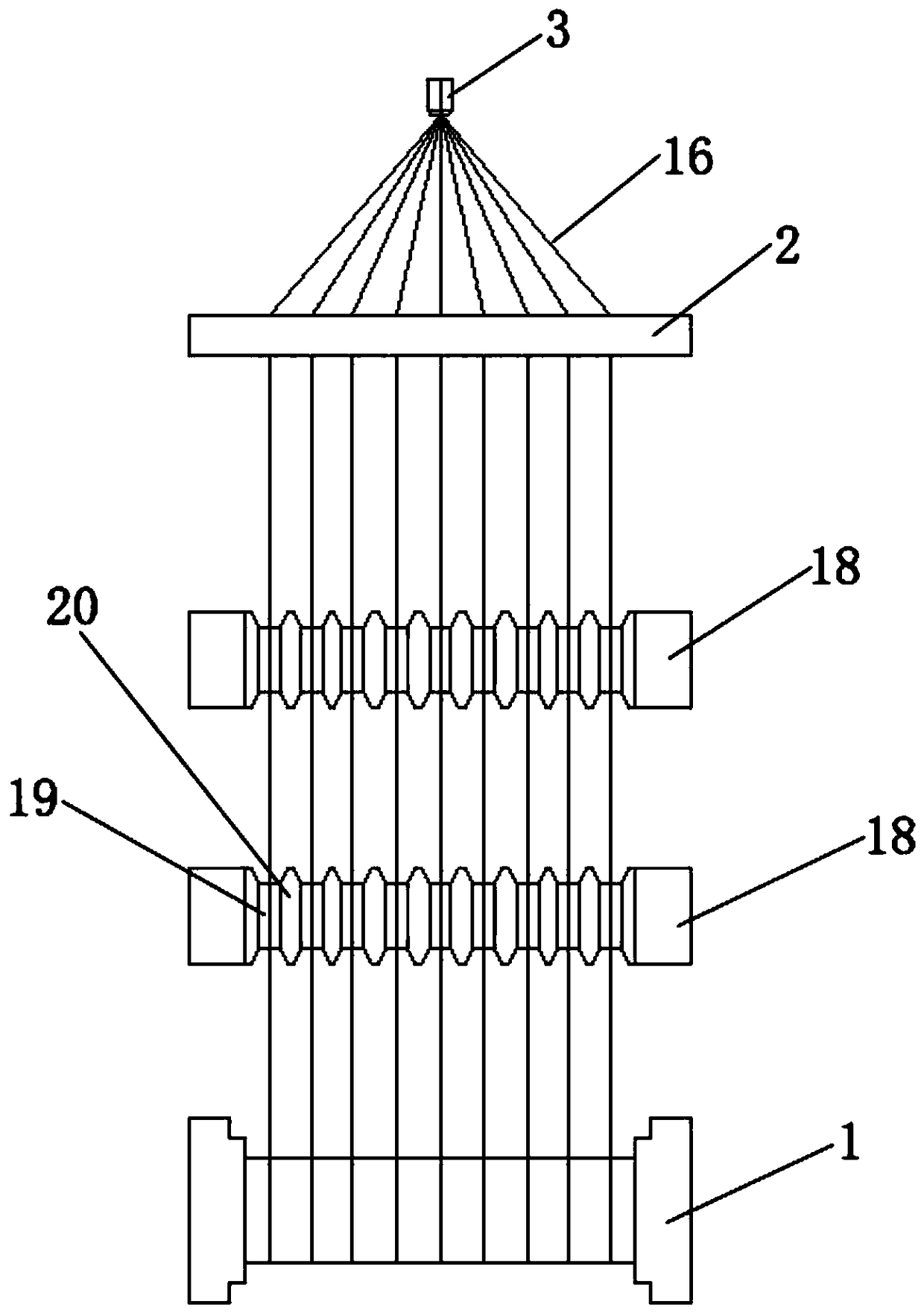

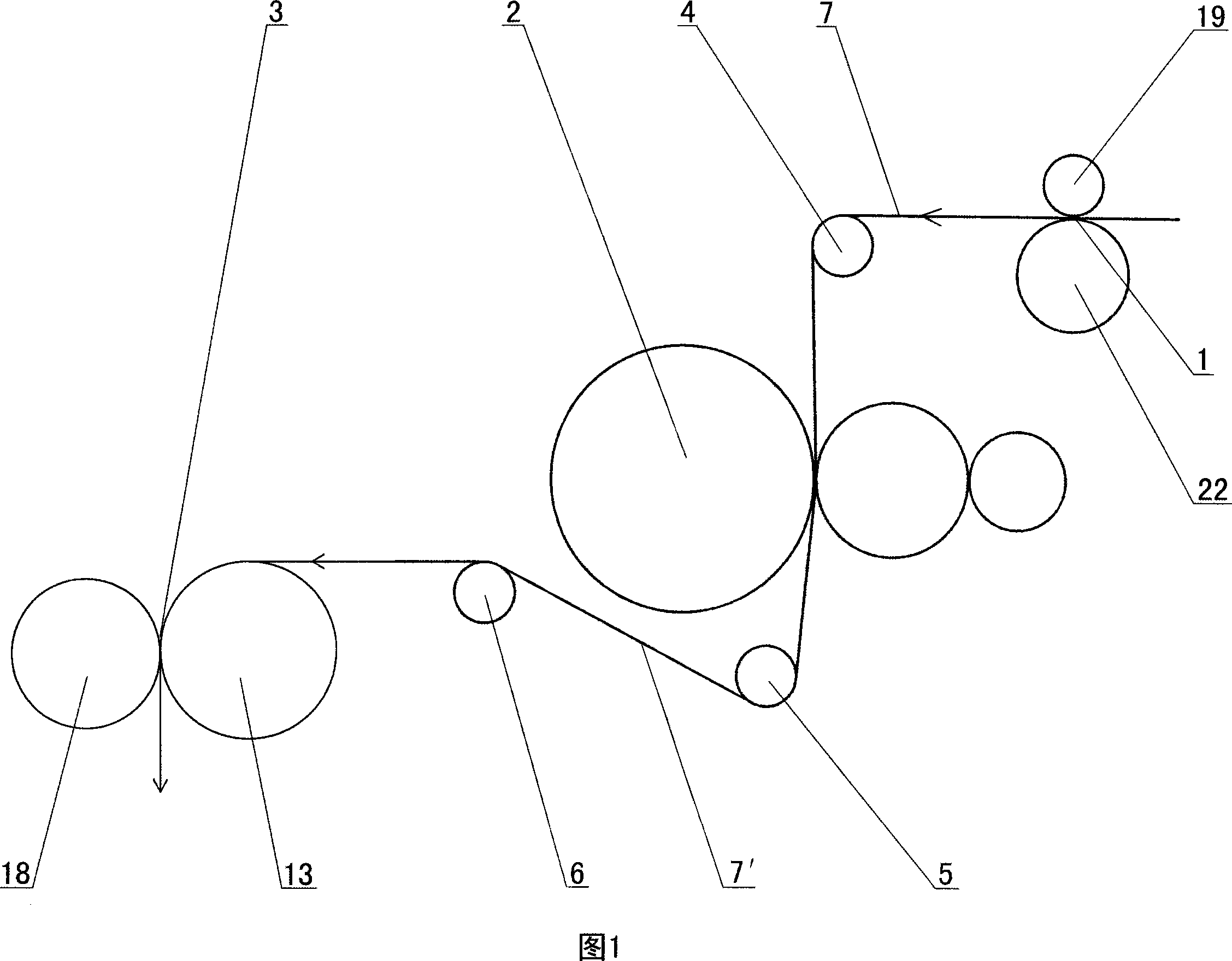

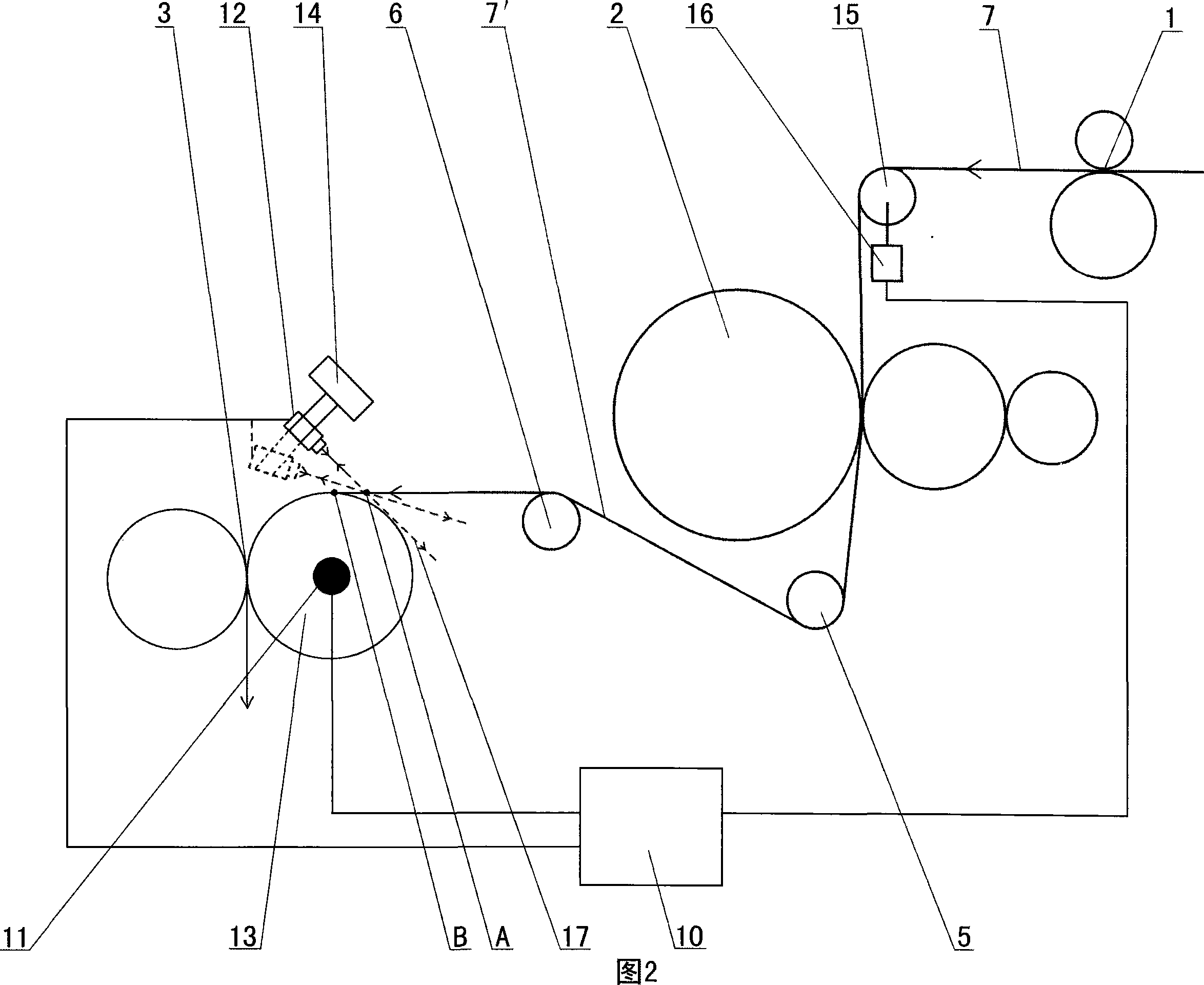

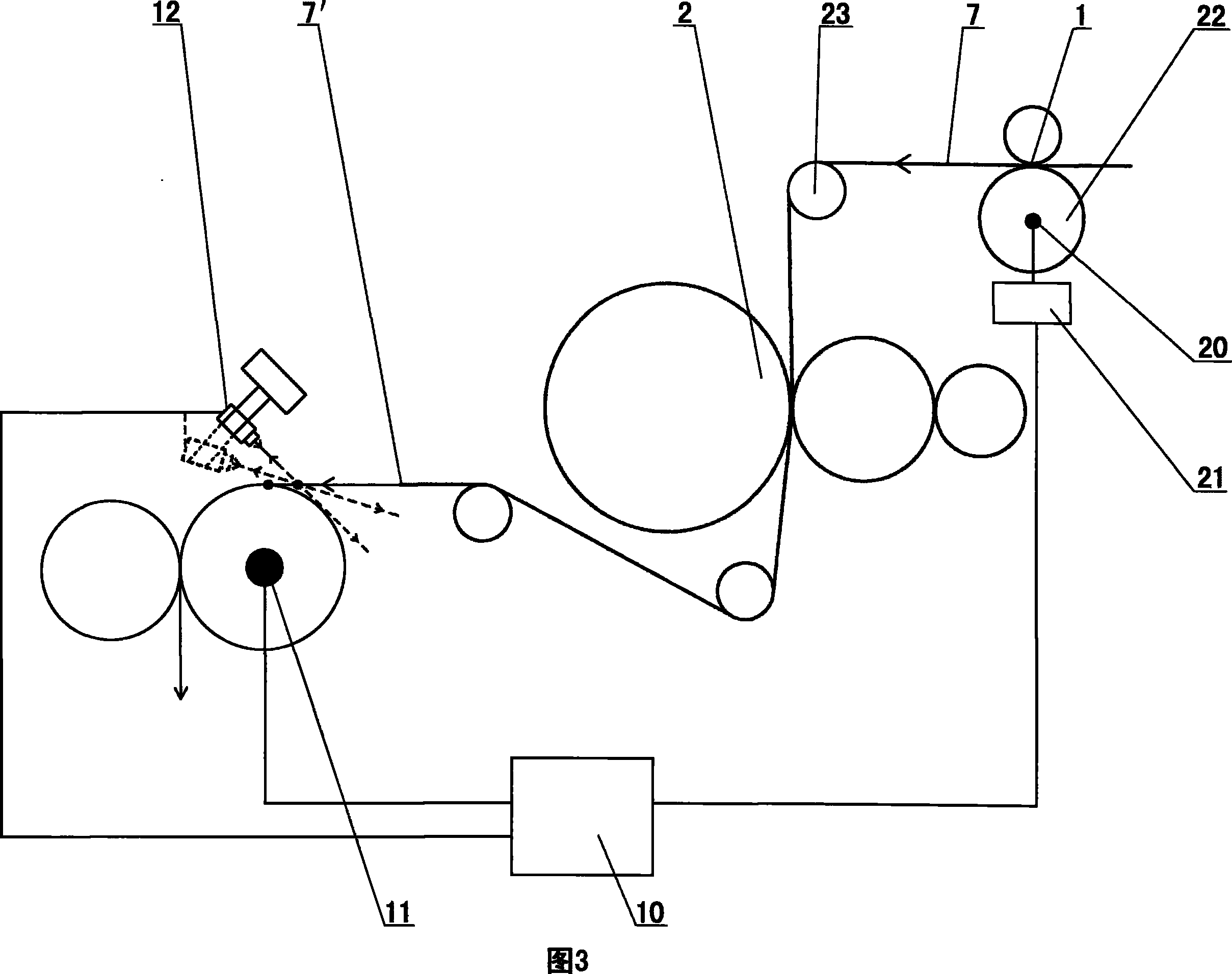

Method for producing equal edition breadth holographic moulding film and its molding device

ActiveCN101216664AHigh precisionCompensation for format errorDecorative surface effectsPhotomechanical apparatusFilm materialTension control

The invention discloses a method for manufacturing a pressed film of an equal-plate-breadth holographic mask and a mold pressing device thereof. The method comprises the following steps: detecting the actual plate breadth of the pressed film of the equal-plate-breadth holographic mask in a constant-tension control section, comparing the detected actual plate breadth with the preset plate breadth to obtain a plate breadth difference, adjusting the tension of a variable-tension control section according to the plate breadth difference, facilitating film material of the variable-tension control section to stretch or shrink after entering the constant-tension control section in order to compensate the plate breadth difference and to produce the high-precision pressed film of the equal-plate-breadth holographic mask. The mold pressing device comprises a set of leading-in traction rollers, a set of mold pressing rollers, a set of leading-out traction rollers, a guide roller and a stretch roller, which are arranged in order. The mold pressing device is characterized in that: the mold pressing device is provided with a tension control device which is adjusted to compensate the plate breadth difference caused by changes of temperature and properties of the film material, so as to control the difference within a certain range, thereby improving the precision of the plate breadth and outputting high-precision pressed films of the equal-plate-breadth holographic mask.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH

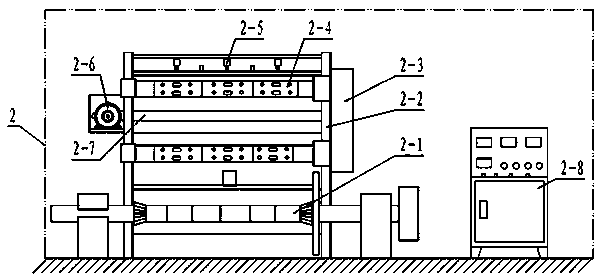

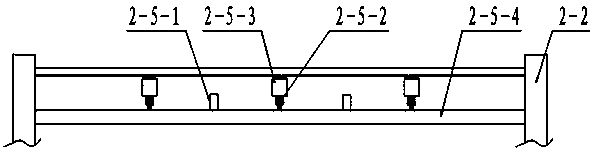

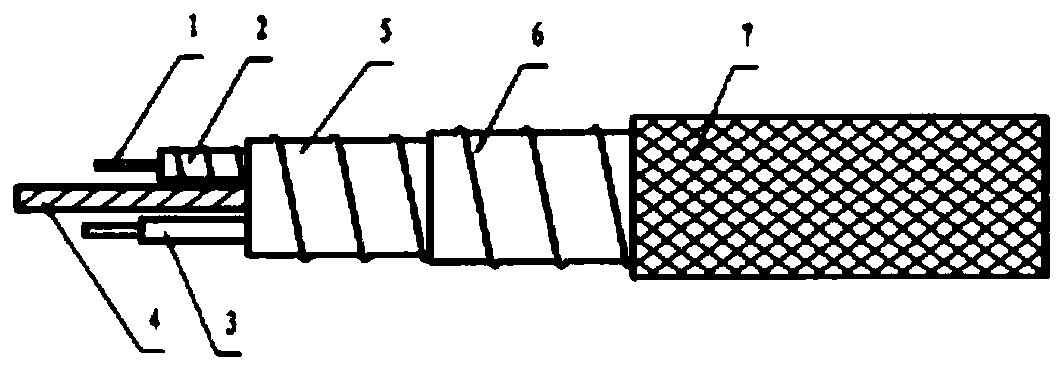

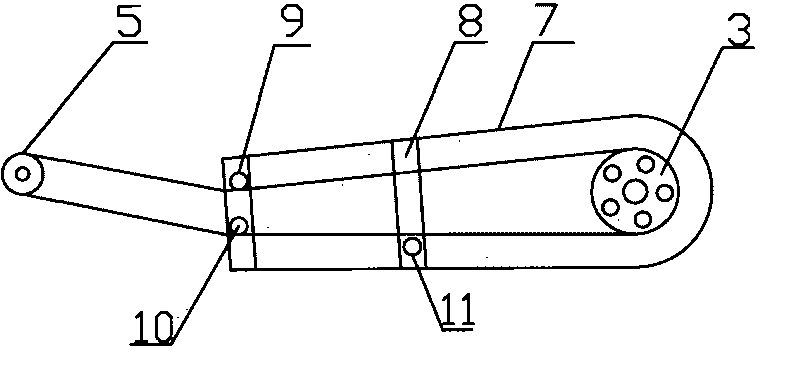

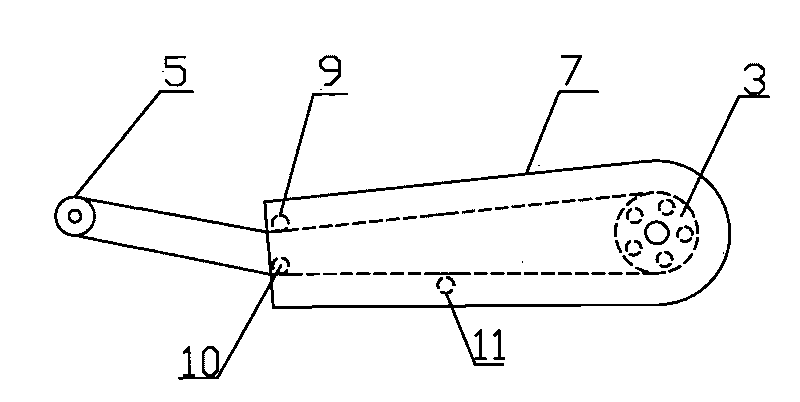

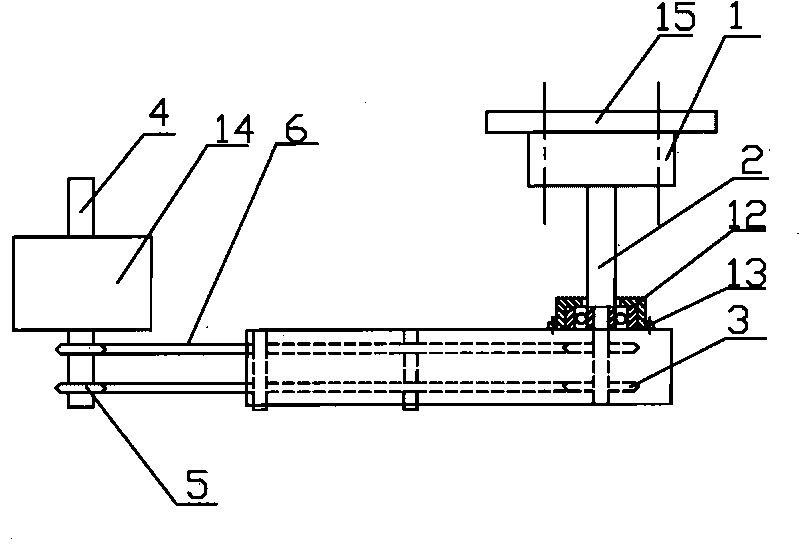

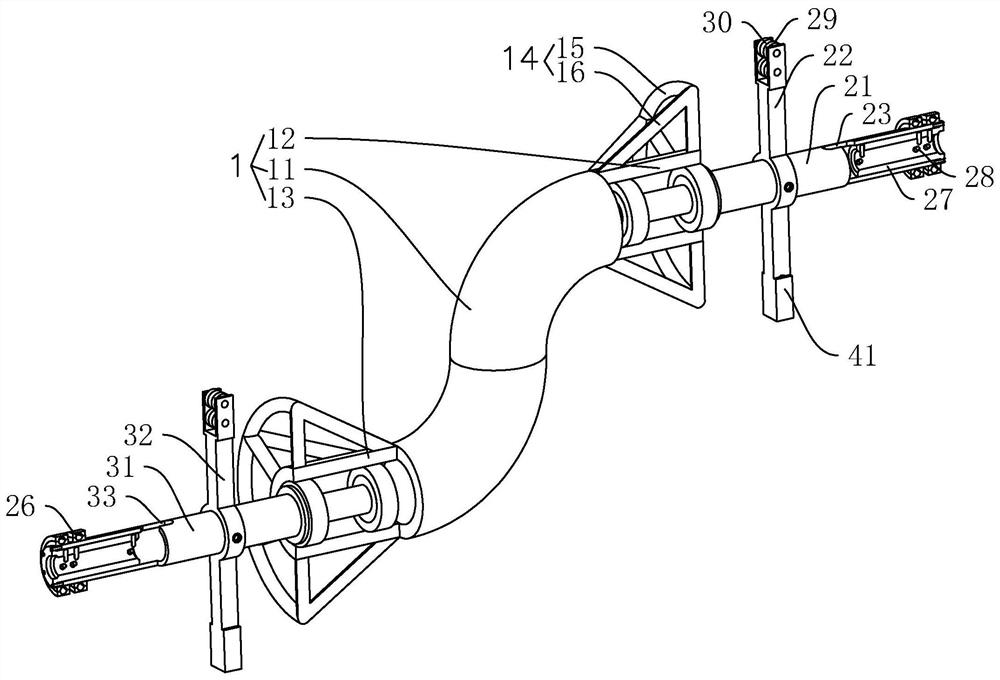

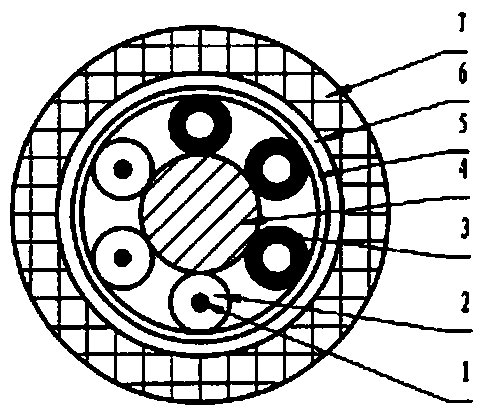

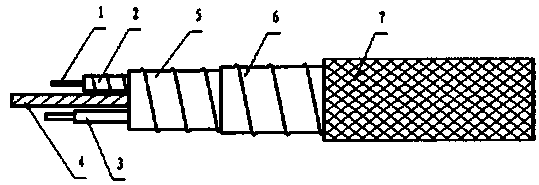

Wrapping machine for cable production line

ActiveCN110610784AAchieve tension controlEasy to controlCable/conductor manufactureProduction lineEngineering

The invention discloses a wrapping machine for a cable production line, and relates to the field of cable manufacturing devices. The wrapping machine comprises a rack, and a wrapping device, a belt releasing transmission mechanism, a wrapping transmission mechanism and a speed measuring device are installed on the rack. The wrapping device comprises a central pipe, a hollow belt releasing shaft and a hollow wrapping shaft which are concentrically arranged. A wrapping disc is fixedly arranged at one end of the wrapping shaft. The belt releasing shaft is arranged in the wrapping shaft, and one end of the belt releasing shaft is detachably connected with a belt coil. The central pipe is arranged in the wrapping shaft in a penetrating mode, and a mold core is fixedly arranged in the central pipe. The belt releasing transmission mechanism comprises a motor a for driving the belt releasing shaft to rotate. The wrapping transmission mechanism is used for driving the wrapping shaft to rotate.The speed measuring device is used for detecting the advancing speed of a to-be-wrapped core wire. The wrapping machine further comprises a controller, and the speed measuring device, the belt releasing transmission mechanism and the wrapping transmission mechanism are all electrically connected with the controller. The wrapping machine can automatically and accurately control and complete adjustment of the wrapping pitch and adjustment of the tension, and can meet the use requirements of wrapping in various technological processes in cable manufacturing.

