Patents

Literature

145results about How to "Improve production line efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

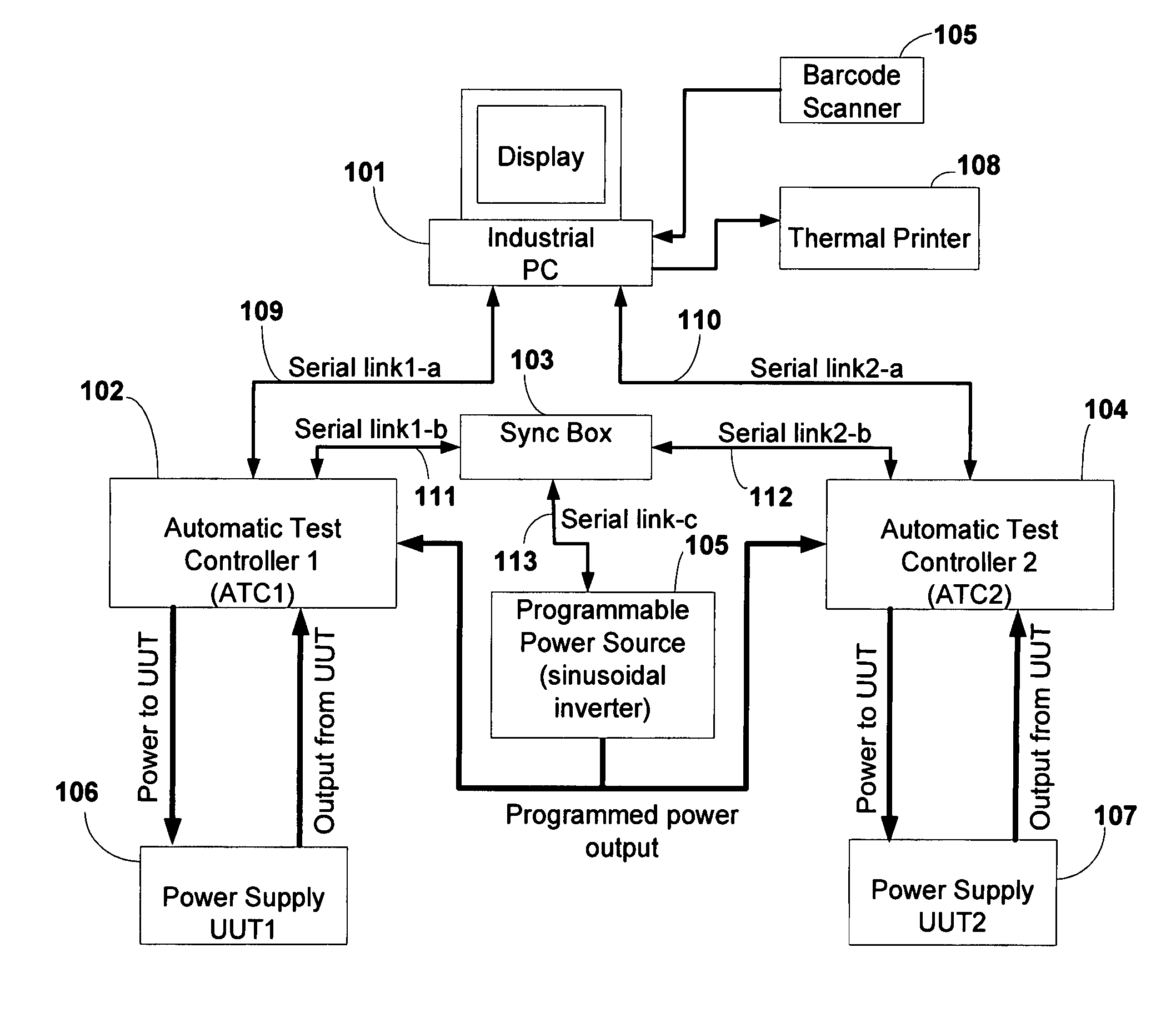

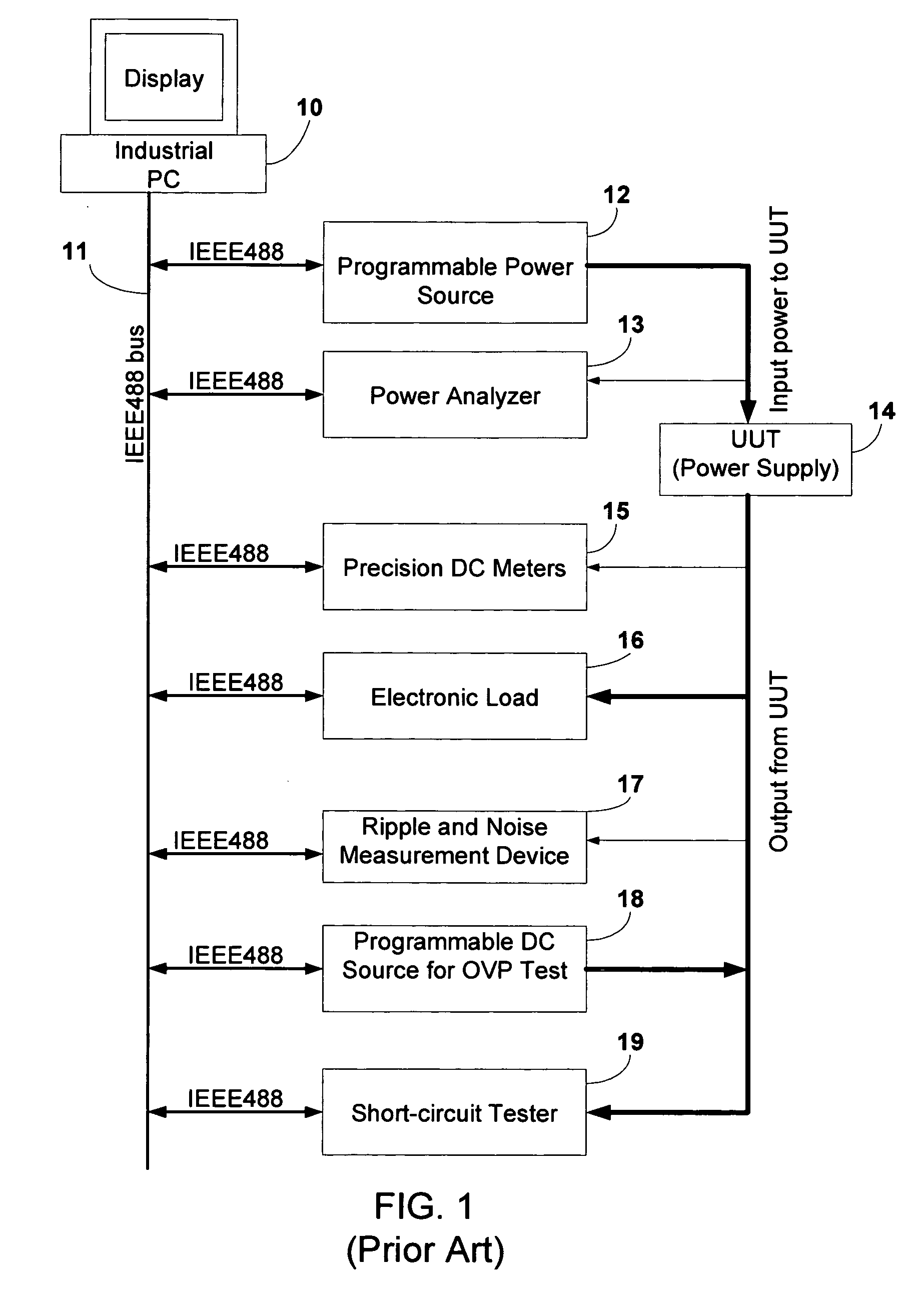

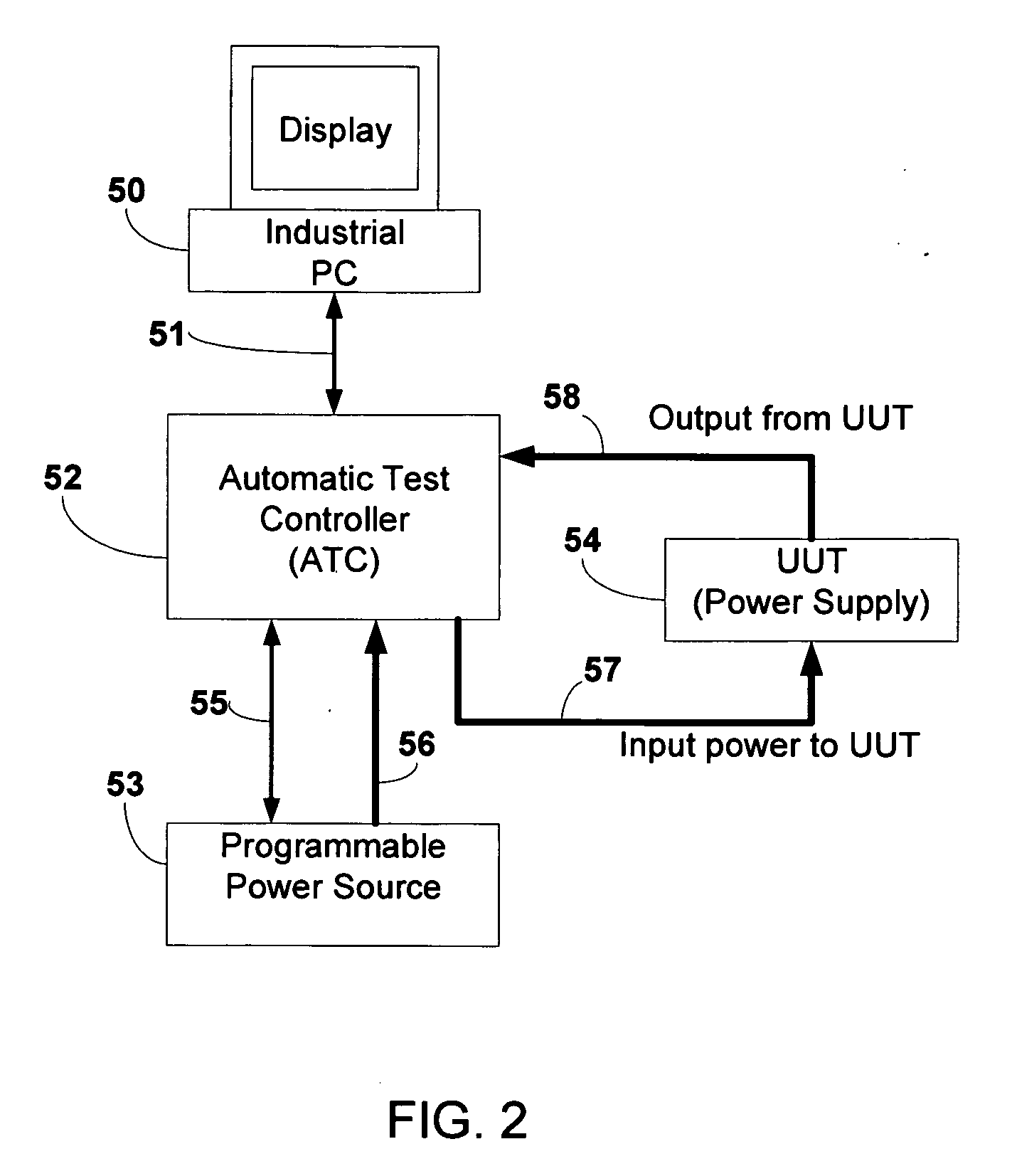

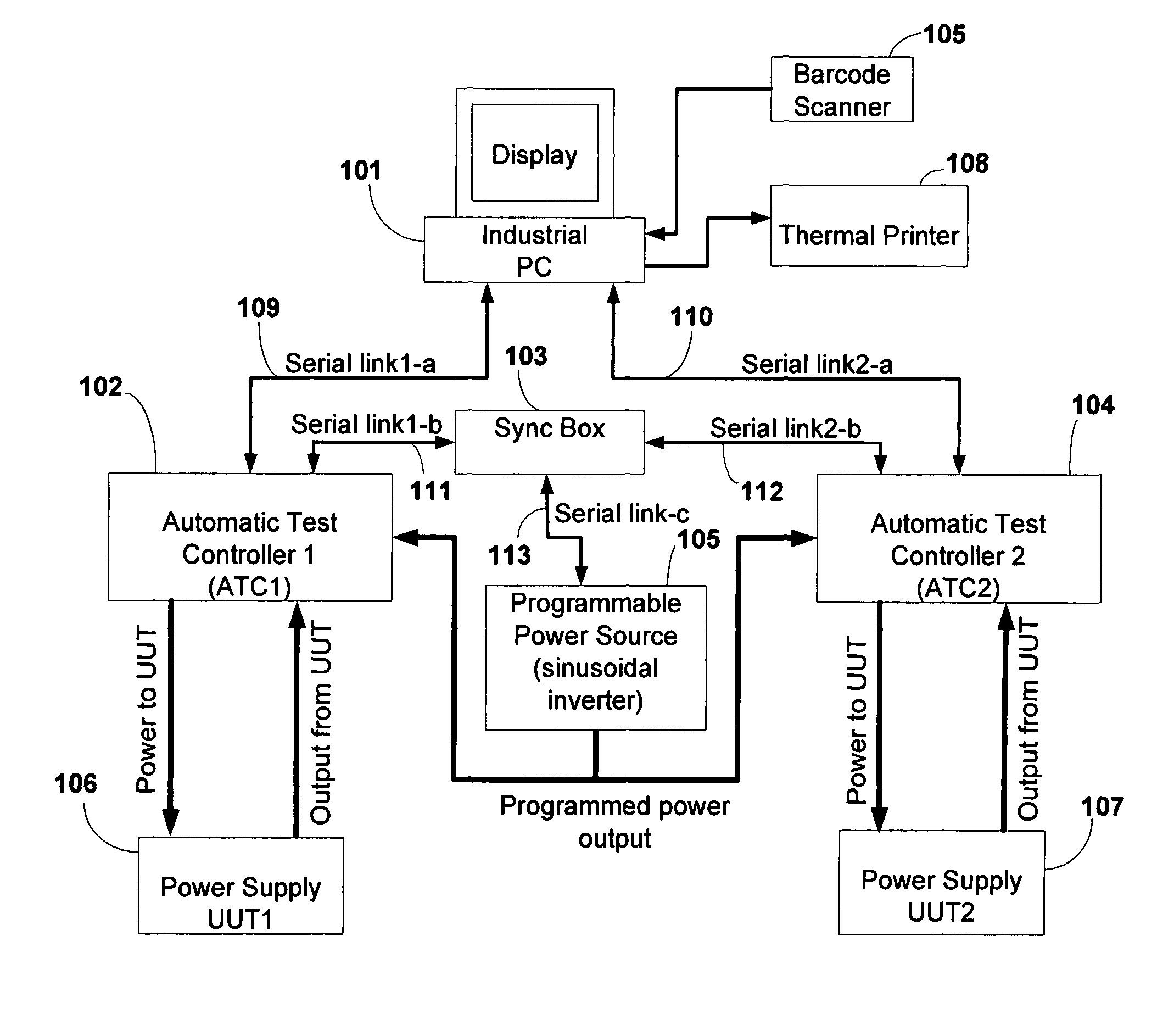

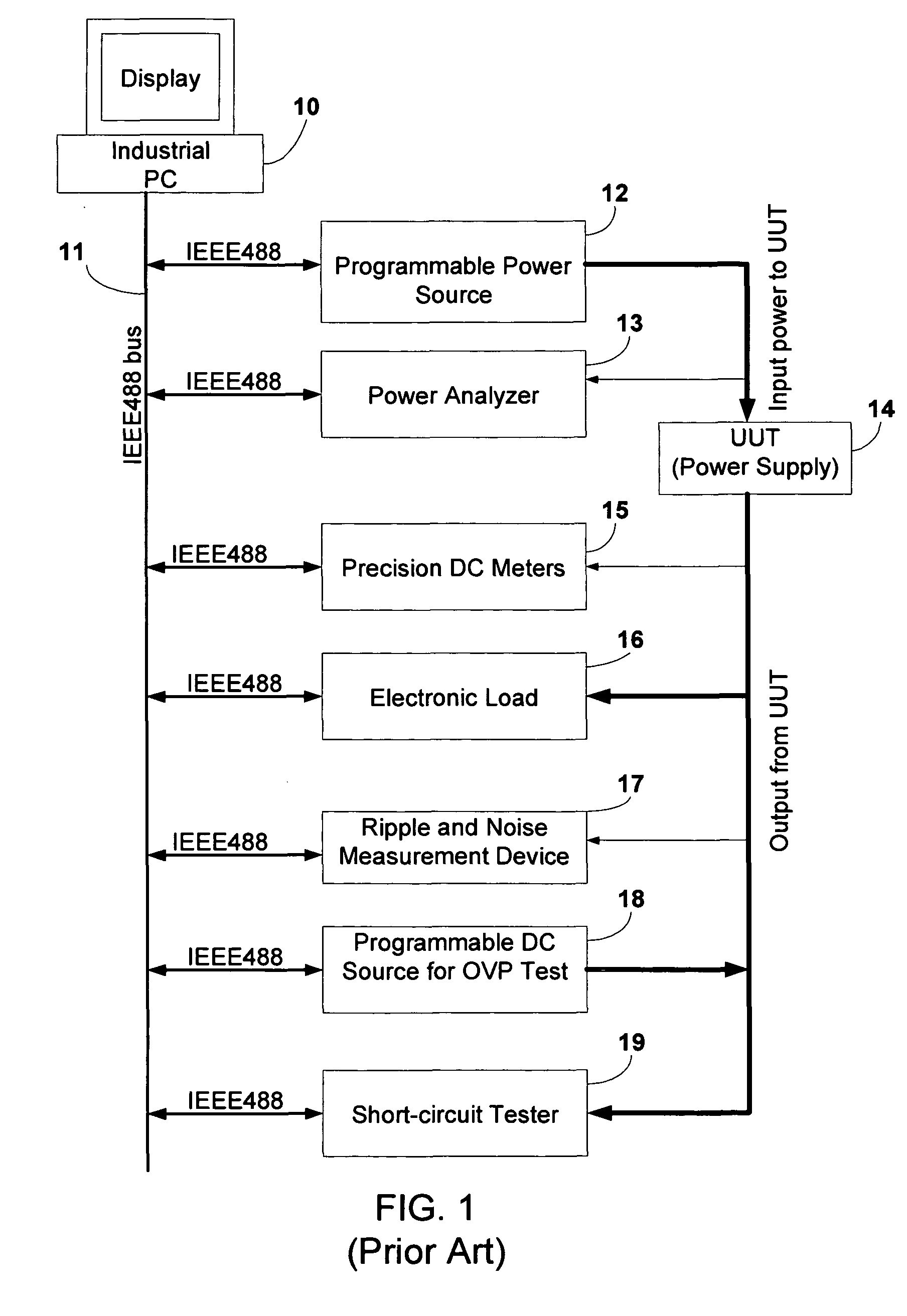

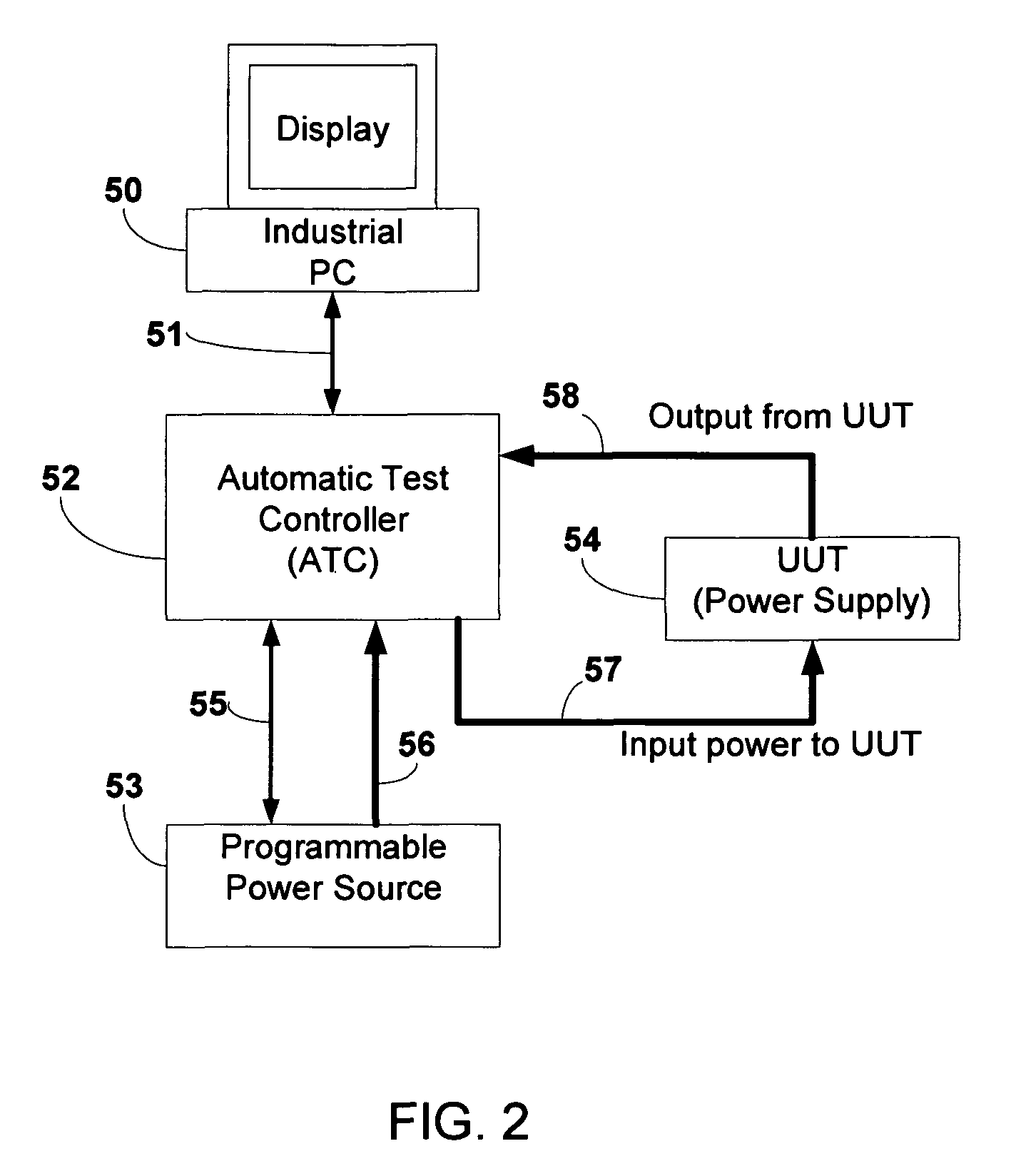

System architecture and apparatus for programmable automatic power supply testing

InactiveUS20100225466A1Low costReduce equipment costsElectric devicesResistance/reactance/impedenceAutomatic test equipmentSystem testing

A cost-effective system architecture and apparatus for programmable automatic power supply testing. The system utilizes board level interface between various system testing modules and an Automatic Test Controller (ATC). The ATC receives coded test requests from the software on an industrial PC and control the various testing modules inside ATC to execute the tests. Test results were sent back to the PC and saved in a result file. A single industrial PC can control two or more ATC's and test two or more power supply units simultaneously. The ATC based test system is lower cost than the conventional Automatic Test Equipment which uses device level interface and standardized test devices.

Owner:SYNERGISTIC TECH SOLUTIONS

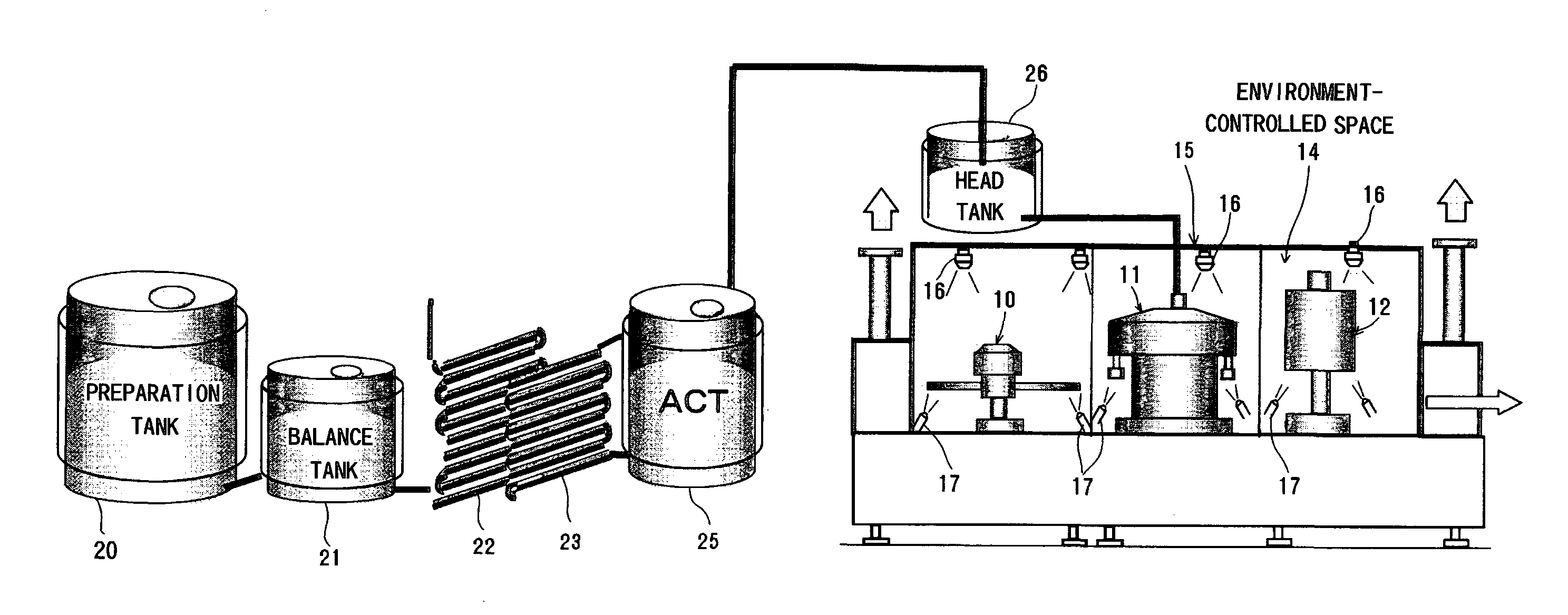

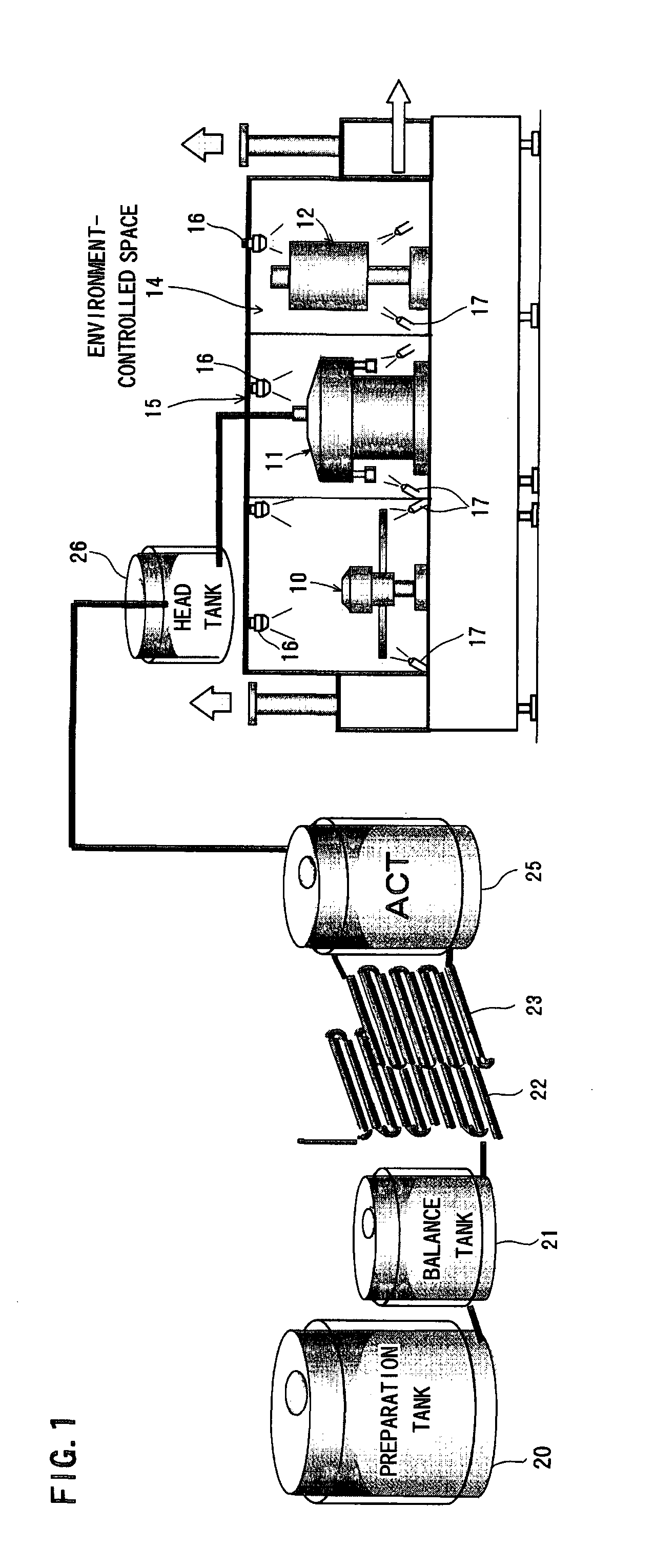

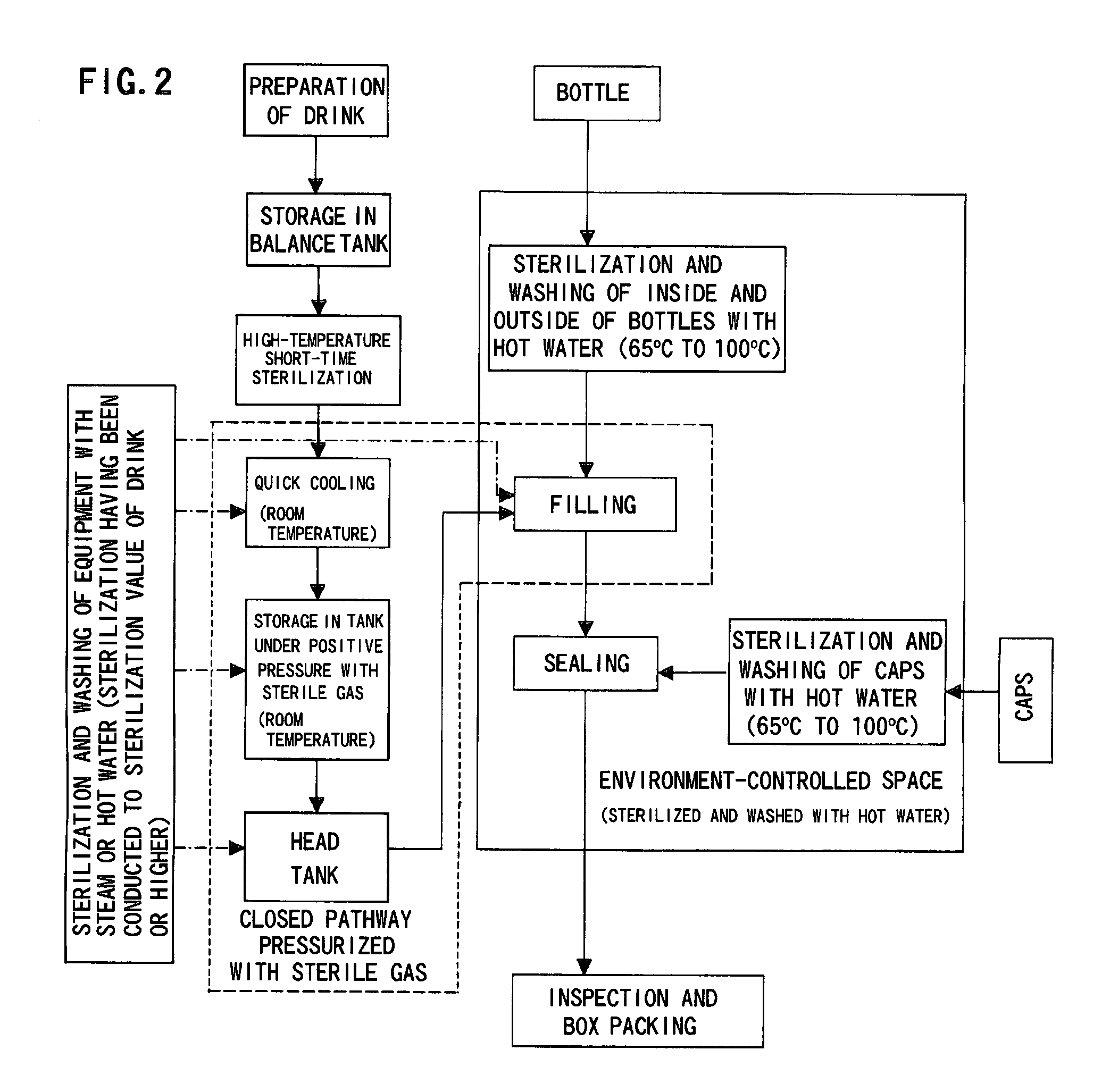

Method for producing packaged drink

InactiveUS20090320415A1Simple equipmentImprove efficiencyPackage sterilisationSolid materialPositive pressureSterile water

It is intended to provide a process for producing a packaged drink whereby filling can be performed at room temperature without resorting to using a chemical or sterile water, the favorable taste and flavor of the content can be maintained while relieving the thermal degradation thereof, it becomes unnecessary to employ a heat-resistant container or to thermally sterilize or cool after sealing, and thus both of the equipment cost and the running cost can be largely reduced. After thermally sterilizing the content to give a definite sterilization value, it is quickly cooled to room temperature and then stored in a storage tank that has been preliminarily sterilized under such conditions as being equal to or exceeding the thermal sterilization conditions for the contents. While maintaining the storage tank under positive pressure with the use of a sterile gas, the content is fed into a filling machine that has been preliminarily sterilized under such conditions as being equal to or exceeding the thermal sterilization conditions for the contents. Thus, the liquid-feeding system ranging from the storage tank to the filling machine is made a closed liquid-feeding pathway free from the invasion of air from the outside. The drink is filled into a container having been sterilized with hot water in an environment-controlled space isolated from the outside wherein the surroundings have been thermally sterilized and washed with hot water at 65° C. to 100° C.

