Early warning device and method for slip of strip steel tension roller units

A technology of early warning device and tension roller, applied in computer control, instruments, heat treatment equipment, etc., can solve the problems of comparison of maximum static friction force, inability to obtain the entrance tension and exit tension of rolled pieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

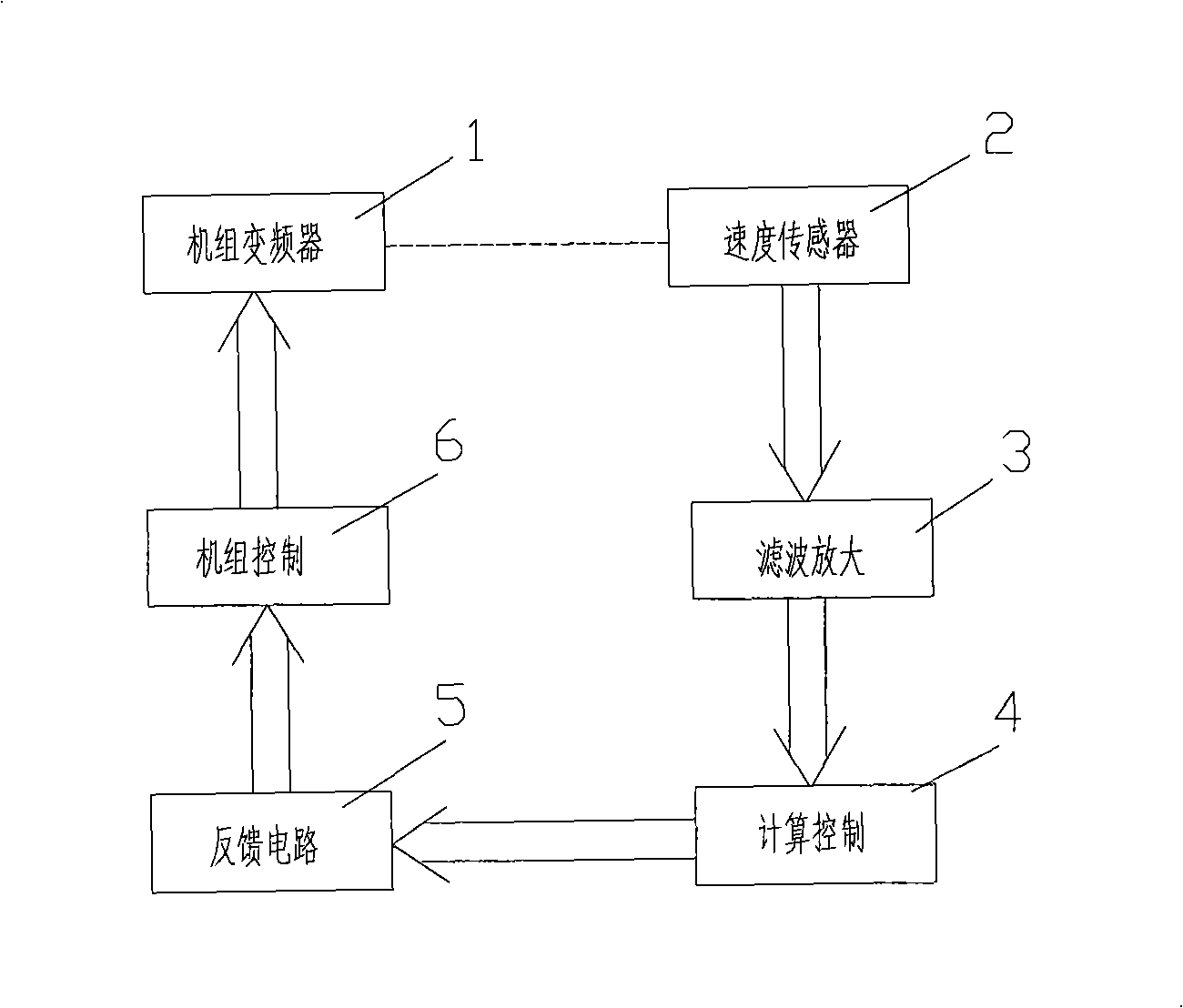

[0022] like figure 1 As shown, a skid pre-warning device for a strip tension roller unit includes a tension roller unit with a frequency converter 1, it also includes a speed sensor 2, a pre-processing circuit 3 with filtering and amplification functions, a calculation control module 4 and Signal feedback circuit 5, the speed sensor is connected to the frequency converter 1, its output end is connected to the pre-processing circuit 3, the pre-processing circuit 3 is connected to the calculation control module 4, and the output end of the calculation control module 4 is connected to the feedback circuit 5, the feedback The circuit 5 is connected to the control system 6 of the tension roller unit.

[0023] An early warning method of the skid early warning device, the method is:

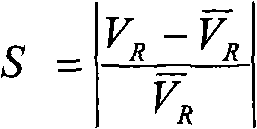

[0024] Step 1, use the rotational speed sensor to receive the tension roller line speed V output by the frequency converter R and strip moving speed V;

[0025] Step 2, the signal of the speed sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com