Owner:CHENGDU DATANG CABLE

Transmission mechanism of seeder

InactiveCN101715672AAchieve tension controlImprove sowing qualityFertiliser equipmentsSeederDrive shaft

The invention discloses a transmission mechanism of a seeder, which comprises an input transmission shaft, a first sprocket wheel, an output transmission shaft, a second sprocket wheel and a chain. The first sprocket wheel is arranged on the input transmission shaft; the second sprocket wheel is arranged on the output transmission shaft; and the chain is arranged on the first and the second sprocket wheels. The transmission mechanism of the seeder is characterized in that: the input transmission shaft is connected with the wheel hub of a tractor rotating wheel; the output transmission shaft is connected with the main shaft gearbox of the seeder; and the chain is provided with a floating tension device. In the transmission mechanism of the seeder of the invention, the input transmission shaft is connected with the transmission mechanism which enables the tractor to go forward, and the transmission chain is provided with the floating tension device which is used for tensioning the loosened chain at the traction section to realize the tension control for the chain, so the synchronization of the input and the output transmission shafts is ensured, the phenomena of miss-seeding and non-uniform seeding density are avoided, and the seeding quality of the farmland is increased.

Owner:蒋宝华 +1

Bed sheet tension control system

The invention discloses a bed sheet tension control system. A drive support is arranged at one end of a bed body in a hanging mode, a tension sensor is arranged outside the upper portion of the drive support, and a bed sheet is pressed between a first friction barrel and a second friction barrel after passing through a bed surface and the tension sensor; the second friction barrel is connected with a motor through a coupler, and the first friction barrel and the second friction barrel are mutually tightly compressed and are located on the inner sides of the drive support. A rolling barrel support is arranged at the other end of the bed body in a hanging mode, one end of an electric clutch is fixedly connected with the rolling barrel support, and the other end of the electric clutch is installed on a driven shaft; a paper bed sheet rolling barrel is sleeved on the driven shaft and is fixed through a chuck. The electric clutch, the motor and the tension sensor are controlled by an automatic tension controller. The bed sheet tension control system can be used in automatic bed sheet replacing equipment on a medical checking bed, achieve bed sheet tension control in the bed sheet replacing process, and guarantee smooth bed sheet replacing and emergency braking.

Owner:HANGZHOU DIANZI UNIV

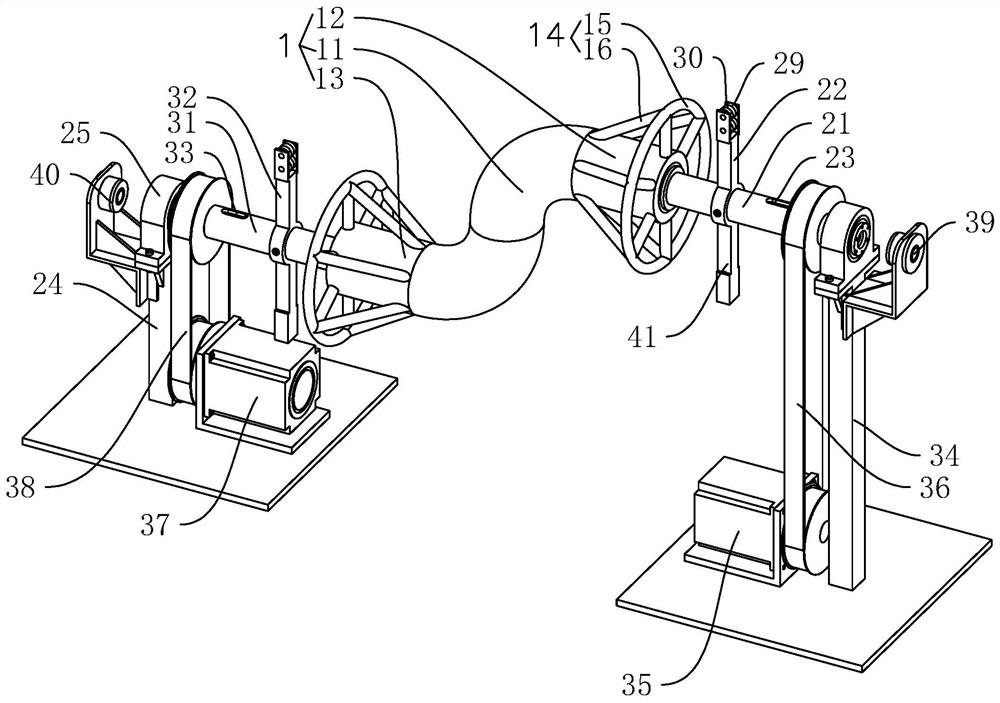

Fiber rope pre-drawing device and pre-drawing method

ActiveCN112663366BPre-Draft RealizationAchieve tension controlRope making machinesFiberStructural engineering

Owner:SHANDONG ROPE TECH CO LTD +2

Sheet tension control system

The invention discloses a bed sheet tension control system. A drive support is arranged at one end of a bed body in a hanging mode, a tension sensor is arranged outside the upper portion of the drive support, and a bed sheet is pressed between a first friction barrel and a second friction barrel after passing through a bed surface and the tension sensor; the second friction barrel is connected with a motor through a coupler, and the first friction barrel and the second friction barrel are mutually tightly compressed and are located on the inner sides of the drive support. A rolling barrel support is arranged at the other end of the bed body in a hanging mode, one end of an electric clutch is fixedly connected with the rolling barrel support, and the other end of the electric clutch is installed on a driven shaft; a paper bed sheet rolling barrel is sleeved on the driven shaft and is fixed through a chuck. The electric clutch, the motor and the tension sensor are controlled by an automatic tension controller. The bed sheet tension control system can be used in automatic bed sheet replacing equipment on a medical checking bed, achieve bed sheet tension control in the bed sheet replacing process, and guarantee smooth bed sheet replacing and emergency braking.

Owner:HANGZHOU DIANZI UNIV

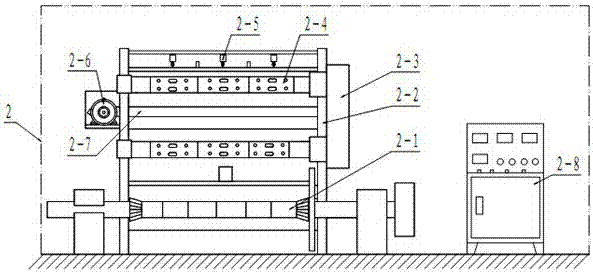

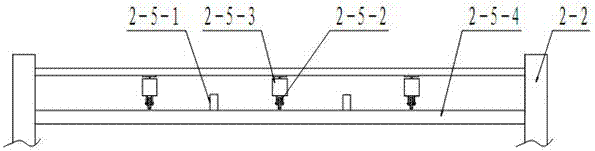

Improved beaming device for sizing machine

InactiveCN105540337AContinuous effective tension adjustmentReduce tensionFilament handlingYarnGear wheel

The invention discloses an improved beaming device for a sizing machine. The improved beaming device is characterized in that warp beam discs are fixedly installed on the outer circle of each of the left end and the right end of a warp beam; a gear is installed and fixed to the part, on the right side of the warp beam discs, on the warp beam through a clamping ring; the part, between the warp beam discs at the left end and the right end, of the warp beam is used for winding yarn on which sizing is conducted; a hole is formed in the center of each of the left end and the right end of the warp beam; spindle heads are installed and fixed in the center holes in the left end and the right end of the warp beam; a first pin shaft on the left side face of a belt wheel is inserted in a first pin shaft hole and a second pin shaft on the left side face of the belt wheel is inserted in a second pin shaft hole; the spindle heads at the left end and the right end of the warp beam are located in a bearing bush at the upper end of a supporting pillar; the lower end of the supporting pillar is welded to a base; adjusting plates are welded to the two sides of the supporting pillar; adjusting screw rods are installed in long slotted holes through nuts; and hooks at the two ends of a belt arranged on the belt wheel in a sleeving manner are hung on hanging rings on the adjusting screw rods. The improved type sizing beaming tension adjusting device is formed.