Owner:TOYO SEIKAN KAISHA LTD

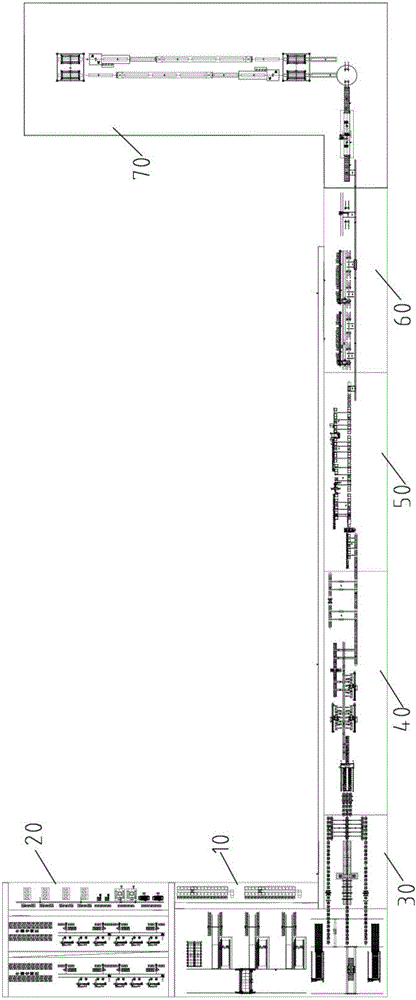

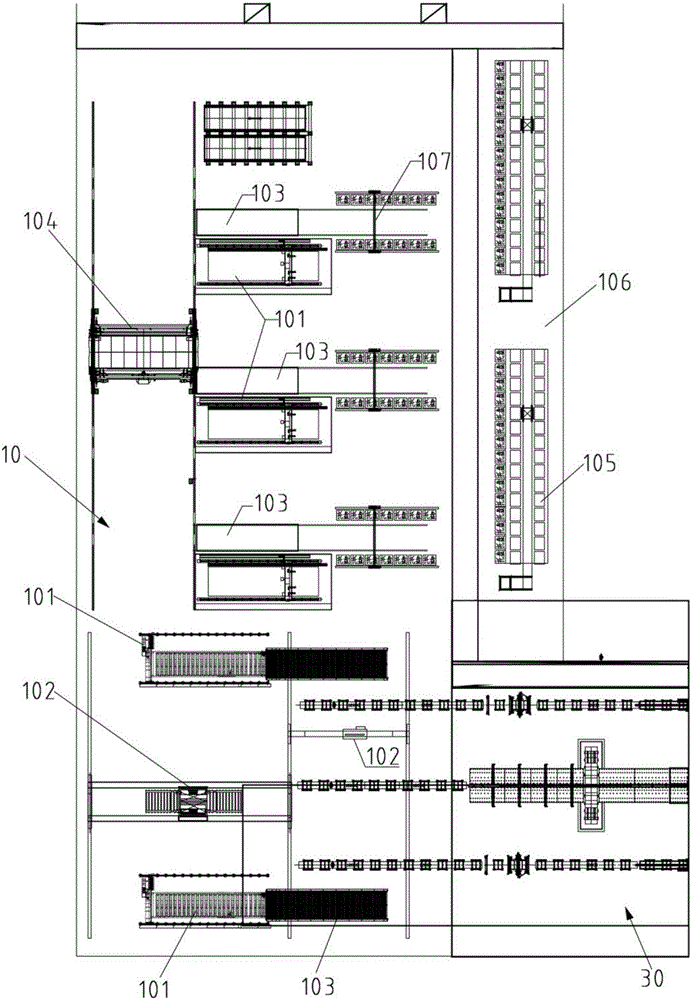

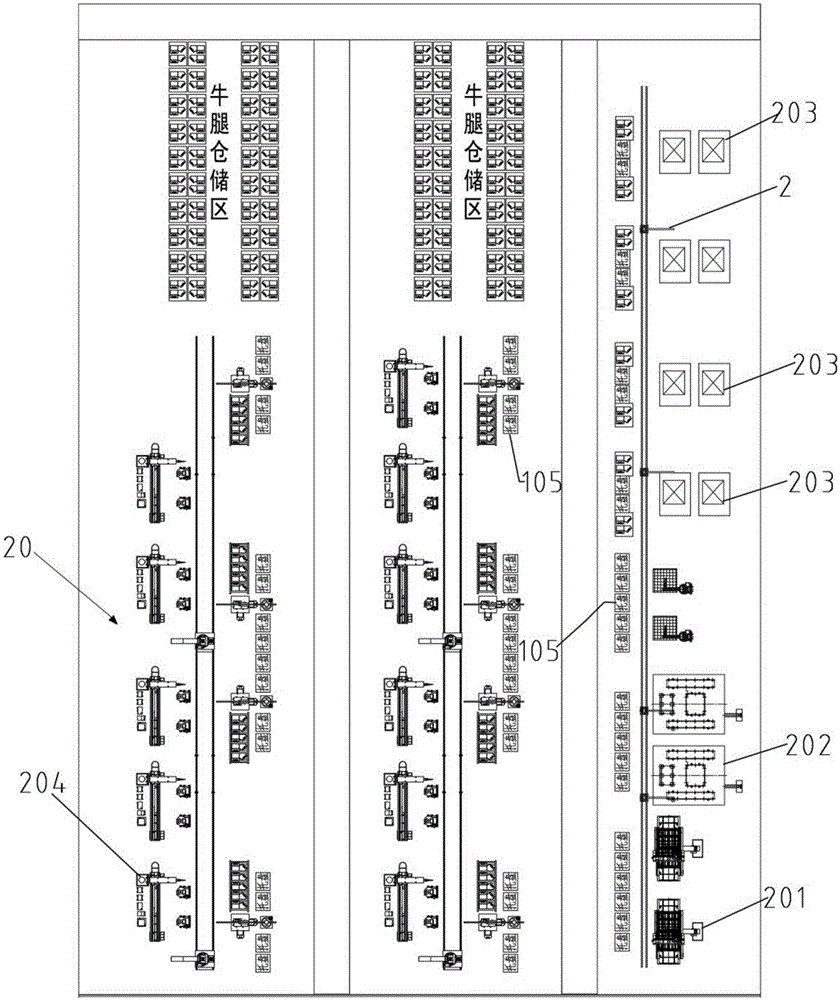

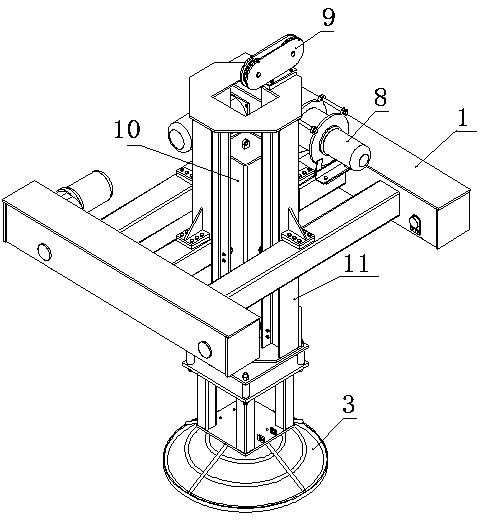

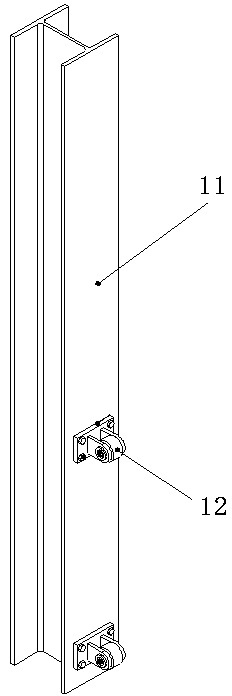

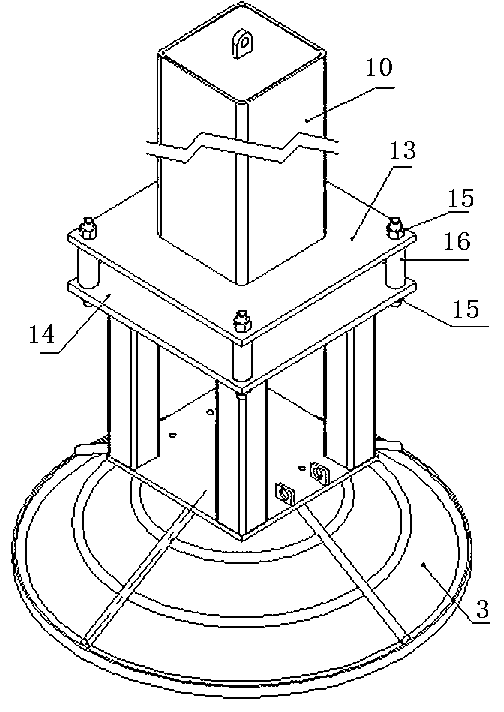

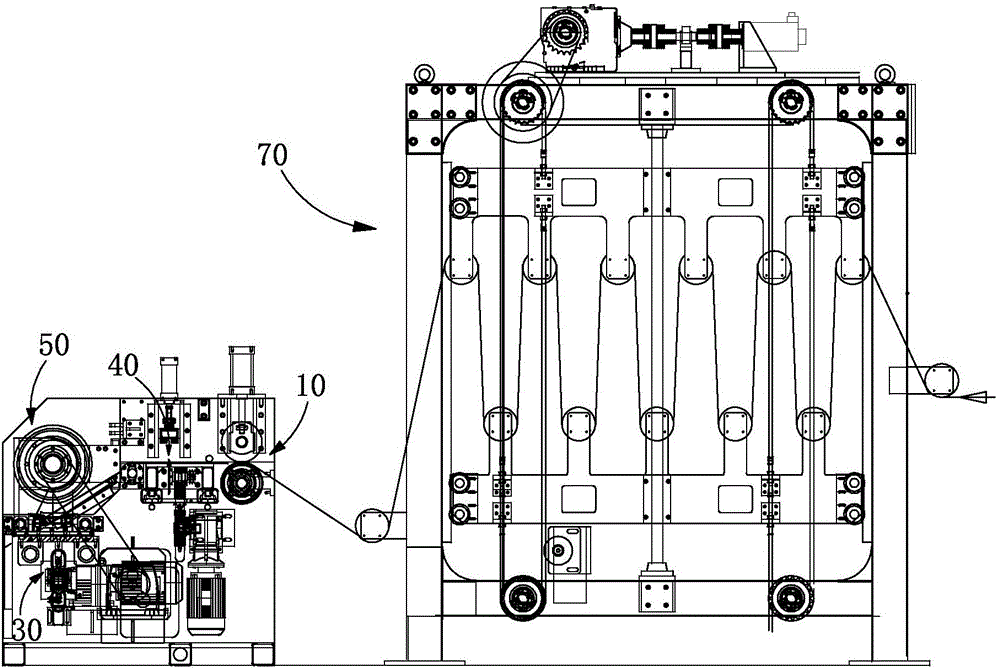

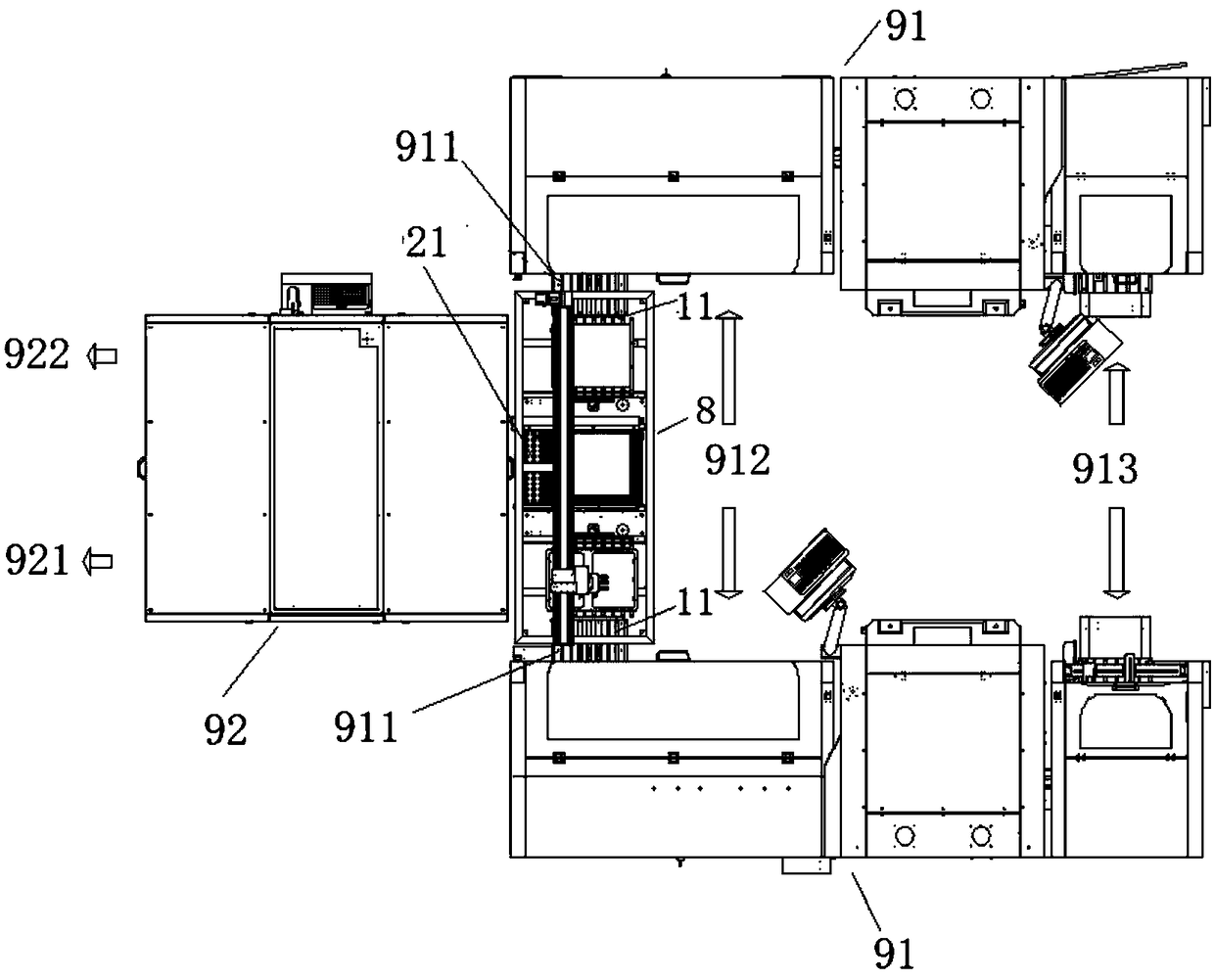

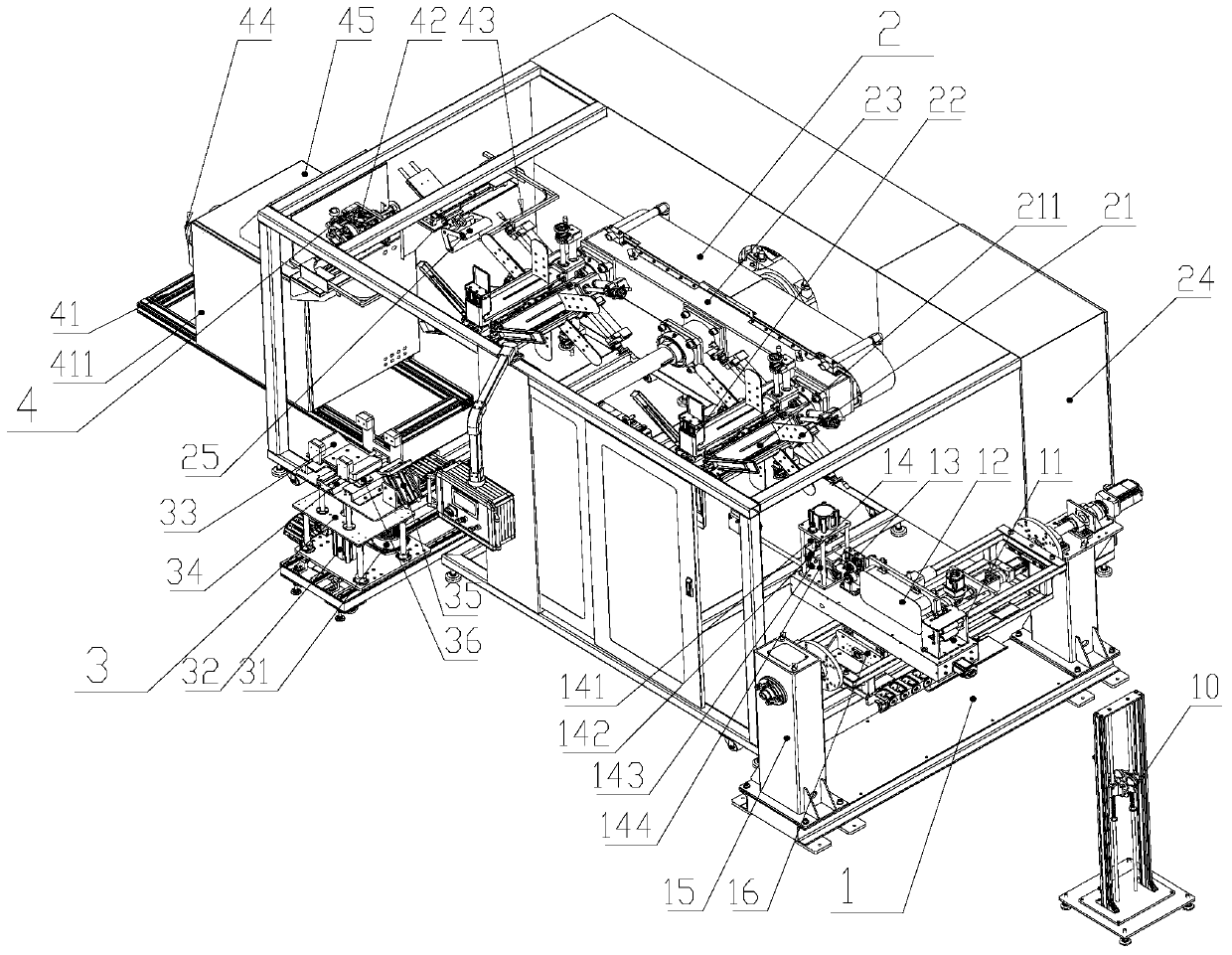

Intelligent production line for H-shaped steel workpieces

ActiveCN106334944AHigh speedAutomate storageOther manufacturing equipments/toolsTotal factory controlProduction lineManufacturing execution system

