Self-cleaning device of belt type sludge dewatering machine

A technology of sludge dewatering machine and dewatering device, applied in water/sludge/sewage treatment, sludge treatment, water/sewage treatment, etc., can solve the problems of large water consumption, increased production cost, unfavorable energy saving and emission reduction, etc. Achieve the effect of improving work efficiency, improving compactness and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

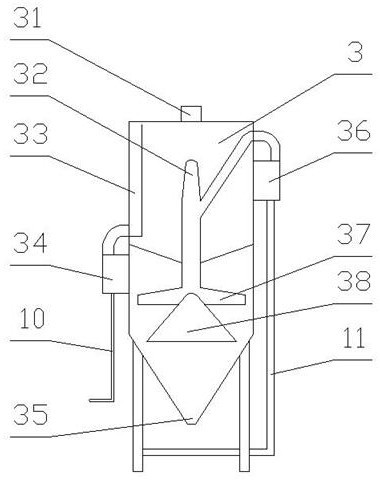

[0024] Embodiment 1, as shown in the figure: a self-cleaning device of a belt-type sludge dewatering machine, including a housing 1, the housing 1 is provided with an upper dehydration device 13 and a lower dehydration device 5, and the lower dehydration device 5 is provided. One end of the dehydration device 5 is provided with a feed plate 4, and the other end of the lower dehydration device 5 is provided with a discharge plate 12, and both sides of the feed plate 4 and the discharge plate 12 are fixed on the housing 1 Above, the upper dehydration device 13 and the lower dehydration device 5 are covered with a filter cloth 17 , and one side of the housing 1 is provided with a water filtration device 3 . The upper dehydration device 13 includes a first upper guide roller 131 , a second upper guide roller 132 , a third upper guide roller 133 , a stretching dehydration device 14 and an upper cleaning device 2 . The lower dehydration device 5 includes a first lower guide roller 5...

Embodiment 2

[0025] Embodiment 2, a self-cleaning device of a belt sludge dewatering machine, the upper dehydration device 13 and the lower dehydration device 5 are covered with a filter cloth 17 and squeezed together by the closing roller 16, and the filter cloth 17 is squeezed After being pressed together, they enter the tensioning and dehydrating device 14 through the driving wheel 15. The said tensioning and dehydrating device 14 includes a tensioning pallet 142, and the said tensioning pallet 142 includes a rising tensioning pallet 142 and a lower tensioning pallet. plate 142, two groups of tensioning groups are provided on the rising tensioning supporting plate 142, and three tensioning groups are provided on the lower tensioning supporting plate 142, and the tensioning groups include tensioning rods 145. One end of the tensioning rod 145 is provided with a tensioning plug 143, and the other end of the tensioning rod 145 is connected with the tensioning wheel 146 through a pin shaft, ...

Embodiment 3

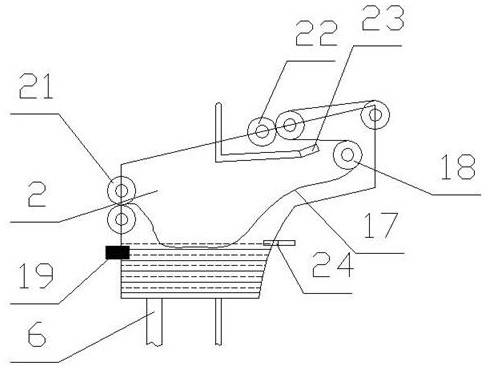

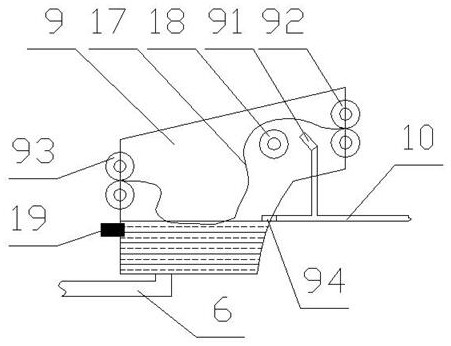

[0026] Embodiment 3, a self-cleaning device of a belt sludge dewatering machine, the upper cleaning device 2 includes a first upper squeeze roller 21 and a second upper squeeze roller 22, and the second upper squeeze roller 22 is provided with a first upper nozzle 23 below the first upper nozzle 23, and a cleaning roller 18 is arranged below the first upper nozzle 23. The inner wall of the upper cleaning device 2 is provided with a second upper nozzle 24, and the second A water level gauge 19 is provided on the inner wall of the upper cleaning device 2 corresponding to the upper spray head 24 , and the first upper spray head 23 and the second upper spray head 24 are connected to the water filter device 3 through the water spray line 10 . The lower cleaning device 9 includes a first lower squeeze roller 93 and a second lower squeeze roller 92, one side of the second lower squeeze roller 92 is provided with a cleaning roller 18, and the cleaning roller 18 is set in the lower cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com