Patents

Literature

30results about How to "To achieve tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

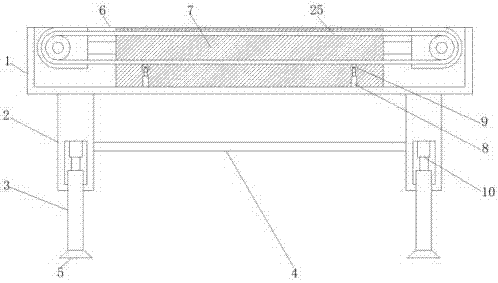

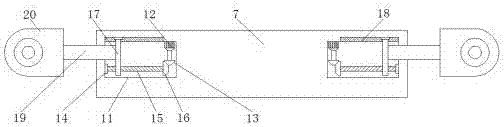

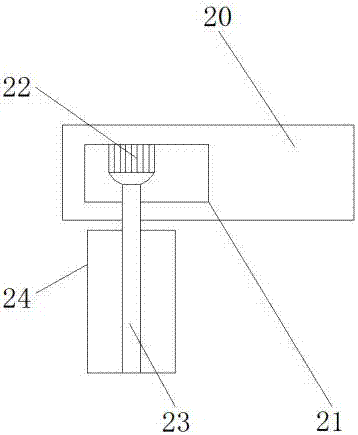

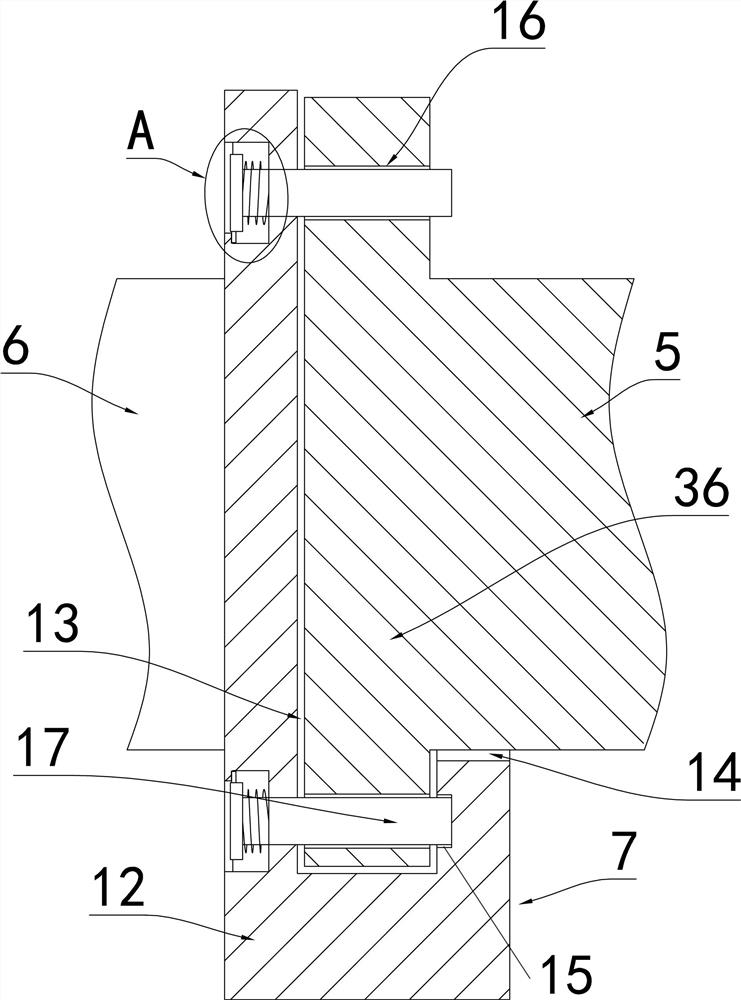

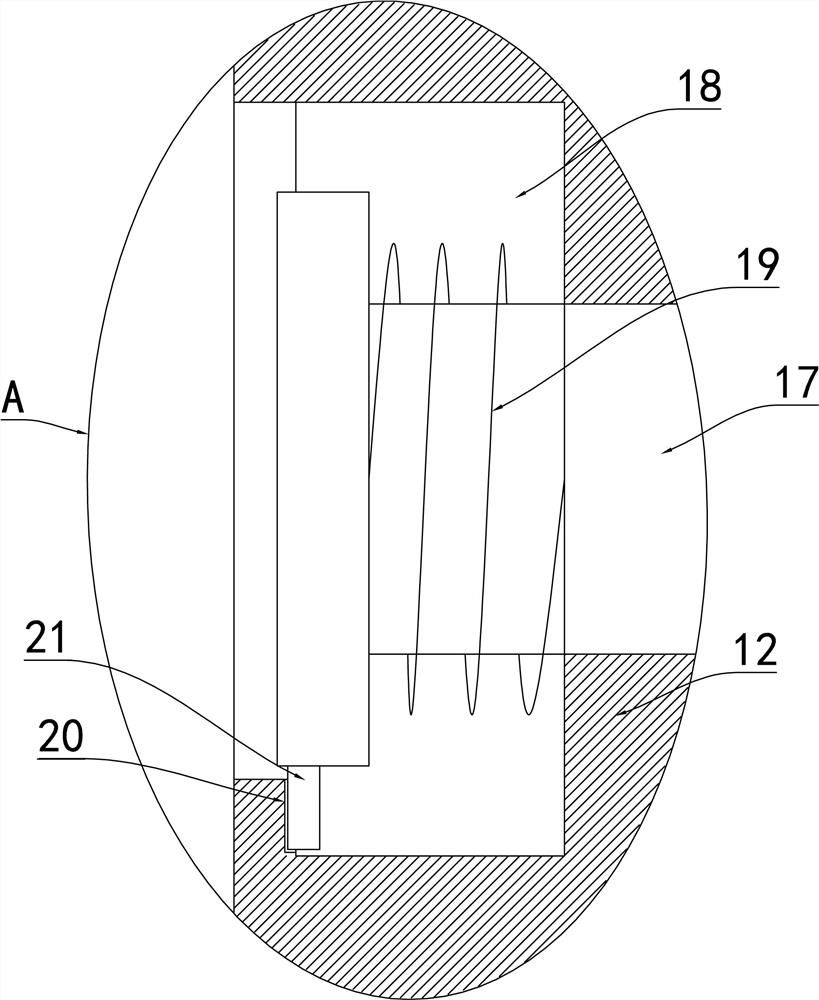

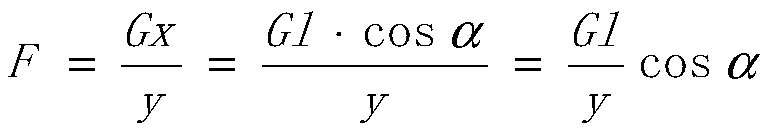

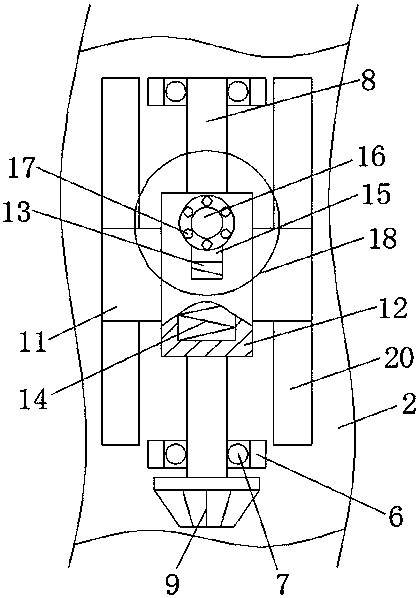

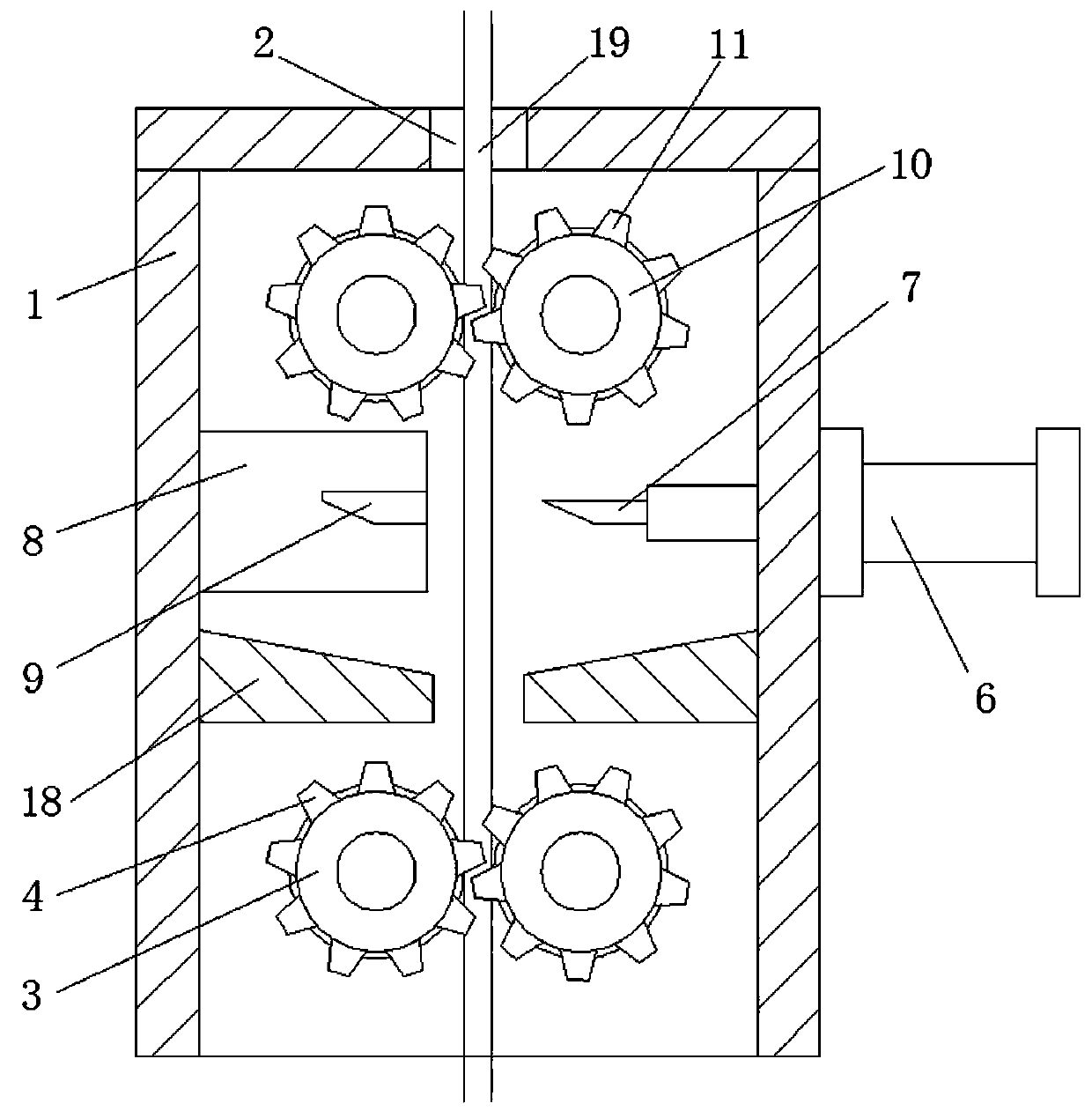

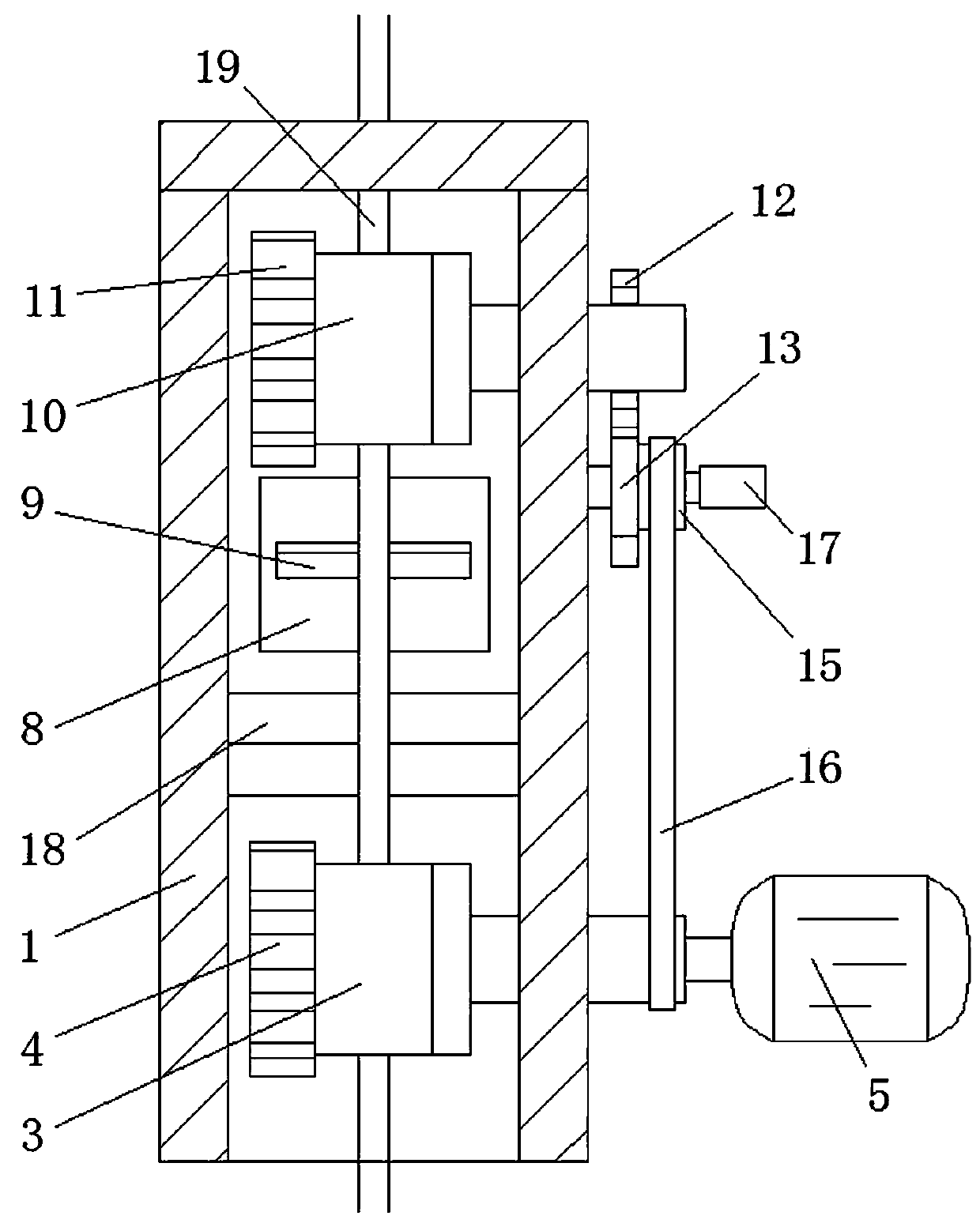

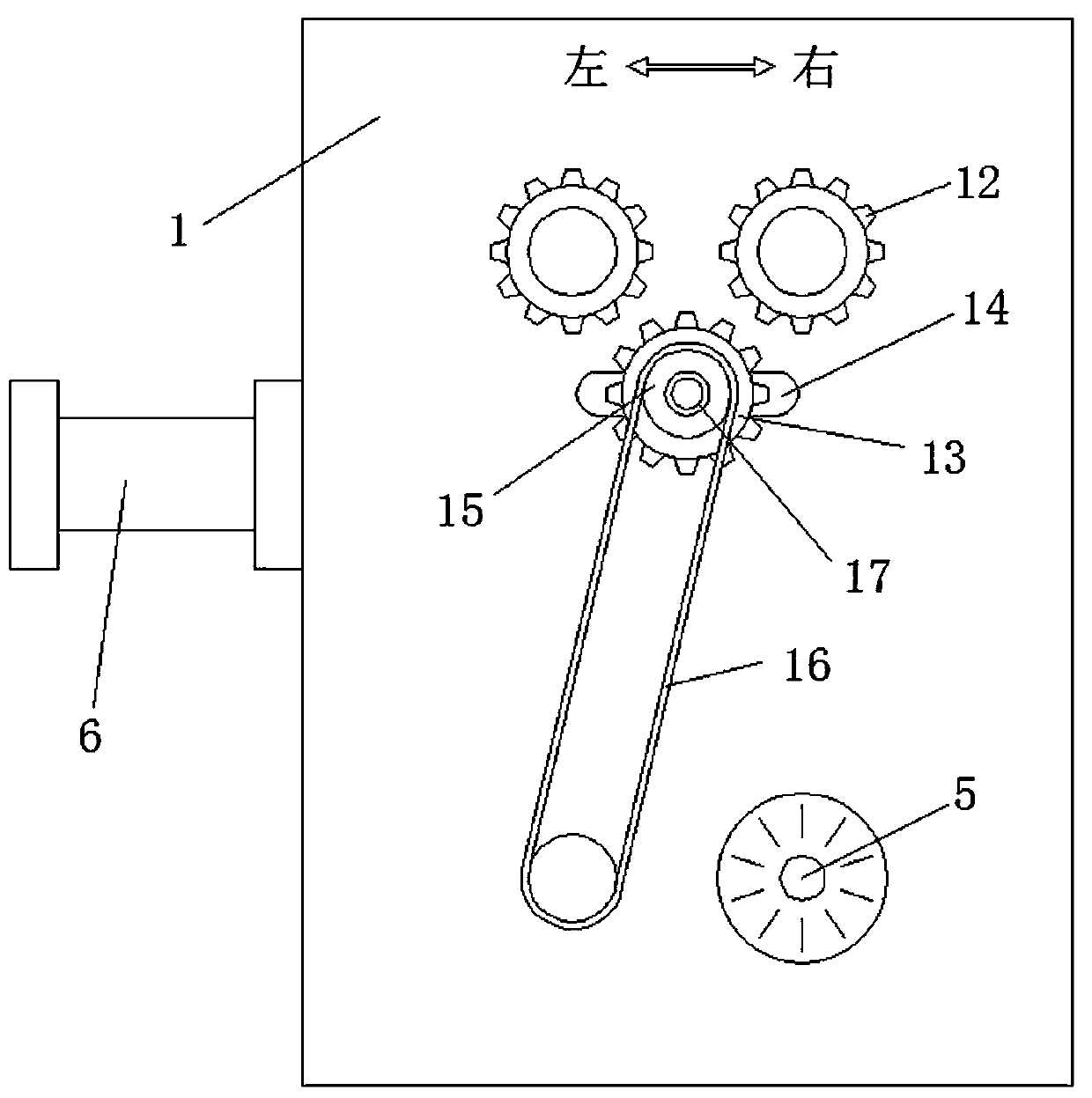

Tensioning gear for belt type conveyor

InactiveCN107973067AReduce tensionTo achieve tensionConveyorsSupporting framesMotor driveArchitectural engineering

