Cradle type tension pay-off device

A pay-off device and cradle-type technology, which is applied in the field of cradle-type tension pay-off devices, can solve the problems of inability to diversify product market demand, difficulty in ensuring product quality, and non-adjustable pay-off tension, so as to save time and manpower, twist Good line effect, improve the effect of pay-off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

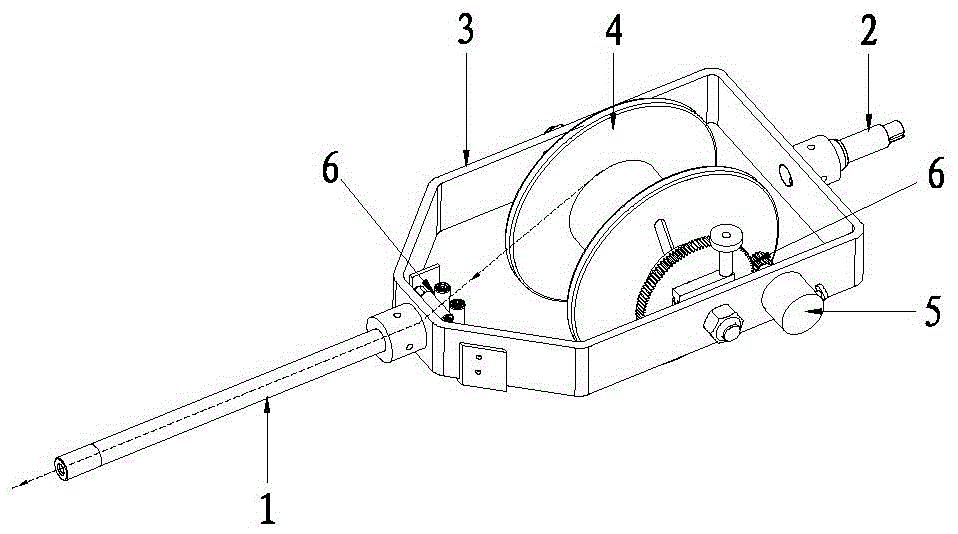

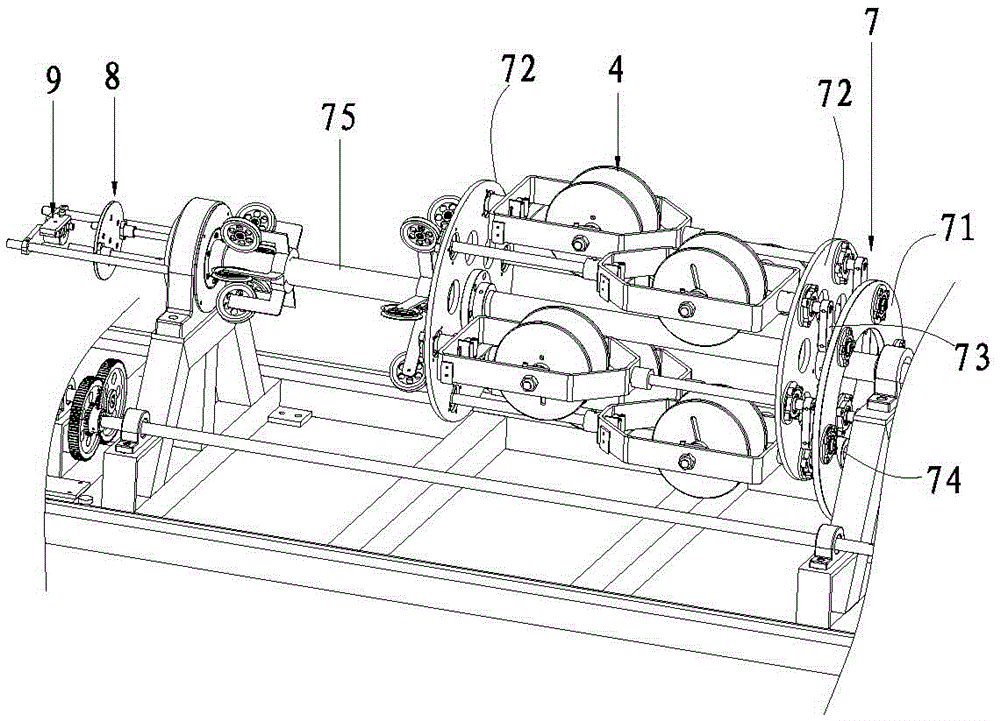

[0013] see figure 1 , a cradle type tension pay-off device provided in this embodiment, which includes a threading shaft 1, a rotating shaft 2, a cradle frame 3, a pay-off shaft 4, a permanent magnet damping adjuster 5 and a transmission gear set 6, the The pay-off shaft 4 is connected and arranged in the cradle frame 3, the permanent magnet damping regulator 5 is arranged on the cradle frame 3, and is connected with the pay-off shaft 4 through the transmission gear set 6, so that The threading shaft 1 is arranged at one end of the cradle frame 3, and is perpendicular to the central axis of the pay-off shaft 4, and the rotating shaft 2 is arranged at the other end of the cradle frame 3, and is connected to the threading shaft. 1 on the same axis.

[0014] Preferably, a guiding thread roller 7 is provided on the inner frame wall of the cradle frame 3 corresponding to the shaft hole of the threading shaft 1, so that the effect of the wire is good.

[0015] Specifically, the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com