The invention belongs to the technical field of production equipment for steel workpieces, and provides an intelligent production line for H-shaped steel workpieces. The intelligent production line comprises a manufacturing execution system, an automatic conveying system, a transfer robot, an intelligent discharging center, a part machining center, an automatic milling and grinding center, a horizontal assembly welding center, a drill saw locking center and a robot assembly welding center. The manufacturing execution system is used for production scheduling, storing a machining technological requirement database and sending machining information to the machining centers. Information of the machining centers interacts in real time, and thus the machining quality condition of the prior procedure is transmitted to the next procedure in real time. According to the intelligent production line for H-shaped steel workpieces, a flow line production mode is adopted, so that the production efficiency is improved. An unmanned logistics and storage way is adopted for parts, automatic storage of non-standard parts is achieved, and the part logistics speed is increased. An H-shaped steel horizontal machining technique is adopted, two flanges are completed at the same time in the assembling process, two weld joints are welded at the same time in the welding process, and thus the machining efficiency is improved.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD

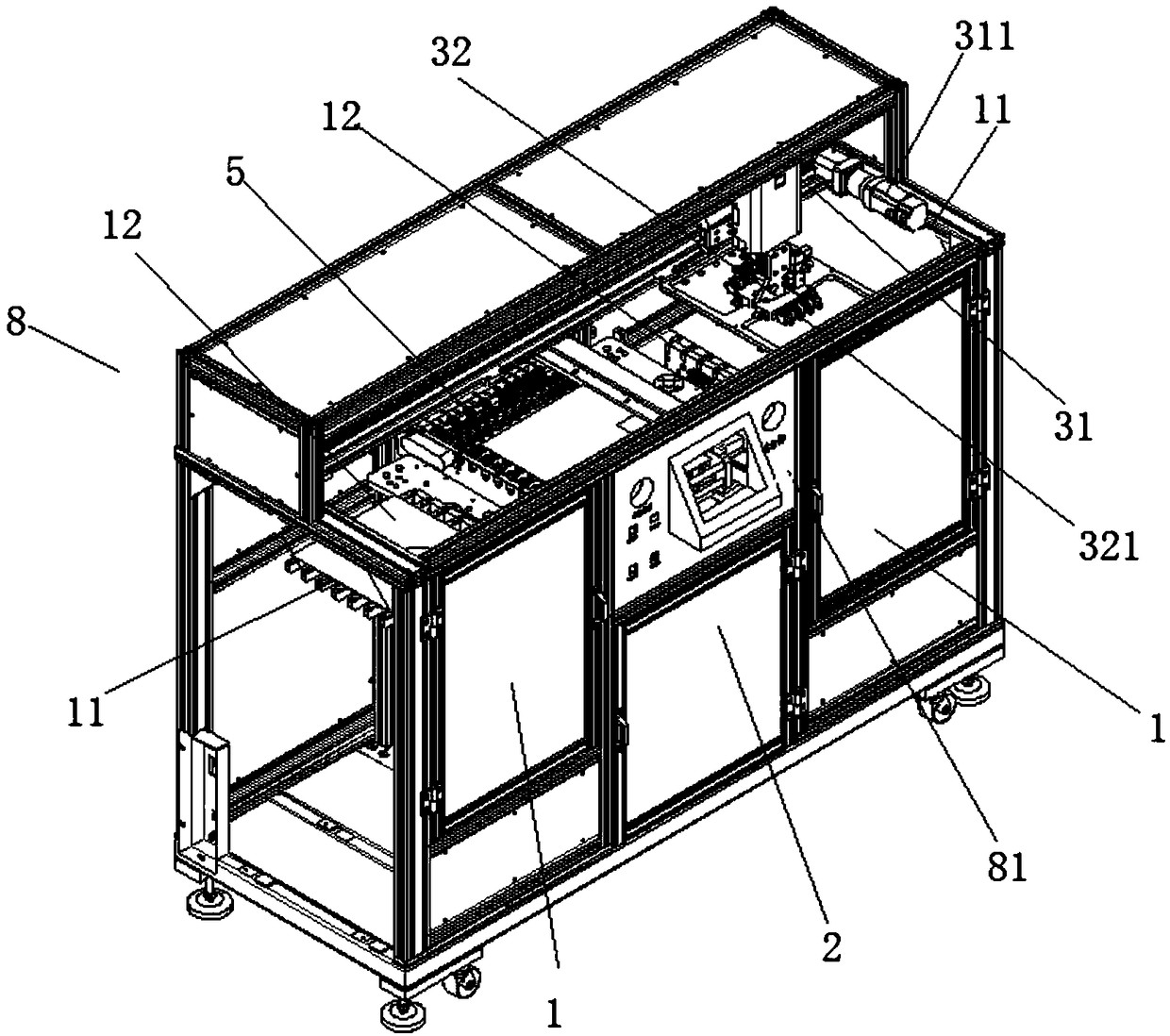

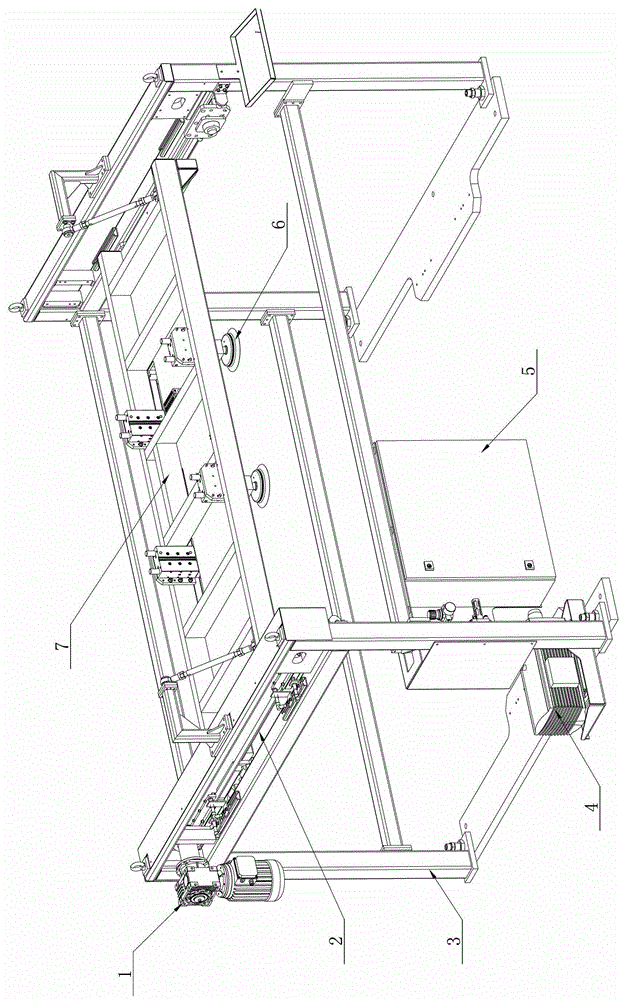

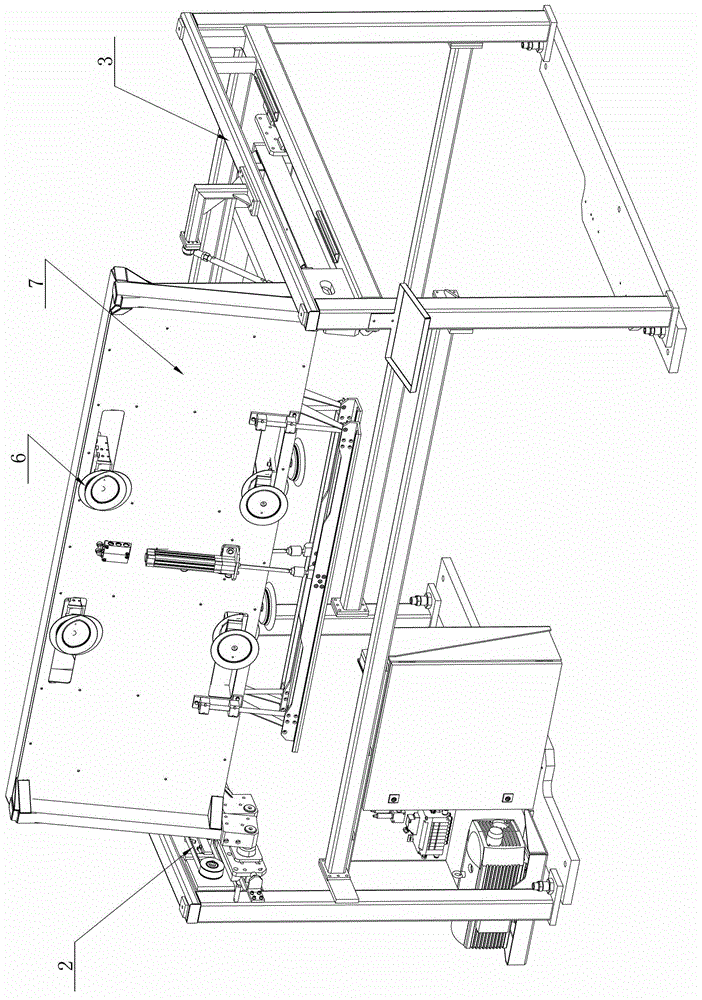

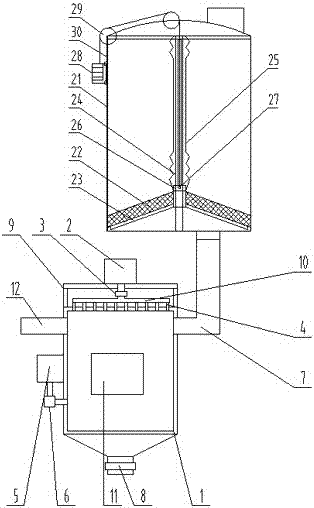

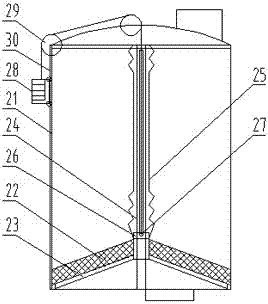

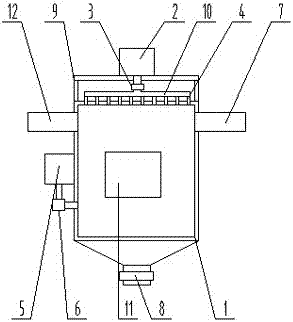

Trowelling machine

ActiveCN103182733AImprove production line efficiencyImprove surface qualityCeramic shaping apparatusNeedle roller bearingProduction line

The invention provides a trowelling machine comprising a transition carriage, a walking mechanism, a cutter head assembly, an electric control cabinet, a rail and an operation platform, wherein the rail is fixedly mounted on a ground; the walking mechanism is in a bridge type structure; the bottoms of two side arm frames of the bridge type structure are provided with walking mechanism double-flange walking wheels to walk in a vertical direction of the rail; an upper transverse beam of the bridge type structure is provided with a transverse beam rail; the bottom of a frame of the transition carriage is provided with transition carriage double-flange walking wheels to transversely move on the transverse beam rail; the cutter head assembly comprises a lifting device, a guide device and a trowelling plate; the lifting device is connected with the trowelling plate through an electric lifting machine; the guide device is in guide connection with a cutter head vertical column by respectively mounting two needle bearings at inner sides of four guide frame stand columns; and the electric control cabinet and the operation platform are mounted on the walking mechanism. According to the trowelling machine disclosed by the invention, the efficiency of a production line and the surface quantity of a cement board are greatly improved, the manpower is saved, the cost is reduced and the performance is good.

Owner:XIANGTAN YUANDA RESIDENTIAL IND CO LTD

System and method for programmable automatic testing of power supplied

InactiveUS8589110B2Low costReduce equipment costsElectric devicesResistance/reactance/impedenceAutomatic test equipmentSystem testing