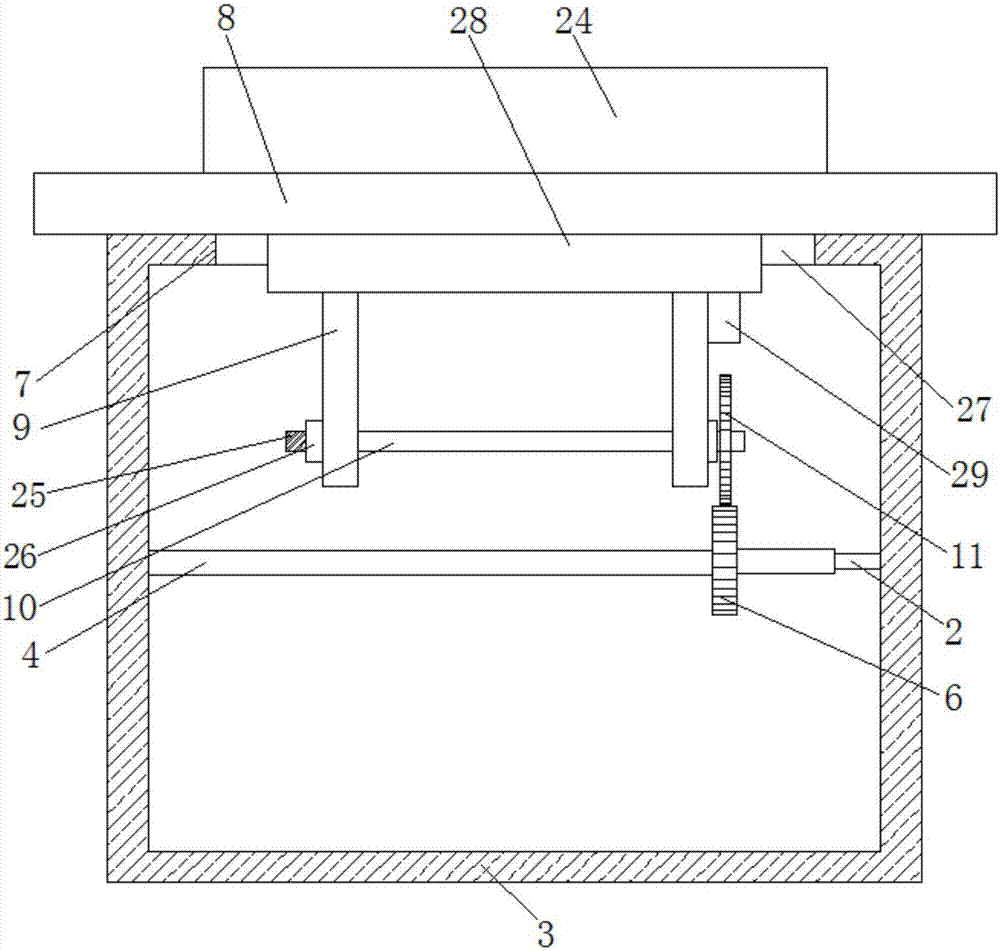

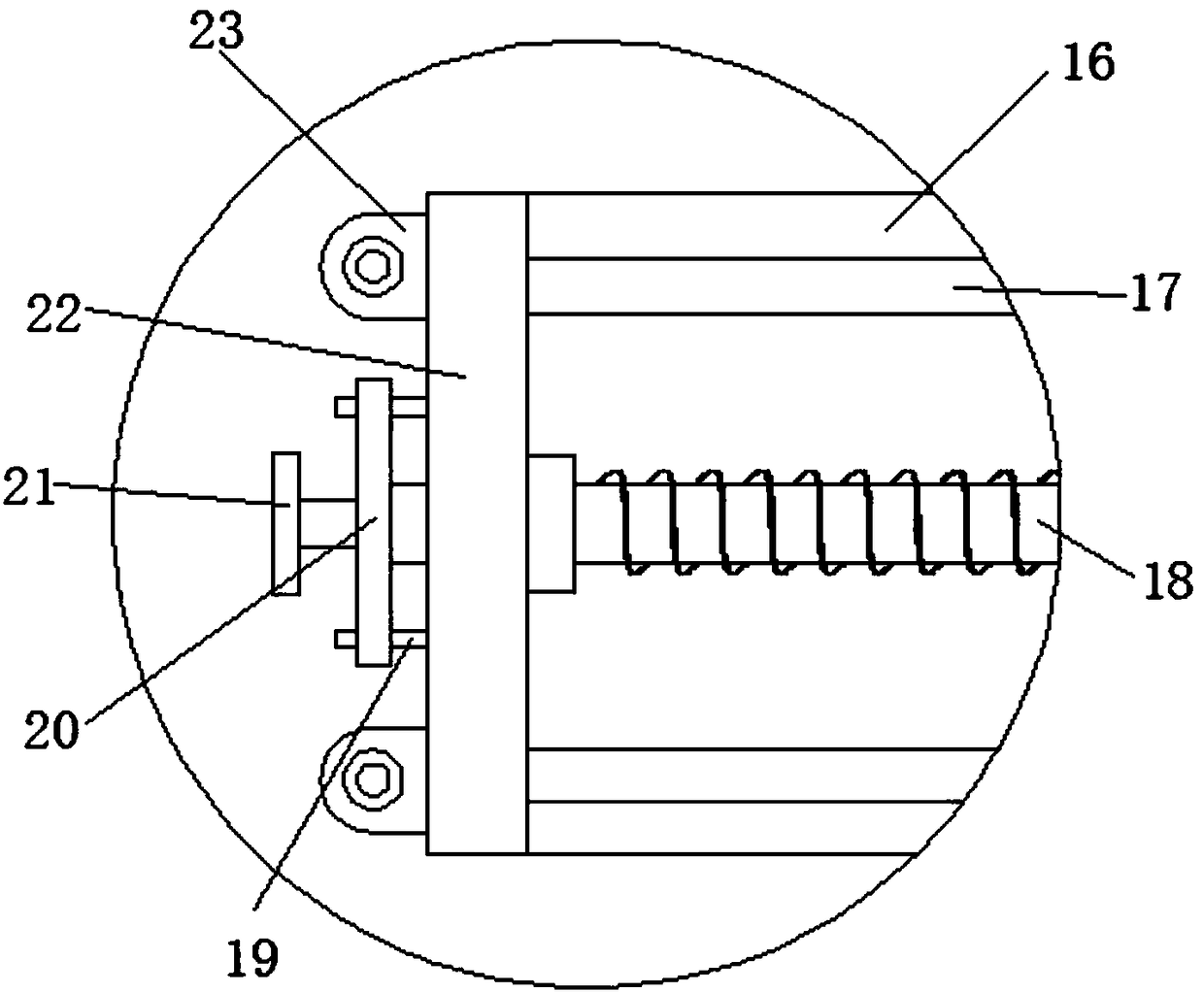

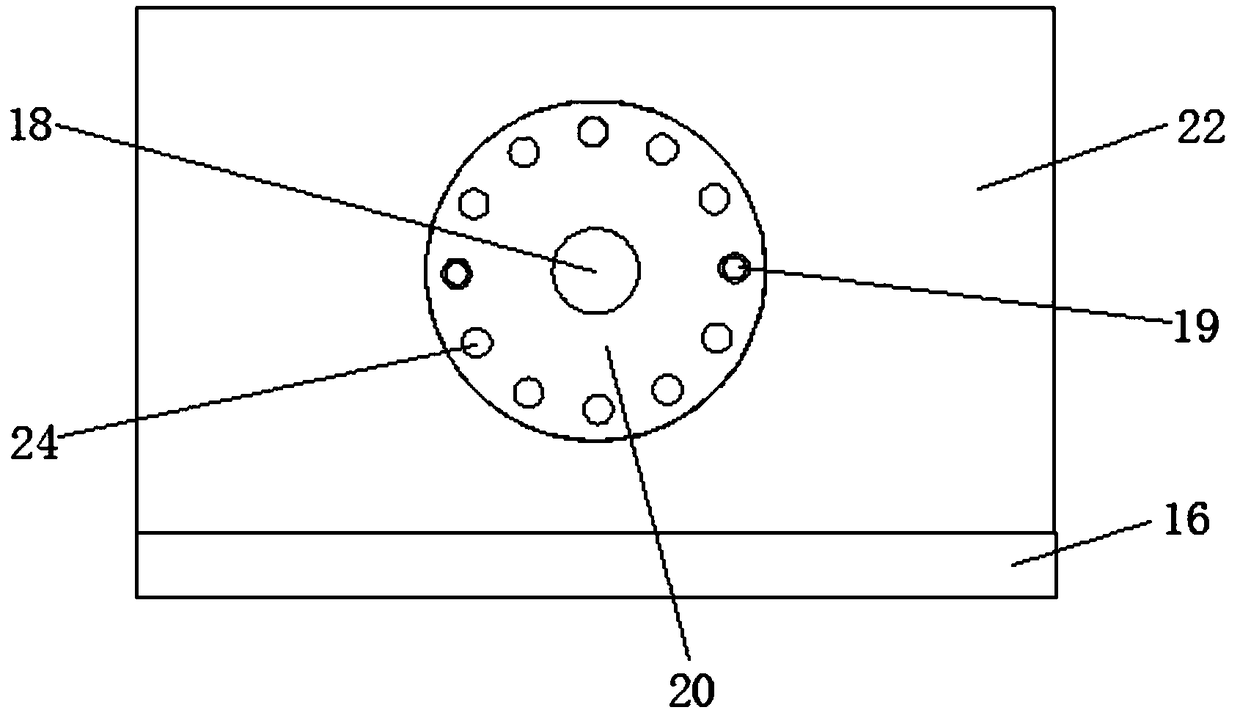

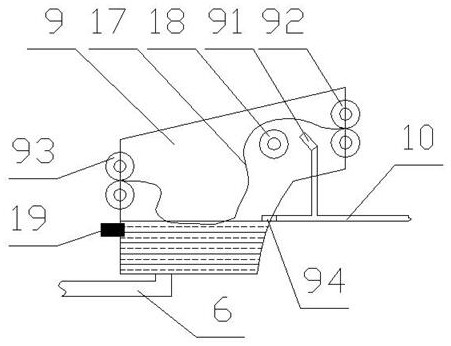

The invention provides a tensioning gear for a belt type conveyor, and relates to the field of belt tensioning equipment. The tensioning gear for the belt type conveyor includes a base plate, fixing rods are fixedly installed at two sides of the bottom of the base plate, the two fixing rods are fixedly connected with each other through a cross rod, and a baffle plate is fixedly installed at the rear surface of the inner wall of the base plate; and the bottom portions of the fixing rods are provided with supporting legs in an inserting mode, first grooves are formed in two sides of the blockingplate, and a first motor is fixedly installed at the top of the inner wall of each of the first grooves. According to the tensioning gear for the belt type conveyor, the first motor drives a second angle gear to rotate through a first angle gear, so that a moving sliding block can be moved left and right with the rotating of a threaded rod to achieve the effect of regulating the distance of the fixing block and the blocking plate, and the effect of tensioning a slack belt can be achieved; and a first hydraulic pushing rod and a contacting wheel are cooperatively used to reinforce the tensioning effect, workers are convenient to tension the belt, the time and the labor can be saved, and the work efficiency can be improved.

Owner:无锡市内河装卸机械有限公司

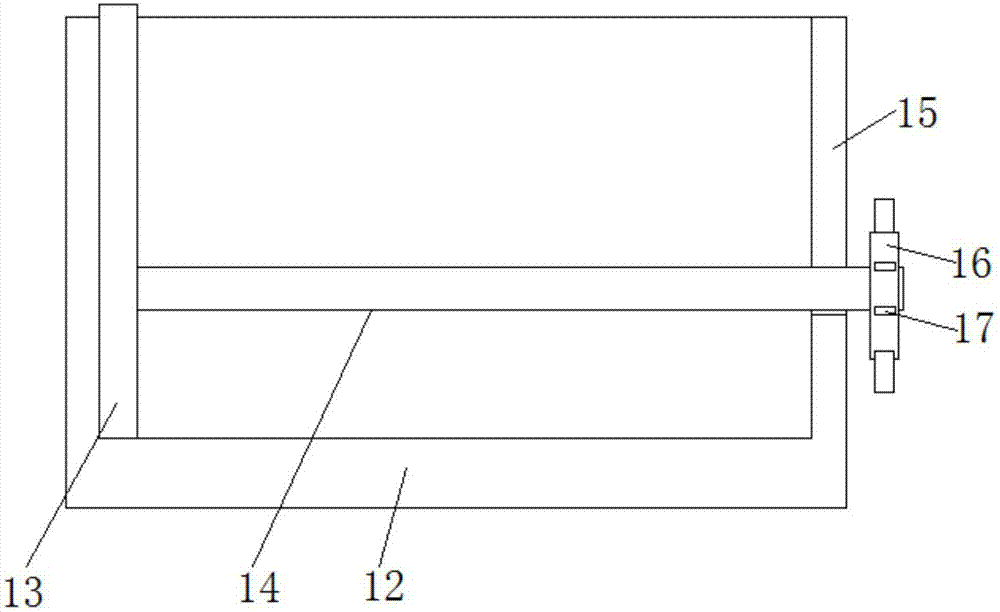

Winding and tightening device of fabric cloth

The invention discloses a winding device for textile cloth, which comprises a base, a motor is fixedly installed on the top of the base, and a winding box is fixedly installed on the top of the base and behind the motor through bolts, and the two sides of the winding box All are in the shape of openings, the output end of the motor runs through the winding box and is fixedly connected to one end of the rotating shaft, and the other end of the rotating shaft is movably connected to one side of the inner wall of the winding box through a shaft seat. In the present invention, by setting the placement box, the rotating rod is passed through the loosely wrapped drum to the plugboard, and then the plugboard is put into the placement box. After the plugboard is put into the placement box, the motor is started, and when the motor is working, The fabric will be separated from the slack roller and wound onto a new roller. When the fabric is detached from the slack roller, the rotating rod will be rotated, and the resistance generated by the cooperation of the rotating wheel and the fixed block will tighten the fabric. This makes the fabric more compact when wound on the new drum.

Owner:梅明会

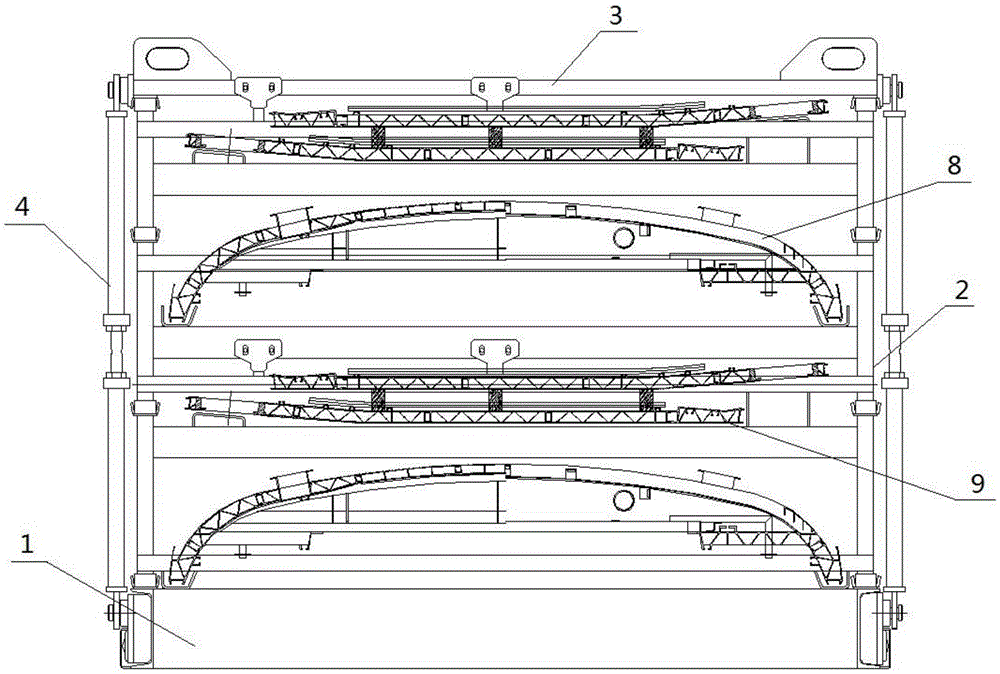

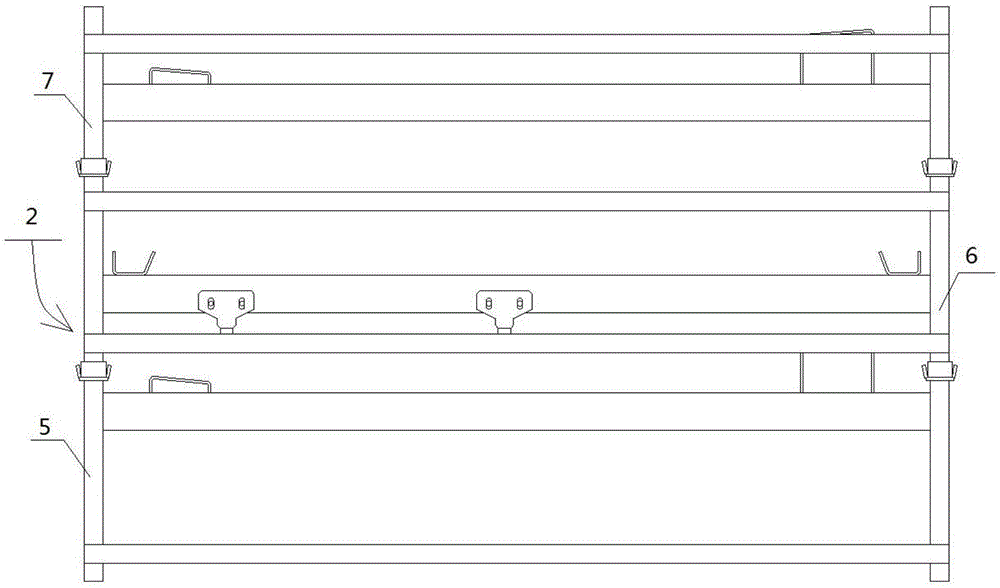

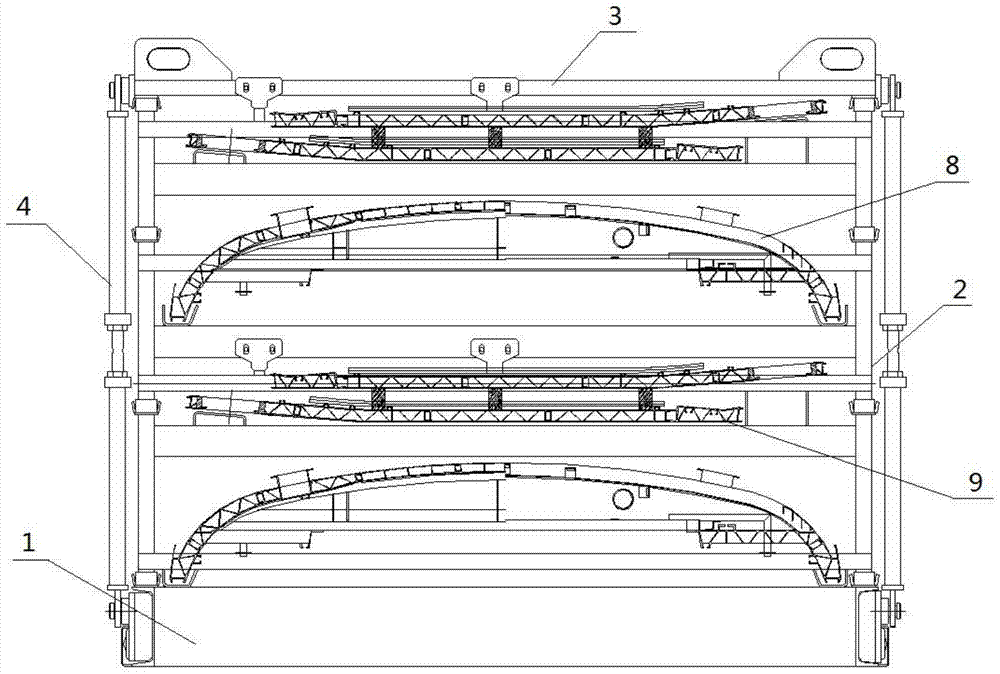

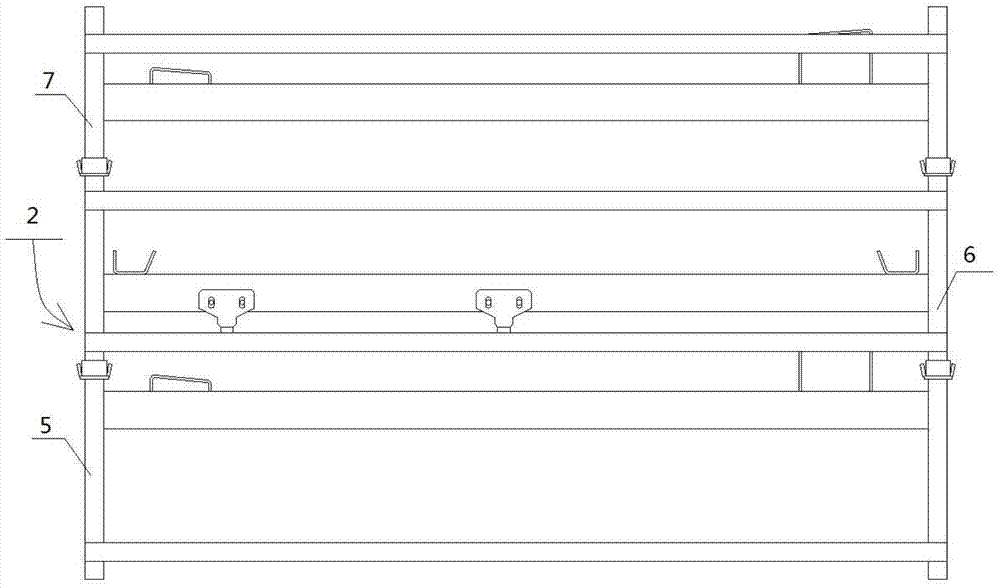

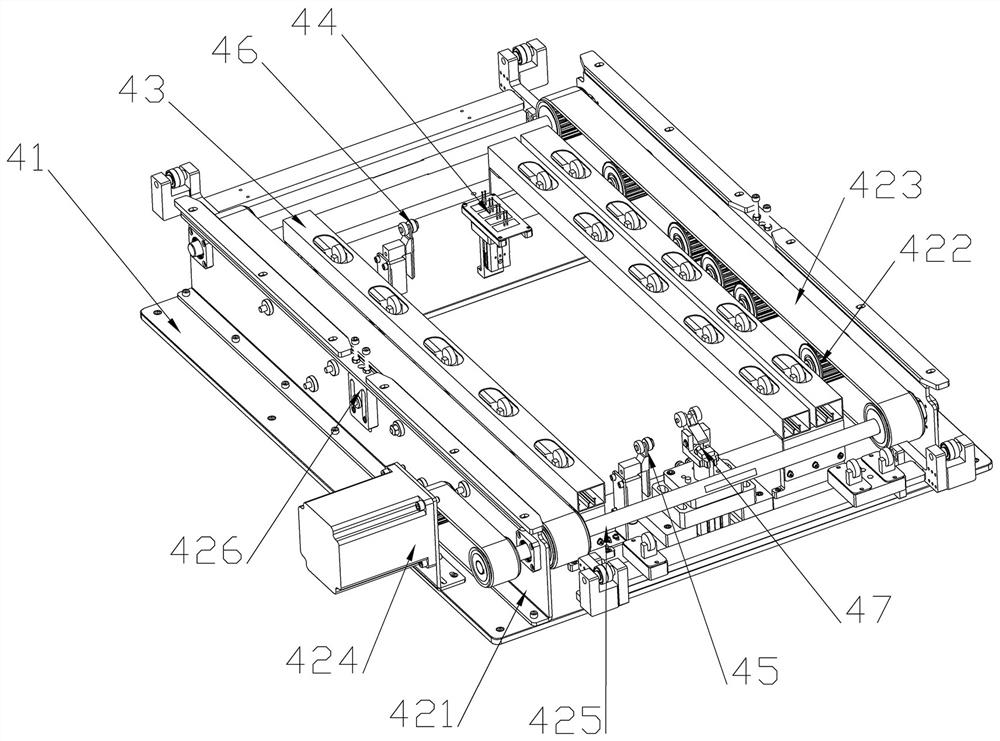

Integrated transport tool for vehicle body large components of rail transit vehicle

ActiveCN105416882AFixed lengthTo achieve tensionPackaging vehiclesContainers for machinesEngineeringMaterial resources

The invention relates to an integrated transport tool for vehicle body large components of a rail transit vehicle. The integrated transport tool comprises a bearing base, a middle support frame, a top cover frame and a plurality of tension devices, wherein the bearing base, the middle support frame and the top cover frame are fixed together sequentially from bottom to top to form a bearing whole, at least two vehicle top large components or at least two sets of vehicle body side wall large components can be placed in the bearing whole, and one vehicle top large component corresponds to one set of vehicle body side wall large components; the length of the bearing whole is matched with the length of the vehicle top large components, and the width of the bearing whole is matched with the width of the vehicle top large components; the plurality of tension devices are symmetrically mounted on two sides of the bearing whole. The integrated transport tool can save the transport cost effectively, the structural design is reasonable, trivial connecting means are not needed, the tool can perform whole hoisting, conveying and storing after being fixed into a whole by the tension devices, is convenient and fast, and saves manpower and material resources for loading and unloading; besides, the integrated transport tool can be used for product storage, has diverse functions and adapts to various conditions well.

Owner:SHANDONG NOLLVETEC LIGHTWEIGHT EQUIP CO LTD

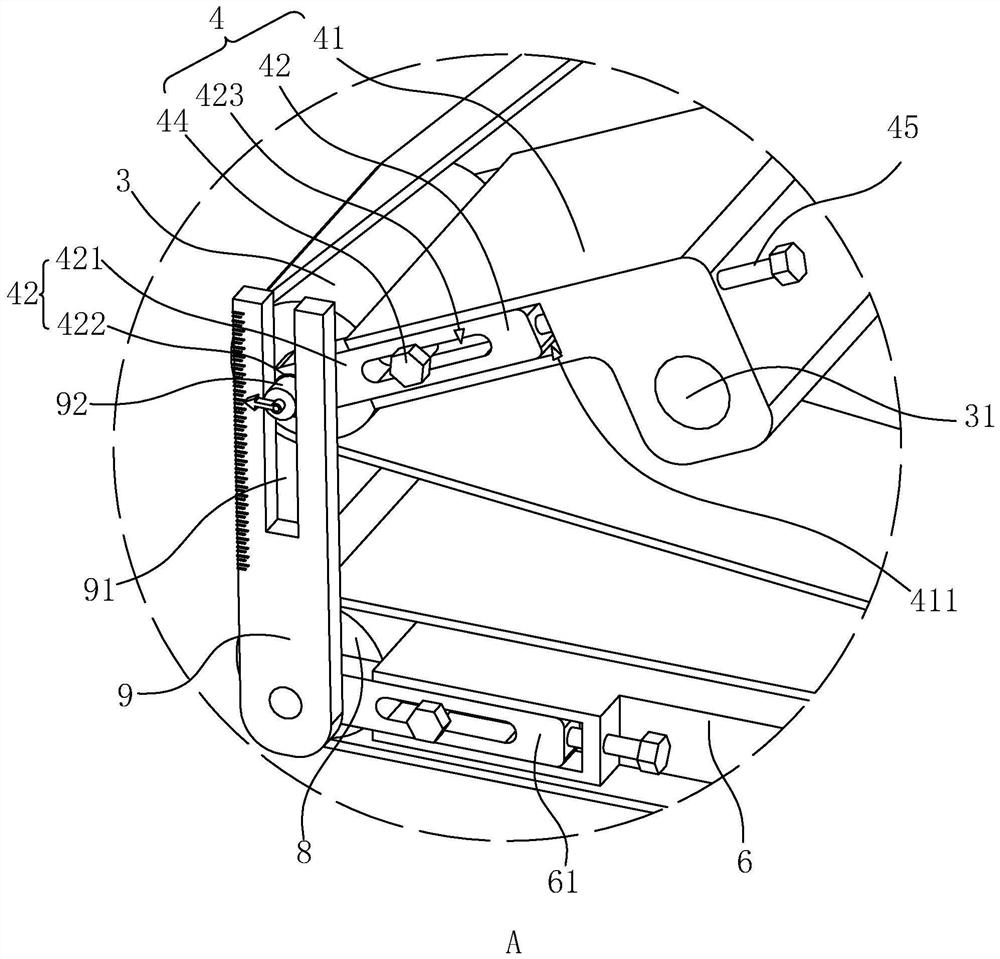

Material pressing and tensioning device

InactiveCN105731151ARelieve pressureTo achieve tensionWebs handlingMechanical engineeringEngineering

