Audio automatic test equipment

An automatic test equipment and audio technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as increasing labor costs, reducing the degree of automation of production lines, and product deviations, reducing labor costs and facilitating daily routines. The effect of maintenance and use, improving the efficiency of the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

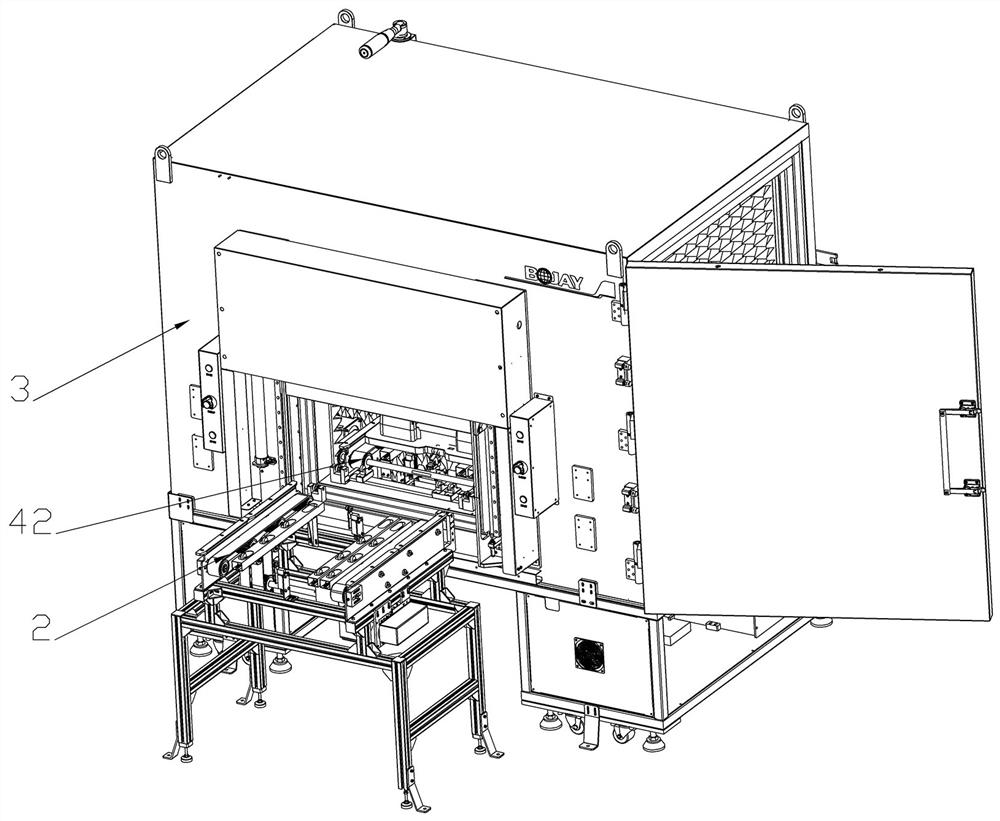

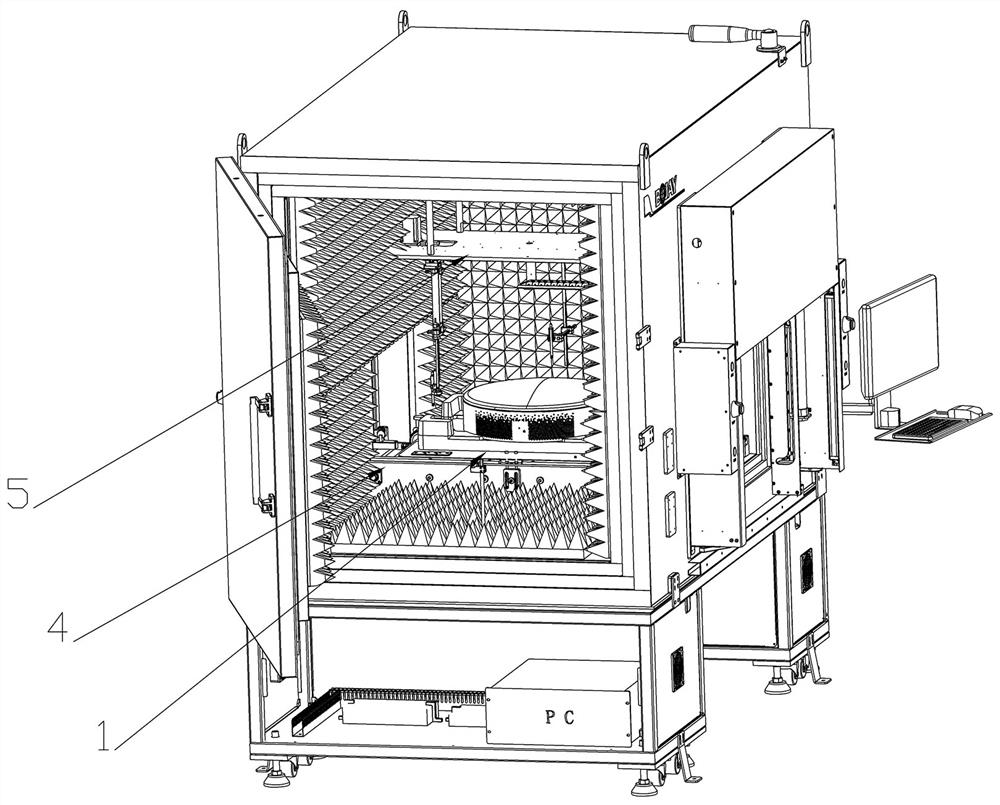

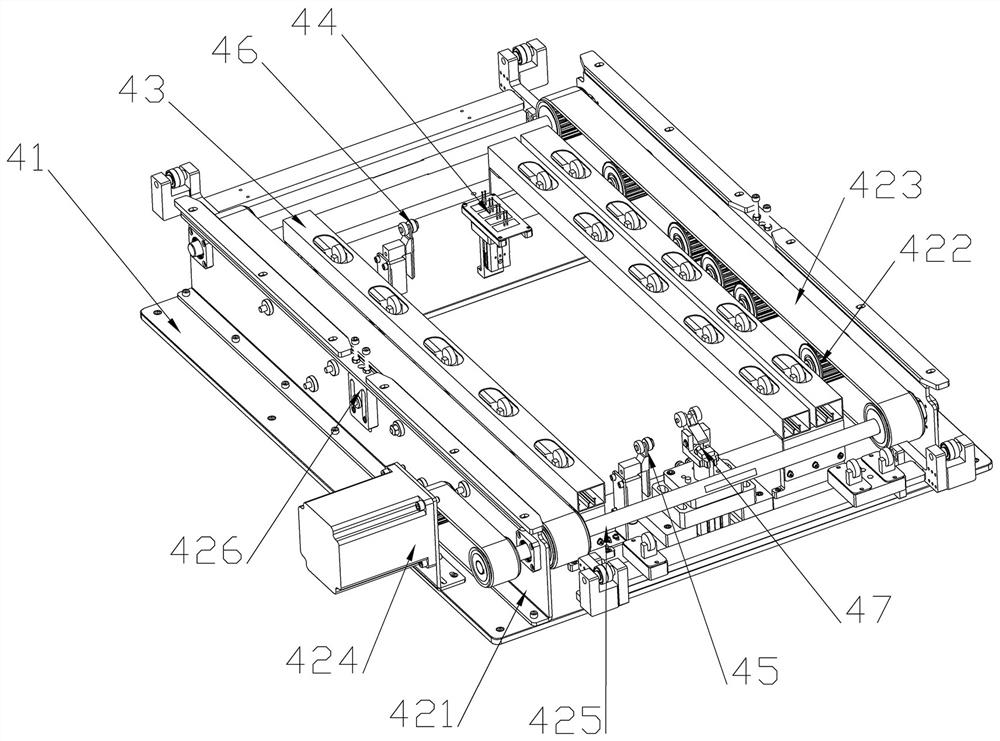

[0021] Such as Figure 1 to Figure 6 As shown, in this embodiment, the present invention includes a test box, a product carrier 1 and a transfer mechanism 2, the transfer mechanism 2 is arranged around the test box, and the product carrier 1 is provided with a Adapted installation slot, the test box includes a soundproof box body 3, a positioning component 4 and a test component 5, the positioning component 4 is arranged in the soundproof box body 3 and cooperates with the transfer mechanism 2, so The test assembly 5 is connected to the inner wall of the soundproof box 3, and the transfer mechanism 2 drives the product carrier 1 to flow into the positioning assembly 4. After the test assembly 5 tests the product, the positioning assembly 4 Cooperate with the transfer mechanism 2 to let the product flow out from the soundproof box body 3, the transfer mechanism 2 at the inflow end is provided with a buffer cylinder and a limit sensor, and the test box is also provided with a ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com