Owner:SYNERGISTIC TECH SOLUTIONS

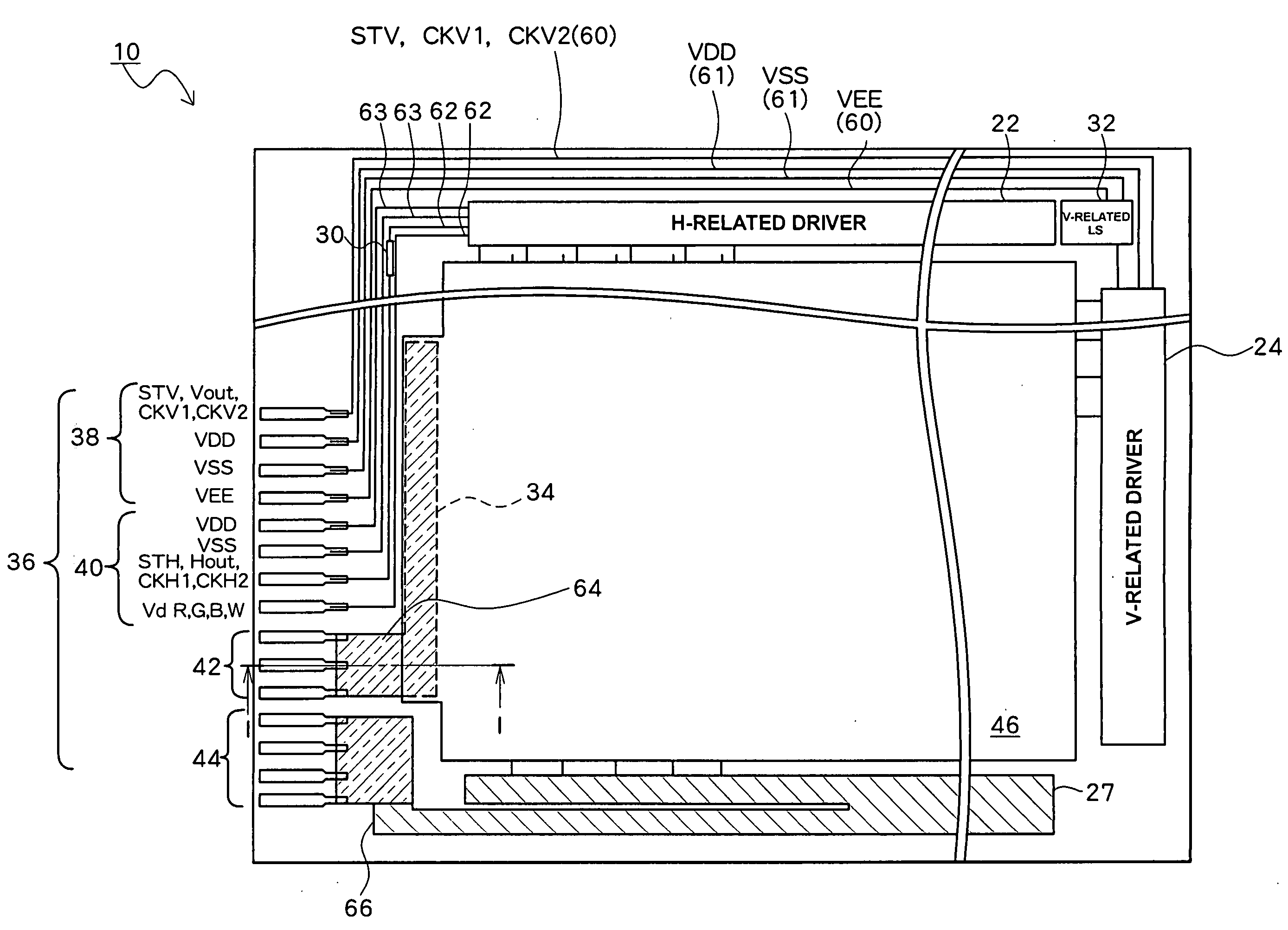

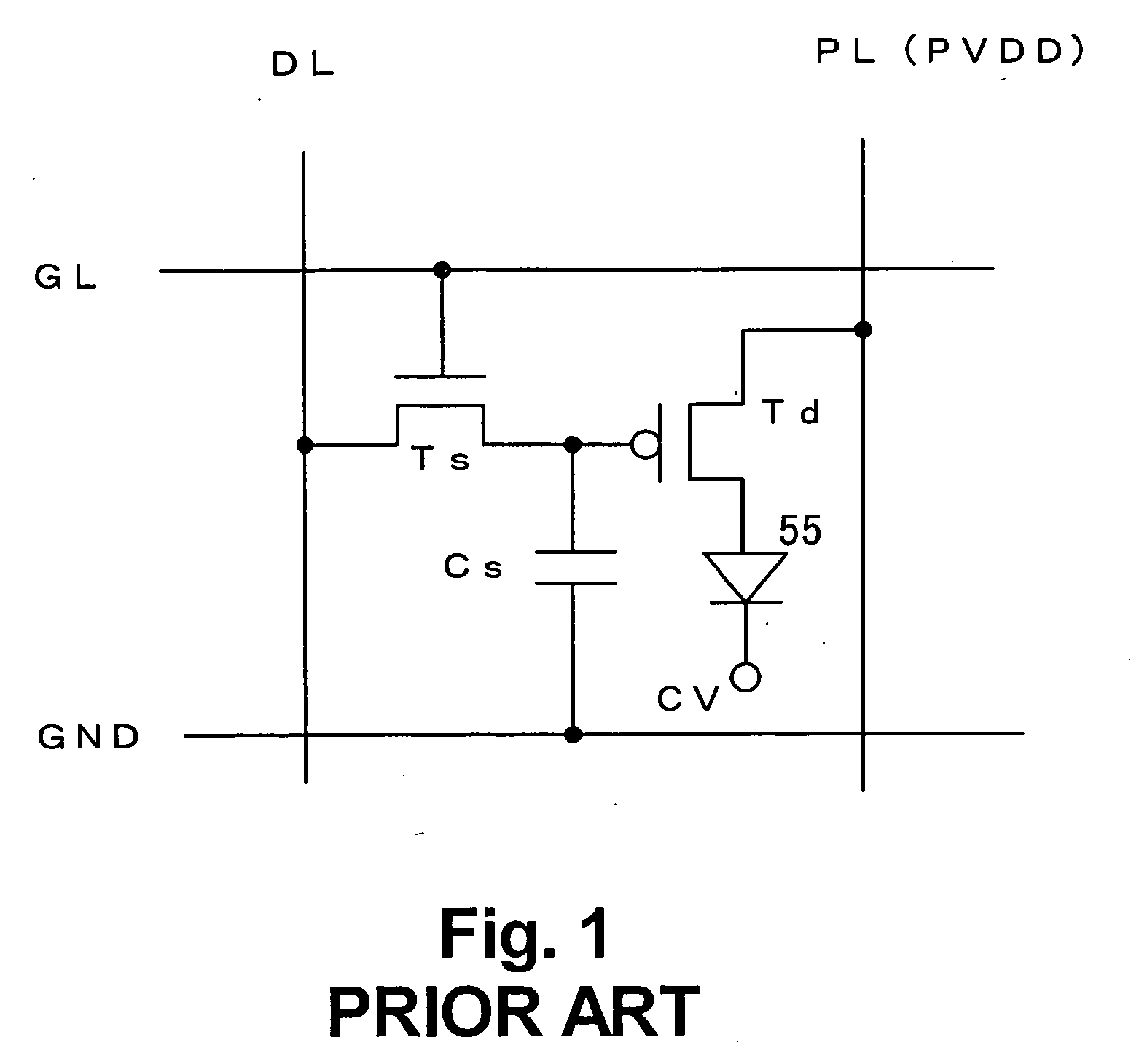

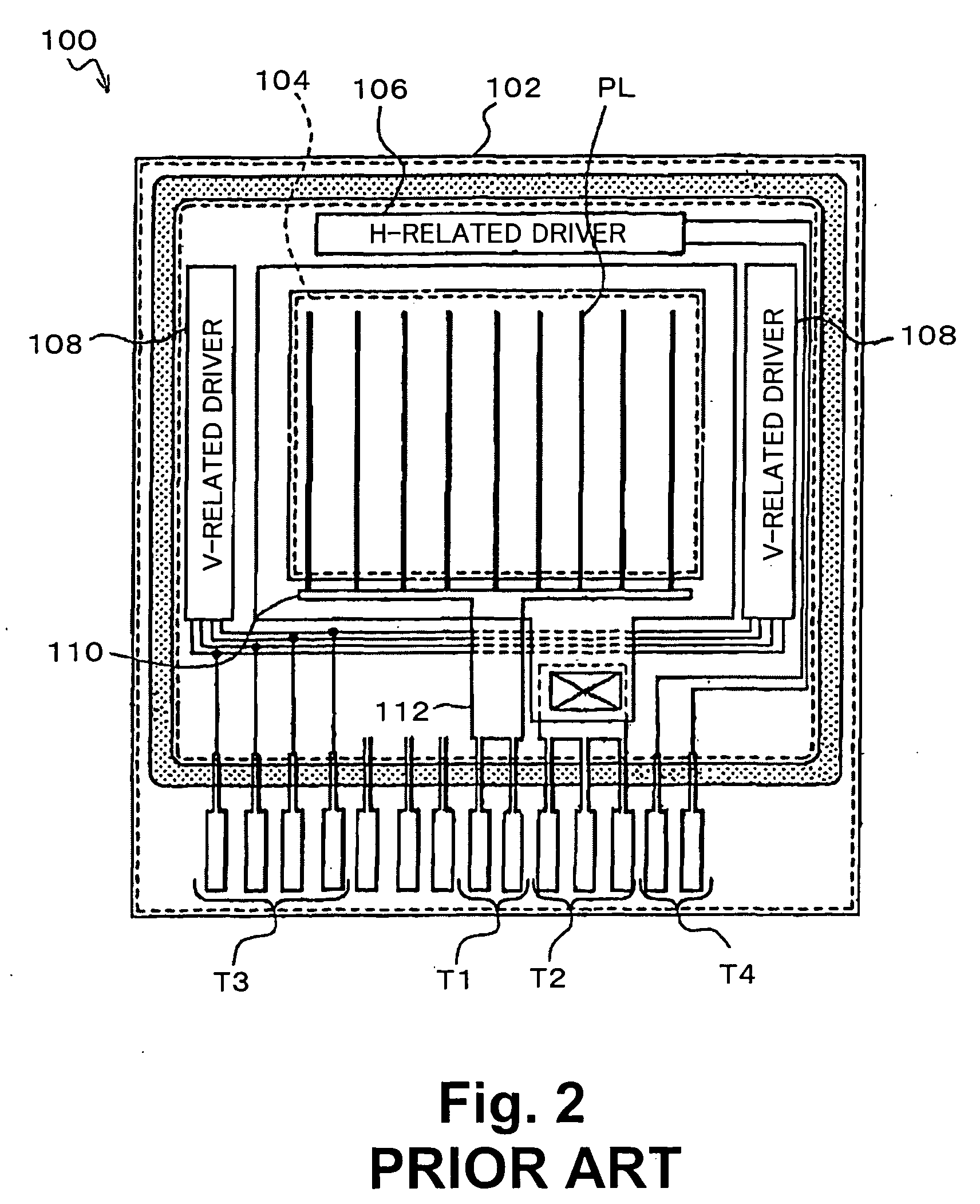

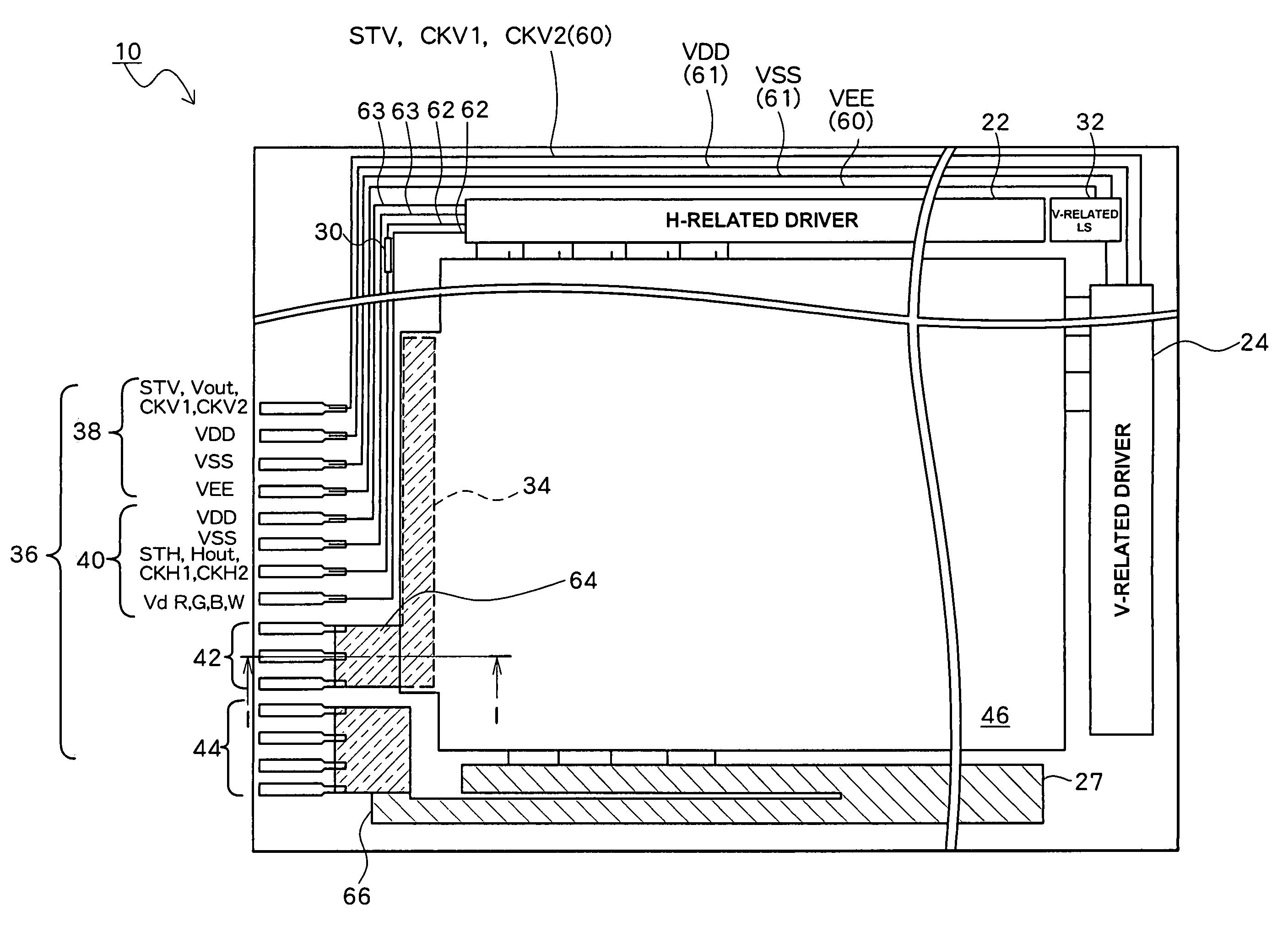

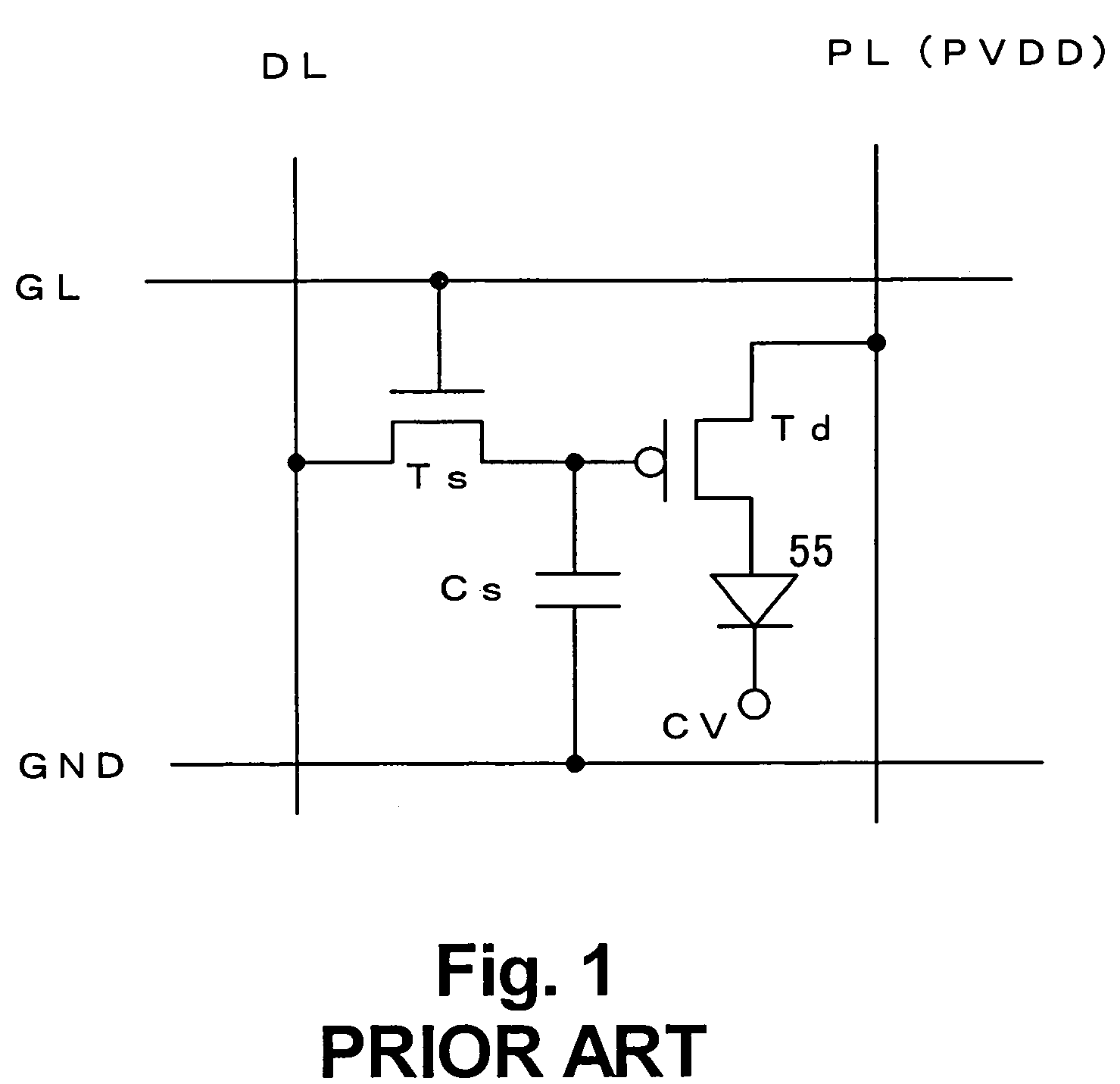

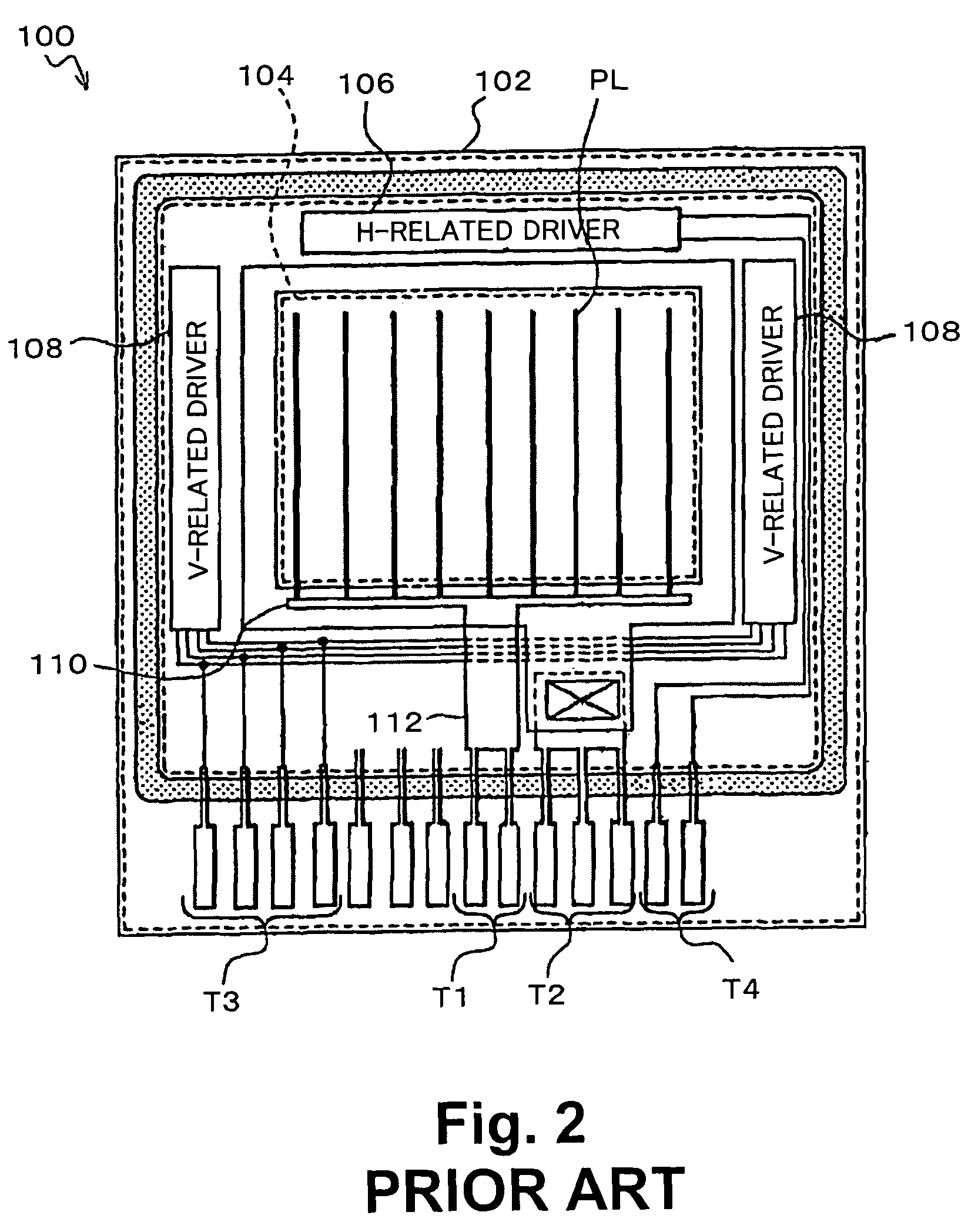

Electroluminescence display device

ActiveUS20070013629A1Reduce in quantityReduce the impactStatic indicating devicesElectroluminescent light sourcesDriver circuitDriving current

In an electroluminescence display device having, on a display panel, a display portion in which pixels are arranged in matrix, an external connection terminal is placed along a lateral side of the display panel and a vertical scan driver circuit is placed on a lateral side of the display panel which opposes the lateral side on which the external connection terminal is placed. Lines for a horizontal scan driver circuit and for the vertical scan driver circuit can be provided only on three sides of the display panel including the side on which the external connection terminal is provided, a side opposing this side, and another side. By not placing the line for the driver circuits on the remaining side, spaces can be secured on this side for a drive current line which supplies power to an electroluminescence element. With this structure, a size of a frame portion can be reduced while securing sufficient width for the drive current common line.

Owner:SANYO ELECTRIC CO LTD

Automatic pairing method and device for TPMS

InactiveCN105501006ADo not disrupt offline rhythmImprove production line efficiencySensing record carriersTyre measurementsProduction lineComputer module

The invention discloses an automatic pairing method and device for a TPMS. The device comprises an identification code scanner for scanning an identification code on a car body, a control module for sending a pairing instruction, a computer host for communicating the identification code scanner with the control module, a display screen for displaying a pairing result and a low-frequency transmitting module for triggering a TPMS sensor in a car tire to send tire data, wherein the computer host is connected with the code scanner, the display screen and the control module, and the control module is also connected with the low-frequency transmitting module. According to the method and device, in a car production line, automatic non-stop pairing can be achieved, the production line efficiency is improved, and the car offline tact is not disrupted; in addition, device configuration is simplified, and the device cost is lowered.