Owner:JIANGYIN LICHNEG MACHINERY CO LTD

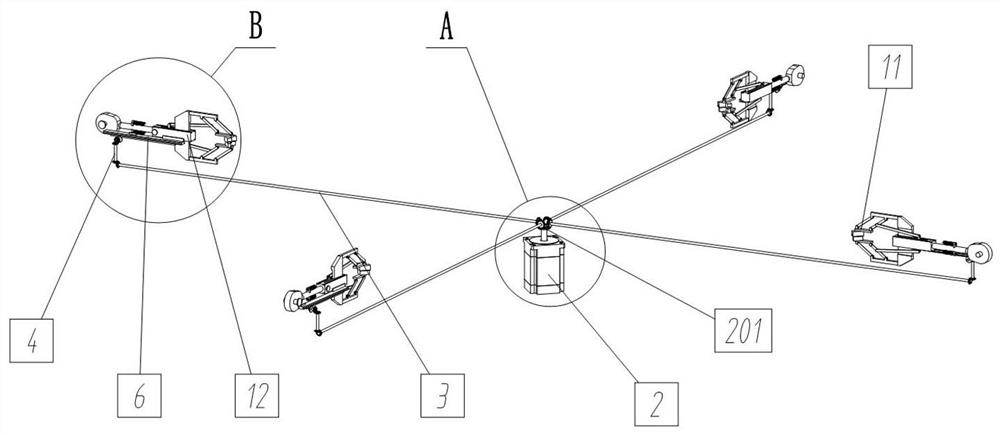

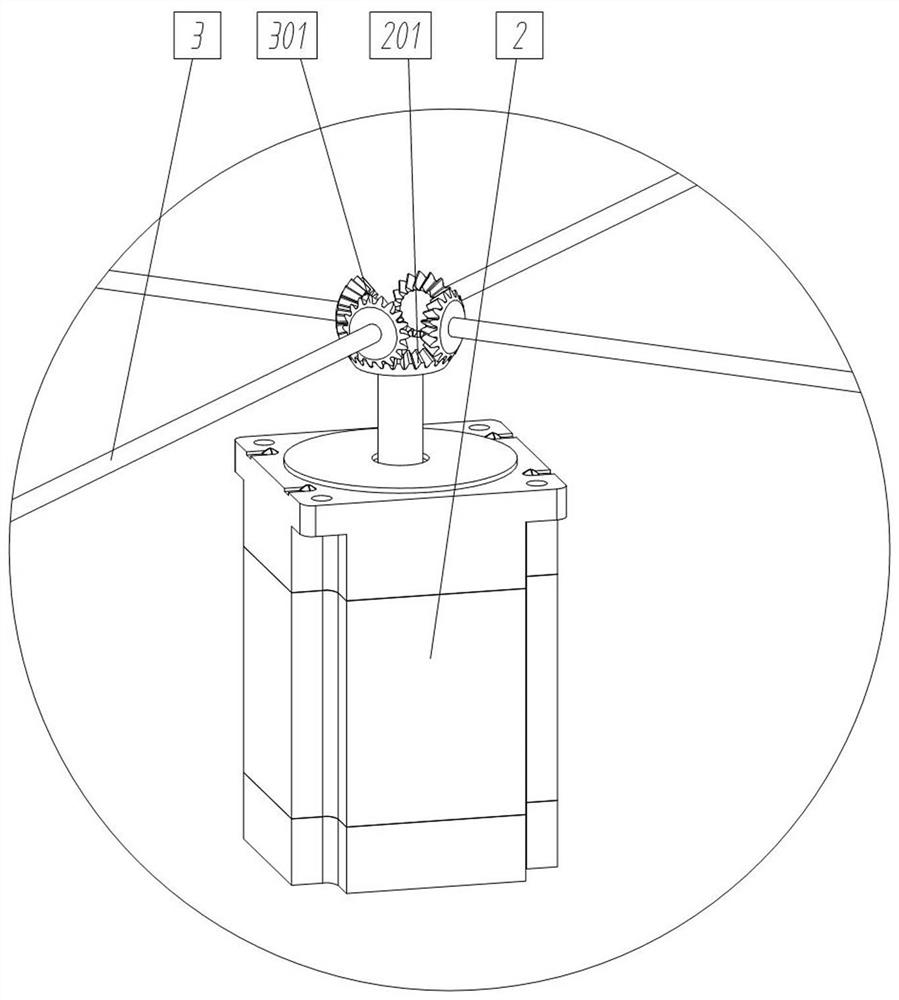

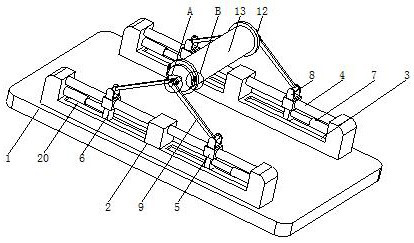

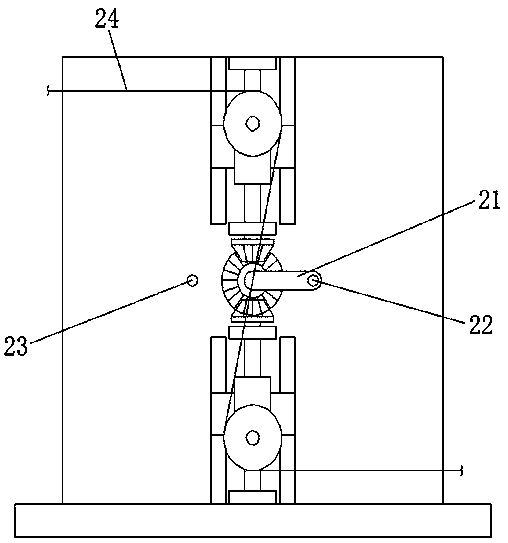

Three-end input/output mechanism

PendingCN107364597AMechanism size is smallQuick responseBundling machine detailsPackaging machinesEngineeringInput/output

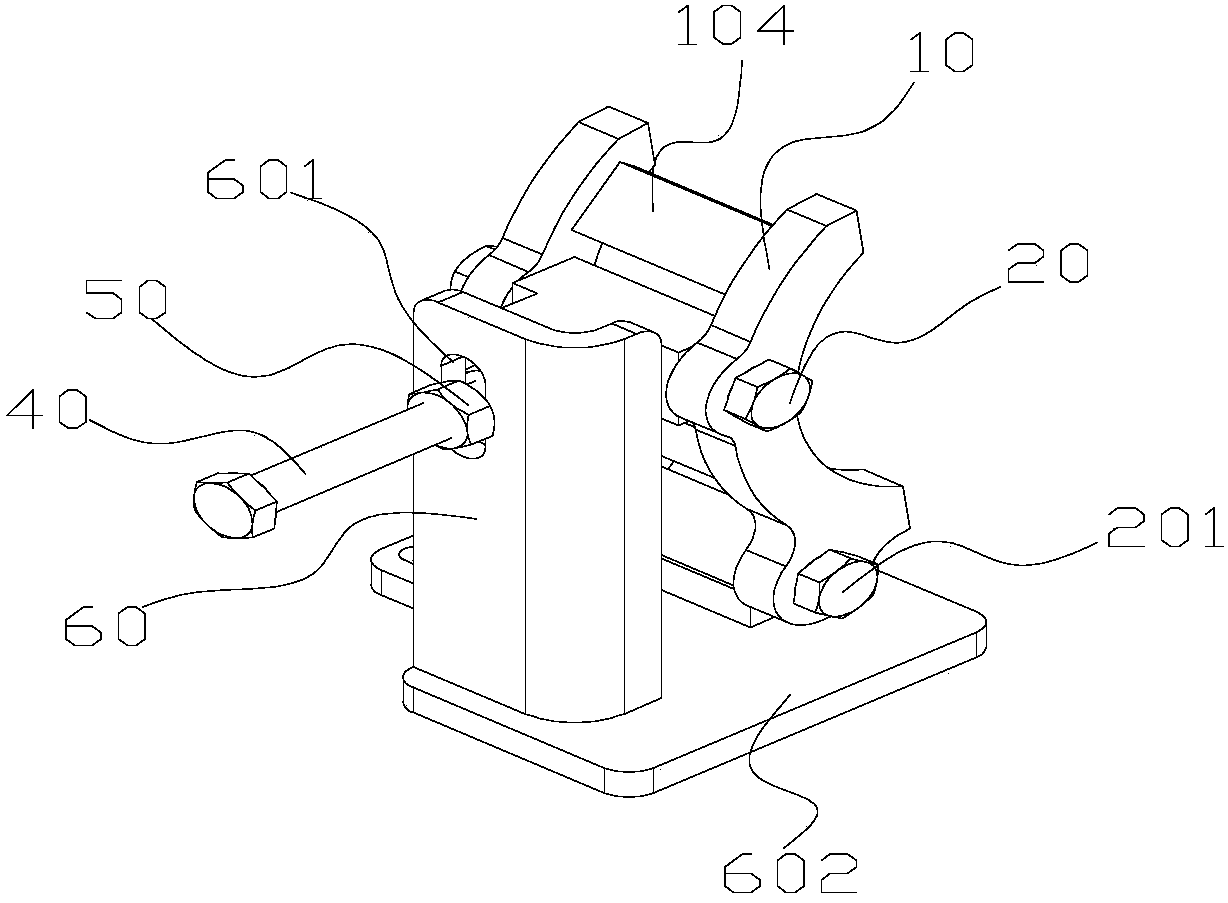

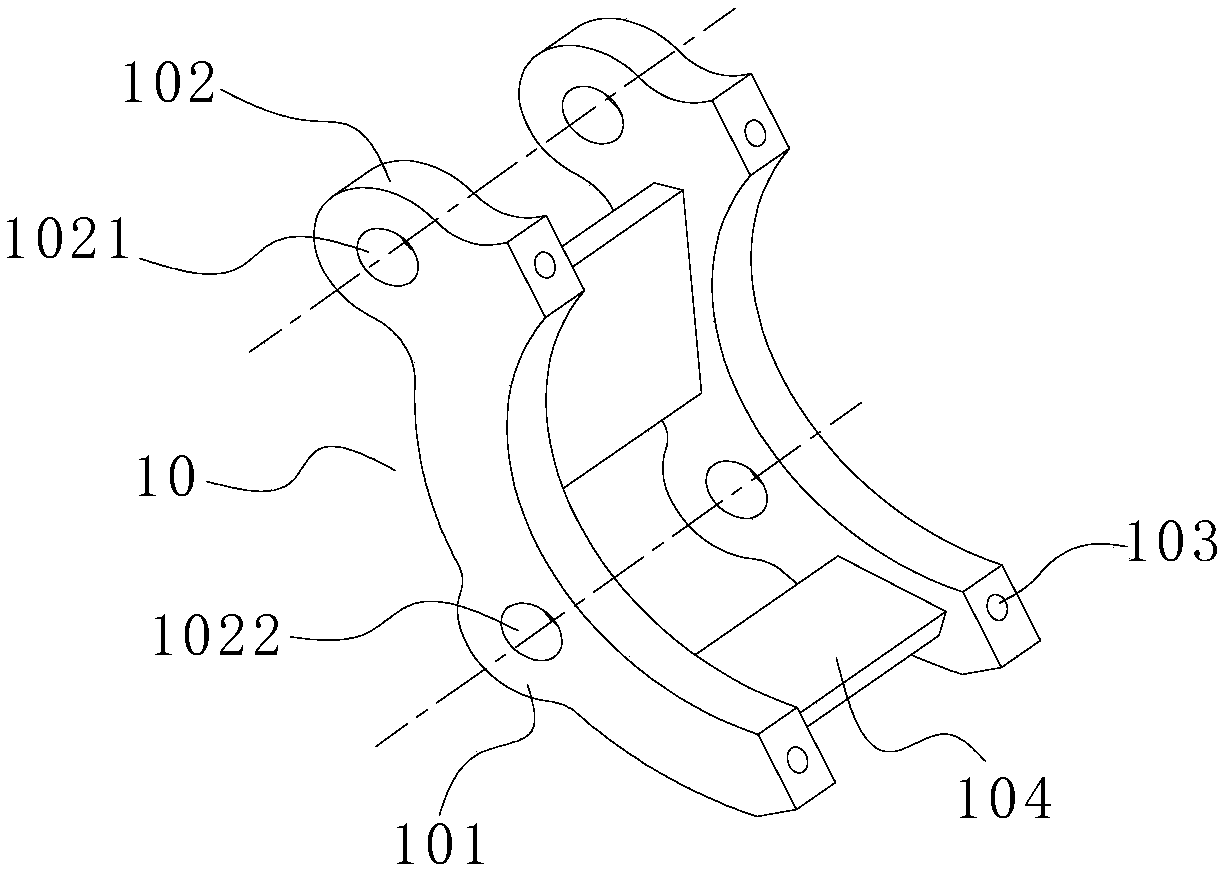

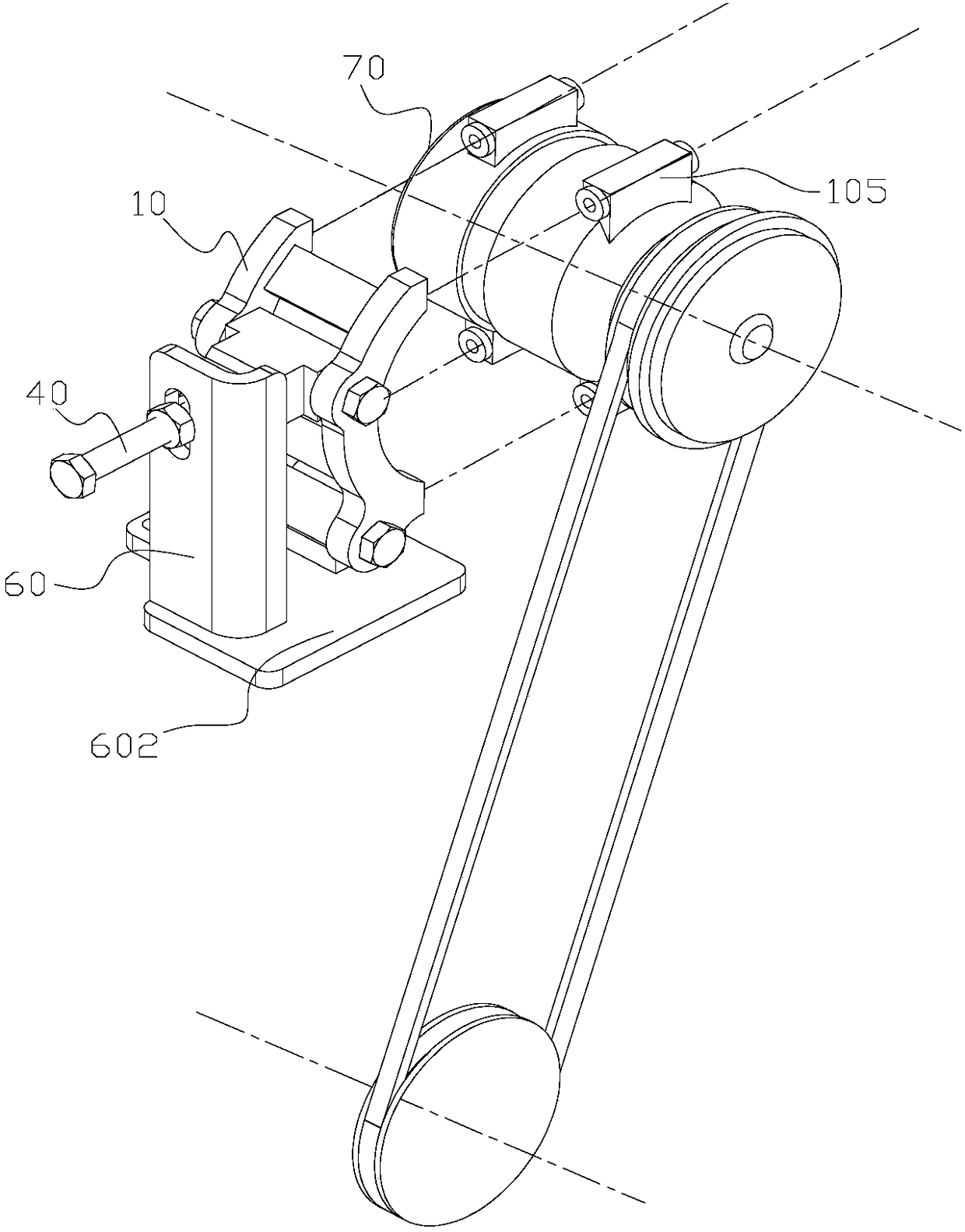

The invention provides a three-end input / output mechanism which comprises a sun gear, an internal-external gear, planet gears, a planet wheel axle, a planet wheel base and a planet wheel base motion control device, wherein the internal-external gear and the planet wheel base are adjacent and are coaxially mounted with the sun gear; the planet wheel axle is fixed on the planet wheel base; the planet gear sleeves the planet wheel axle; the number of the planet gears is 2, 3, 4, 5 or 6; the planet gears are meshed with an annular gear of the internal-external gear and the sun gear at the same time; the sun gear, the internal-external gear and the planet wheel base form three input / output ends; the planet wheel base motion control device is used for setting a motion threshold of the motion of the planet wheel base. The three-end input / output mechanism provided by the invention is applied to the linkage and detection of the tensioning and cutting of an automatic cable tying tool and to twice or more tensioning, and also can realize 'inert forwarding and positive retreating' of the output action.

Owner:SHENZHEN SWIFT AUTOMATION TECH CO LTD

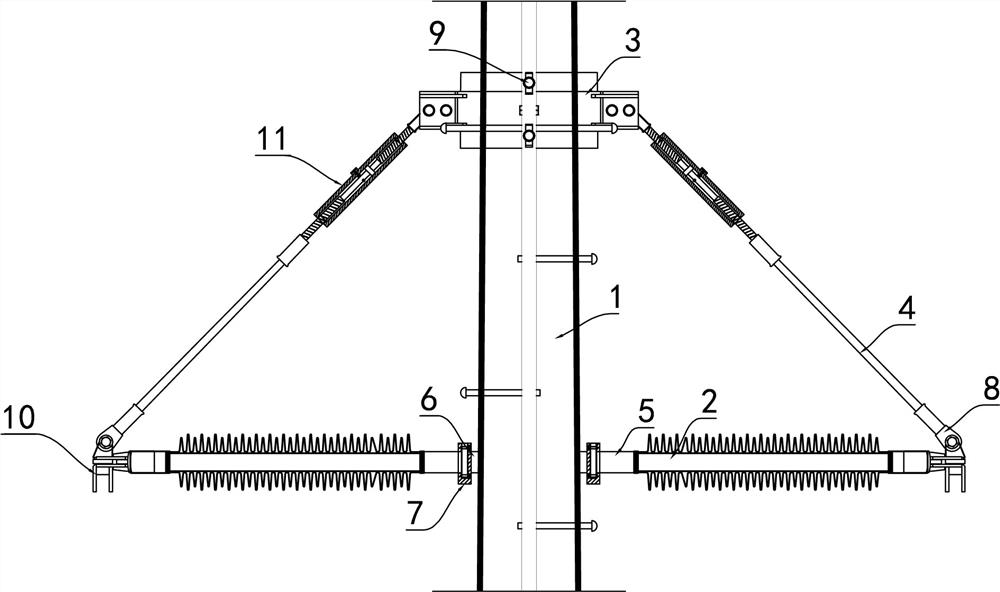

35KV double-loop compound insulation cross arm linear steel pipe pole structure

ActiveCN113690829APrevent looseningAchieve installationSuspension arrangements for electric cablesTowersMaterials scienceSteel tube

A 35KV double-loop compound insulation cross arm linear steel pipe pole structure comprises a pole body; a second fixing rod is fixedly connected to the pole body; the second fixing rod is connected with a first fixing rod through a detachable connecting mechanism; a compound insulation cross arm is installed at the other end of the first fixing rod; and a wire suspension fitting and a diagonal draw bar are hinged to the other side of the compound insulation cross arm. The diagonal draw bar is connected with a lead double-hanging-point component through an adjusting mechanism capable of being locked, and the lead double-hanging-point component is installed above the pole body. According to the 35KV double-loop compound insulation cross arm linear steel pipe pole structure provided by the invention, the windage yaw distance of the wire suspension fitting is reduced; the compound insulation cross arm is short, the width of a line corridor can be reduced to a large extent, and the installation of the compound insulation cross arm is faster and more convenient.

Owner:CHINA THREE GORGES UNIV

Intelligent barrier gate moment balance weight mechanism

ActiveCN110409339AGuaranteed real-time torque counterweight balanceEnsure counterweight balanceTraffic restrictionsEngineeringTraffic flow

The invention relates to the technical field of intelligent terminals, and discloses an intelligent barrier gate moment balance weight mechanism. The intelligent barrier gate moment balance weight mechanism comprises a core rotating shaft and a gate rod body fixedly sleeving the outer portion of the core rotating shaft, wherein a connecting block fixedly sleeves the outer portion of the core rotating shaft, a balance rod is fixedly connected to one side of the connecting block, a dynamic chute is formed in the front face of the balance rod, a balance weight positioning rod is arranged at the end portion of the balance rod, the balance weight positioning rod is fixedly installed at the inner bottom of a barrier gate case, and a limiting groove is formed in the front face of the balance weight positioning rod. According to the invention, the traditional tension spring balance weight is replaced with an always-tensioned balance weight steel cable, so that the tensioned balance weight steel cable is always equal to the reaction force according to the acting force, and the real-time torque balance weight of the gate rod body can be ensured, so that extra impact amplitude cannot be brought by the balance weight when the gate rod body is suddenly stopped and steered, and under the condition of the large traffic flow, the gate rod body can be stably performed when the gate rod body lifts the rod, falls the rod and suddenly stops lifting the rod, and the stability of a gate transmission system is effectively ensured.

Owner:南京乐焱焱科技有限公司

Wasted and used plastic pulverizing device

The invention discloses a wasted and used plastic pulverizing device which comprises a pulverizing box body; a supporting plate is fixedly connected between supporting legs; a driving motor is fixed to the middle part of the supporting plate; an output shaft of the driving motor is fixedly connected with a driving pulley; a pulverizing roll is rotatably arranged in the pulverizing box body; a driven pulley is fixed to the outer side end of the pulverizing roll; the driving pulley is connected with the driven pulley through a conveying belt; a mounting plate is arranged on the side wall of thepulverizing box body; connecting lugs are fixed to the four corners of the mounting plate; the connecting lugs and the pulverizing box body are fixed through screws; the two sides of the mounting plate are fixedly connected with connecting seats; a lead screw is rotatably connected between the connecting seats; the lead screw is in threaded connection with a sliding seat; an adjustment wheel is arranged on the inner side of the conveying belt; the adjustment wheel is rotatably mounted at on the sliding seat; and the outer side end of the lead screw is fixedly connected with a fixing disc coaxially. The problem that a conveying belt of an existing wasted and used plastic pulverizing device is prone to loosening in a long-time using process is solved.