Owner:JIHUA 3542 TEXTILE CO LTD

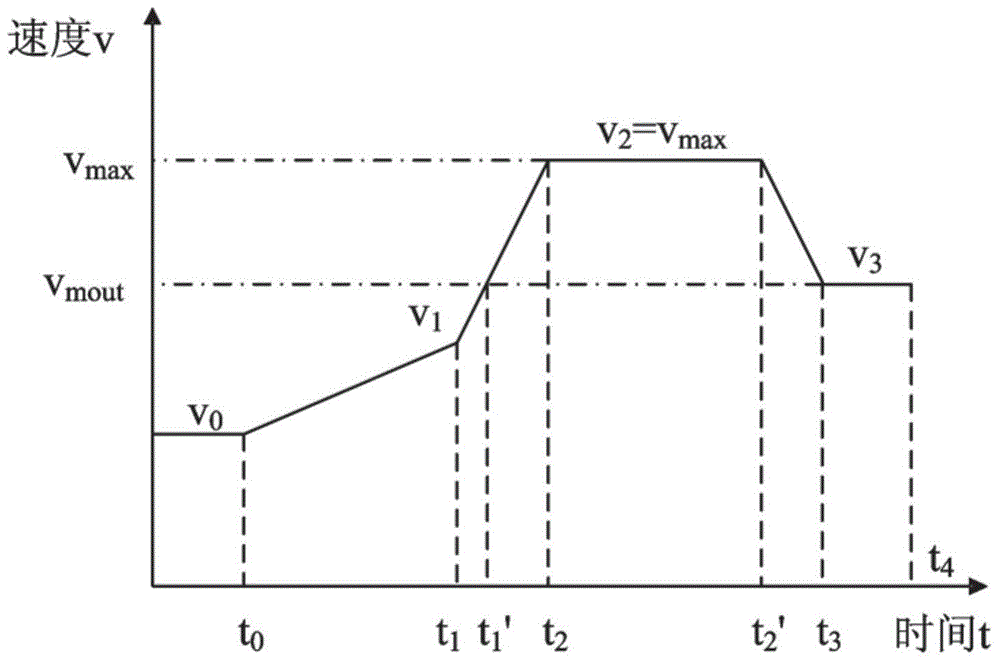

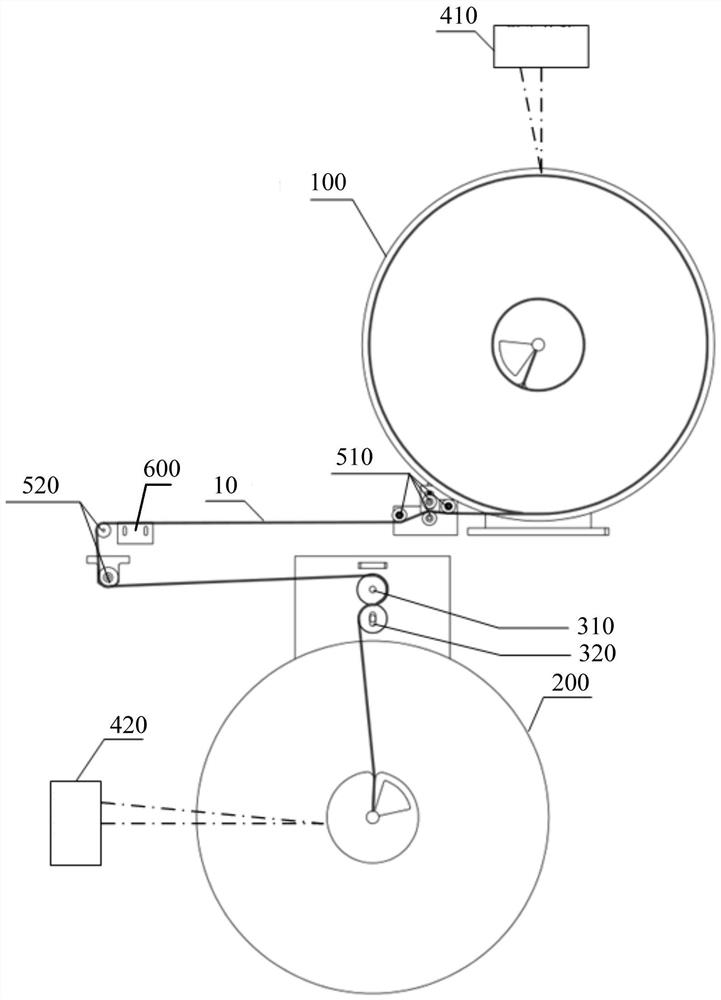

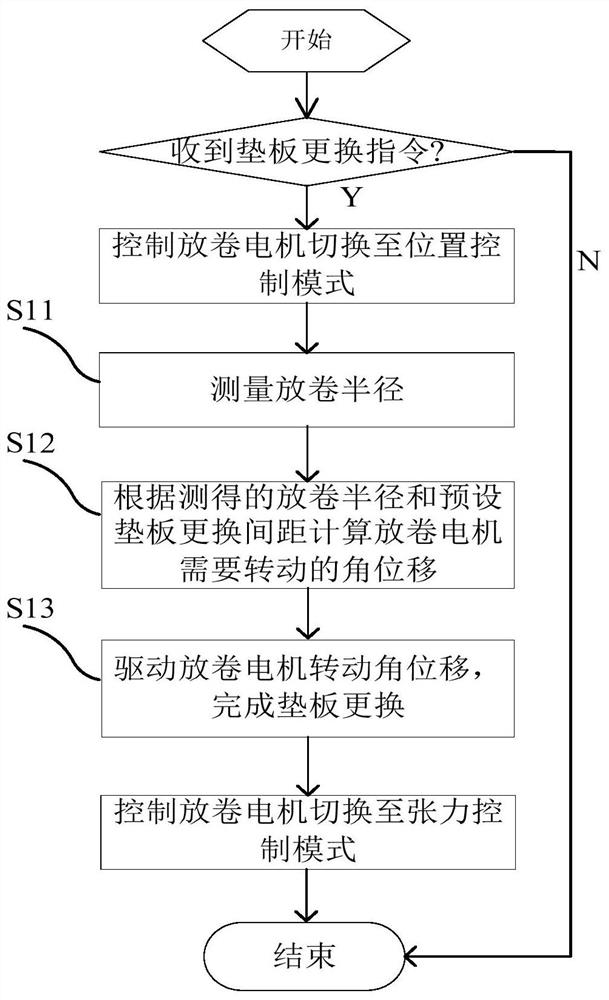

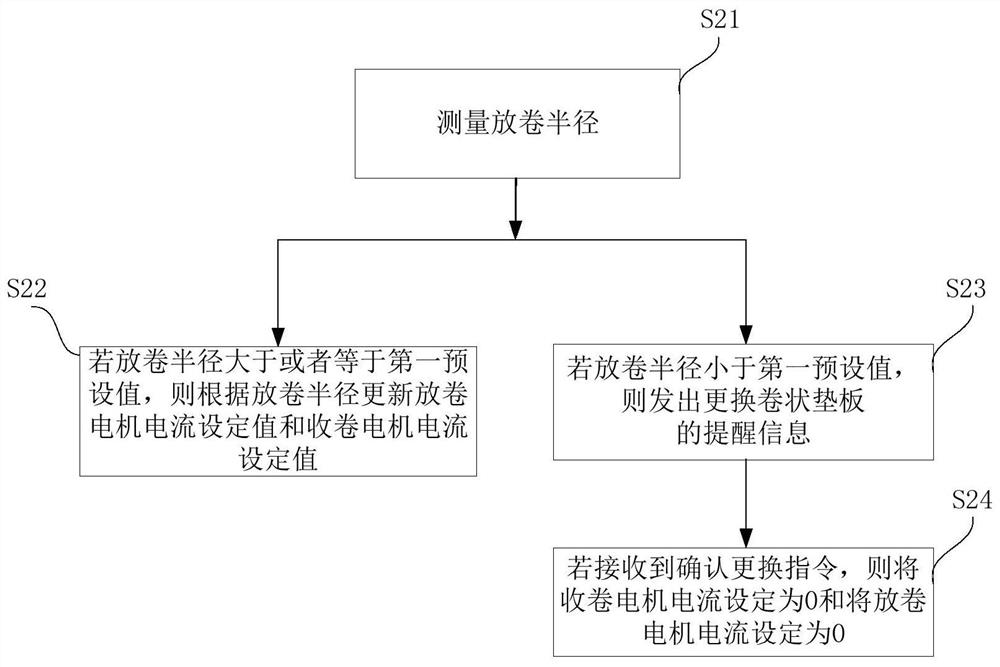

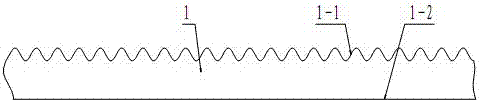

Automatic replacing device and method for base plate for numerical control code drilling

PendingCN112008796AGood drilling process effectReplacement spacing is preciseMetal working apparatusElectric machineryControl mode

The invention discloses an automatic replacement device and method for a base plate for numerical control code drilling. The automatic replacement method of the base plate for the numerical control code drilling comprises the following steps that an unwinding motor is controlled to be switched between a position control mode and a tension control mode; after a base plate replacement instruction isreceived, the unwinding motor is controlled to be switched to the position control mode; and after the base plate is replaced, the unwinding motor is controlled to be switched to the tension controlmode. According to the automatic replacement method of the base plate for numerical control code drilling, the actual requirement for automatic replacement of the base plate is considered; by combining the characteristic of flexible switching of control modes of the unwinding driving mechanism and the characteristic of real-time tension control of the base plate, the device has the advantages of being more flexible and higher in universality, real-time tension control over a base plate winding belt can be achieved, and therefore the base plate can be kept in a tensioned state in the code drilling process, and a good code drilling process effect is obtained; and meanwhile, the universal requirements that the base plate replacement interval is accurate enough and the base plate replacement interval parameter is adjustable are met.