Owner:GUANGDONG COAGENT ELECTRONICS SCI & TECH

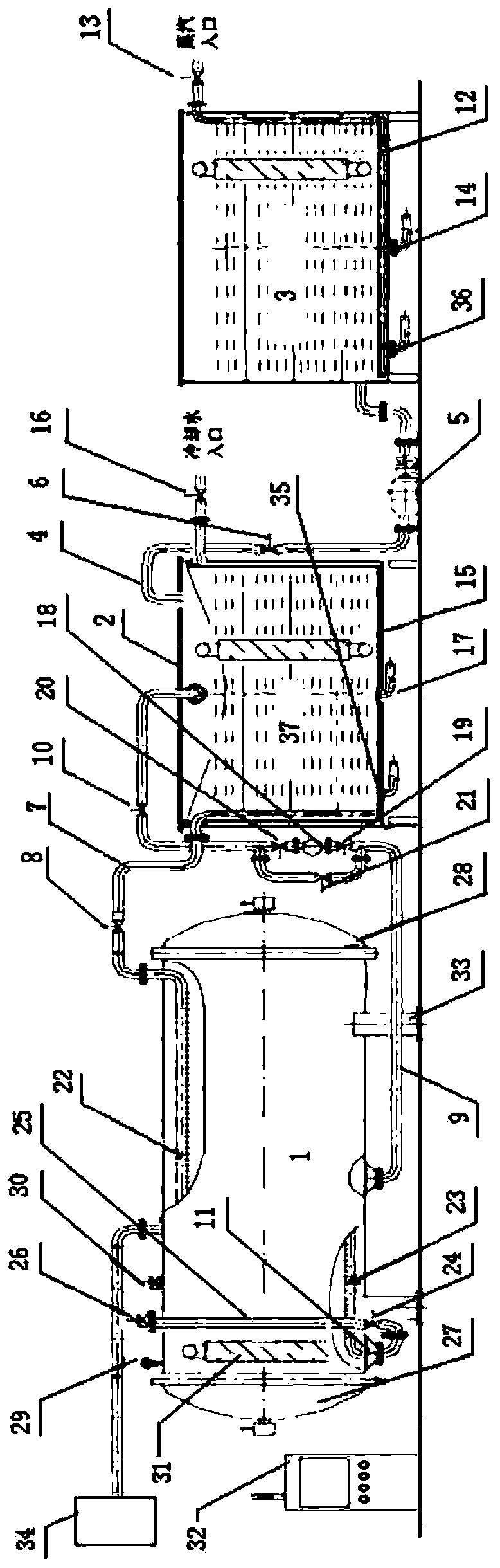

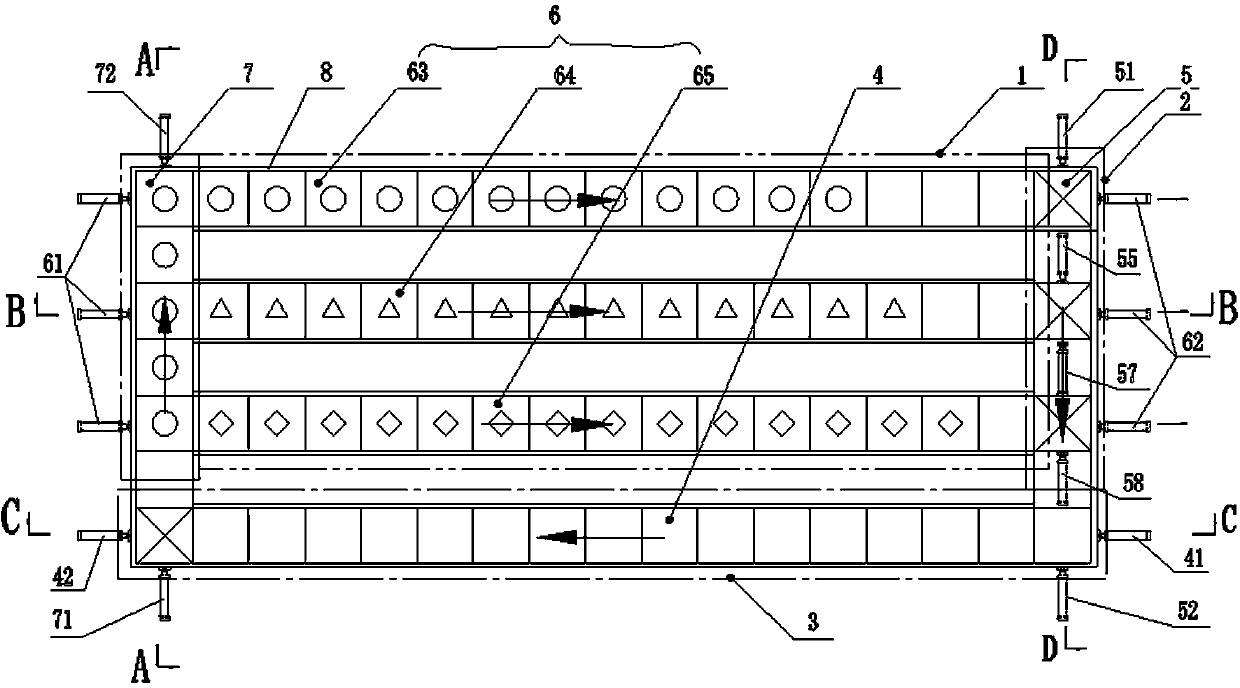

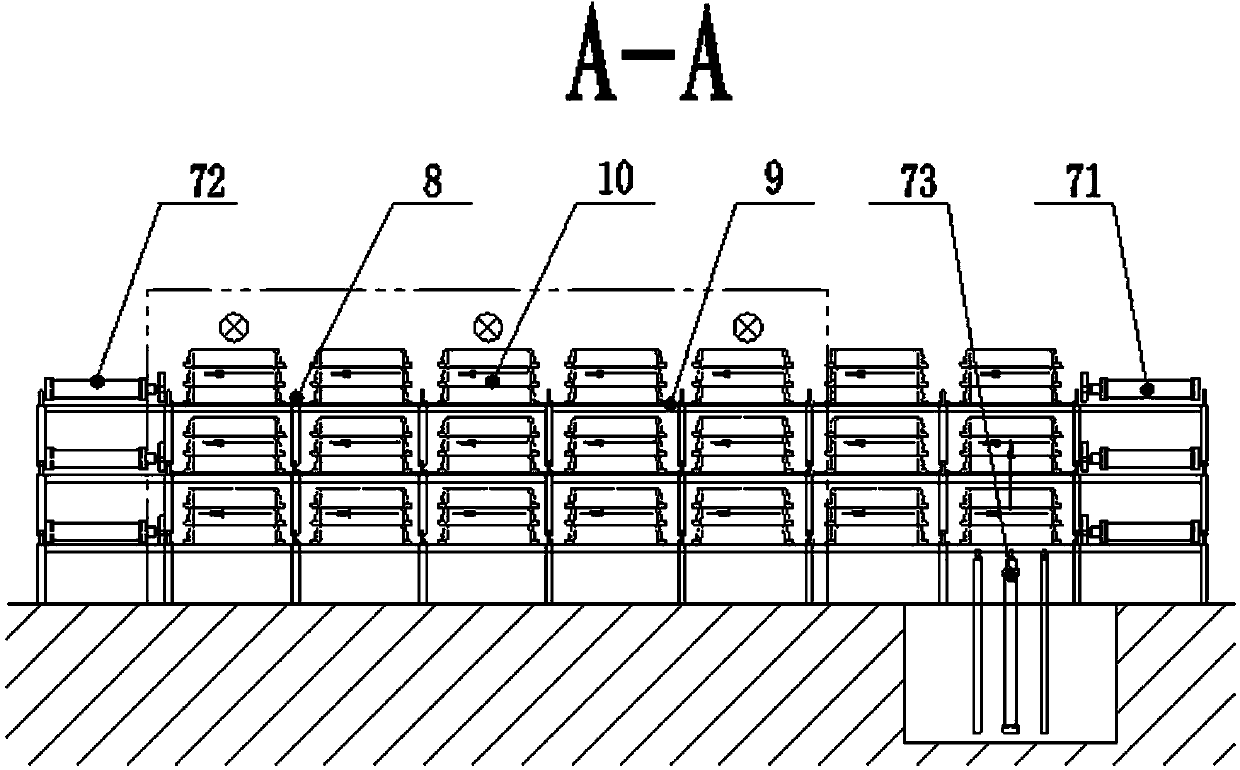

Static pressure-variable pickling system

The invention discloses a static pressure-variable pickling system. The static pressure-variable pickling system comprises a pickling tank, a pickling liquid stewing pool, a cooling storage pool and a control system, wherein the pickling liquid stewing pool, the cooling storage pool and the pickling tank are sequentially communicated with one another through liquid transmission pipelines, a pressure regulating device which conducts air exhaust and inflation on a tank body is arranged at the top end of the pickling tank, and the pressure regulating device is electrically connected with the control system. An air inlet hole is formed in the bottom of the pickling tank, a control valve which is electrically connected with the control system is arranged on the air inlet hole, and the control system controls the pressure regulating device and the first control valve so that the pressure state of the pickling tank can be switched among the negative pressure state, the normal pressure state and the positive pressure state by turns and in sequence. The static pressure-variable pickling system integrates stewing of pickling liquid and cooling of the pickling liquid and pickling conducted through the pickling tank, the operation of the whole system is controlled through the automatic control system, therefore, full automation is achieved, and the pickling efficiency is greatly improved due to the conversion of the pickling mode.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