Owner:合肥善腾塑料科技有限公司

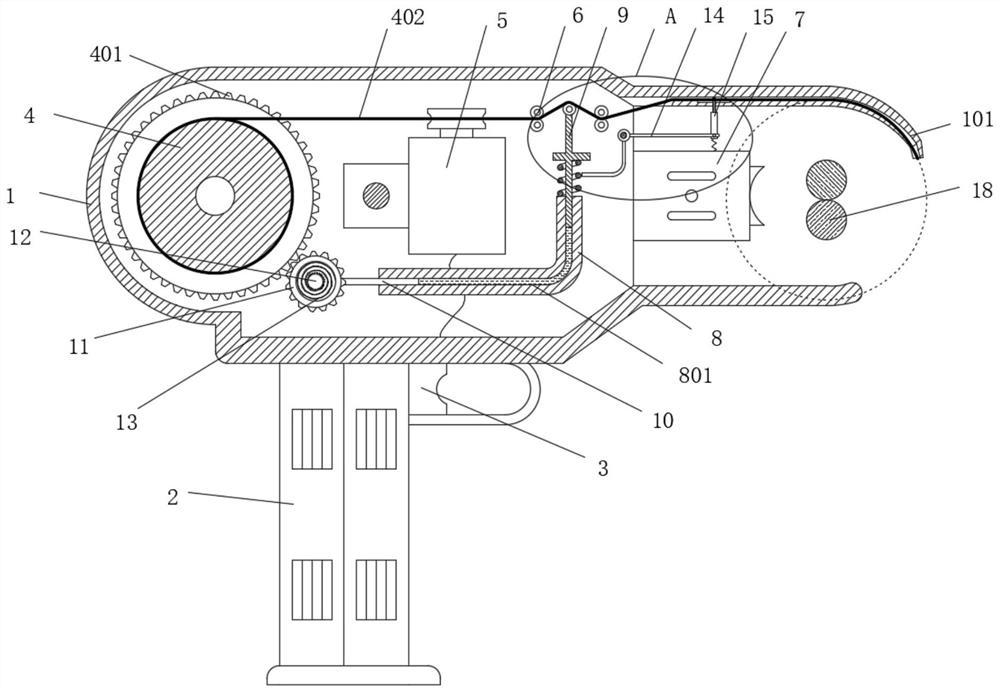

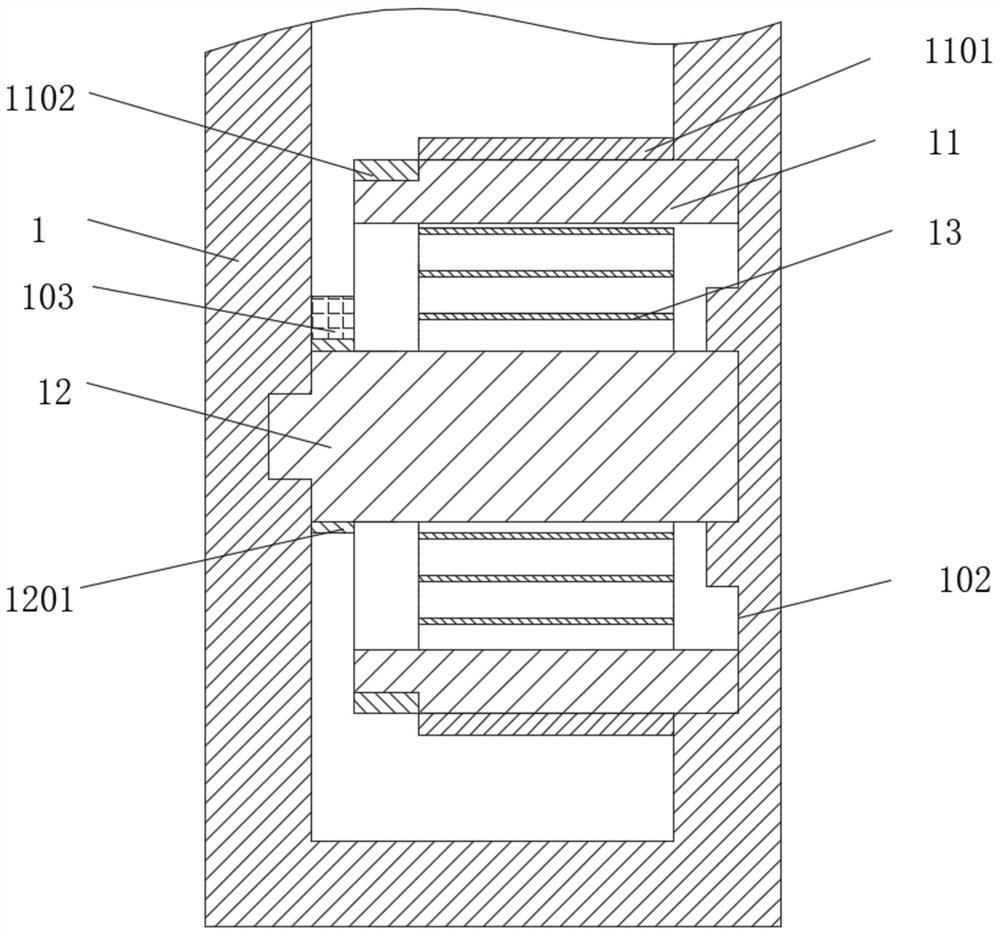

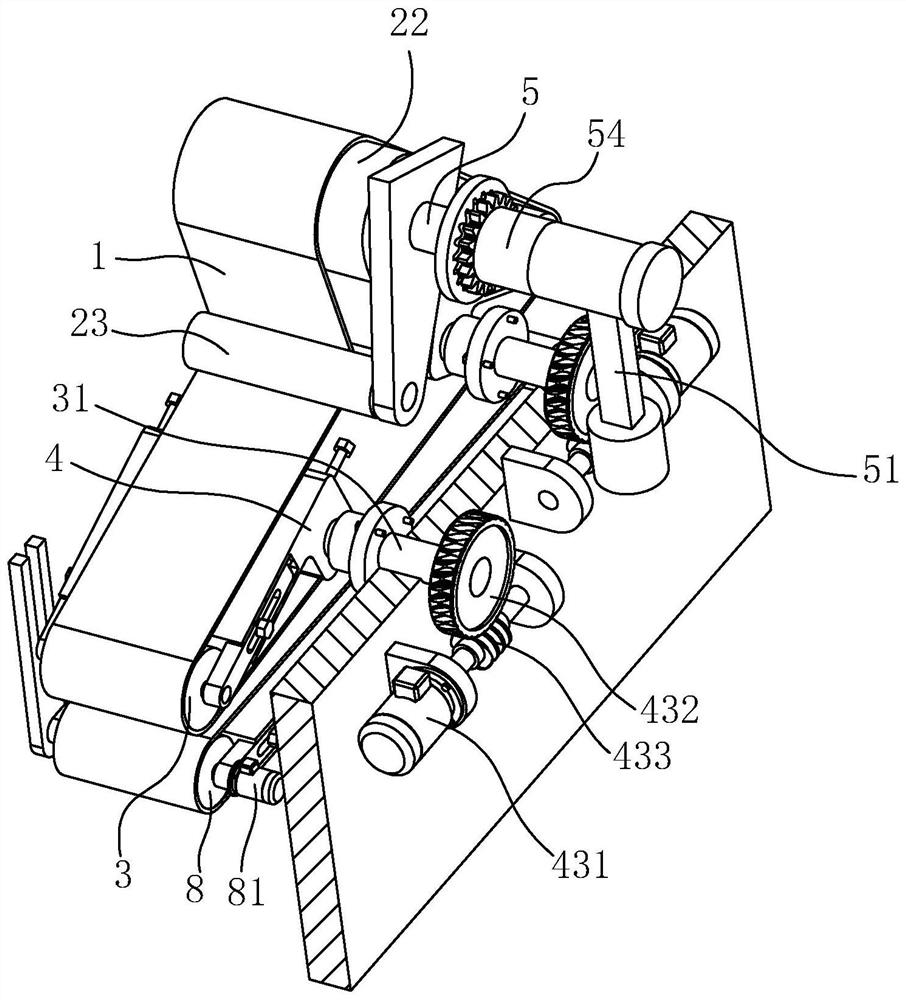

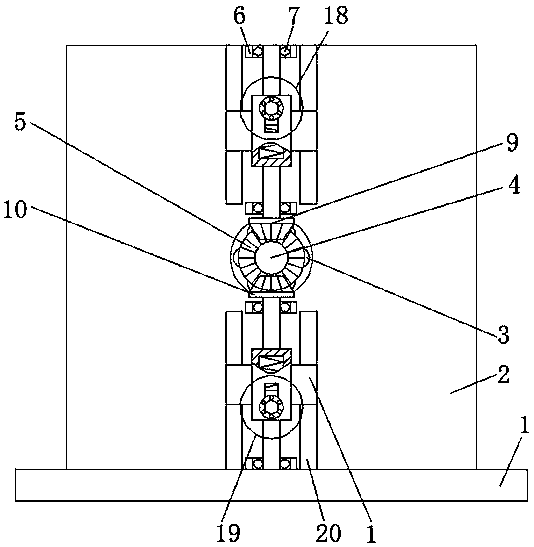

Steel bar binding machine for construction site

ActiveCN113235938ASaving wireEnsure stability and securityBuilding material handlingElectric machineryRebar

The invention relates to the technical field of building construction, and discloses a reinforcing steel bar binding machine for a construction site. A wire winding drum is movably mounted at one end in a machine shell; a wire guiding wheel is fixedly mounted at the top position, between a conveying motor and a torsion motor, in the machine shell; a transmission device is fixedly installed at the position, located at the bottom between the conveying motor and the torsion motor, in the machine shell; a hydraulic hole is formed in the transmission device; the top of the hydraulic hole is movably sleeved with a pressure rod; the bottom end of the hydraulic hole is movably sleeved with a clamping strip; the outer ring of the wire winding drum is fixedly sleeved with an outer gear; a transmission sleeve is movably installed in an installation groove; a limiting shaft is movably installed in the middle of the installation groove; tooth keys meshed with the outer gear are evenly and fixedly installed on the outer ring of the transmission sleeve; and a coil spring is movably connected between the transmission sleeve and a limiting shaft. Through the arrangement of the outer gear, and the transmission sleeve, the transmission device, a pressure rod and other structures are matched to act together, so that the binding quality is improved, and the iron wire cost is saved.

Owner:中建三局科创产业发展有限公司

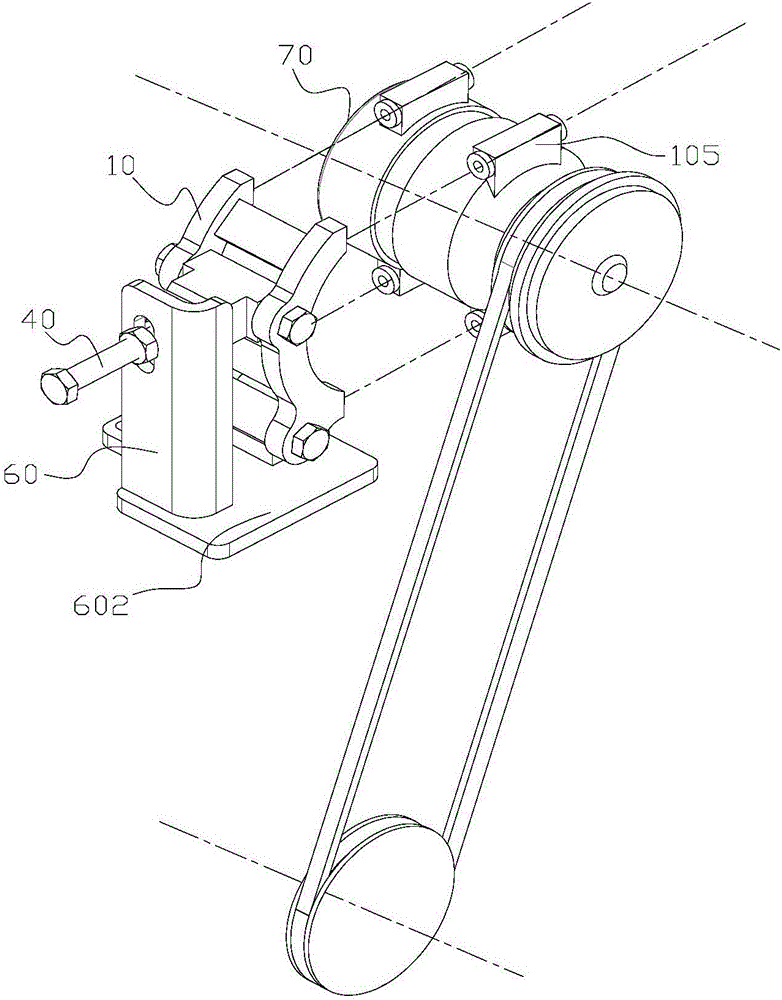

Tensioner and compressor

ActiveCN106838167BReach the telescopic lengthTo achieve the purpose of tensionGearingArchitectural engineering

The invention discloses a tensioning device and a compressor provided with the same. The tensioning device comprises fixing plates, a connecting rod with one threaded end, a stop plate with a through groove and a nut, wherein one end of the connecting rod is hinged to the fixing plates while the other end with a thread passes through the through groove of the stop plate, the nut is in thread fit with the tail end of the connecting rod and is screwed into the thread, a circumscribed circle diameter of the nut is greater than a width of the through groove, the fixing plates are hinged to a base and are fixed on the compressor, and the stop plate is fixed on the base. The fixing plates can drive the compressor to rotate by being hinged to the base.

Owner:广东佳明机器有限公司

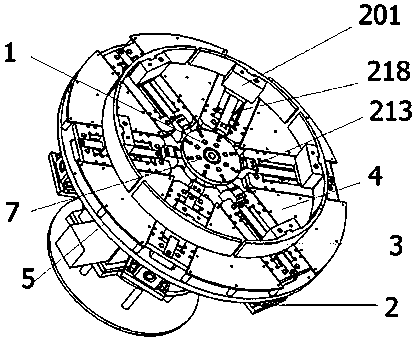

Cloth tensioning device of embroidery machine for cross-stitch textile processing

The invention discloses a cloth tensioning device of an embroidery machine for cross-stitch textile processing, relates to the technical field of textile embroidery, and solves the problems that in the tensioning process of existing cloth, undulate folds appear on the cloth, and meanwhile, due to the fact that a roller shaft is prone to rotating, the cloth moves, the tensioning effect is poor, and the processing quality is affected. The device comprises a support main body, four sets of tensioning sliding seats slidably connected to the four corners of the inner side of the support main body respectively and provided with cloth clamping mechanisms on the inner sides, and four sets of sliding driving assemblies slidably connected to the inner sides of the four corners of the support main body respectively. Cloth loosening or moving is avoided; the cloth is clamped through a hinge parallelogram, so that parallel clamping of the cloth is guaranteed, the undulate folds of the cloth are effectively avoided, and the embroidery quality is guaranteed; and good economic benefits are achieved.