Owner:SUZHOU VEGA TECH CO LTD

A pvc diaphragm cutting machine

ActiveCN104176553BImprove cut qualitySimplify production stepsArticle deliveryWebs handlingDrive shaftEngineering

The invention discloses a PVC membrane dividing and cutting machine which comprises a feeding mechanism, a dividing and cutting actuating mechanism, a material collecting mechanism, a drive motor, a transmission shaft, a transmission mechanism, a rack and a control cabinet, wherein the feeding mechanism, the dividing and cutting actuating mechanism and the material collecting mechanism are mounted on the rack; the drive motor is mounted on the frame on one side of the rack; the transmission mechanism is mounted on the frame on the other side of the rack; the drive motor is connected with the transmission mechanism through the transmission shaft; power is transmitted to the feeding mechanism, the dividing and cutting actuating mechanism and the material collecting mechanism by the transmission mechanism. The PVC membrane dividing and cutting machine has the characteristics as follows: the dividing and cutting actuating mechanism is provided with a group of direct cutters and a group of disc cutters, which are distributed at intervals; the direct cutters are fixed on the cross beam of the rack, and the disc cutters are mounted on the top cross beam of the rack through a drive air cylinder; and besides, the PVC membranes are cut into strips simultaneously with rickracks left on the edges, so that the labor intensity of operators is reduced, and the working efficiency is improved.

Owner:HEBEI JINDA PLASTIC

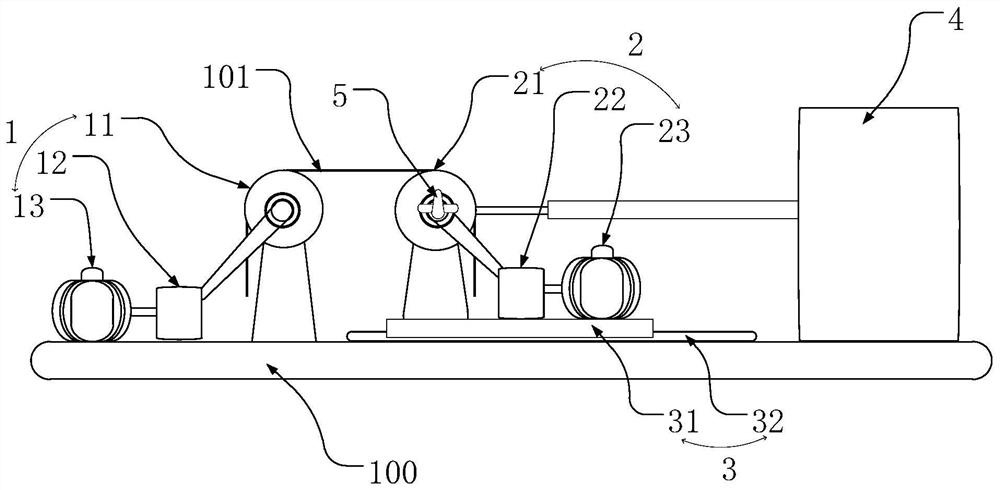

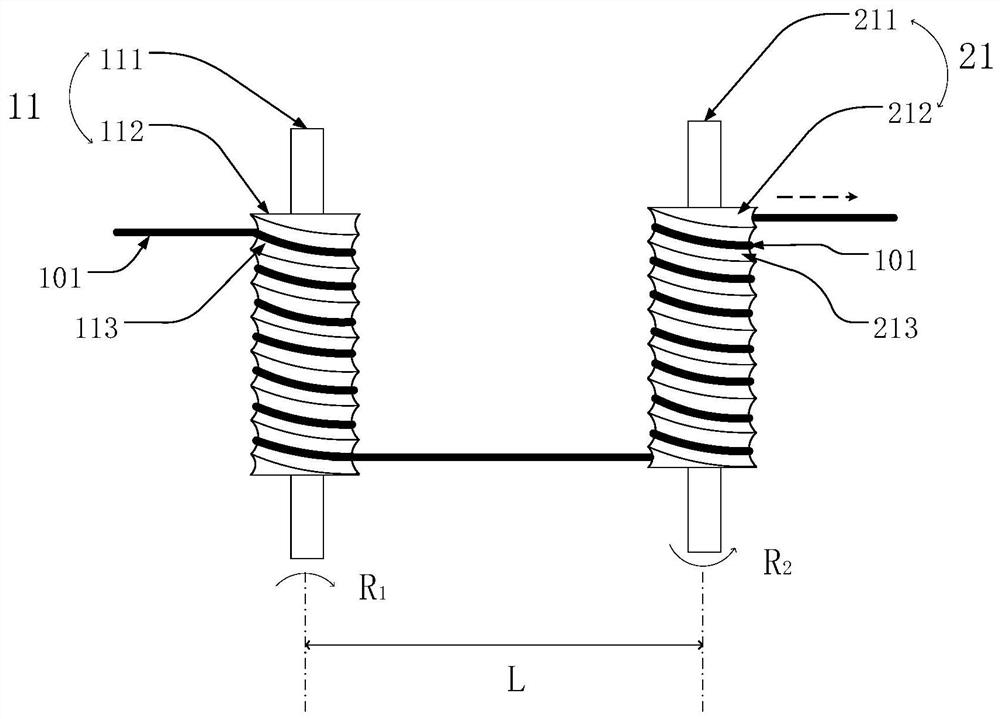

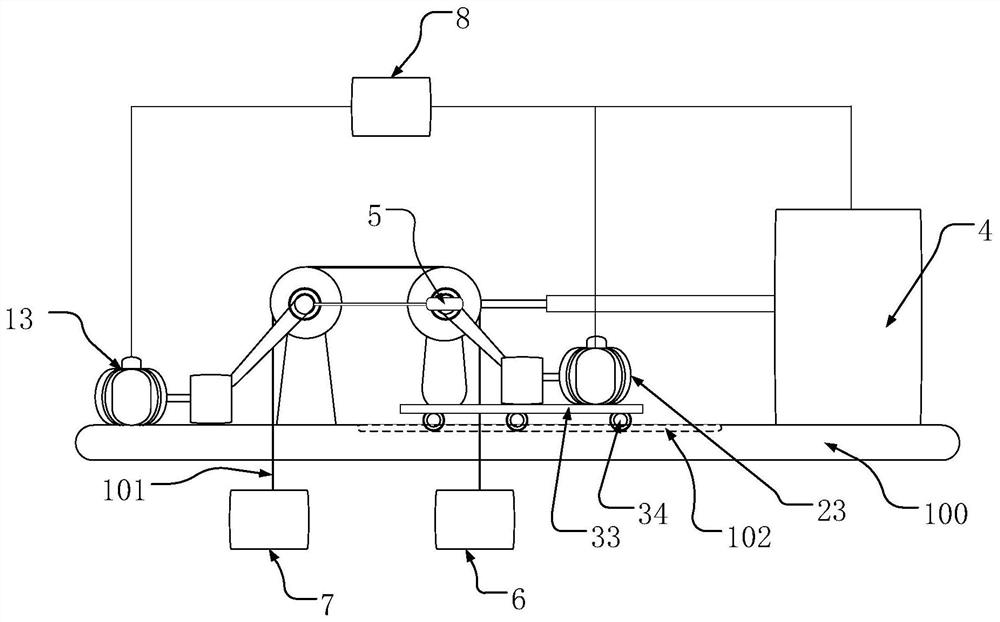

A multi-axis synchronous control device

ActiveCN102874637BAchieve tension controlSave adjustment timeWebs handlingElectric machineSynchronous control

The invention discloses a multi-shaft synchronous control device, which comprises an unwinding roller, a transmission roller, a winding roller and a control device, wherein the control device comprises a winding control device for controlling the winding roller, a transmission control device for controlling the transmission roller and a main controller for controlling the running of the parts. By adopting the multi-shaft synchronous control device, when tension control experiment teaching and scientific research are developed, a brake device and a tension controller can be eliminated, and servo synchronous driving and tension control of a plurality of motors are realized; the adjustment time and a space occupied by equipment are saved; and the multi-shaft synchronous control device controls the parts precisely.

Owner:海南经济特区中质猎鹰智能勘测科技有限公司

Method for preparing transmission tube blank made from filament wound composite material

ActiveCN102092139BImprove moisture resistanceStrong mold resistanceTubular articlesGlass fiberHigh humidity

The invention discloses a method for preparing a transmission tube blank made from a filament wound composite material, and relates to a method for preparing a transmission tube blank. The invention aims to solve the problem that a dynamic load transmission tube blank made of a metal material is easily resonated with other metal parts to threaten the safety of an aircraft, and has low humidity resistance and moldproof property. The method comprises the following steps of: 1, preheating a mold; 2, covering a film on the mold; 3, heating the mold; 4, arranging glass fibers on a fiber tensioner; 5, dragging the glass fibers into the mold; 6, arranging carbon fibers on the fiber tensioner; 7, winding a main structural layer; 8, winding the glass fibers; 9, regulating winding parameters and winding again; 10, curing and molding; 11, demolding; and 12, performing surface treatment. The composite material wound transmission tube blank has the advantages of high humidity resistance and high moldproof property, avoids resonance with other metal parts, and greatly improves the safety of the aircraft.