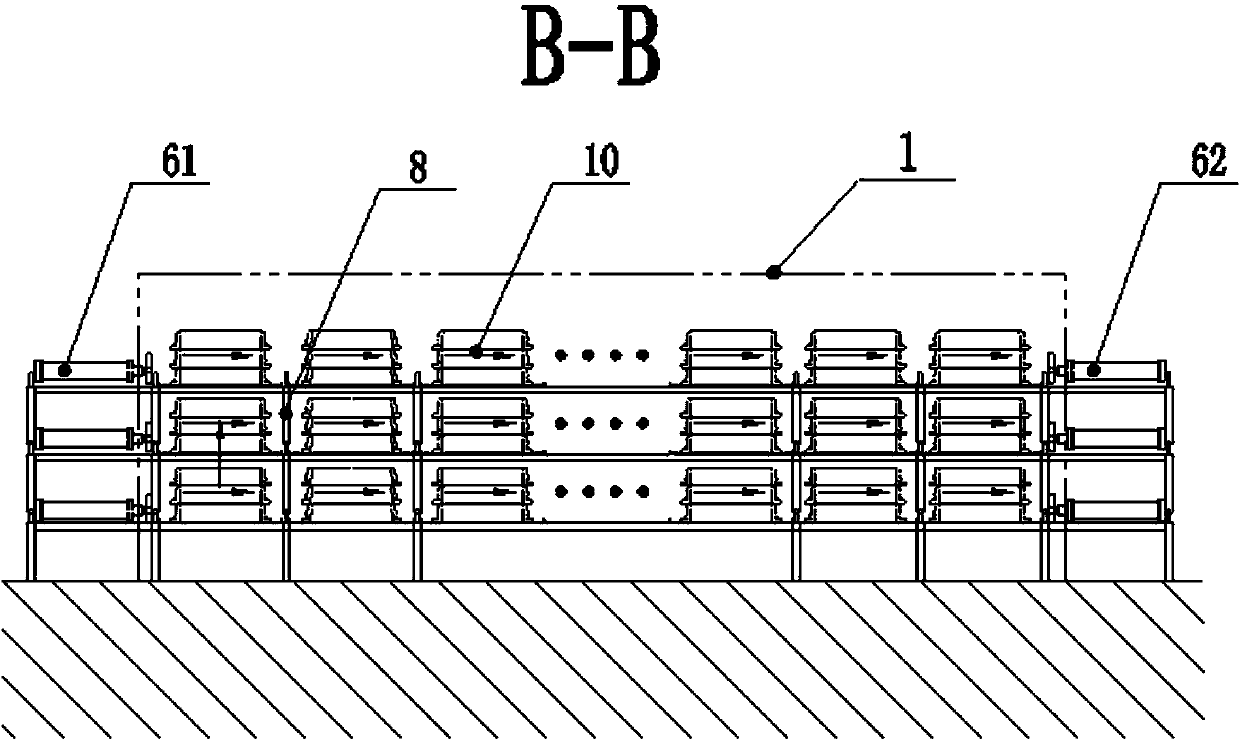

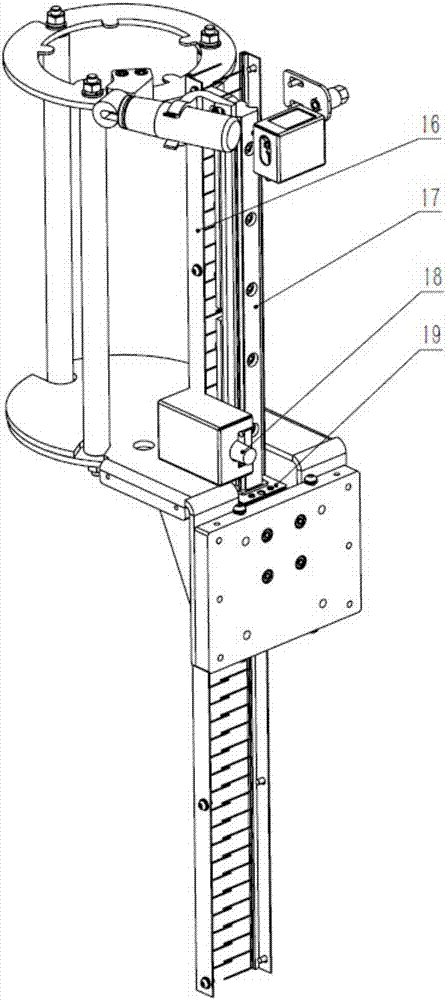

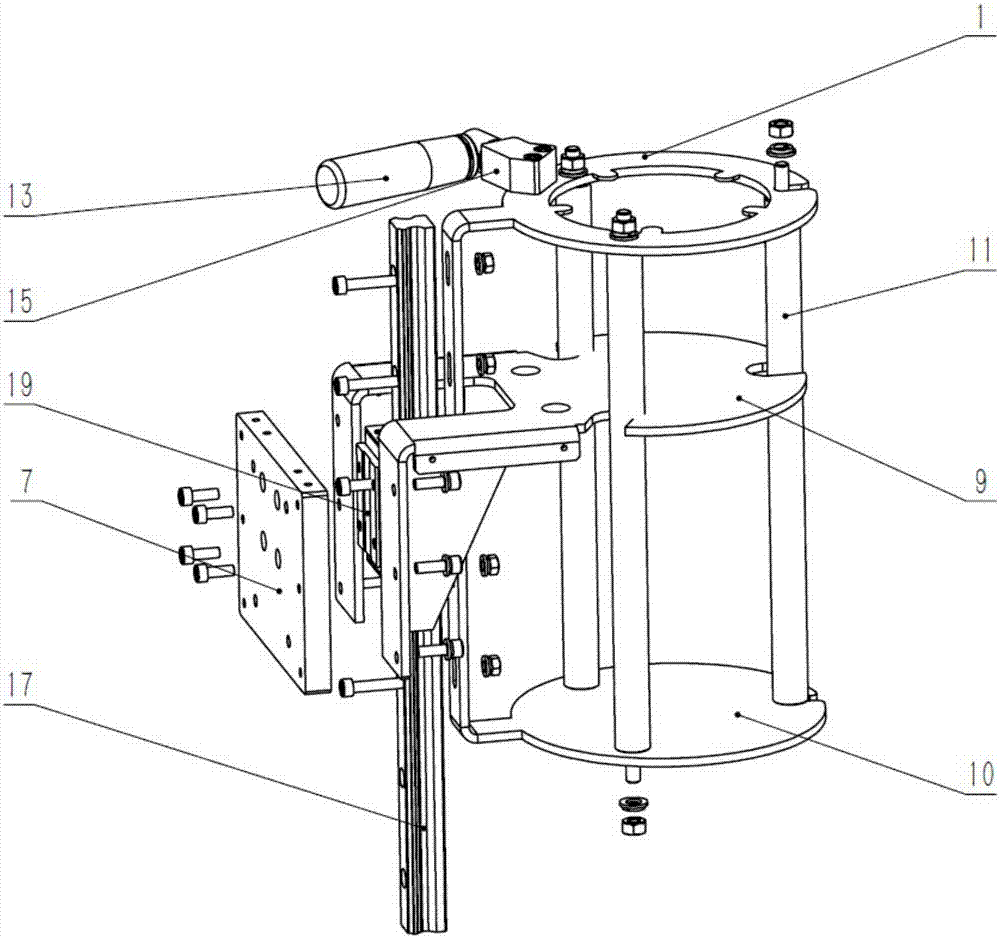

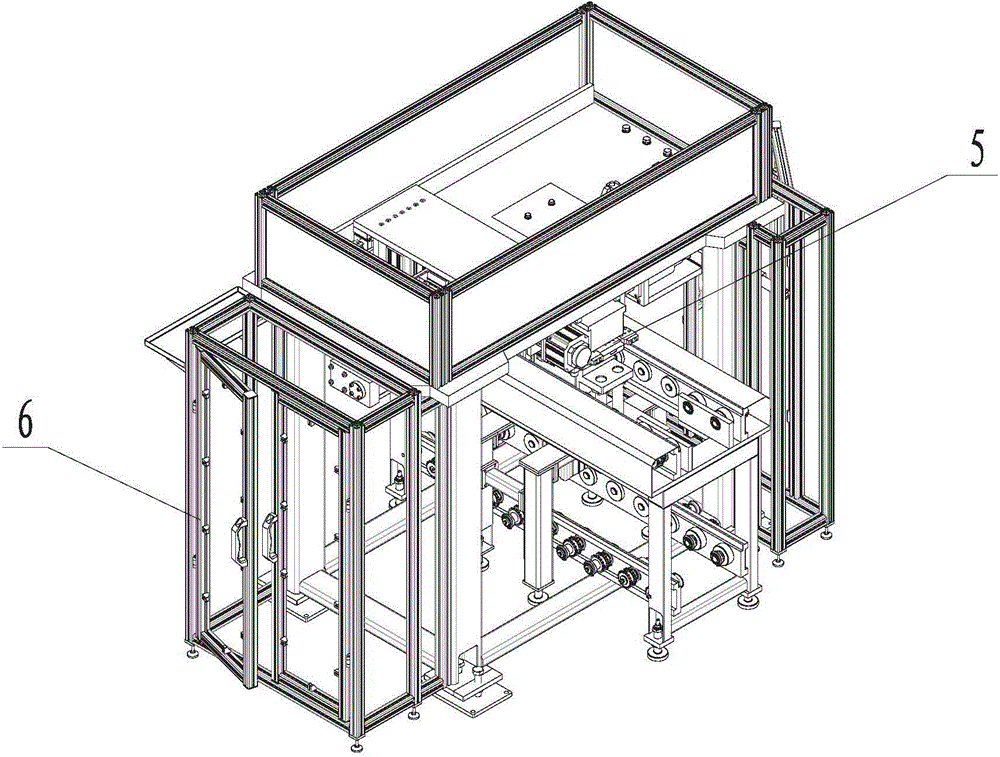

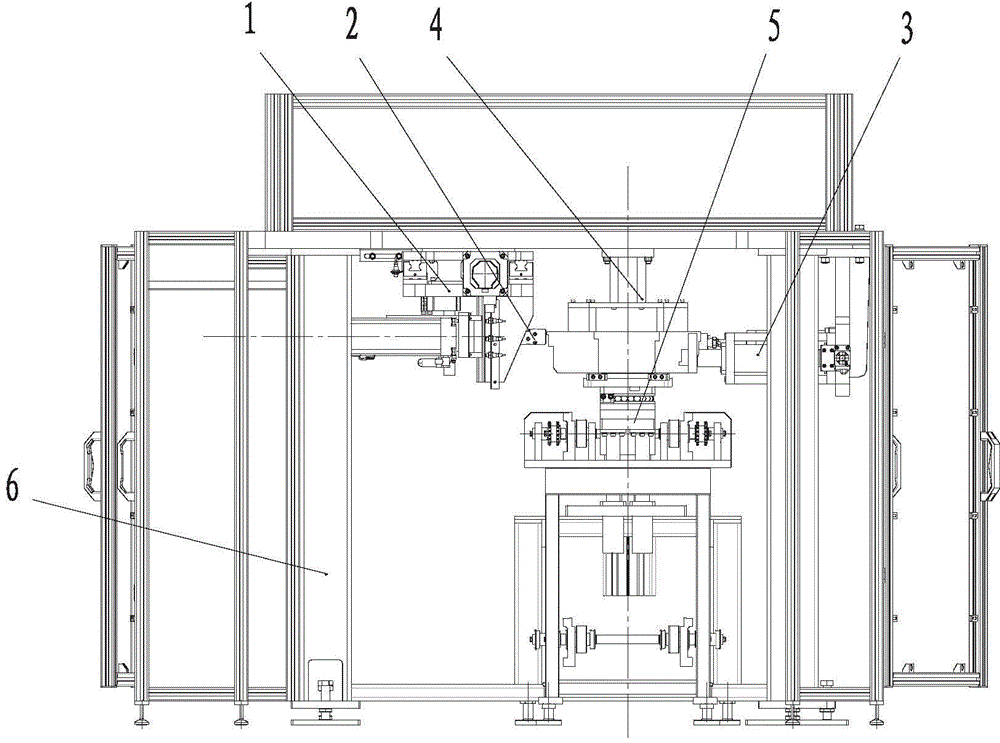

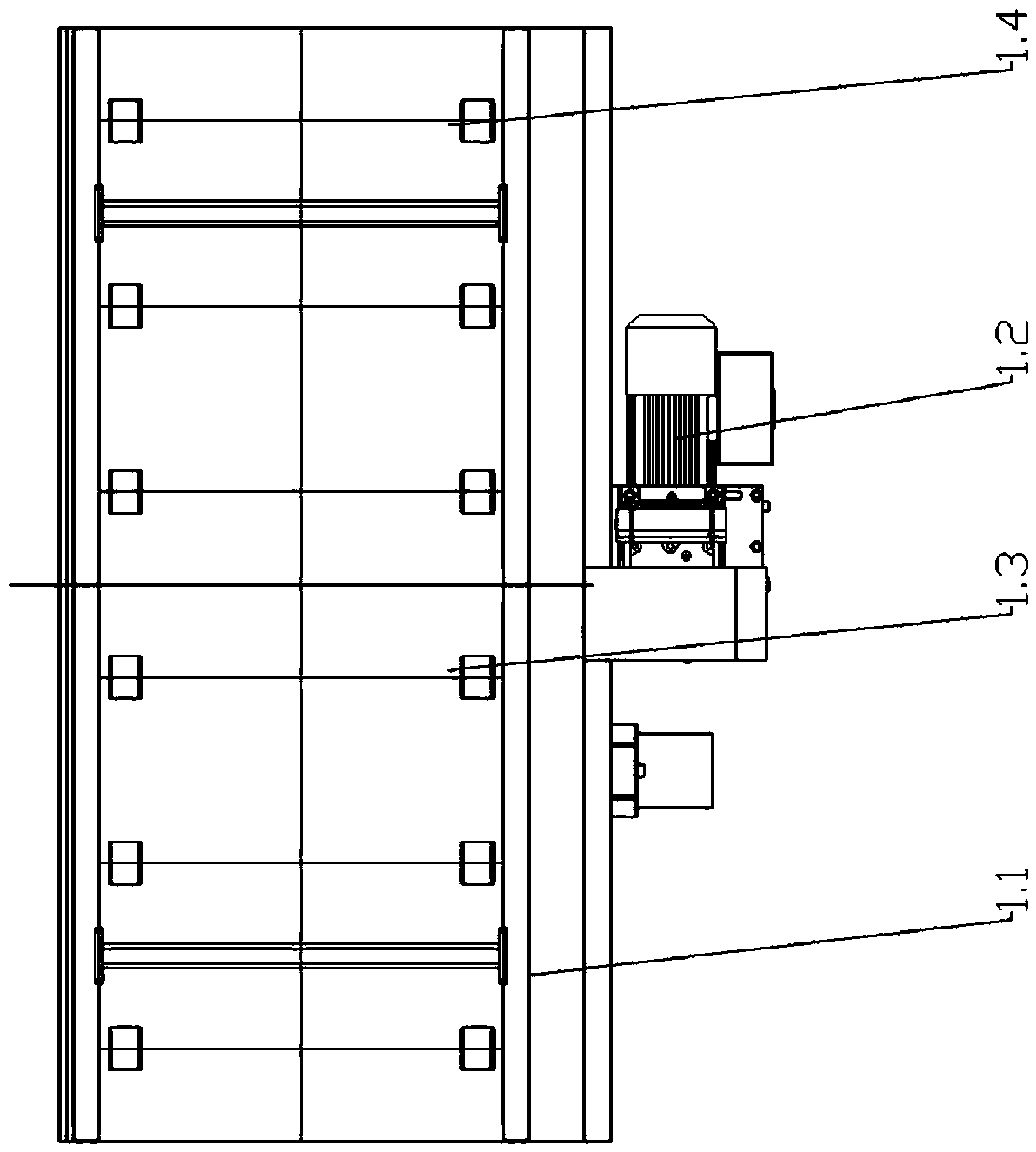

Integrated sand core feeding and discharging device for drying room

ActiveCN103736934ARealize in and outRealize automatic circulationFoundry mouldsFoundry coresNuclear engineering

The invention discloses an integrated sand core feeding and discharging device for a drying room, and relates to the technical field of cast molding core treatment. The device comprises more than two core storing channels which are formed in parallel, and flowing and rotating channels which are connected with core feeding channels, wherein two ends of each core storing channel are respectively connected with the core feeding channels and core discharging channels; the flowing and rotating channels are parallel to the core storing channels; the flowing and rotating channels, the core feeding channels, the core storing channels and the core discharging channels are the same in the structure and respectively comprise brackets; tracks are arranged on the brackets; sand core trays are arranged on the tracks; sand core tray jacking mechanisms are respectively arranged at the inlet ends of the flowing and rotating channels, the core feeding channels, the core storing channels and the core discharging channels; the sand core trays in which sand cores are placed are promoted by the sand core tray jacking mechanisms to sequentially enter the flowing and rotating channels, the core feeding channels and the core storing channels, then the sand cores are taken out from the core discharging channels, and the empty trays are pushed to the flowing and rotating channels. The device is simple in structure, convenient to operate and high in working efficiency, and can be used for guaranteeing the drying quality and lightening the working intensity of a worker.

Owner:XINXING HEBEI ENG & RES INC

UV gloss oil used for laser embossing transfer equipment

ActiveCN105315731ALow viscosityHigh viscosityPolyether coatingsPrinting after-treatmentHyperbranched polyesterPliability

The invention discloses UV gloss oil used for laser embossing transfer equipment. The UV gloss oil is characterized by comprising the following components in parts by weight: 2-10 parts of a light initiator, 1-5 parts of 2-ethylhexyl acrylate, 1-5 parts of a base material lubricant, 45-75 parts of a pre-polymer and 18-35 parts of a monomer, wherein the pre-polymer is amine modified polyether acrylate or ester-epoxy acrylate or superbranched polyester acrylate or a combination of the amine modified polyether acrylate and the ester-epoxy acrylate in same parts by weight; the monomer is 1,6-hexanediol diacrylate or ethoxylated trimethylolpropane triacrylate. The UV gloss oil disclosed by the invention is fast in curing speed, good in flexibility and high in glossiness and can satisfy an embossing transfer laser process, so that the laser embossing transfer effect is good.

Owner:杜广清

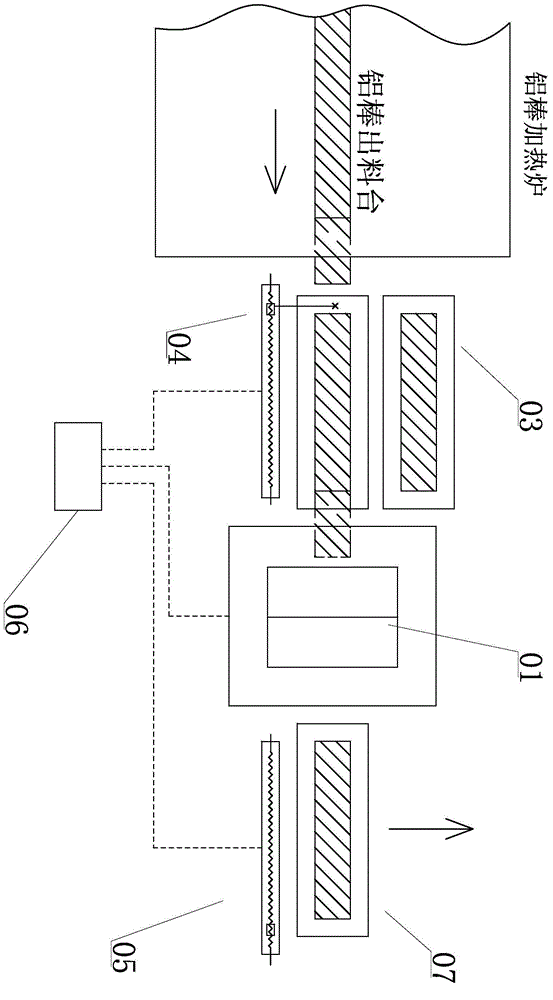

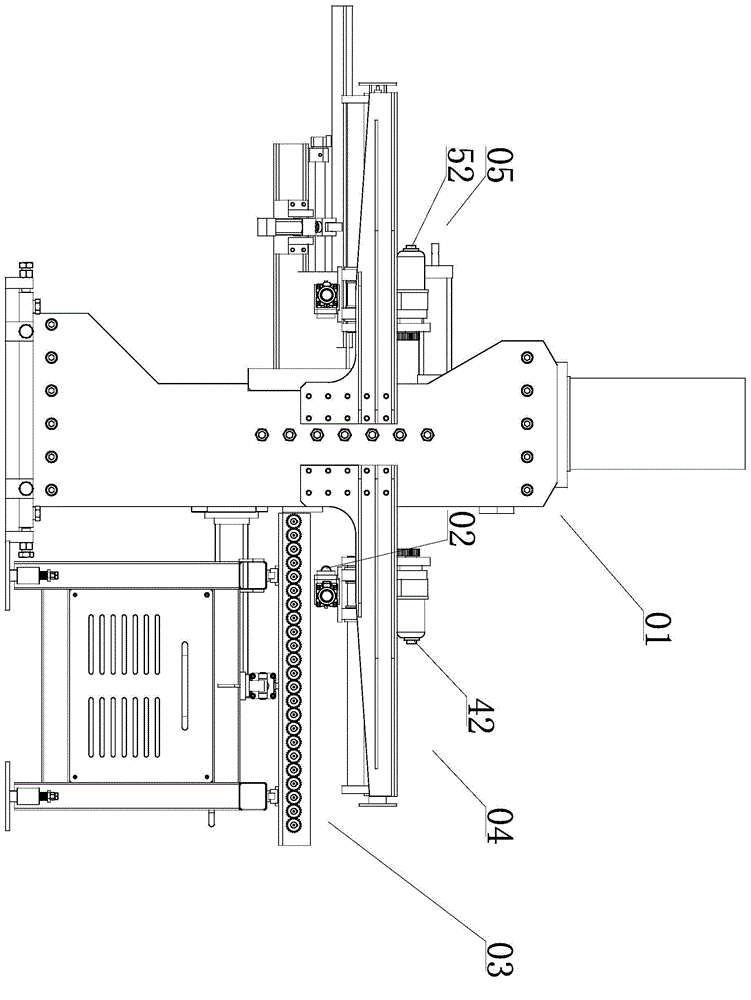

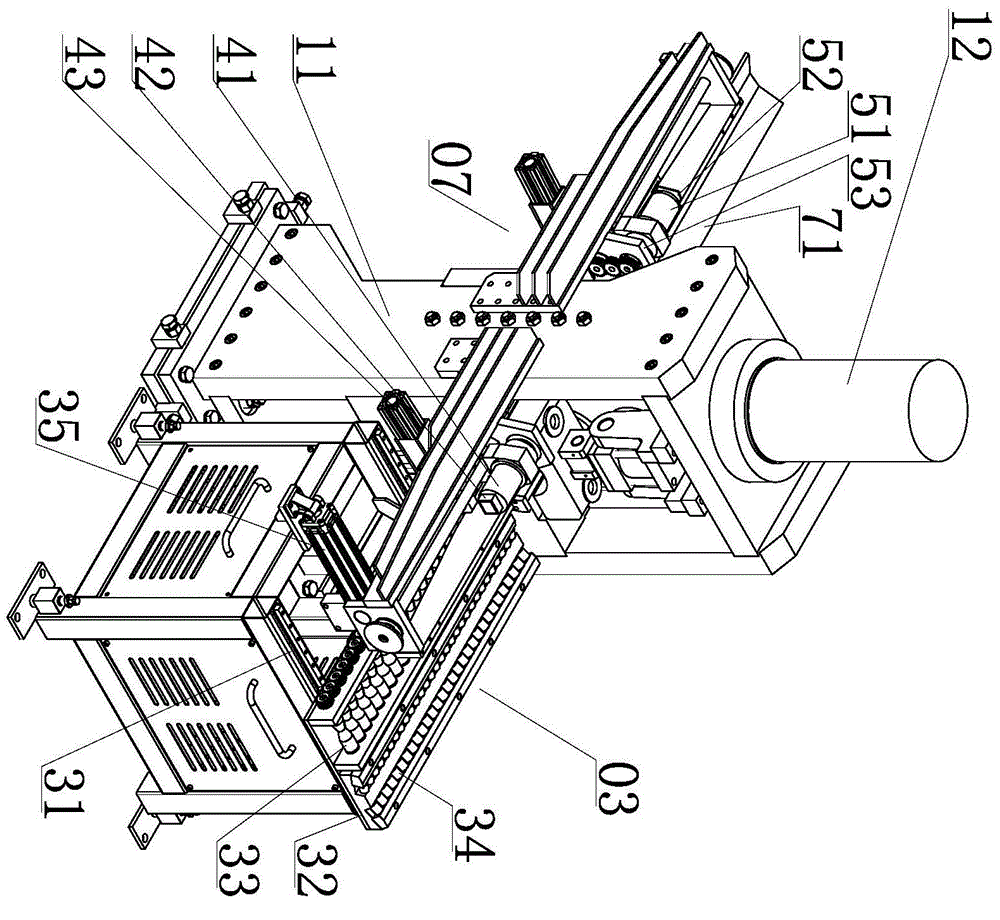

Aluminum bar length measurement hot-shear device having double-shearing function and application thereof

ActiveCN104874852ALow failure rateSave materialMeasurement/indication equipmentsStock shearing machinesMeasurement deviceLength measurement

The invention discloses an aluminum bar length measurement hot-shear device having a double-shearing function and application thereof. The aluminum bar length measurement hot-shear device comprises a hot-shear machine, a photoelectric switch, a short bar storage table, a first measurement device, a second measurement device arranged on the other side of the hot-shear machine and PLC connected with the hot-shear machine, the photoelectric switch, the first measurement device and the second measurement device respectively. The first measurement device comprises a first motor, a first encoder, a first lead screw, a first moving block and a pushing air cylinder arranged on the first moving block. The photoelectric switch is arranged on the first moving block. The second measurement device comprises a second motor, a second lead screw, a second encoder, a second moving block and a limiting baffle arranged on the second moving block. A magnetic switch is arranged on the second moving block. The aluminum bar length measurement hot-shear device has the advantages of saving materials and labors, achieving automatic machining and improving working efficiency and the rate of finished products.