Owner:南通市金璐艺卧室用品有限公司

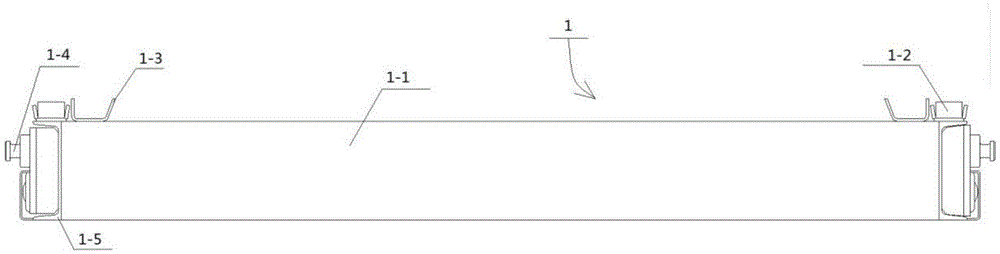

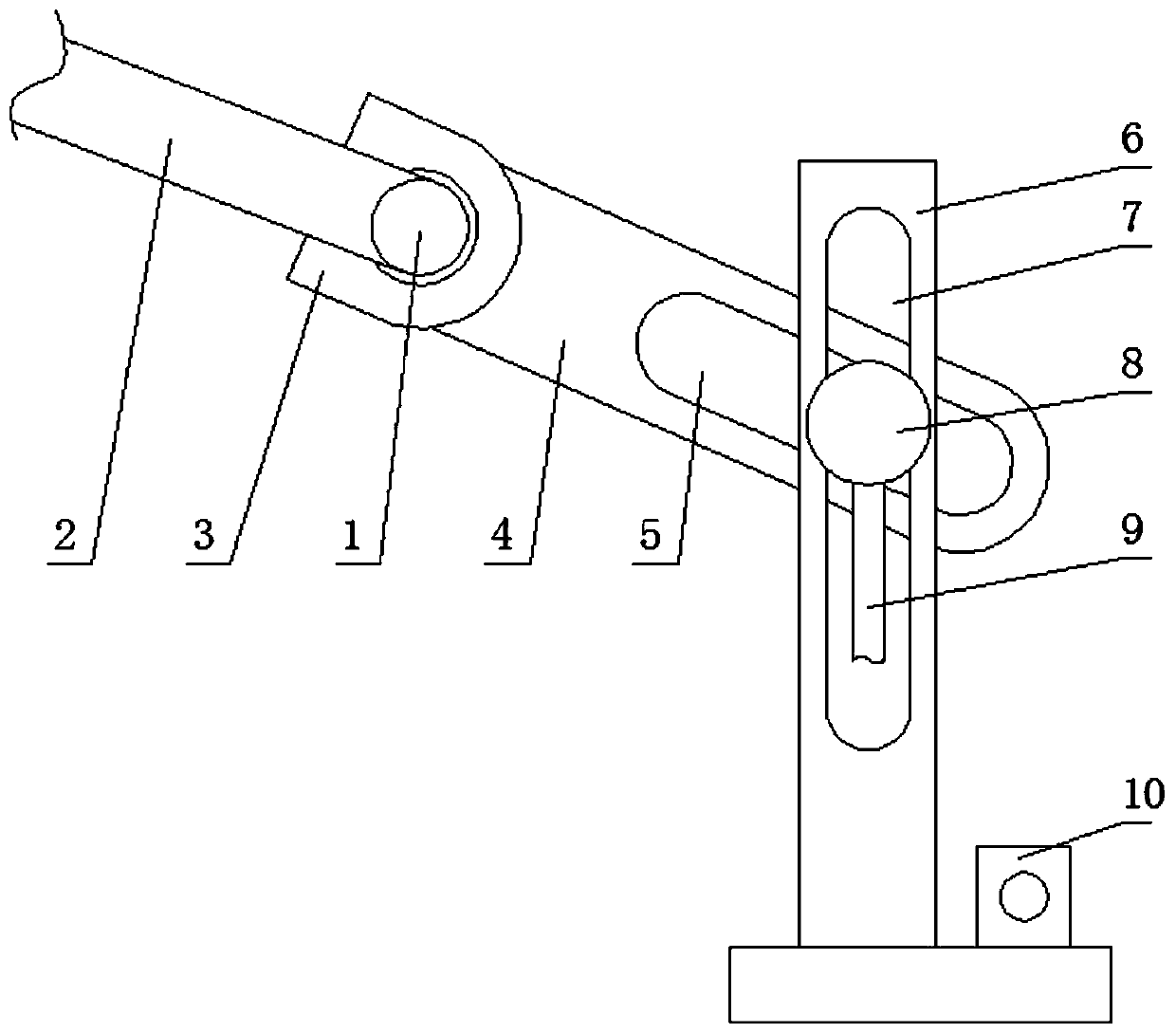

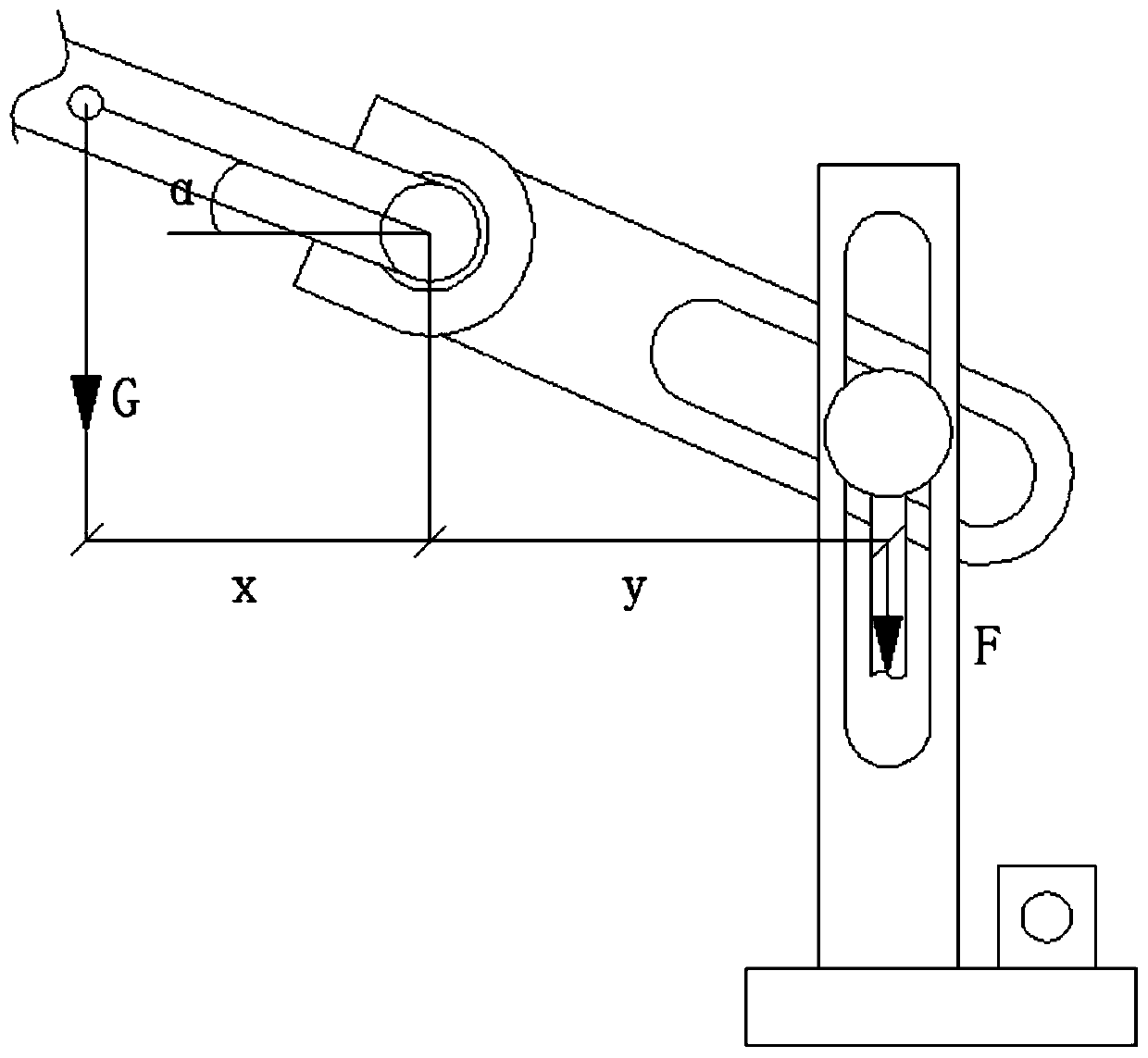

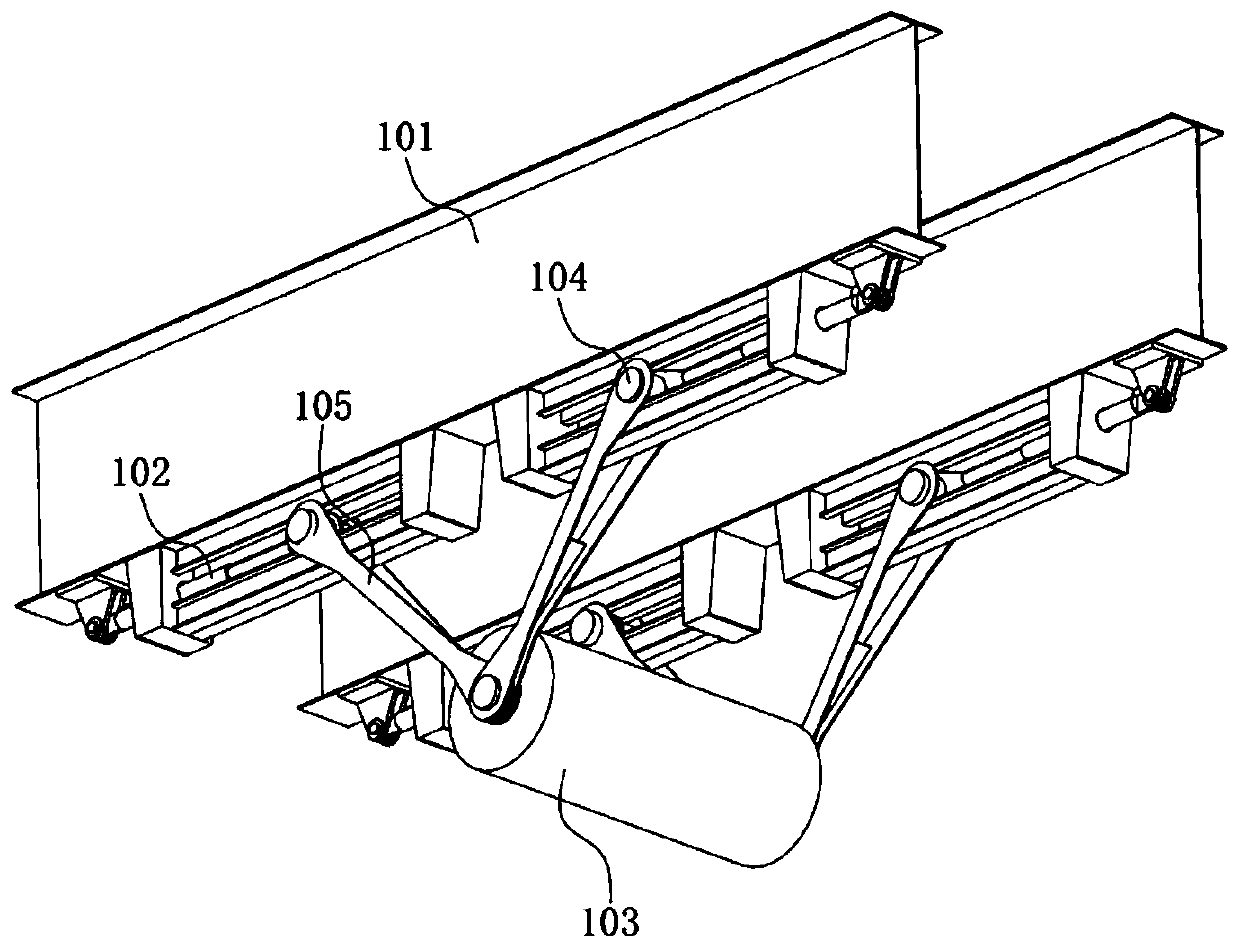

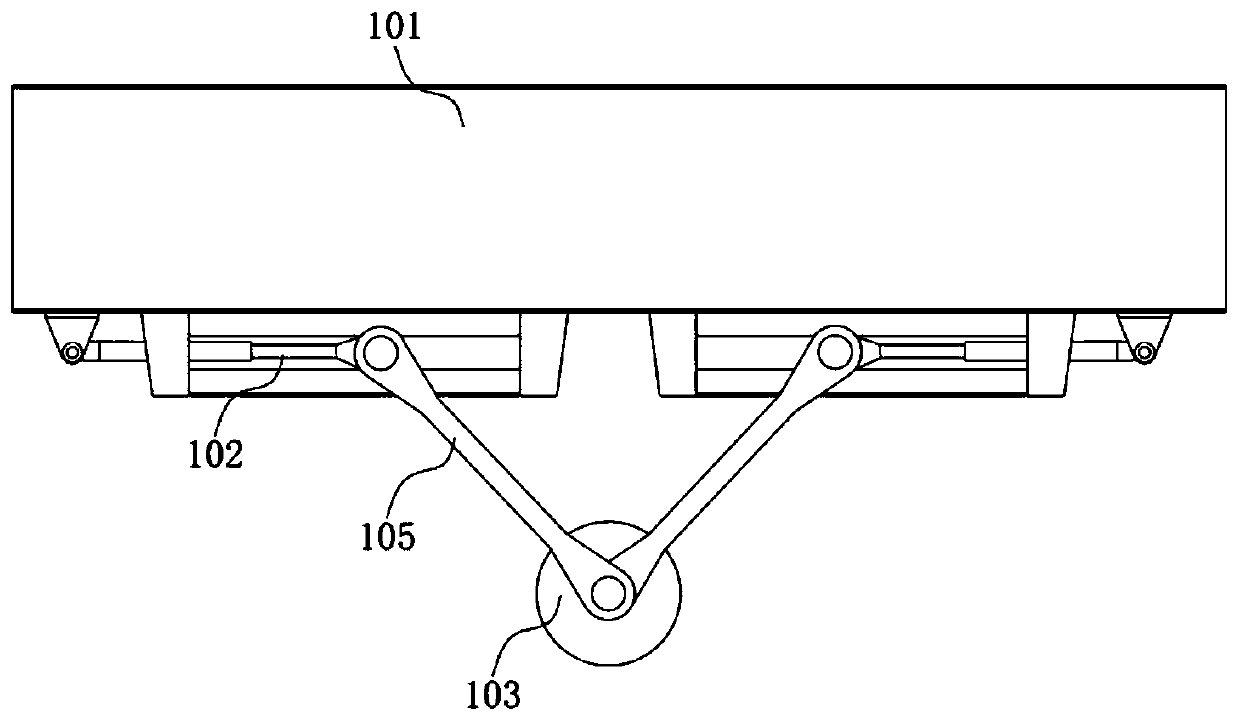

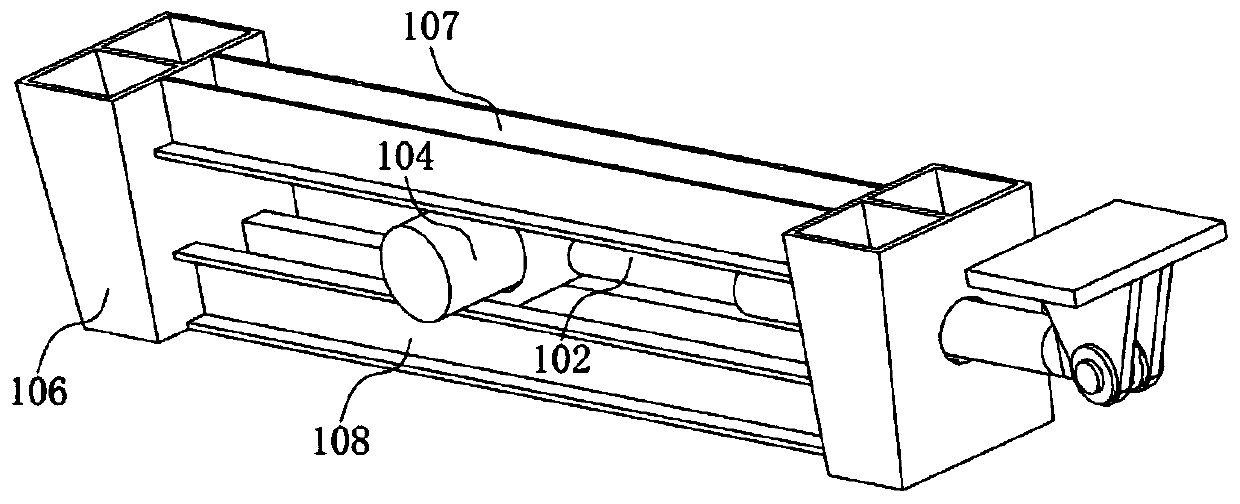

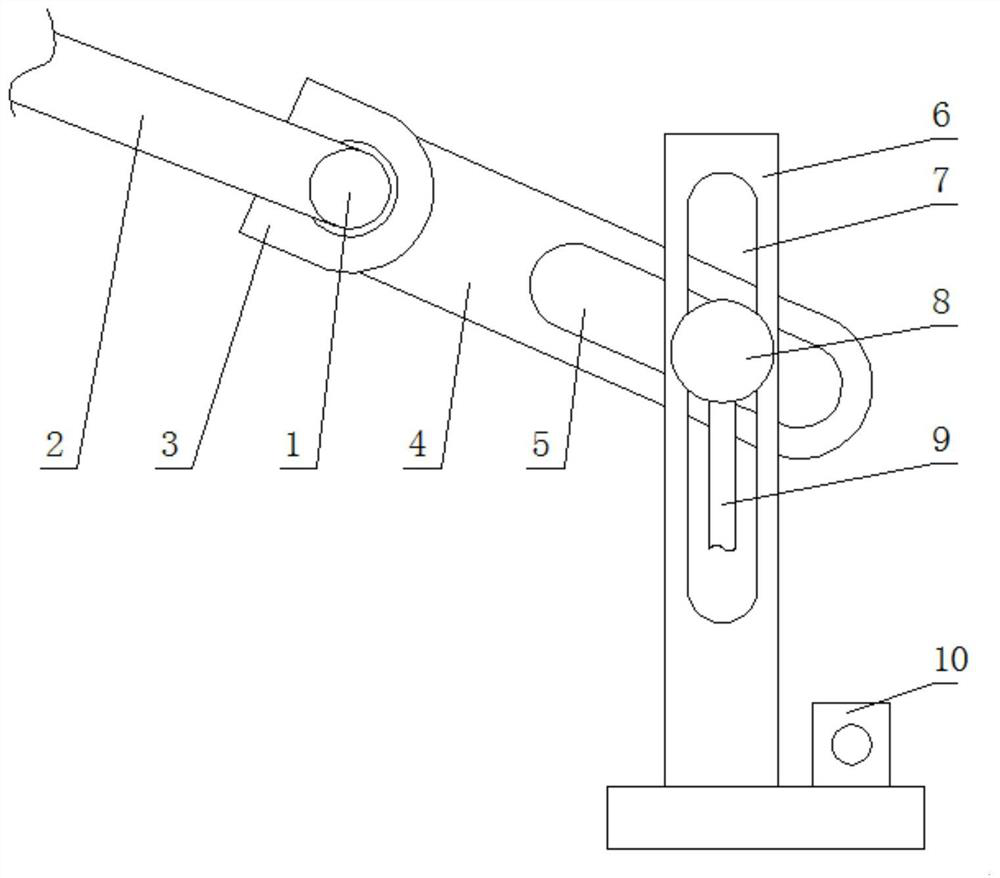

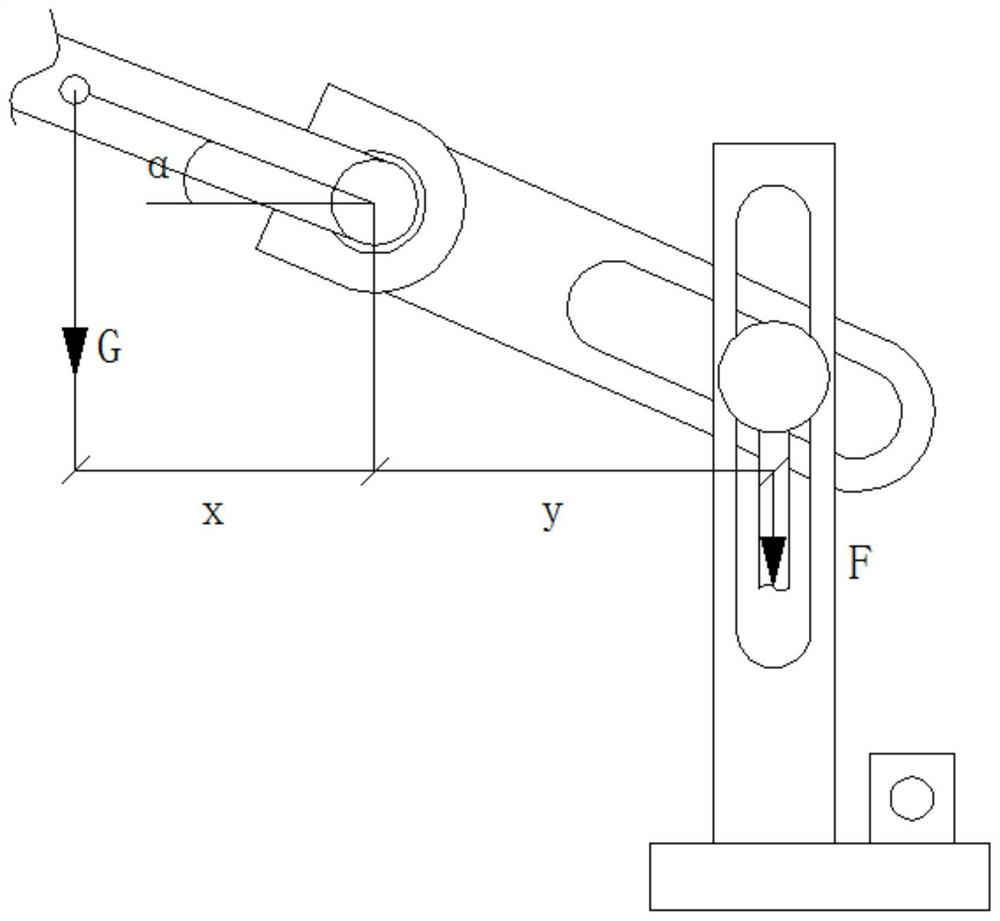

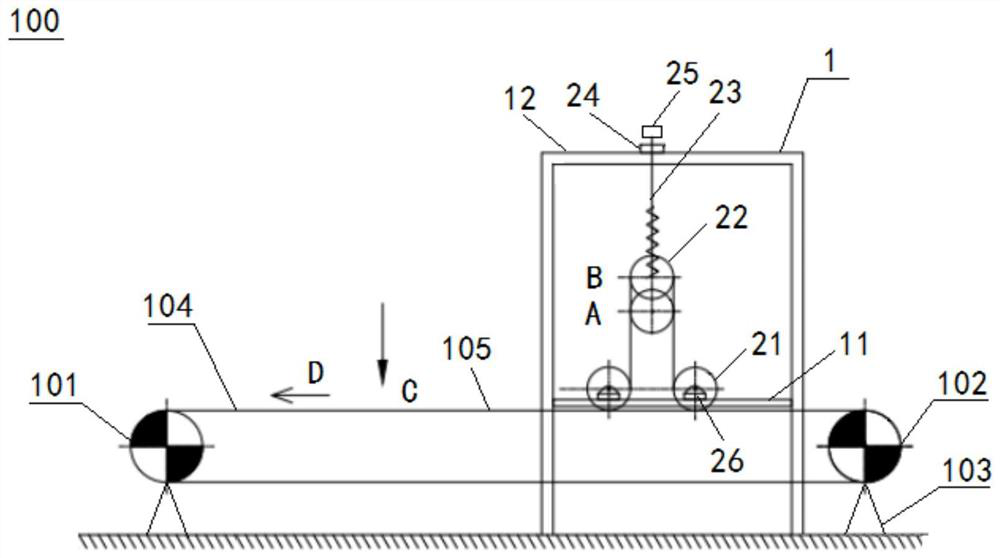

Belt tensioning device and belt conveyor of cantilever-type bucket-wheel stacker-reclaimer

PendingCN111361934ATo achieve tensionSimple structureConveyorsLoading/unloadingTransmission beltEngineering

The invention relates to the technical field of loading and unloading for large-sized dry bulk, in particular to a belt tensioning device. The device comprises a supporting base, a retractable drivingmechanism and a diverted roller. The supporting base is provided with slide grooves, and slide blocks are slidingly arranged in the slide grooves. The retractable driving mechanism is arranged on thesupporting base, and the slide blocks are driven to slide in the slide grooves when the retractable driving mechanism extends and retracts. The diverted roller is used for tensioning a transmission belt, the movement direction of the diverted roller is perpendicular to that of the slide blocks, the end of the diverted roller is connected with the slide blocks through connection rods, the first end of each connection rod is hinged to one side block, the second end of each connection rod is hinged to one end of the diverted roller, and an included angle a between the tensioning direction of thediverted roller and the connection rods is smaller than 45 degrees. A belt conveyor of a cantilever-type bucket-wheel stacker-reclaimer comprises the belt tensioning device. According to the belt tensioning device, through horizontal extension and retraction of an oil cylinder, the diverted roller moves up and down, the effect of tensioning the belt is achieved, and the belt tensioning device hasthe advantages of being low in weight and capable of achieving the small pressure of the oil cylinder.

Owner:HUADIAN CAOFEIDIAN HEAVY IND

Tensioning device and compressor

ActiveCN106838167AReach the telescopic lengthTo achieve the purpose of tensionGearingArchitectural engineeringEngineering

The invention discloses a tensioning device and a compressor provided with the same. The tensioning device comprises fixing plates, a connecting rod with one threaded end, a stop plate with a through groove and a nut, wherein one end of the connecting rod is hinged to the fixing plates while the other end with a thread passes through the through groove of the stop plate, the nut is in thread fit with the tail end of the connecting rod and is screwed into the thread, a circumscribed circle diameter of the nut is greater than a width of the through groove, the fixing plates are hinged to a base and are fixed on the compressor, and the stop plate is fixed on the base. The fixing plates can drive the compressor to rotate by being hinged to the base.

Owner:广东佳明机器有限公司

Fan guide cylinder positioning device

PendingCN110936311AAvoid damageGuaranteed roundnessWork holdersElectric machineryStructural engineering

The invention provides a fan guide cylinder positioning device, which comprises a main shaft component and a table top bottom plate, wherein the main shaft component comprises a main shaft, and the upper end of the main shaft is fixedly connected with the center of the table top bottom plate through a connecting sleeve; the upper surface of the table top bottom plate is provided with n mounting holes, and the mounting holes are uniformly distributed around the center of the table top bottom plate and extend in the radial direction; the outer side of each mounting hole is correspondingly provided with a tensioning arc, and extension lines of the adjacent tensioning arcs are connected to form a tensioning ring in a surrounding manner; the table top bottom plate is provided with diameter adjusting mechanisms at the positions of the mounting holes; each diameter adjusting mechanism comprises a mounting frame and a first motor, and the mounting frame is mounted at the position of the mounting hole and connected with the corresponding tensioning arc in a matched mode; and the first motor drives the mounting frame to slide back and forth along the mounting hole so as to change the inner diameter of the tensioning ring.

Owner:浙江科贸智能机电股份有限公司

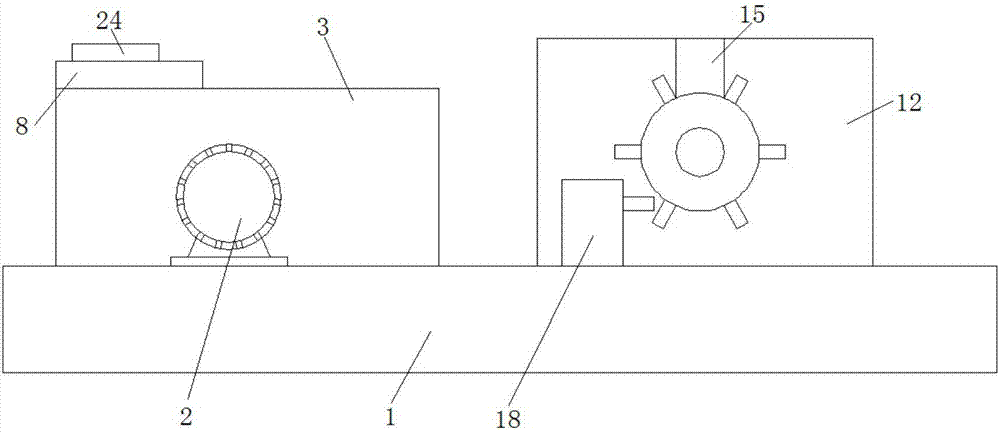

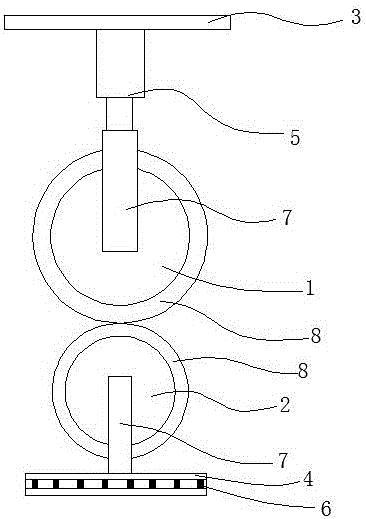

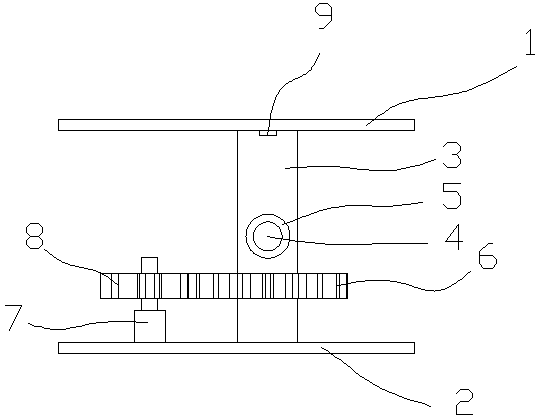

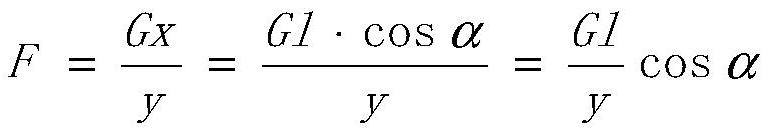

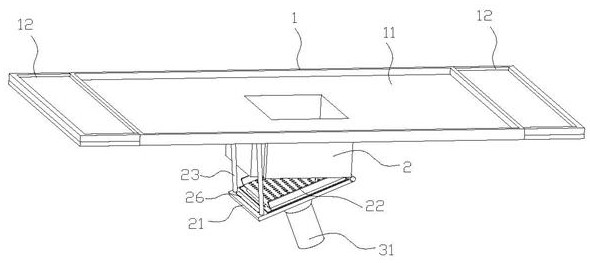

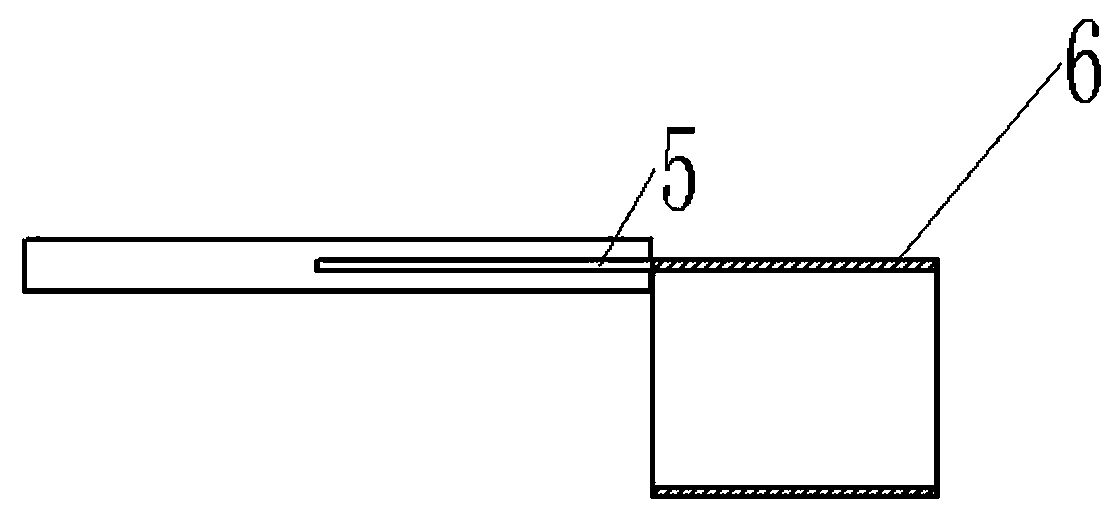

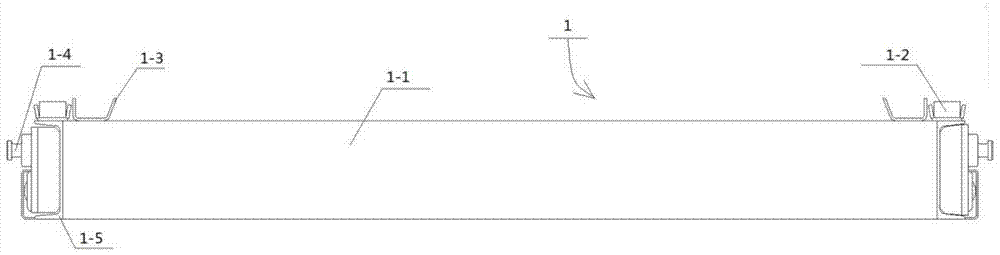

Wire rope tensioning device

The invention discloses a wire rope tensioning device. The wire rope tensioning device comprises an upper bottom board (1), a lower bottom board (2) and a tensioning roller (3), and is characterized in that the tensioning roller (3) is located between the upper bottom board (1) and the lower bottom board (2), the tensioning roller (3) is provided with a hole (5) through which a wire rope penetrates, a large gear (6) is arranged on the tensioning roller (3) and located below the hole (5), the lower bottom board (2) is provided with a gear motor (7), the gear motor (7) is connected with a small gear (8) meshed with the large gear (6), and the upper bottom board (1) is provided with a tension control sensor (9) for controlling the small gear (8) to rotate. The wire rope tensioning device does not need manual operation, and is high in degree of automation.

Owner:CHONGQING HENGTAI CABLE GRP

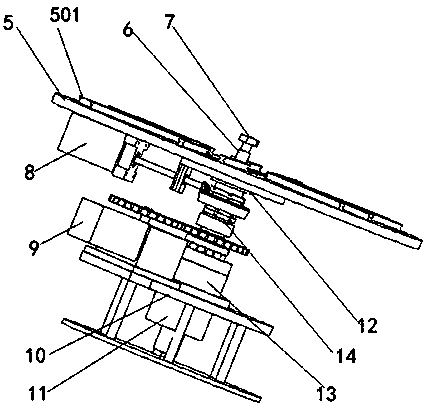

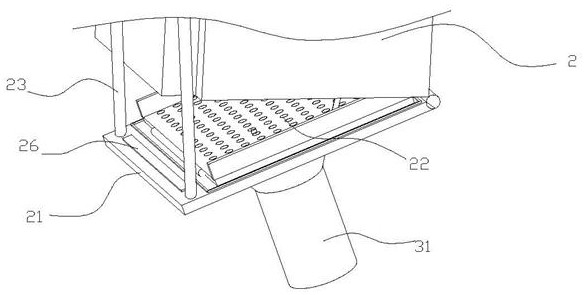

Cotton pressing and conveying mechanism and antiperspirant pad forming equipment

ActiveCN113371502ASpacing real-time adjustmentImprove the pressing effectConveyorsLaminationAgricultural engineeringStructural engineering

The invention relates to a cotton pressing and conveying mechanism and antiperspirant pad forming equipment. The cotton pressing and conveying mechanism comprises a machine frame and further comprises an upper conveying belt and a lower conveying belt, the upper conveying belt comprises a driving roller, a driven roller and a conveying belt, the conveying belt surrounds the driving roller and the driven roller, the driving roller is connected to the machine frame, the side wall of the machine frame is rotationally connected with a rotating shaft and a driving mechanism, the peripheral side of the rotating shaft is connected with a roller frame in a rotation-stopping mode, the driven roller is rotationally connected to the roller frame, the driving mechanism comprises a driving source, a turbine and a worm, the turbine is fixed to the rotating shaft, and the driving source drives the turbine through the worm. The cotton pressing and conveying mechanism has the advantages that the distance can be adjusted in real time according to the cotton pressing thickness requirement, and therefore the better cotton pressing effect is achieved.