Owner:HARBIN FRP INST

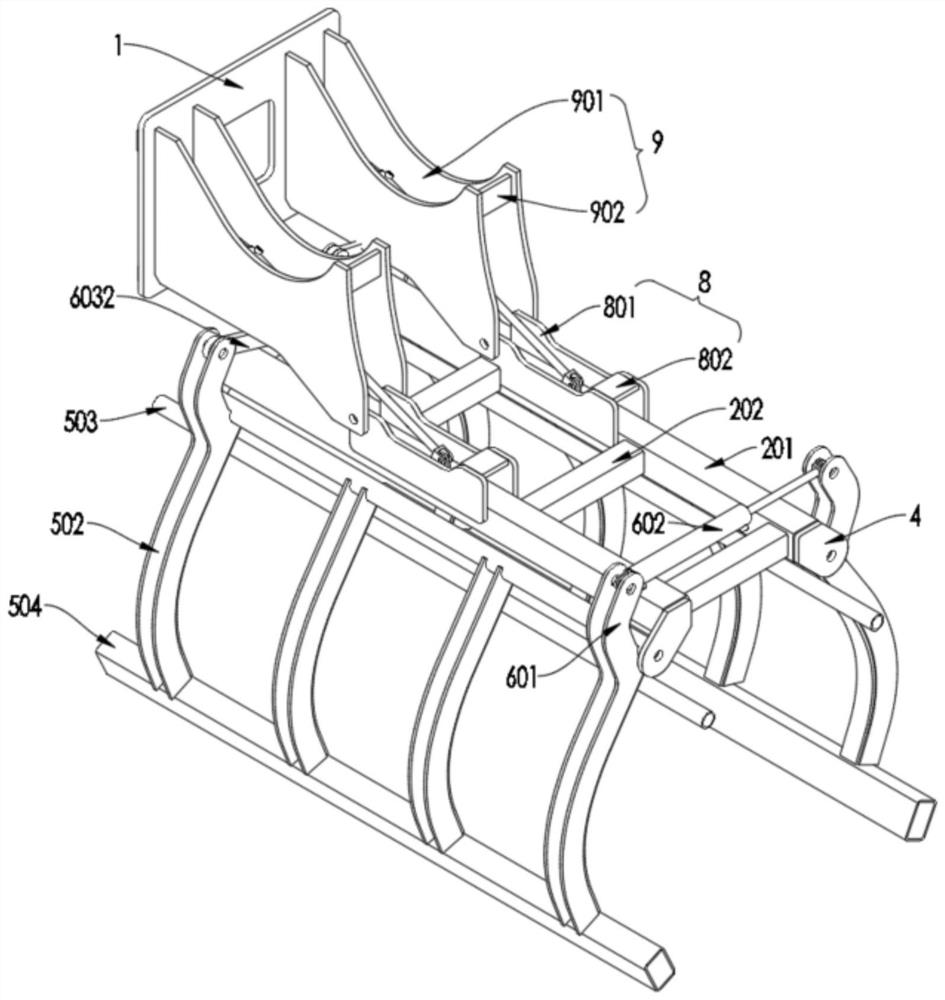

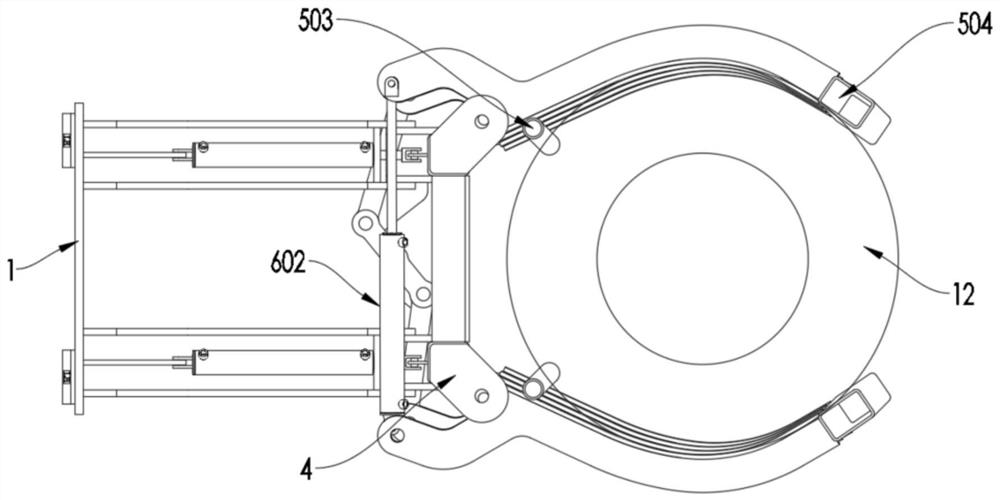

A tipping tire clamp

ActiveCN113023196BPrevent extrusionSafe and reliable clampingConveyorsStorage devicesHydraulic cylinderClassical mechanics

The invention relates to a tipping tire clamp, comprising a fixing seat; a mounting frame, which can be swingably installed on the fixing seat, and a corresponding swing driving hydraulic cylinder is telescopically connected between the mounting frame and the fixing seat, and the mounting frame The two sides of the upper and lower ends are respectively fixed with corresponding fixed mounting parts; the clamping arm mechanism includes a set of fixed shafts that are rotatably installed between the fixed mounting parts on both sides of the mounting frame, and the fixed shafts are respectively fixed to the outside There are a plurality of arc-shaped rods arranged at intervals, the outer ends of the arc-shaped rods are respectively fixed with corresponding limit square tubes, and the inner sides of the arc-shaped rods are respectively fixed with corresponding limit round tubes; the clamp arm drive mechanism , including two sets of drive plates integrally fixed on the arc rods located at the uppermost and lower ends, the telescopic device between the upper set of drive plates has a corresponding clamping drive cylinder, and the lower set of drive plates A set of corresponding synchronous linkages is installed between the plates. The invention has the advantages of simple structure, low cost and light weight.

Owner:LONGHE INTELLIGENT EQUIP MFG CO LTD

Tension-adjustable copper wire winding device for transformer production

InactiveCN109961946ATo achieve tensionAchieve tension controlInductances/transformers/magnets manufactureCopper wireGear wheel

The invention discloses a tension-adjustable copper wire winding device for transformer production, which comprises a base. The upper surface of the base is fixedly connected with an installation plate. The middle of the installation plate is fixedly connected with a first bearing. The inner ring of the first bearing is fixedly connected with a rotating shaft. One end of the rotating shaft is fixedly connected with a driving taper gear. The surface of the installation plate is fixedly connected with bearing seats. The inside of each bearing seat is fixedly connected with a second bearing. Theinner ring of each second bearing is fixedly connected with a threaded rod. According to the tension-adjustable copper wire winding device for transformer production, a first tensioning wheel and a second tensioning wheel can be adjusted. An adjusting rod is rotated through a handle, the adjusting rod drives the rotating shaft to rotate, the rotating shaft is in threaded connection with a positioning block, the positioning block drives a telescopic pipe to slide up and down, and thus, the first tensioning wheel and the second tensioning wheel are driven to slide for adjustment. The problem that a common tensioning device for copper wires is inconvenient to adjust is solved.