Owner:浙江亿维护理用品有限公司

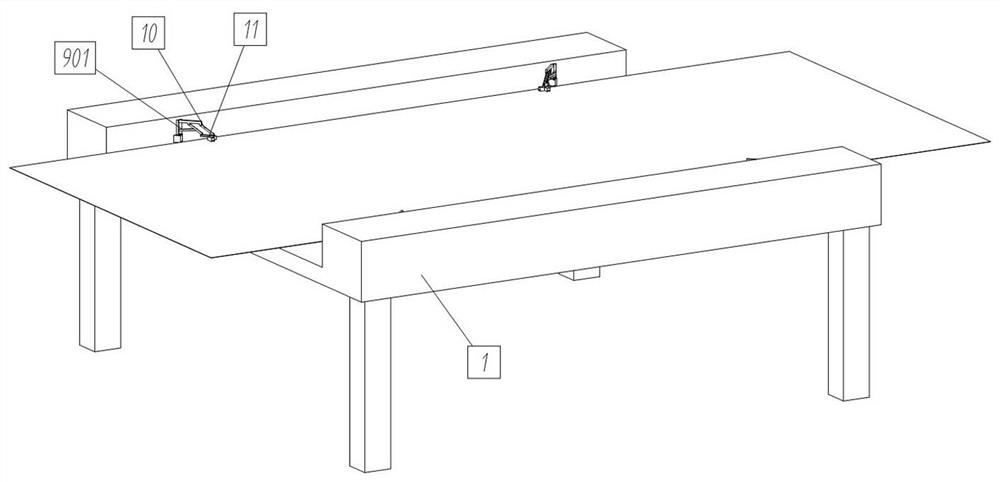

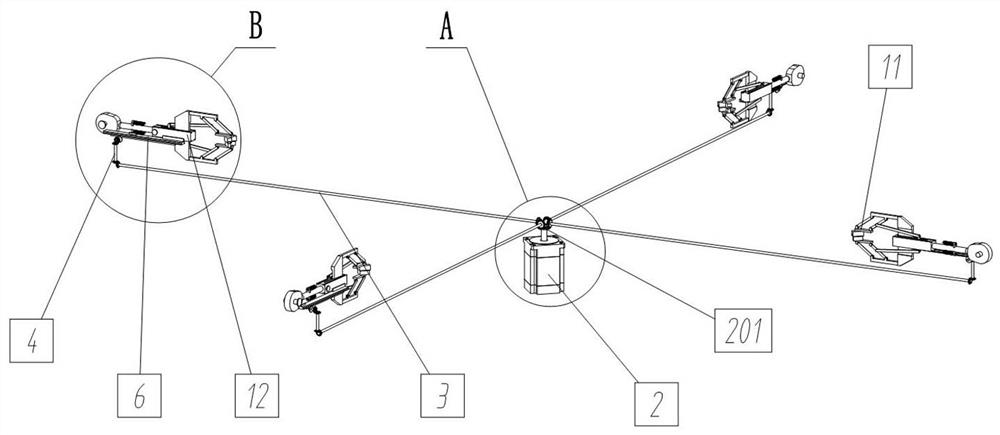

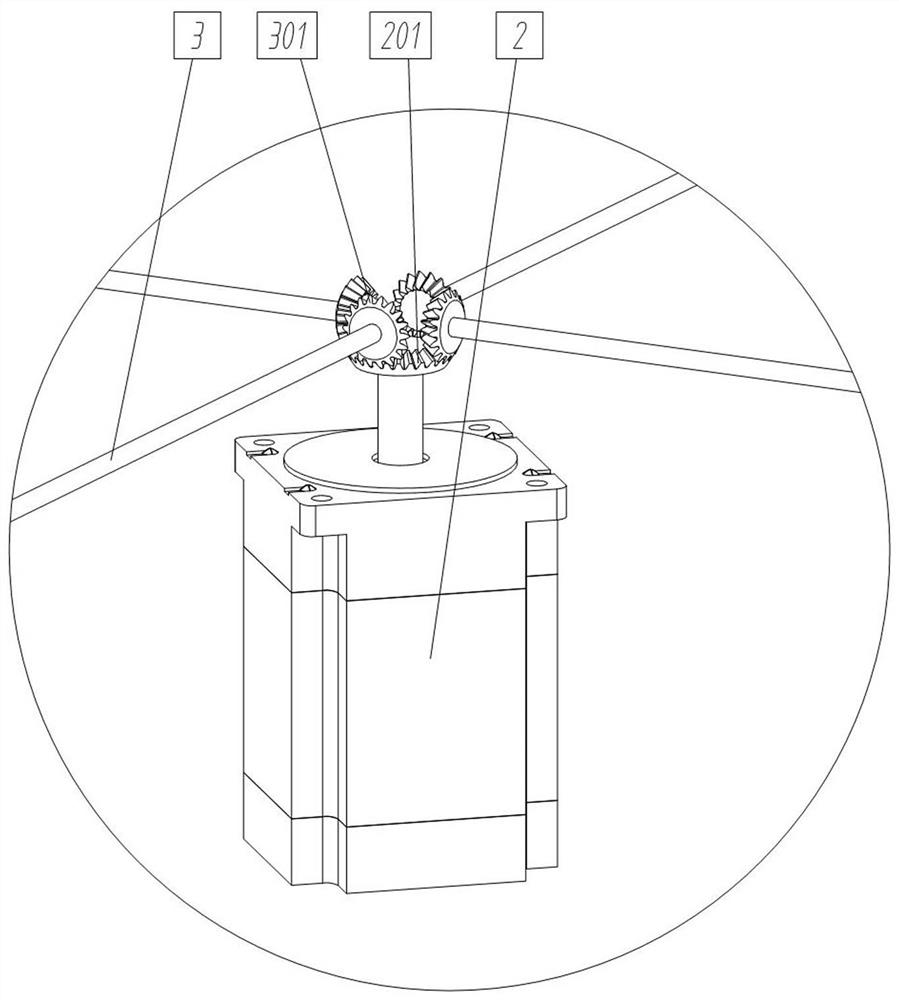

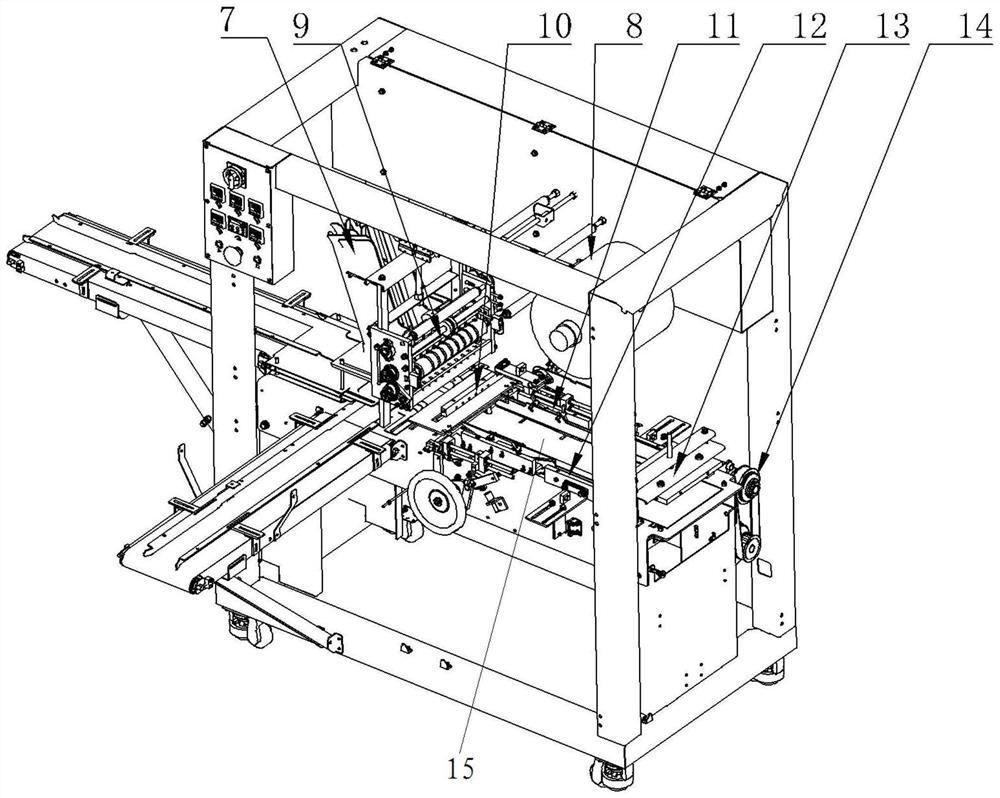

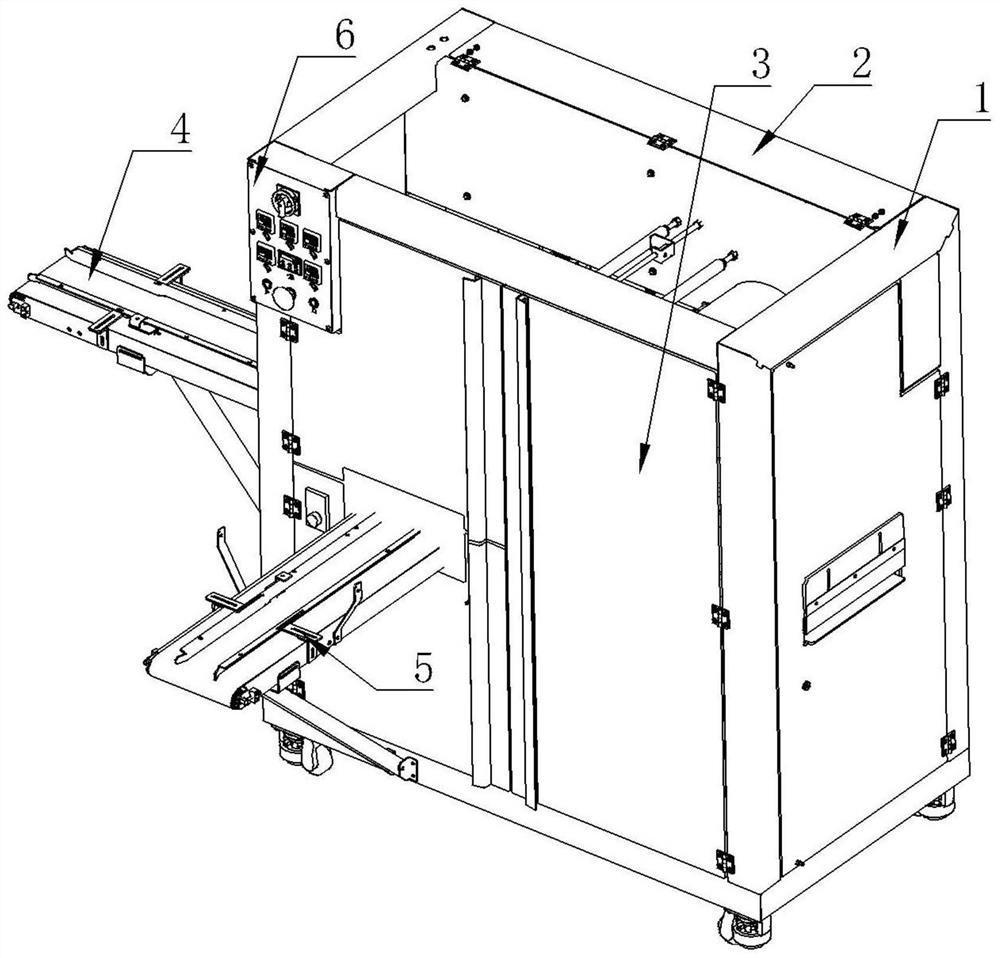

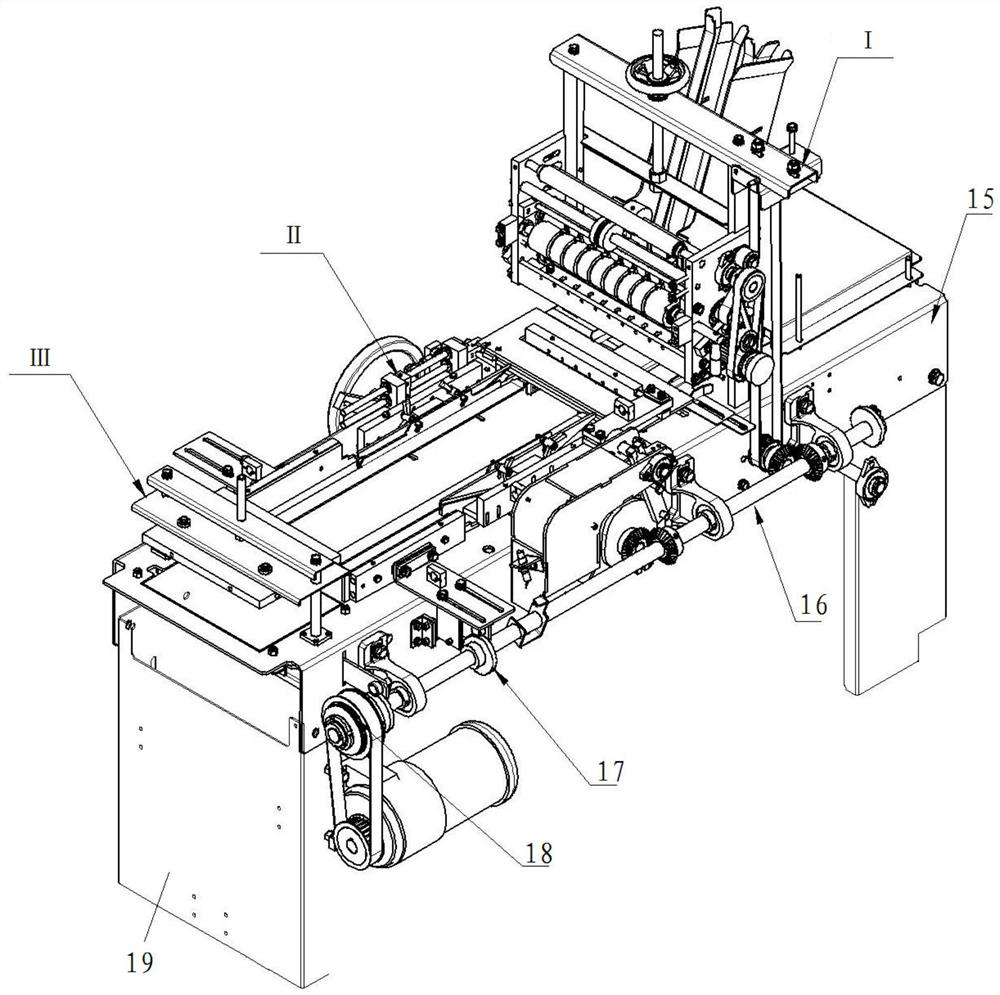

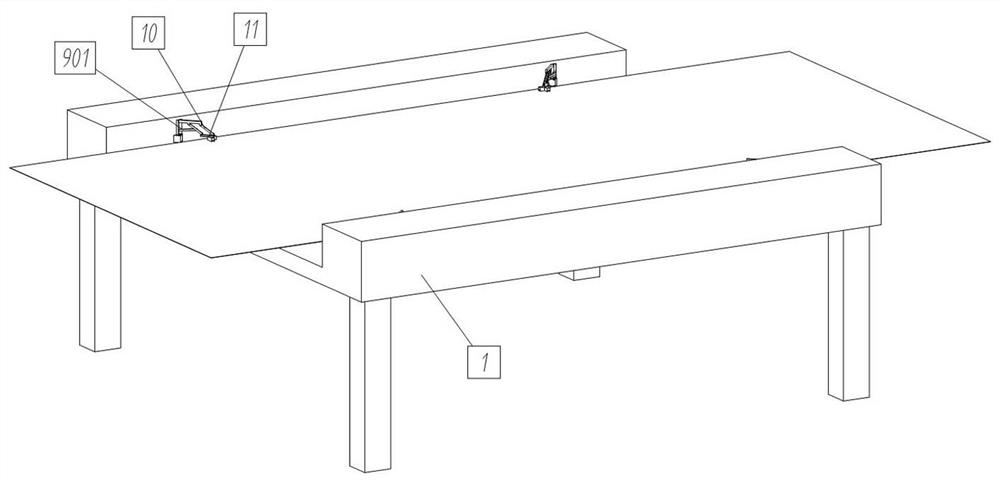

Three-dimensional packaging machine for transparent film

PendingCN113800066AEasy to processHigh strengthWrapping material feeding apparatusFilament handlingPhysicsEngineering

The invention relates to a three-dimensional packaging machine for a transparent film. The three-dimensional packaging machine comprises a large flat plate workbench, the large flat plate workbench is provided with a plurality of mounting holes and mounting grooves which are formed by laser cutting, the long edges of the two sides of the large flat plate workbench are bent downwards to form an inverted-U-shaped section, all the functional subassemblies are sequentially fixed to the large flat plate workbench from one side to the other side through the mounting holes and / or the mounting grooves, and all the functional subassemblies are not directly fixed or positioned. The large flat plate workbench completely replaces conventional parts such as a front panel, a rear panel, a left vertical plate, a right vertical plate and a shaping support of an existing three-dimensional packaging machine for the transparent film, and installation and positioning are convenient and accurate; and the installation process is clear, the relation between the subassemblies is clear, the assembly progress of other subassemblies cannot be affected even if small problems occur or a certain part is machined slowly, and the examination efficiency and the management convenience are improved.

Owner:上海全驰机械有限公司

A torque balance counterweight mechanism of an intelligent barrier gate

ActiveCN110409339BGuaranteed real-time torque counterweight balanceEnsure counterweight balanceTraffic restrictionsTraffic flowControl theory

The present invention relates to the technical field of intelligent terminals, and discloses a torque balance counterweight mechanism of an intelligent barrier gate, which includes a core shaft and a gate lever body fixedly socketed outside the core shaft, and a connection block is fixedly socketed outside the core shaft. One side of the connecting block is fixedly connected with a balance bar, the front of the balance bar is provided with a moving chute, the end of the balance bar is provided with a counterweight positioning bar, and the counterweight positioning bar is fixedly installed on the inner bottom of the barrier gate chassis, and the counterweight positioning The front of the bar is provided with a limiting groove. The present invention replaces the traditional tension spring counterweight by setting a counterweight cable that is always tensioned, so that the tensioned counterweight cable is always equal to the action force and reaction force, and can ensure the real-time torque counterweight balance of the brake lever body , so that no additional impact amplitude will be brought by the counterweight when the brake lever body is turned in an emergency stop. In the case of heavy traffic flow, the brake lever body can be carried out smoothly when lifting the lever, dropping the lever, and lifting the lever in an emergency stop. Effectively guarantee the stability of the turnstile transmission system.

Owner:南京乐焱焱科技有限公司

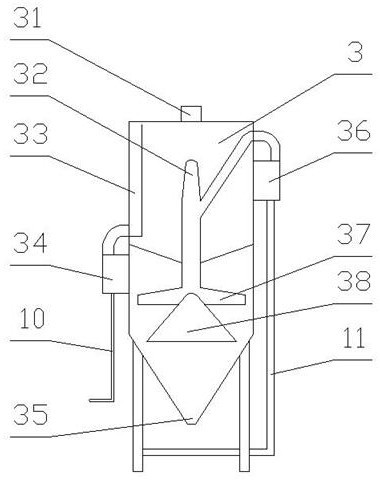

An intelligent detection and recovery system for heavy-duty equipment reducer oil leakage

ActiveCN111530155BDischarge in timeImprove filtering effectDetection of fluid at leakage pointStationary filtering element filtersFiltrationEngineering

The present invention relates to the technical field of reducers, in particular to an intelligent oil leakage detection and recovery system for heavy-duty equipment reducers, comprising: a flexible body with a recessed area and a connecting part; The bottom is sealed or opened, and the sealing plate is connected with a pipeline; the sealing plate is located on one side of the tank body and is equipped with a filter plate to filter the oil; an elastic connection structure is set between the sealing plate and the tank body for sealing the sealing plate Tension to the tank body, the bottom of the side wall of the tank body is provided with an electromagnetic structure, which obtains magnetism when energized and repels the first permanent magnet on the sealing plate to obtain an open end; it is set between the sealing plate and the bonding surface of the filter plate There is a pressure sensing sheet, and the sensed pressure value is used as the basis for electromagnetic structure control and oil leakage detection. The invention can realize the effective filtering and recycling of the oil leakage, and can detect the amount of oil leakage, so that urgent problems can be quickly discovered and effectively treated.

Owner:JIANGSU GUOMAO REDUCER GRP CO LTD

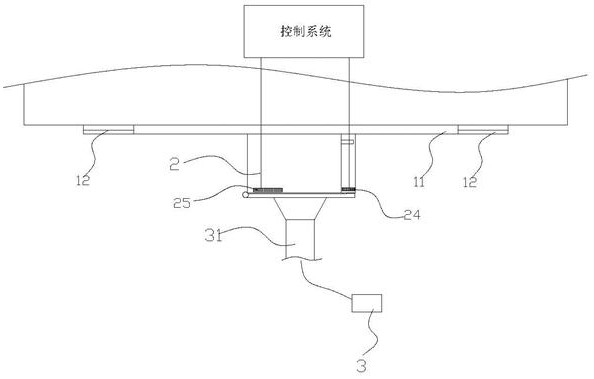

Self-cleaning device of belt type sludge dewatering machine

PendingCN112851077ATo achieve tensionImprove firmnessSludge treatmentTreatment involving filtrationWater filterProcess engineering

A self-cleaning device of a belt type sludge dewatering machine comprises a shell, an upper dewatering device and a lower dewatering device are arranged in the shell, a feeding plate is arranged at one end of the lower dewatering device, a discharging plate is arranged at the other end of the lower dewatering device, the two sides of the feeding plate and the two sides of the discharging plate are fixed to the shell, and the upper dewatering device and the lower dewatering device are both sleeved with filter cloth. A water filtering device is arranged on one side of the shell. Through the arrangement of the upper cleaning device and the lower cleaning device, cleaning of the filter cloth is achieved, and due to the fact that water used in the upper cleaning device and the lower cleaning device comes from the dewatering device, energy conservation and emission reduction are achieved, and the production cost is reduced; through the arrangement of the tensioning dewatering device, the tensioning effect on the filter cloth is achieved, the compactness of the filter cloth during passing is improved, the filter cloth can be automatically tensioned after the filter cloth is loosened, and the working efficiency is improved; and through the arrangement of the water filtering device, water generated in the dewatering equipment is filtered.

Owner:江苏康德龙环保有限公司

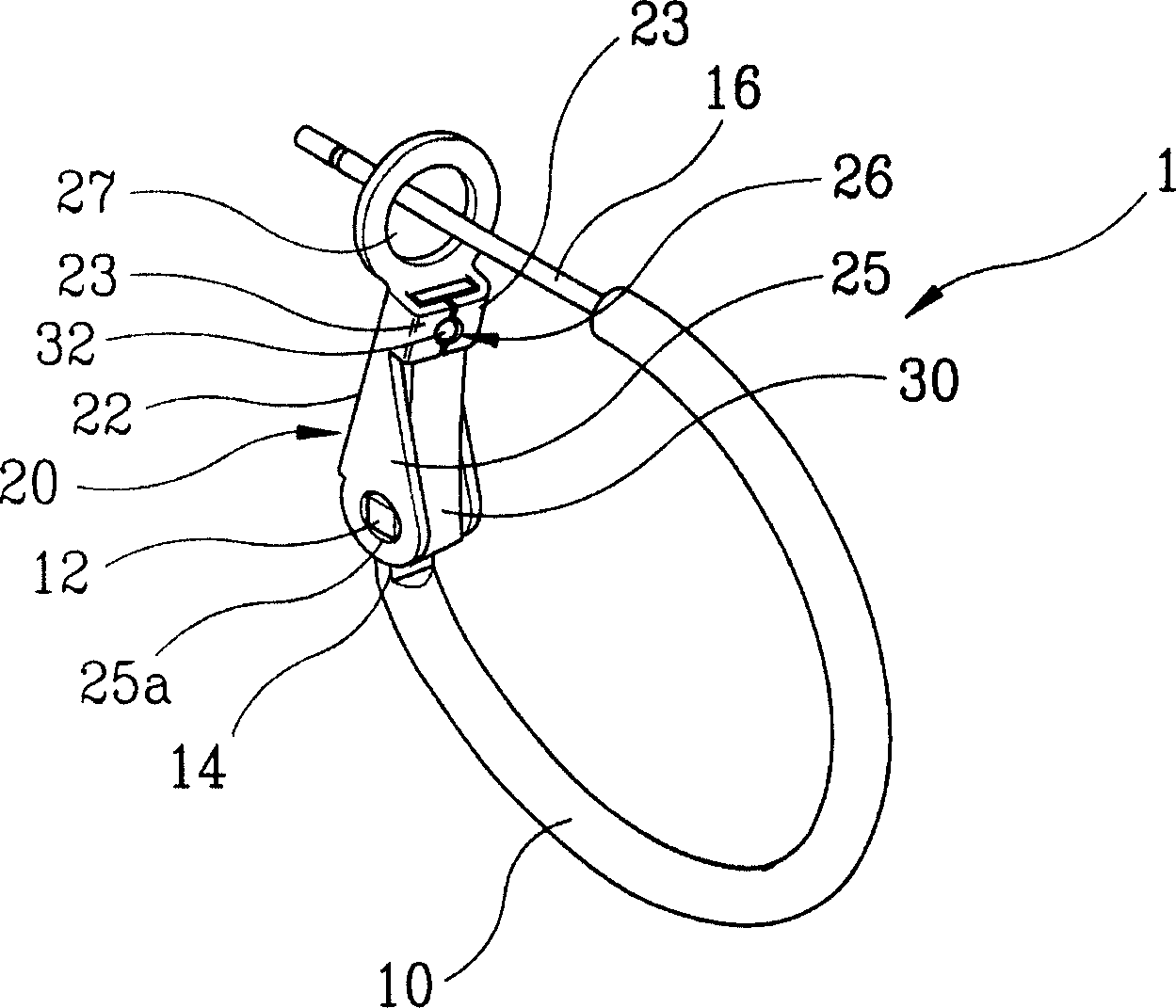

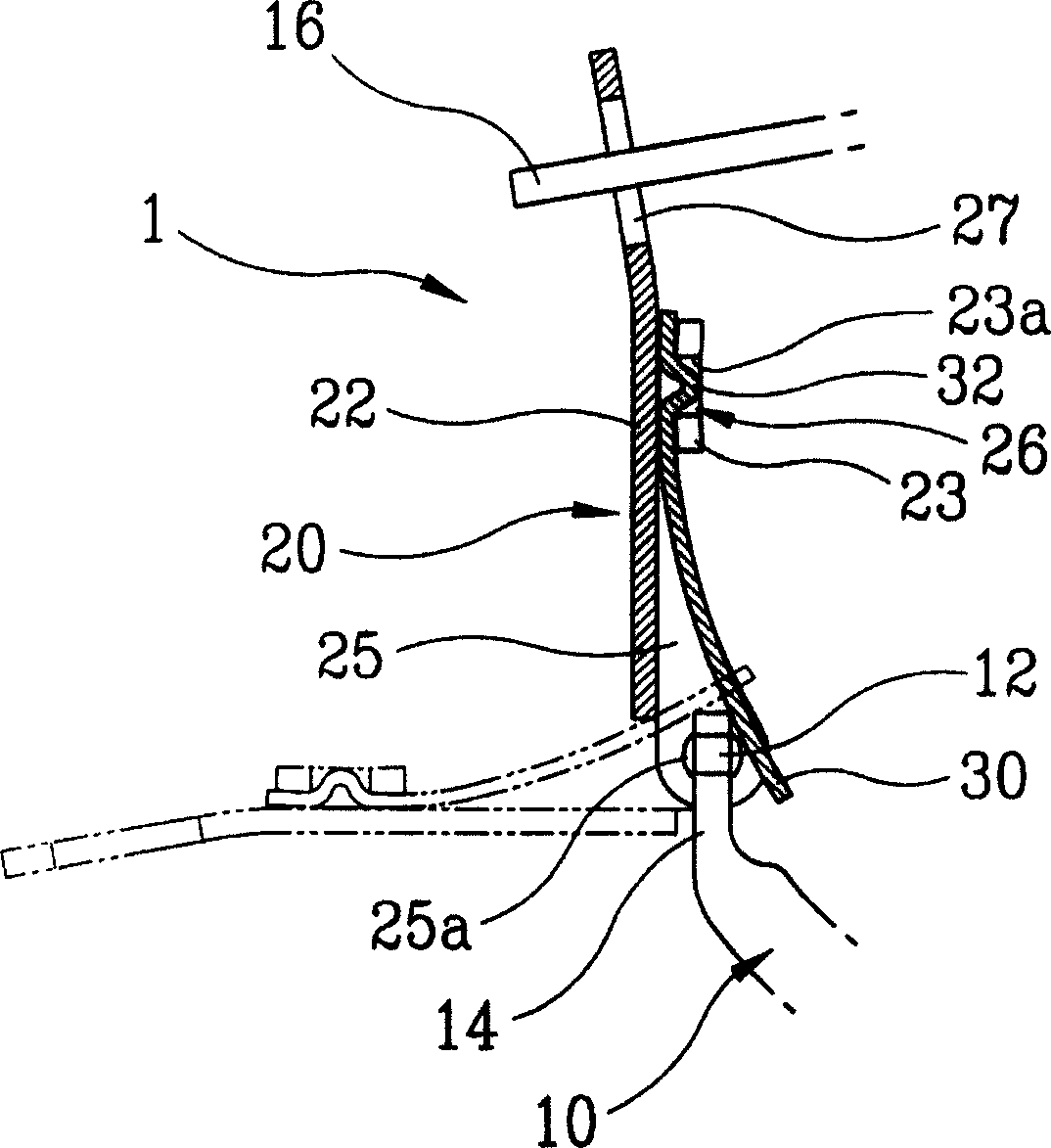

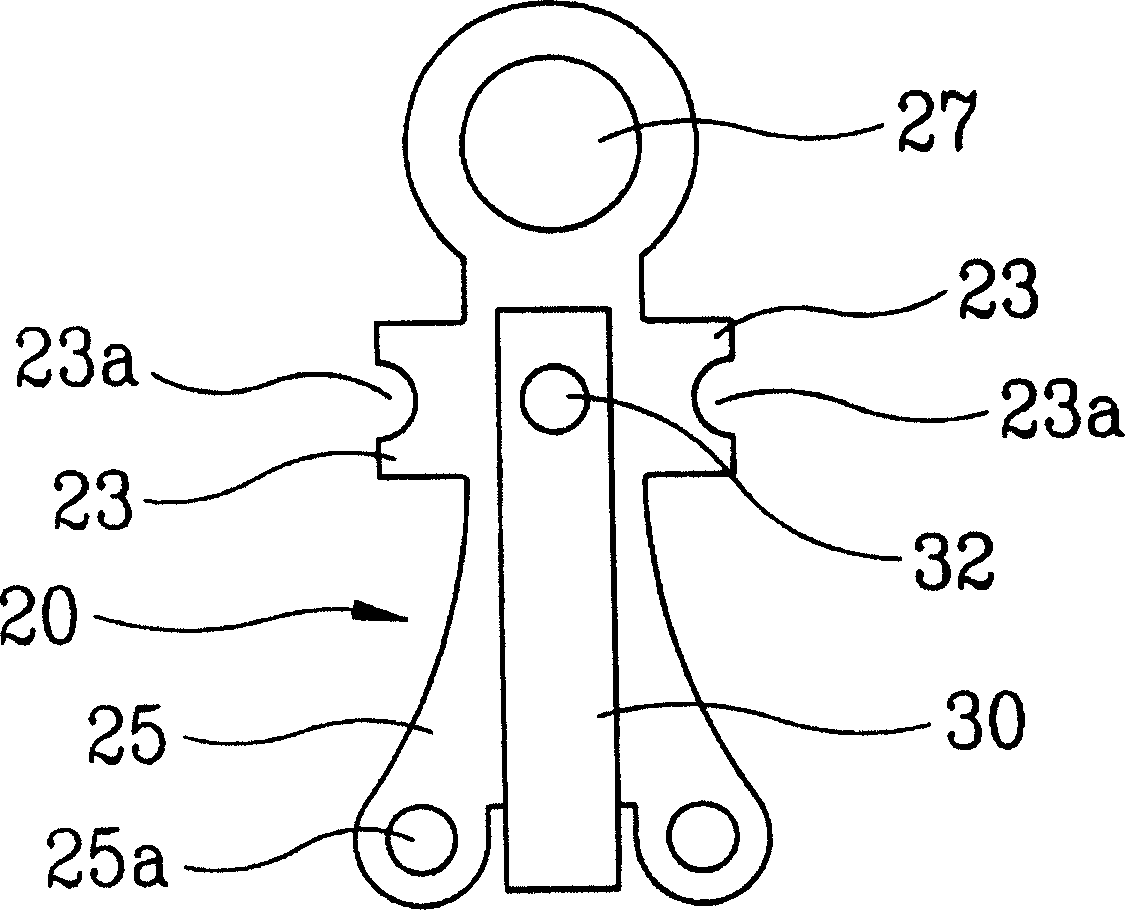

Tension locking device for ring

The invention relates to a tension locking device for earrings. The feature of this device is that an embossed protrusion is formed on one side of the plate spring of the tension locking device designed to be able to pick and hang earrings on the earlobe arbitrarily, and the fixing pieces formed on both sides of the tension locking device are formed by bending To fix and support the embossed protrusion, and make the embossed protrusion be movably clamped by the fixing piece, thereby not only preventing the separation or disengagement of the plate spring, but also preventing damage to the Stress concentration occurs locally on the fixed piece or the plate spring, fundamentally preventing the fixed piece on the tension lock device or the plate spring connected to the tension lock device from being partially broken. In addition, since the present invention can realize the tension action of the tension locking device with a small force, the feeling and effect when the user wears the earrings is improved.

Owner:金裕坤

An embroidery machine cloth tensioning device for cross-stitch textile processing

The invention discloses a cloth tensioning device for an embroidery machine for cross-stitch textile processing, relates to the technical field of textile embroidery, and solves the problem that the existing cloth has ripples during the tensioning process, and at the same time, the roller shaft is prone to rotation. The movement of the cloth, the tensioning effect is not good, and the problems that affect the processing quality include the main body of the bracket; the tensioning sliding seat, there are four sets of tensioning sliding seats, and the four sets of tensioning sliding seats are respectively slidably connected to the four corners inside the main body of the bracket. The inner side of the tensioning slide seat is provided with a cloth clamping mechanism; there are four sets of sliding drive assemblies, and the four sets of sliding drive assemblies are respectively slidably connected to the inner sides of the four corners of the main body of the bracket. The invention avoids the loosening or moving of the cloth, realizes the clamping of the cloth through the parallelogram of the hinge, ensures the parallel clamping of the cloth, effectively avoids the pleats of the cloth, ensures the embroidery quality, and has good economic benefits.

Owner:南通市金璐艺卧室用品有限公司

Scraper mechanism for waste asphalt recycling process and using method thereof

InactiveCN112575647AAdjustable tightnessTo achieve tensionRoads maintainenceHydraulic cylinderSlide plate

The invention belongs to the technical field of asphalt recycling and particularly relates to a scraper mechanism for a waste asphalt recycling process and a using method thereof. The scraper mechanism comprises a fixing base, a positioning plate is fixedly connected to the top of the fixing base, a positioning groove is formed in the top of the positioning plate, and a positioning rod is fixedlyconnected to the inner wall of the positioning groove; a sliding sleeve is slidably connected to the surface of the positioning rod, a sliding plate is fixedly connected to the bottom of the sliding sleeve, the bottom of the sliding plate is slidably connected with the inner wall of the positioning groove, a hydraulic cylinder is fixedly connected to one side of the sliding plate, the end of the hydraulic cylinder is fixedly connected with the inner wall of the positioning groove, and a limiting base is fixedly connected to the top of the sliding sleeve. Through cooperative use of the hydraulic cylinder, the sliding plate, the fixed rod, the sliding sleeve and the limiting rod, the roller can be conveniently moved up and down, so that the chain tensioning effect can be achieved, the chaintensioning mechanism can conveniently and effectively adjust the tightness of the chain, and then practicability is improved.

Owner:扬州得路达交通科技有限公司

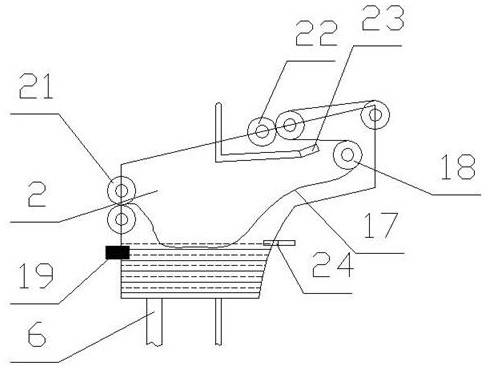

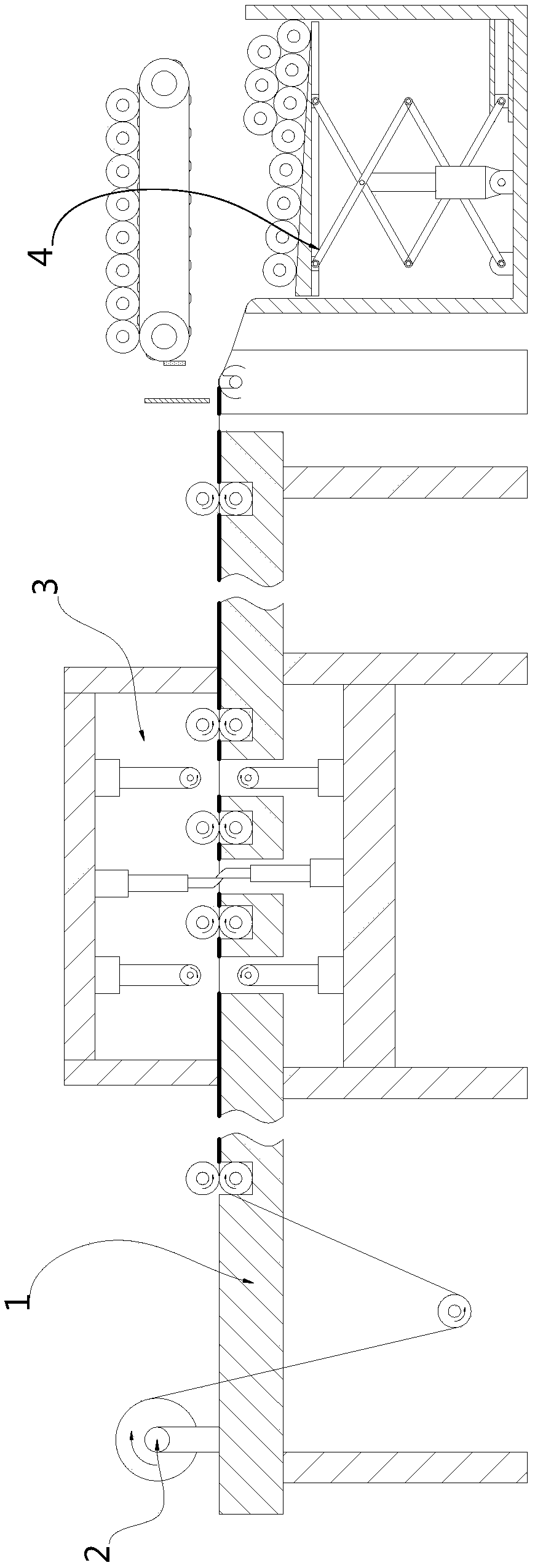

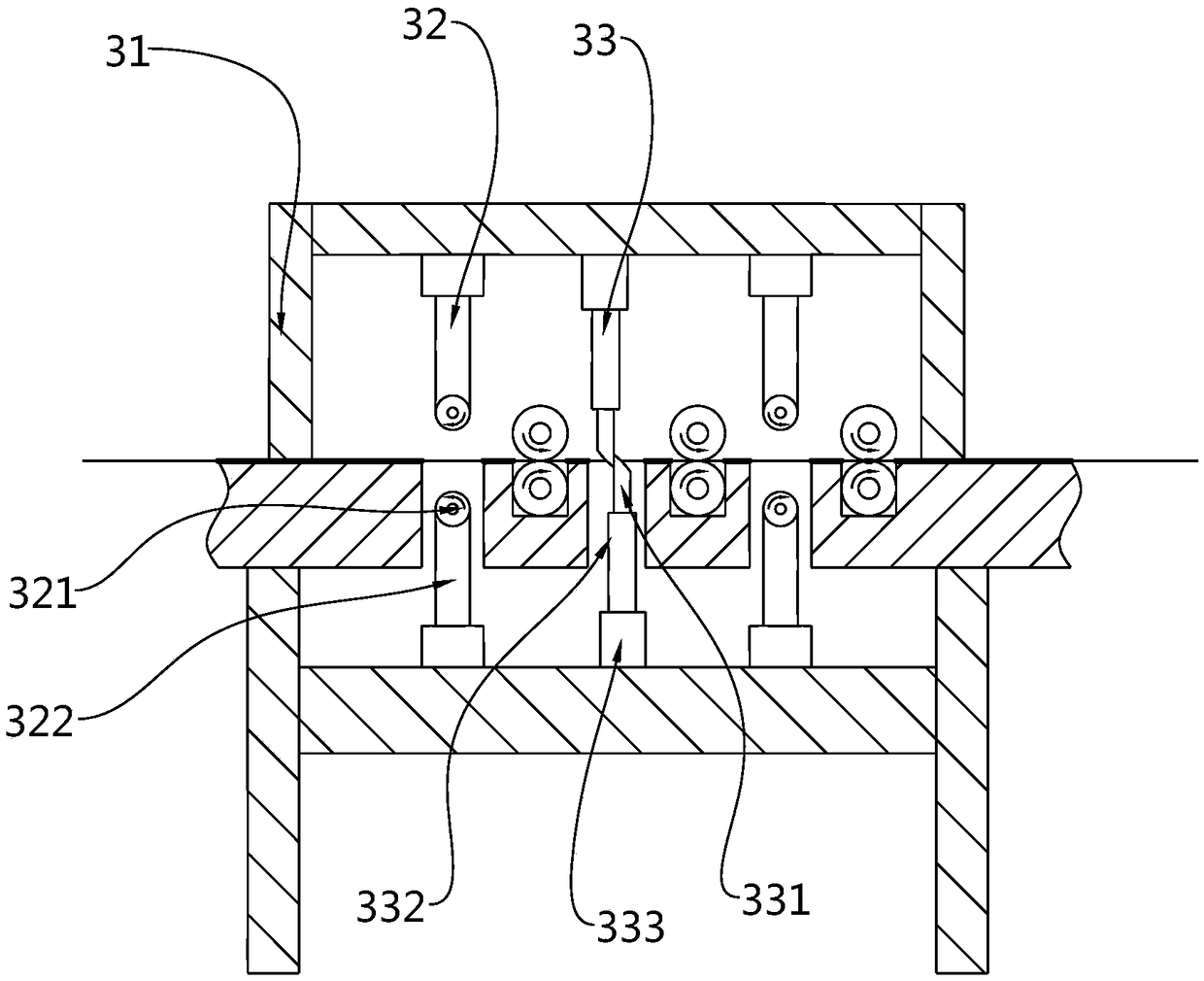

Continuous shearing system suitable for elastic lace fabric

InactiveCN108789540AImprove qualityImprove work efficiencySevering textilesMetal working apparatusEngineeringScissors mechanism

The invention discloses a continuous shearing system suitable for elastic lace fabric. The continuous shearing system comprises a main rack. A main roller is arranged at the end portion of the main rack. The main rack is provided with a plurality of pairs of transmission rollers in the fabric conveying direction. A tailoring device is arranged at the middle portion of the main rack, and a recycling device is arranged on the discharging side of the main rack. The tailoring device comprises an auxiliary rack connected with the main rack, and the auxiliary rack is provided with two pairs of fabric tensioning mechanisms. A shear mechanism is arranged between the two pairs of fabric tensioning mechanisms and comprises a pair of shearing tools which are in up-down intersection fit. The recyclingdevice comprises a rolling mechanism, a roller transmission mechanism is arranged above the rolling mechanism through a pair of guide plates, and one side of the rolling mechanism is connected with aroller recycling mechanism through an inclined guide rail. The intermittent actions are adopted in a pair of shearing tools which are in up-down intersection fit in the tailoring process. The continuous shearing system has the beneficial effects that the lace fabric tailoring quality is good, tailoring continuity is good, and the work efficiency is high.

Owner:湖州成得丝绸有限公司

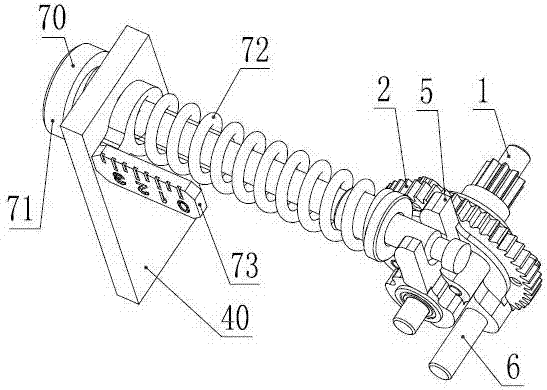

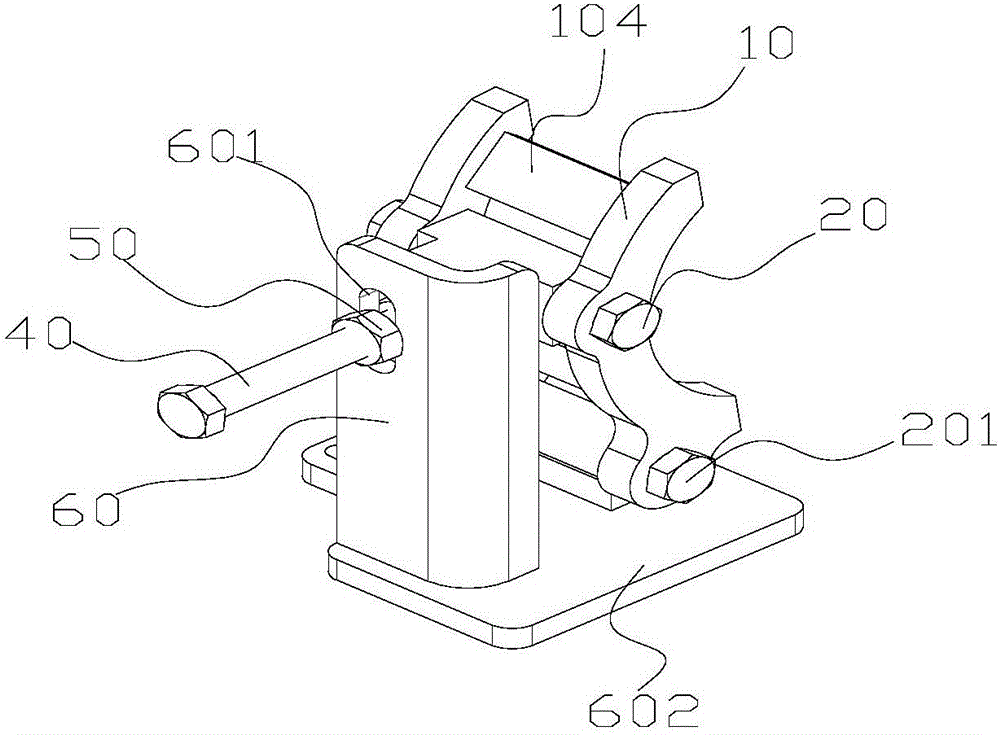

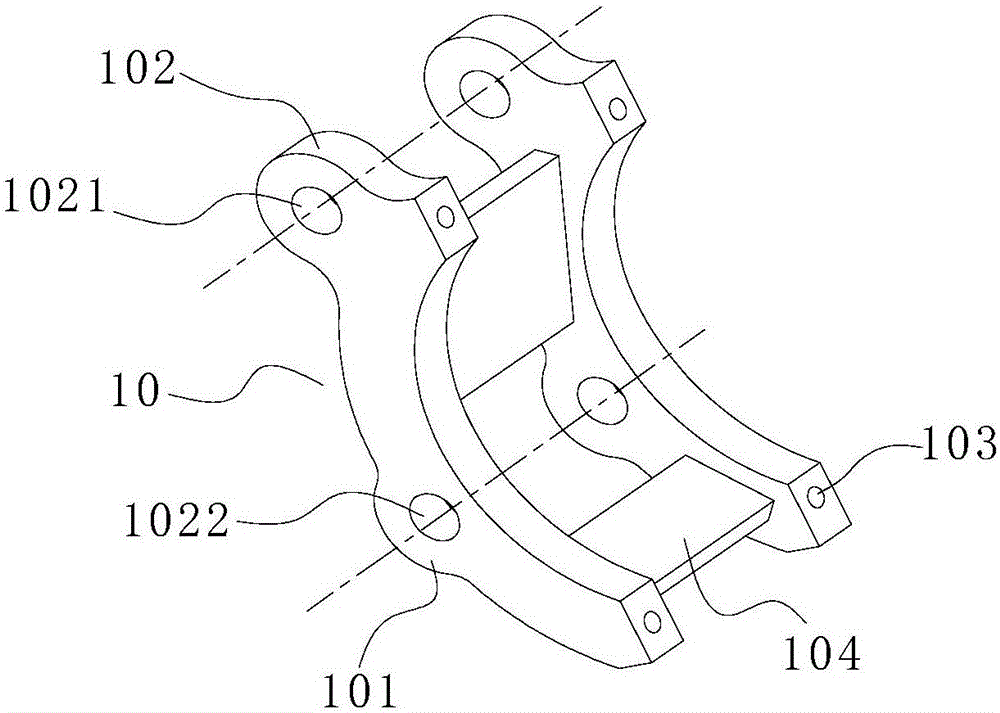

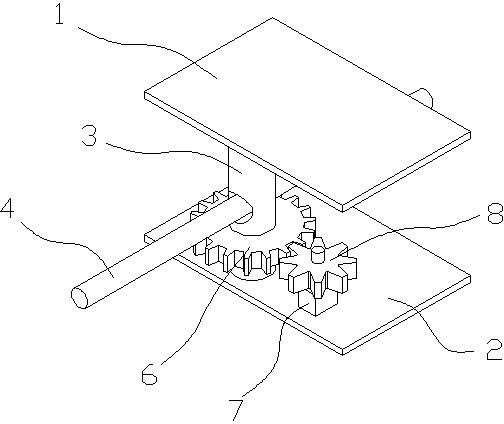

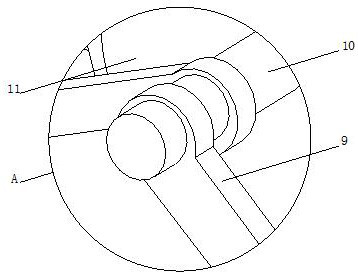

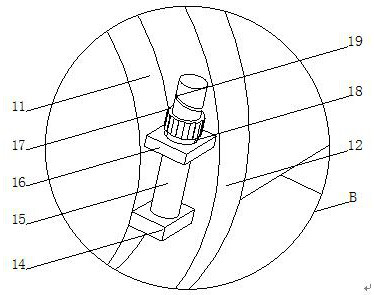

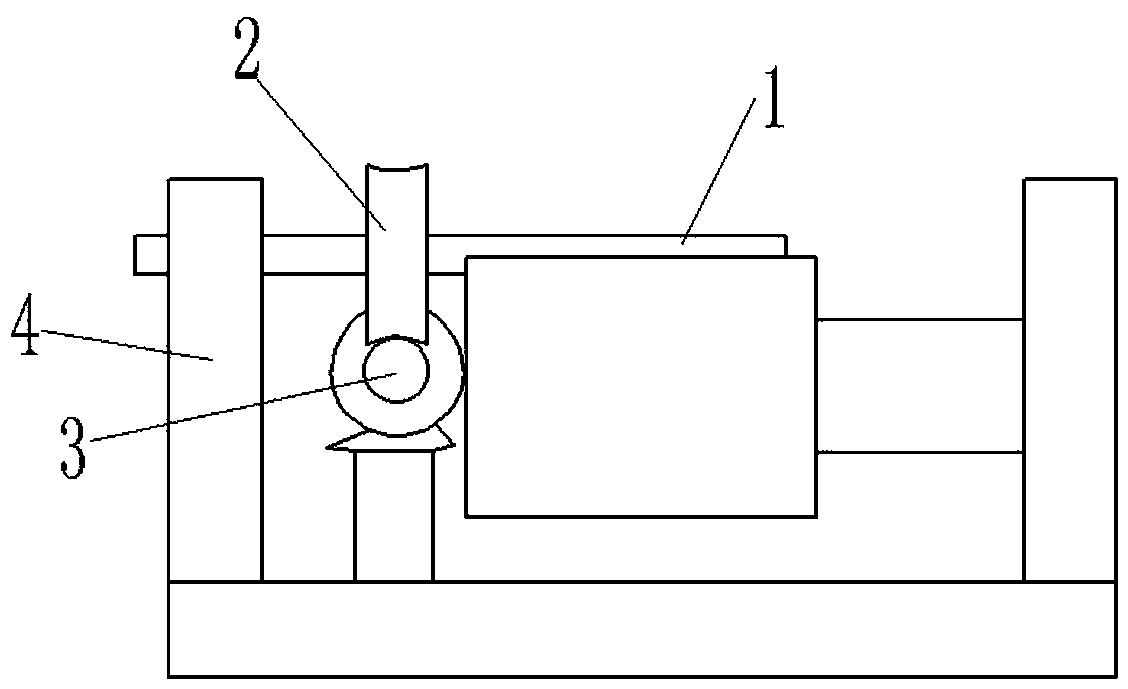

Industrial conveying belt self-tensioning device

PendingCN109649958ATo achieve tensionTranslation travel limitConveyorsIndustrial engineeringLeather belt

The invention discloses an industrial conveying belt self-tensioning device. The industrial conveying belt self-tensioning device is characterized in that the industrial conveying belt self-tensioningdevice comprises a clamping and connecting body 1, a worm gear 2, a worm 3 and a rack 4, the clamping and connecting body 1 is a columnar body, an inserting groove 5 is formed in one end of the clamping and connecting body 1, one end of the clamping and connecting body 1 is of a Y-shaped structure, and the clamping and connecting body 1 and a conveying belt 6 are in inserted connection through the inserting groove 5. The industrial conveying belt self-tensioning device has the beneficial effects that the device can conduct tensioning in any period within the limited usage period of the belt,and limitation from the horizontal motion stroke of original tensioning wheels is avoided.