Owner:JIANGSU GUANGTE ELECTRIC

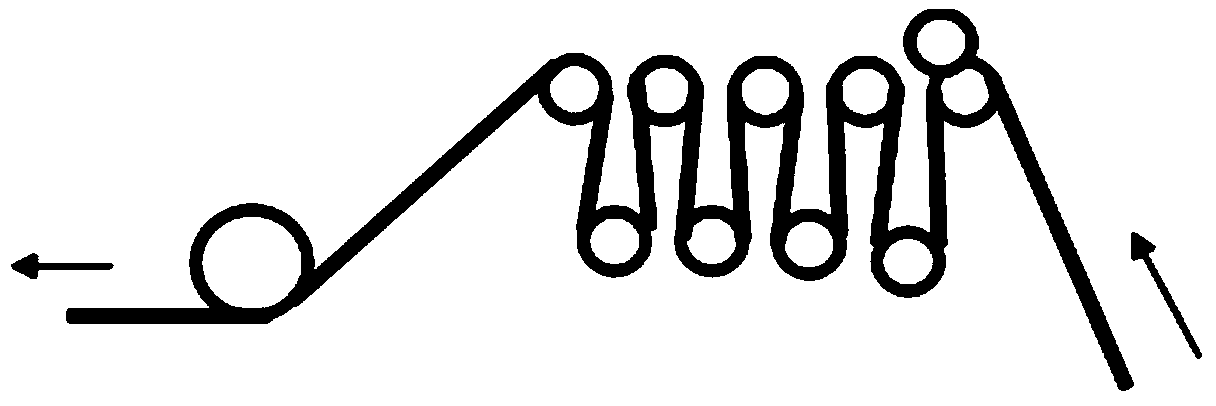

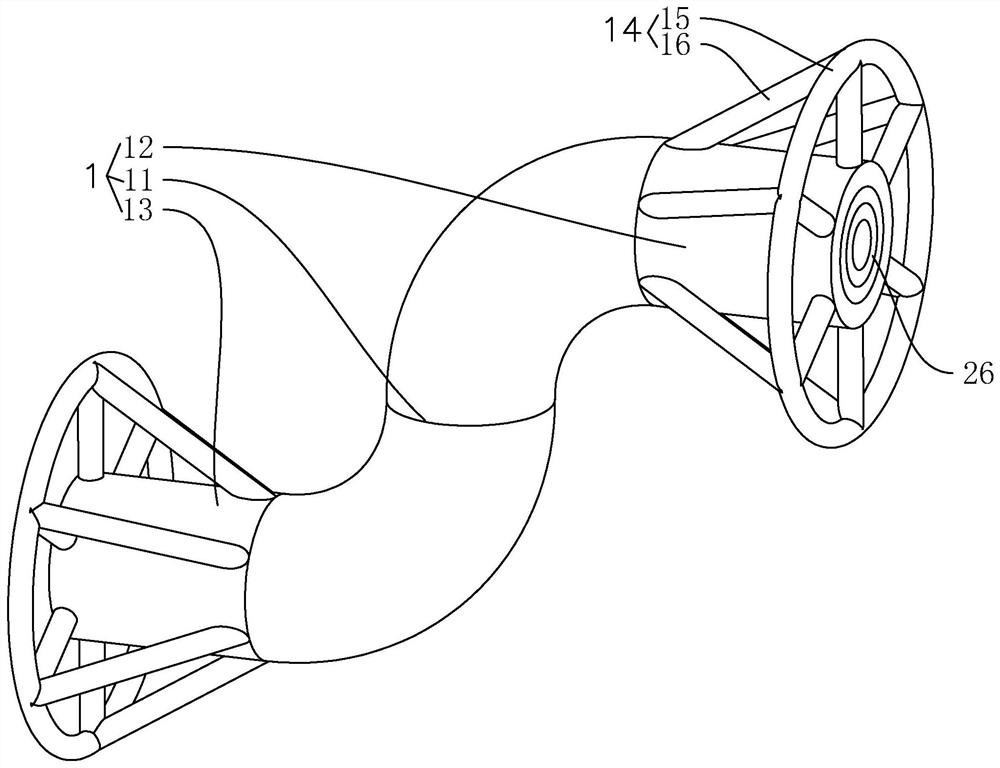

Wire storage device for wire winding

InactiveCN111646302AAchieve tension controlReduce output speedFilament handlingWire rodStructural engineering

The invention discloses a wire storage device for wire winding, and relates to wire winding. The wire storage device for the wire winding aims at solving the problem that the wire storage amount is lower, according to the technical solution key points of the wire storage device, the wire storage device for the wire winding comprises a wire storage barrel, an inlet wire winding mechanism and an outlet wire winding mechanism, wherein the wire storage cylinder comprises a bent section, a horizontal wire inlet section and a horizontal wire outlet section, the bent section is bent in an arc shape twice, the wire inlet winding mechanism comprises a wire inlet hollow shaft and a wire inlet swing arm, a wire outlet hole is formed in the shaft wall of the wire inlet hollow shaft in a penetrating mode, the wire outlet winding mechanism comprises a wire outlet hollow shaft and a wire outlet swing arm, and a wire inlet hole is formed in the shaft wall of the wire outlet hollow shaft in a penetrating mode. According to the wire storage device for the wire winding, the storage capacity of wires is effectively improved, and mutual influences of tension at the two ends of the wires are avoided.

Owner:JIAXING JIECHENG MACHINERY

Winding device of wire drawing machine

InactiveCN108637143ADurable and stable wire feeding speedLess prone to adverse phenomenaEngineeringGuide wires

The invention discloses a winding device of a wire drawing machine. The winding device comprises a single wire winding roller, a guide wire roller set, a guide wire plate, a stranded wire mold, a tension regulating and controlling device, a stranded wire porcelain eye and a stranded wire winding roller; the tension regulating and controlling device comprises a hair felt clamp, a first guide wire wheel, a tension wheel, a second guide wire wheel, a tension adjusting plate, a spring assembly, a fixed shaft rotating wheel and a floating guide wire wheel which are assembled on one installing platein an integrated manner, a plurality of single wires obtained after stretching treatment are jointly and flatly arranged through the single wire winding roller and the guide wire roller set to then penetrate all wire penetration holes in the guide wire plate, the single wires then form stranded wires through the stranded wire mold, the stranded wires are sequentially wound through the stranded wire winding roller after passing through the hair felt clamp, a first guide wire wheel, a tension wheel, a second guide wire wheel, the floating guide wire wheel and the stranded wire porcelain eye. According to the winding device, wire arrangement is regular and orderly, under durable and stable tension control, stranded wire winding operation is continuously carried out, and the production efficiency and the wire stranding quality are better improved.

Owner:HANGZHOU JINSHENG METAL PROD

Method for producing equal edition breadth holographic moulding film and its molding device

ActiveCN101216664BControl format precisionQuick responseDecorative surface effectsPhotomechanical apparatusEngineeringFilm material

The invention discloses a method for manufacturing a pressed film of an equal-plate-breadth holographic mask and a mold pressing device thereof. The method comprises the following steps: detecting the actual plate breadth of the pressed film of the equal-plate-breadth holographic mask in a constant-tension control section, comparing the detected actual plate breadth with the preset plate breadth to obtain a plate breadth difference, adjusting the tension of a variable-tension control section according to the plate breadth difference, facilitating film material of the variable-tension control section to stretch or shrink after entering the constant-tension control section in order to compensate the plate breadth difference and to produce the high-precision pressed film of the equal-plate-breadth holographic mask. The mold pressing device comprises a set of leading-in traction rollers, a set of mold pressing rollers, a set of leading-out traction rollers, a guide roller and a stretch roller, which are arranged in order. The mold pressing device is characterized in that: the mold pressing device is provided with a tension control device which is adjusted to compensate the plate breadth difference caused by changes of temperature and properties of the film material, so as to control the difference within a certain range, thereby improving the precision of the plate breadth and outputting high-precision pressed films of the equal-plate-breadth holographic mask.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH

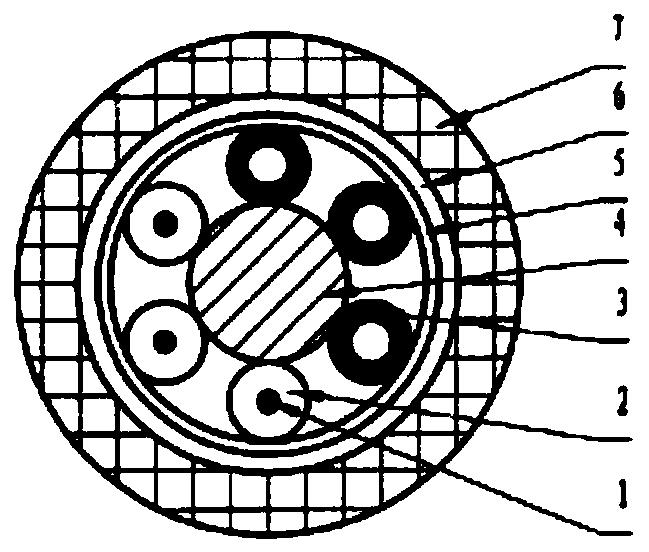

A super-strong, super-flexible, high-temperature-resistant optoelectronic hybrid cable and its manufacturing method

ActiveCN109637712BAvoid damageThe overall thickness is thinPower cablesFibre mechanical structuresYarnElectric machinery

The present invention has disclosed super, super soft, high -temperature -resistant photoelectric mixed cables and its manufacturing methods and charter machines, involving the field of photoelectric hybrid cable manufacturing.Strengthen the inner layer of the cornea yarn, and the outer club and flame -retardant belt layer outside the cable core, the flame retardant layer outsourced woven the outer layer of the aramid yarn;Putting the transmission mechanism, the transmission mechanism and the speed measuring device; the wrap device includes the wrapped plate, the roll, the central pipe, the band shaft and the wrap shaft, and the transmission mechanism and the transmission mechanism of the bag, And with a transmission device, the speed measuring device includes fixed racks, spring A, lower pressure wheels, fixed wheels, guide pipes and speed sensors, and also has a controller used to control according to the detection signal.The optoelectronic mixed cable can be suitable for environmental high temperature and strong space, and simple processing and manufacturing. The charter machine can complete the packaging process.

Owner:CHENGDU DATANG CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com