Owner:南通欧炫工业制带有限公司

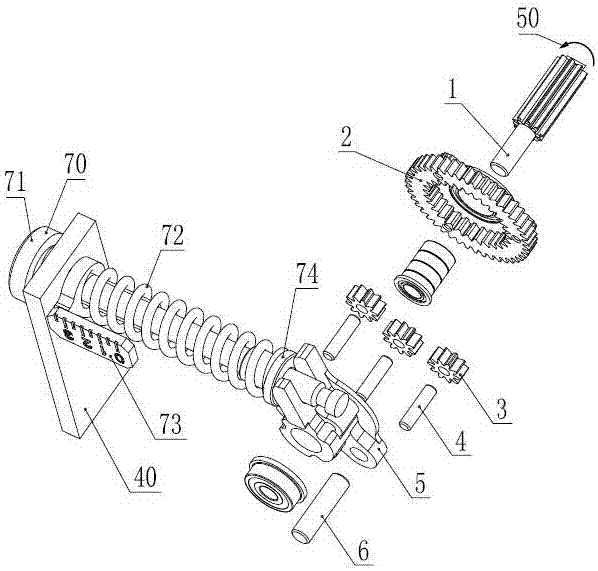

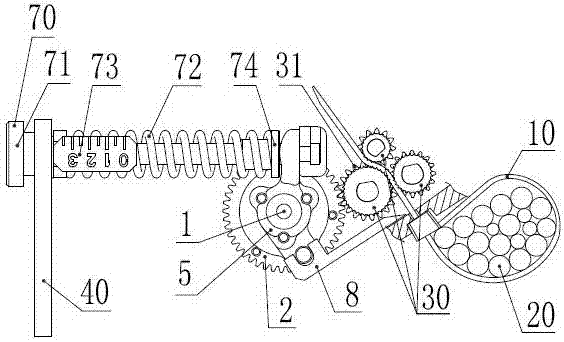

Tension-adjustable copper wire winding device for transformer production

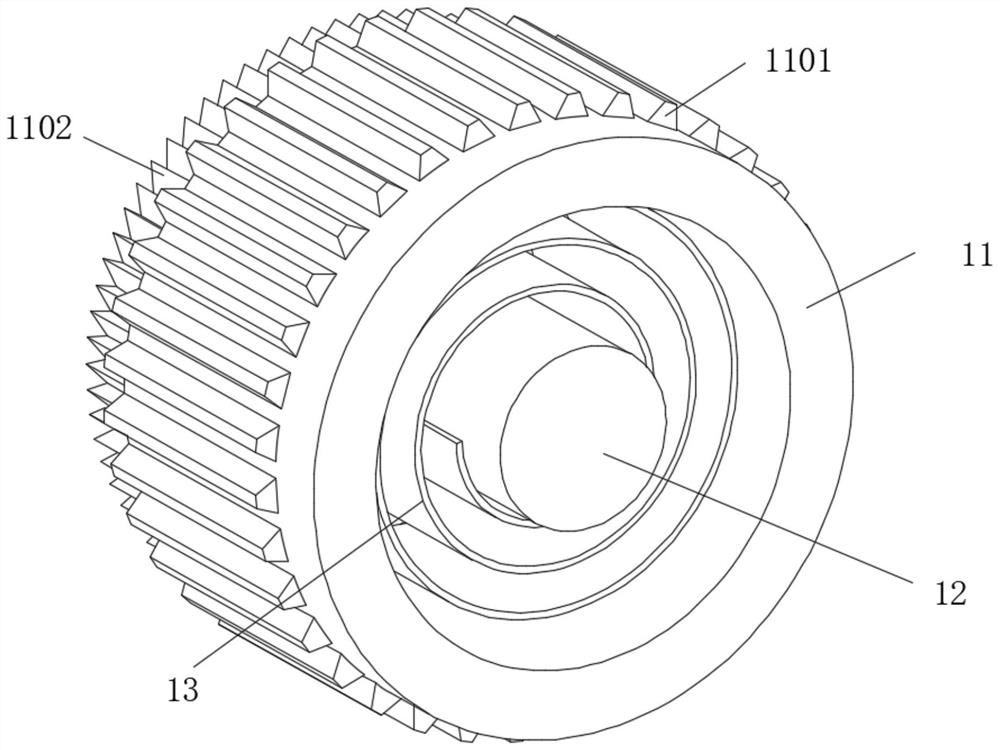

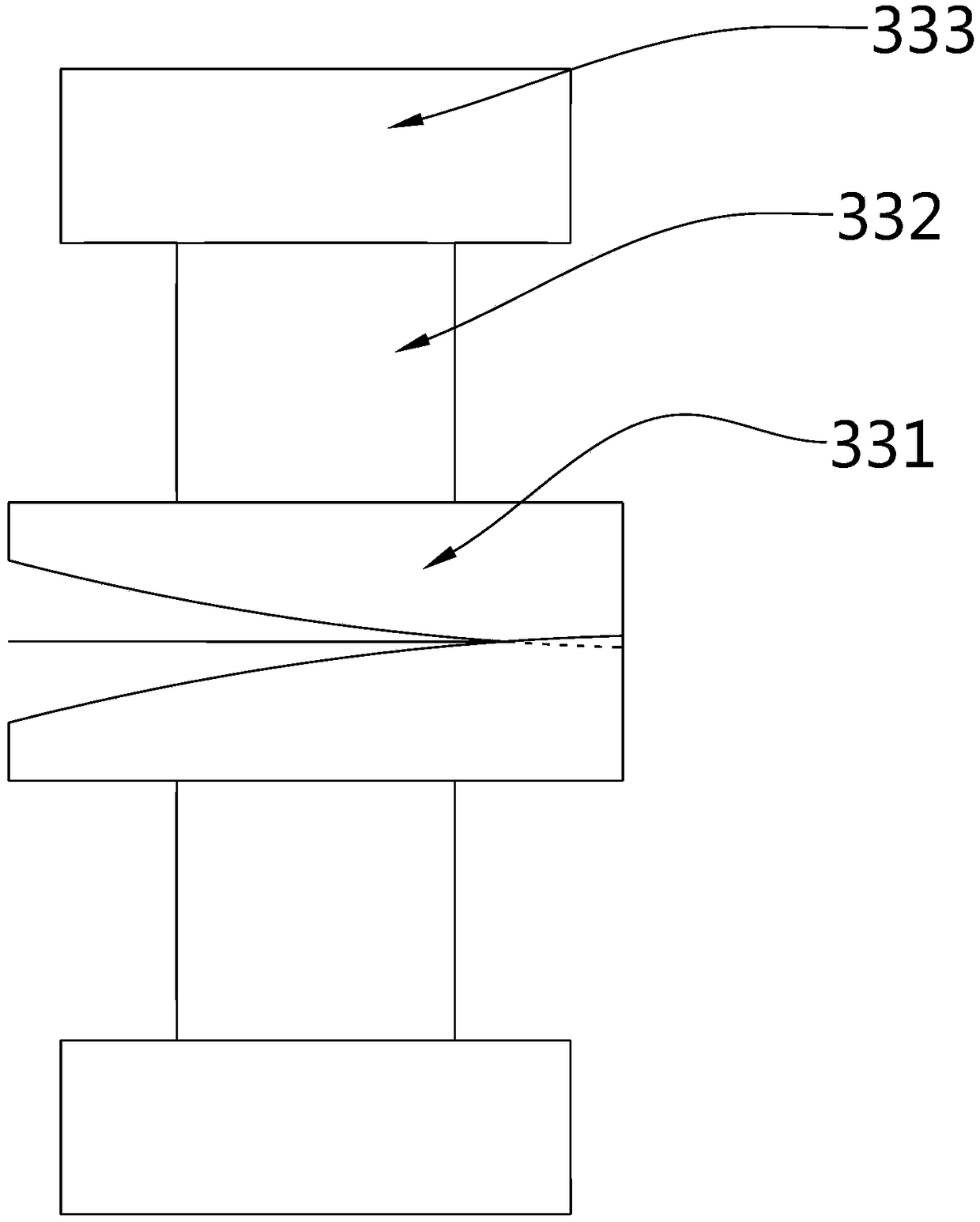

InactiveCN109961946ATo achieve tensionAchieve tension controlInductances/transformers/magnets manufactureCopper wireGear wheel

The invention discloses a tension-adjustable copper wire winding device for transformer production, which comprises a base. The upper surface of the base is fixedly connected with an installation plate. The middle of the installation plate is fixedly connected with a first bearing. The inner ring of the first bearing is fixedly connected with a rotating shaft. One end of the rotating shaft is fixedly connected with a driving taper gear. The surface of the installation plate is fixedly connected with bearing seats. The inside of each bearing seat is fixedly connected with a second bearing. Theinner ring of each second bearing is fixedly connected with a threaded rod. According to the tension-adjustable copper wire winding device for transformer production, a first tensioning wheel and a second tensioning wheel can be adjusted. An adjusting rod is rotated through a handle, the adjusting rod drives the rotating shaft to rotate, the rotating shaft is in threaded connection with a positioning block, the positioning block drives a telescopic pipe to slide up and down, and thus, the first tensioning wheel and the second tensioning wheel are driven to slide for adjustment. The problem that a common tensioning device for copper wires is inconvenient to adjust is solved.

Owner:JIANGSU GUANGTE ELECTRIC

Integrated transport tooling for large body parts of rail transit vehicles

ActiveCN105416882BFixed lengthTo achieve tensionPackaging vehiclesContainers for machinesEngineeringMaterial resources

The invention relates to an integrated transport tool for vehicle body large components of a rail transit vehicle. The integrated transport tool comprises a bearing base, a middle support frame, a top cover frame and a plurality of tension devices, wherein the bearing base, the middle support frame and the top cover frame are fixed together sequentially from bottom to top to form a bearing whole, at least two vehicle top large components or at least two sets of vehicle body side wall large components can be placed in the bearing whole, and one vehicle top large component corresponds to one set of vehicle body side wall large components; the length of the bearing whole is matched with the length of the vehicle top large components, and the width of the bearing whole is matched with the width of the vehicle top large components; the plurality of tension devices are symmetrically mounted on two sides of the bearing whole. The integrated transport tool can save the transport cost effectively, the structural design is reasonable, trivial connecting means are not needed, the tool can perform whole hoisting, conveying and storing after being fixed into a whole by the tension devices, is convenient and fast, and saves manpower and material resources for loading and unloading; besides, the integrated transport tool can be used for product storage, has diverse functions and adapts to various conditions well.

Owner:SHANDONG NOLLVETEC LIGHTWEIGHT EQUIP CO LTD

Belt tensioning device and belt conveyor applying same

The invention belongs to the technical field of metallurgical belt feeding, and discloses a belt tensioning device and a belt conveyor applying the same. The belt tensioning device comprises a fixing frame and an adjusting device fixed in the fixing frame, the adjusting device comprises a pair of fixed steering rollers fixed in the fixing frame, a tensioning roller located above the fixed steering rollers and a spiral tensioning rod assembly, one end of the spiral tensioning rod assembly is connected with the tensioning roller, and the other end of the spiral tensioning rod assembly is connected with the fixing frame. The adjusting device is connected to the upper belt face of a belt of the belt conveyor, and the upper belt face sequentially passes through the first fixed steering roller and the tensioning roller in the pair of fixed steering rollers and then moves out of the second fixed steering roller in the pair of fixed steering rollers. The spiral tensioning rod assembly is configured to be capable of adjusting the displacement amount of the tensioning roller so as to adjust the tightness amount of the belt. The belt tensioning device is simple in structure and convenient to operate, and is not limited by sites in the application process.

Owner:BERIS ENG & RES CORP +1

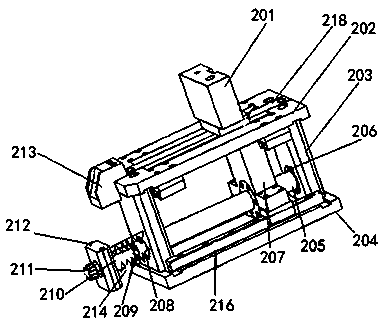

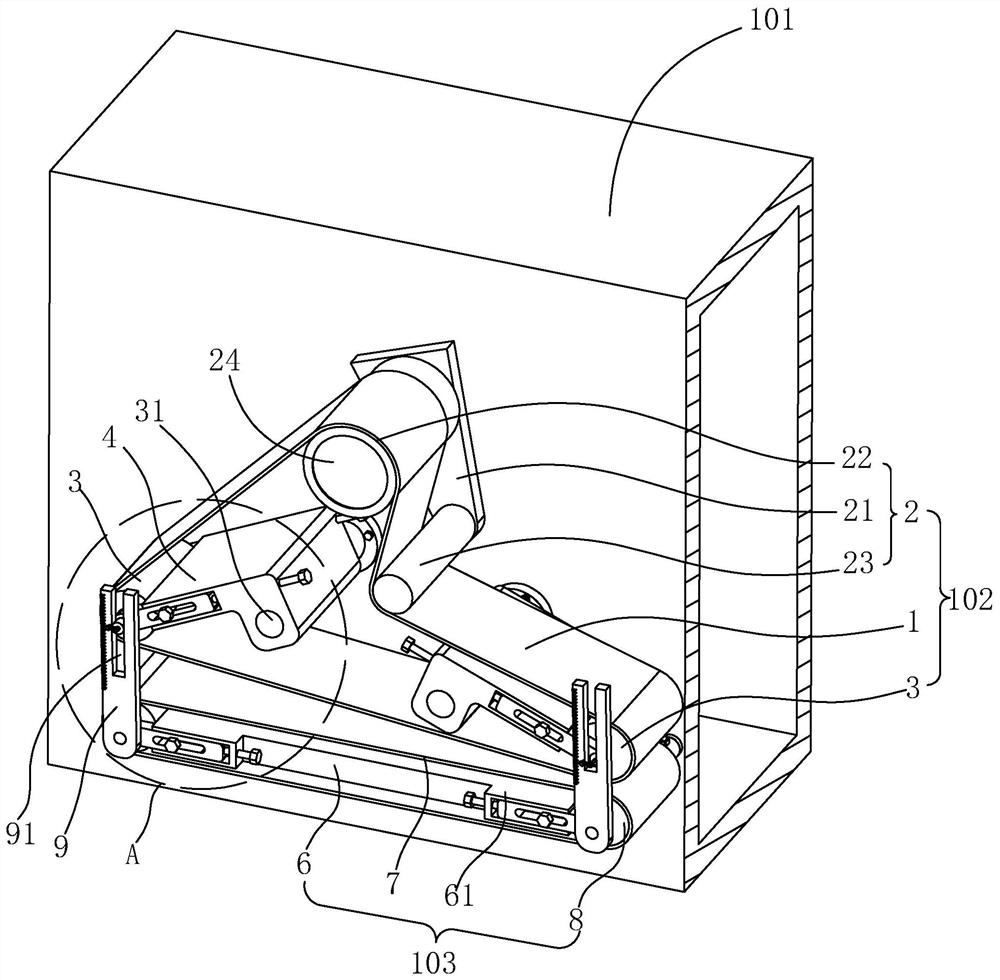

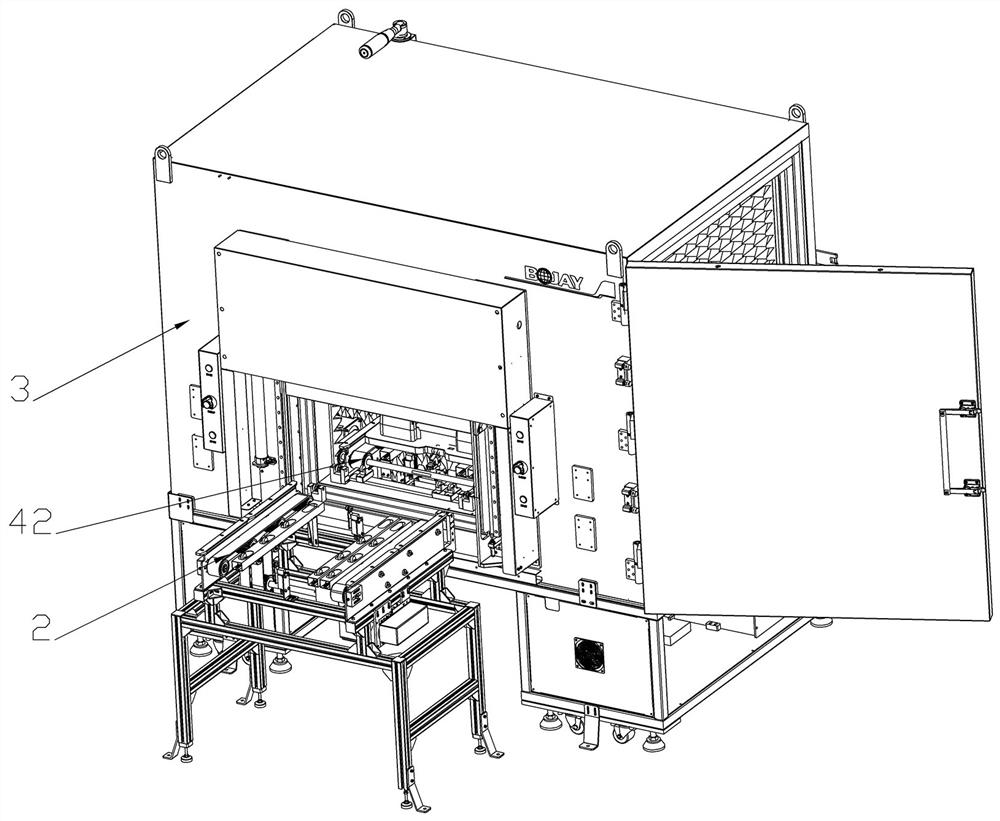

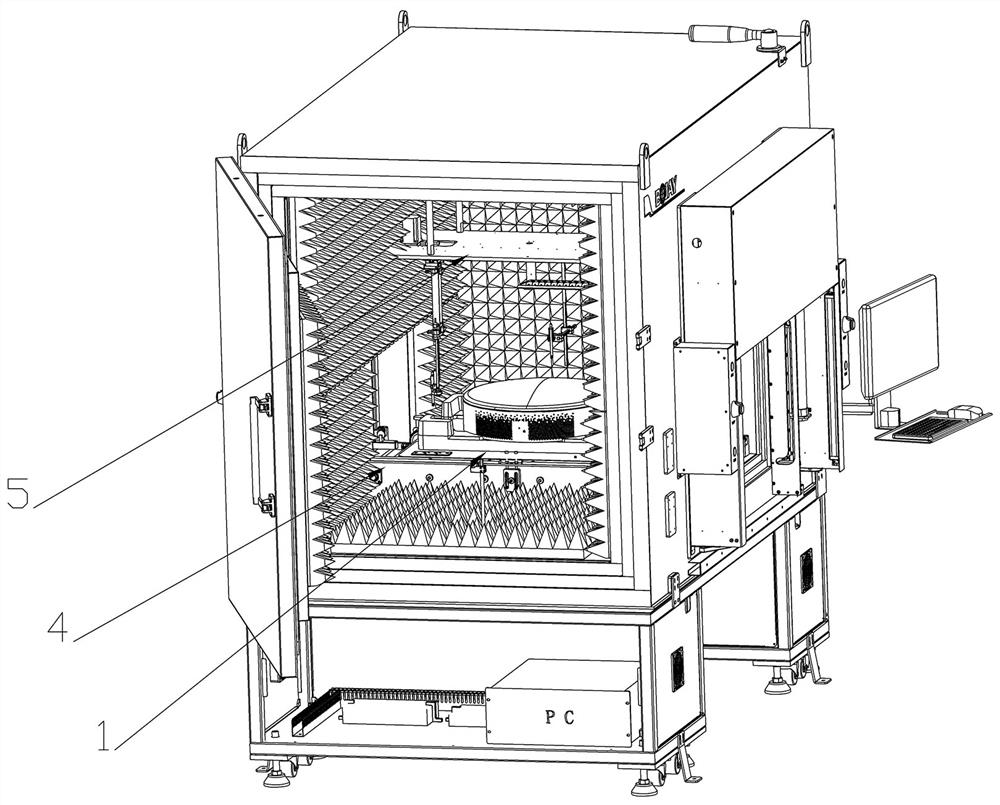

Audio automatic test equipment

PendingCN114062829ATo achieve tensionQuick Orientation TestSubsonic/sonic/ultrasonic wave measurementElectrical testingAutomatic test equipmentEngineering

The invention discloses automatic audio testing equipment, and aims to provide automatic audio testing equipment which is high in automation degree, good in sound insulation effect and capable of reducing labor cost. The equipment comprises a test box, a product carrier and a transfer mechanism, the transfer mechanism is arranged on the periphery of the test box, the product carrier is provided with a mounting groove matched with a product, the test box comprises a sound insulation box body, a positioning assembly and a test assembly, the positioning assembly is arranged in the sound insulation box body and is matched with the transferring mechanism, the testing assembly is connected with the inner wall of the sound insulation box body, the transferring mechanism drives a product carrier to flow into the positioning assembly, and after the testing assembly tests a product, the positioning assembly is matched with the transferring mechanism to enable the products to flow out of the sound insulation box body. The equipment is applied to the technical field of audio testing of electronic products.

Owner:ZHUHAI BOJAY ELECTRONICS

Thread cutting machine for processing wear-resistant socks

InactiveCN110359193AReached teleportationTo achieve tensionNeedle severing devicesSewing-machine control devicesSOCKSWear resistant

The invention relates to a thread cutting machine for processing wear-resistant socks. The thread cutting machine comprises a machine shell and a cutter component, a thread feeding hole is formed in the side wal of the machine shell, one end, away from the thread feeding hole, in the machine shell is rotatably connected with two tensioning wheels, the cutter component is positioned in the middle between the thread feeding hole and the tensioning wheels, and the cutter component is fixedly connected with the machine shell; transmission teeth are arranged on each tensioning wheel, the transmission teeth on the tensioning wheels are in meshed arrangement, and a driving motor for driving the tensioning wheels is arranged on the machine shell. By arranging the tensioning wheels, sewing threadsin the thread cutting machine can be tensioned, and elasticity of the sewing threads can be lowered, so that thread cutting effect is ensured; the thread cutting machine has the advantages of simple structure, convenience for operation and high practicability.

Owner:湖南莎丽袜业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com