Owner:佛山市法比澳挤压机械科技有限公司

Small-rolling-diameter full-automatic winding device

ActiveCN106115322ANot easy to stretchGuaranteed product performanceWebs handlingEngineeringMaterial storage

The invention discloses a small-rolling-diameter full-automatic winding device. The small-rolling-diameter full-automatic winding device comprises a traction mechanism, a gas expansion shaft auxiliary tight jacking mechanism, a winding mechanism, an automatic cutting mechanism, an automatic unwinding mechanism, an automatic conveying and conveying mechanism and a material storage mechanism, wherein the traction mechanism, the gas expansion shaft auxiliary tight jacking mechanism, the winding mechanism, the automatic cutting mechanism, the automatic unwinding mechanism, the automatic conveying and conveying mechanism and the material storage mechanism are sequentially arranged on a rack. The winding, cutting, unwinding and weighing mechanisms of the small-rolling-diameter full-automatic winding device all achieve automation, by adjusting, controlling and feeding back the tensile force of a sheet, the winding tension degree is adjusted through a winding motor, the sheet winding tension is constant tension, and the product performance is guaranteed; and meanwhile, the unwinding mechanism is designed at the position of the center of a current winding shaft, the wound sheet can be fast unwound, in the unwinding process, the material storage mechanism stores the sheet at the same time, the material storage mechanism performs discharging on the sheet when winding is started, it is guaranteed that a product is not prone to stretching, the product performance is improved, and the wound sheet is weighed and subjected to labeling. The whole device structure effectively improves the production line efficiency, time is saved, operation is convenient, the effect is remarkable, and the labor cost is greatly saved.

Owner:SUZHOU JWELL MACHINERY

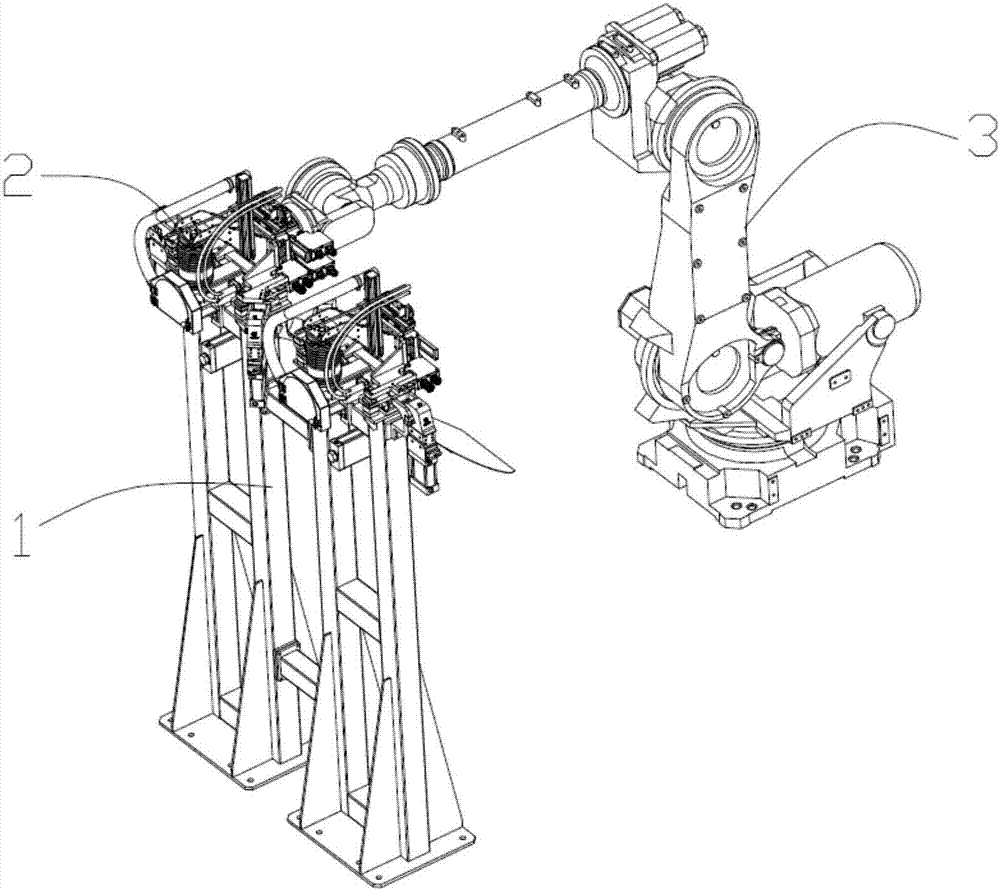

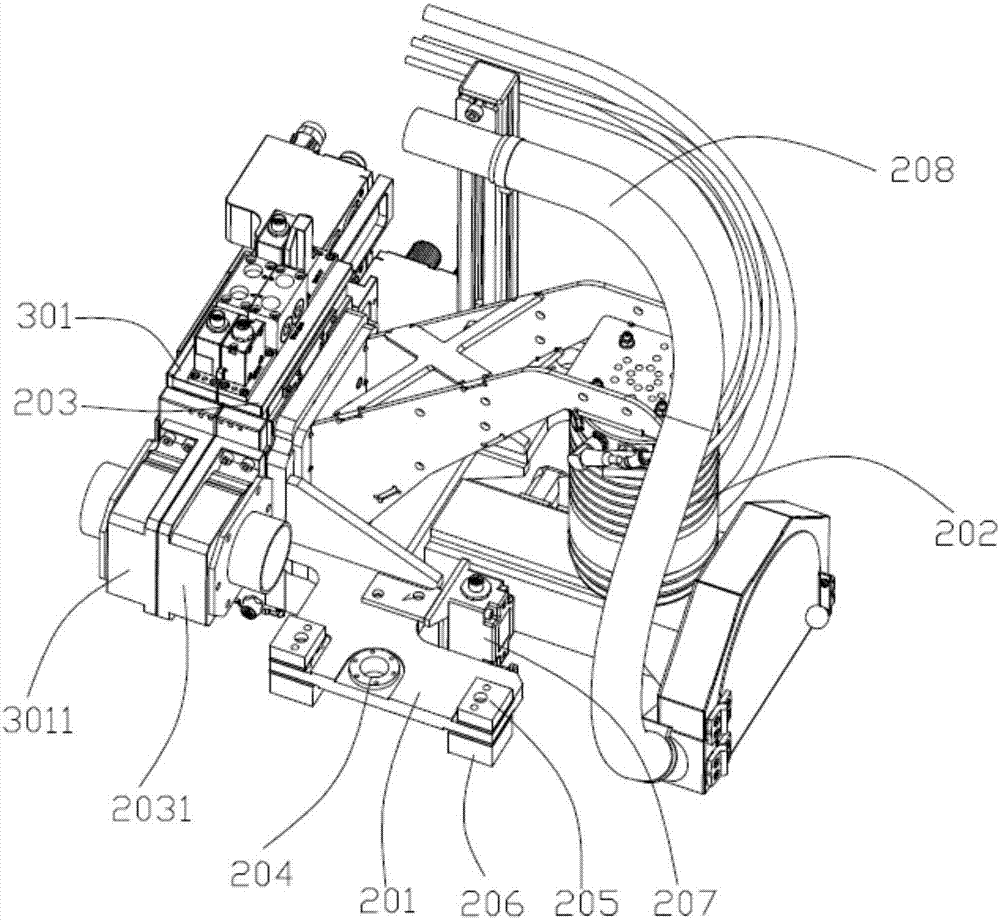

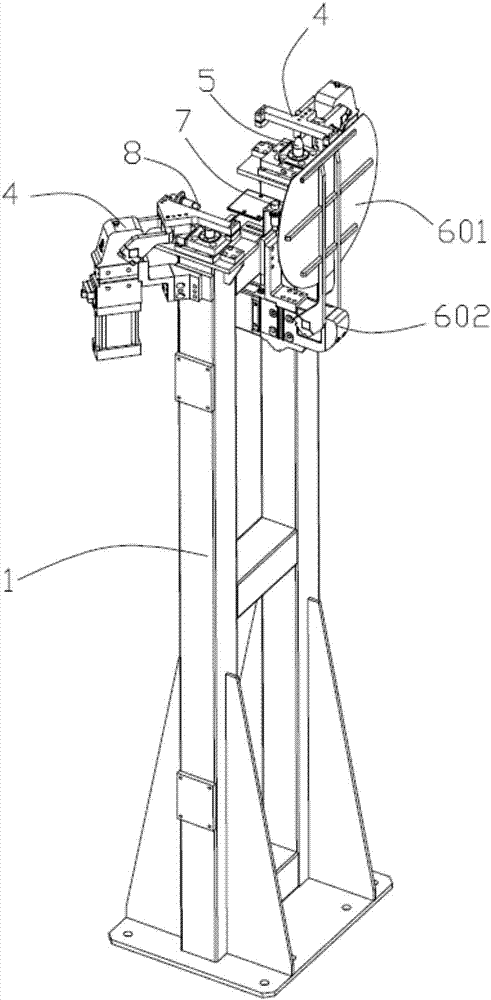

Intelligent abrasive paper sticking device used for robot grinding and polishing

PendingCN107199509ASolve manual dependenciesReduce enterprise labor costsGrinding wheel securing apparatusGrinding feed controlGrindingEmery paper

Owner:YUYI INTELLIGENT TECH SHANGHAI CO LTD

Transmission aligning device and butt joint equipment

The invention provides a transmission aligning device. The transmission aligning device comprises a transmission mechanism, the transmission mechanism is provided with a conveying surface for supporting and conveying materials, the transmission aligning device further comprises a lifting aligning mechanism, the lifting aligning mechanism starts aligning operations when ascending to contact the materials and stops the aligning operations when descending to be separated from the materials, and the materials are delivered to the conveying surface to make the materials be conveyed along the presetposition on the conveying surface. According to the transmission aligning device and butt joint equipment, automatic aligning is performed on the conveyed materials through the lifting aligning mechanism, regular conveying of the materials is facilitated, material damage generated in the conveying and material fetching-placing process is avoided, the production efficiency is improved and the qualified rate is increased, and the cost is lowered.

Owner:JOINT STARS TECH

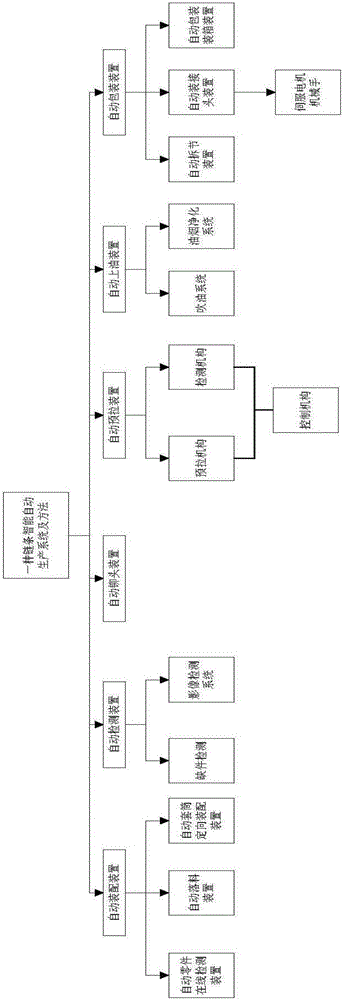

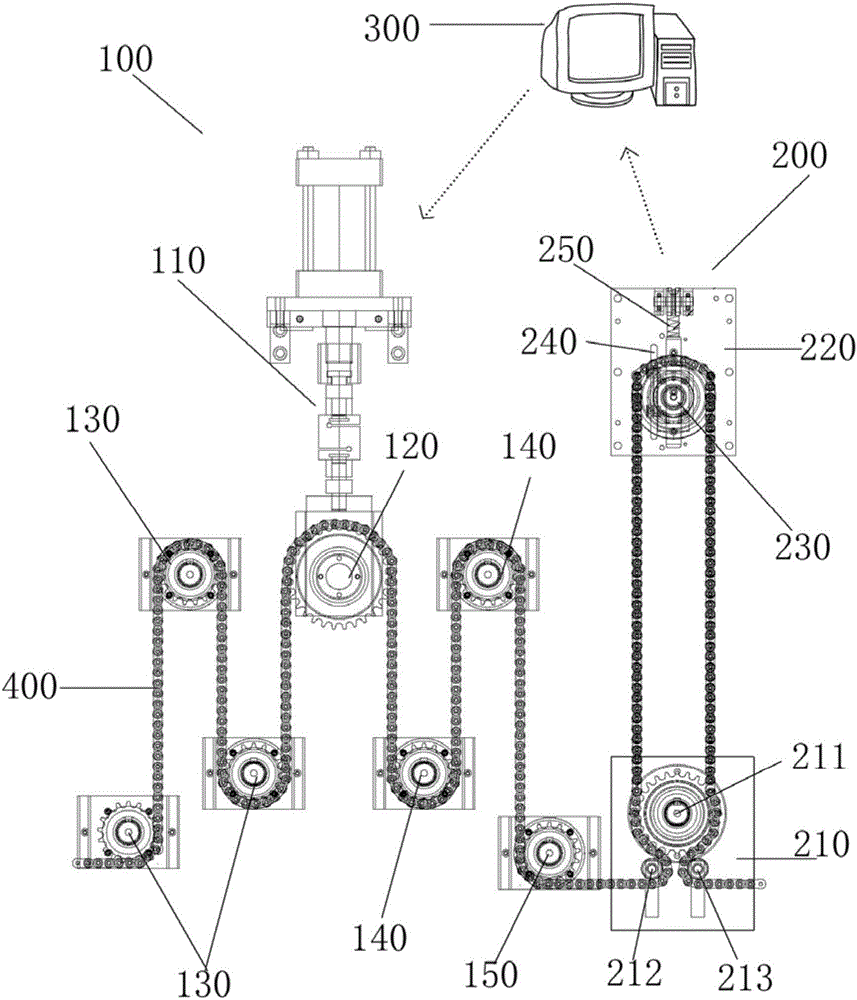

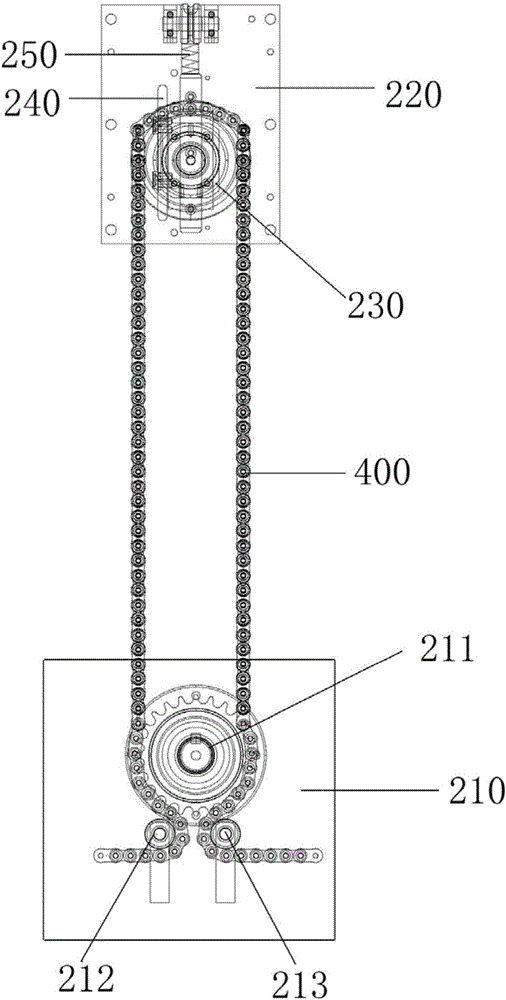

Automatic production system of chain

The invention discloses an automatic production system of a chain. The automatic production system comprises an automatic assembling device, an automatic detecting device, an automatic head riveting device, an automatic pretensioning device, an automatic oiling device and an automatic packaging and boxing device, all of which are sequentially arranged in the chain advancing direction. The automatic pretensioning device comprises a pretensioning mechanism, a detecting mechanism and a control mechanism, the pretensioning mechanism and the detecting mechanism allow the chain to penetrate in sequence, and the control mechanism is connected to the pretensioning mechanism and the detecting mechanism in a communication manner. The tension with the adjustable magnitude is provided by the pretensioning mechanism to tension the chain. The detecting mechanism is used for detecting the tensioning state of the chain. The control mechanism receives signals about the tensioning state of the chain from the detecting mechanism and indicates the pretensioning mechanism to adjust the magnitude of the tension according to the signals. The system is convenient to operate and high in automation degree, the tension can be detected and adjusted in real time in the pretensioning process, and the production efficiency and the product percent of pass are effectively improved.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

Grinding head replacing system and robot grinding system

PendingCN107984389AWill not affect normal productionAvoid waiting in lineGrinding wheel securing apparatusGrinding/polishing safety devicesEconomic benefitsAssembly line

The invention relates to a grinding head replacing system and a robot grinding system equipped with the grinding head replacing system. The grinding head replacing system comprises a parking table which is arranged beside a grinding robot in an off-line mode, and the parking table is provided with two grinding head parking positions, wherein one of the grinding head parking positions is used for bearing a to-be-offline grinding head, and the other grinding head parking position is provided with a to-be-online grinding head. The two grinding head parking positions are provided with mounting mechanisms for fixing and mounting the grinding heads correspondingly. Each grinding head comprises a grinding machine, a grinding head support used for being mounted on the corresponding grinding head parking position, and a quickly-replacing female disc matched with a quickly-replacing male disc on the grinding robot. The grinding machines and the quickly-replacing female discs are both mounted onthe grinding head supports. According to the grinding head replacing system and the robot grinding system, the switching work of the to-be-offline grinding head and the to-be-online grinding head canbe achieved, the situation that normal production cannot be influenced by replacing operation of grinding wheels is ensured, the situation that due to grinding wheel replacing, an assembly line stopsto wait is avoided, and the production efficiency and economic benefits can be improved.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

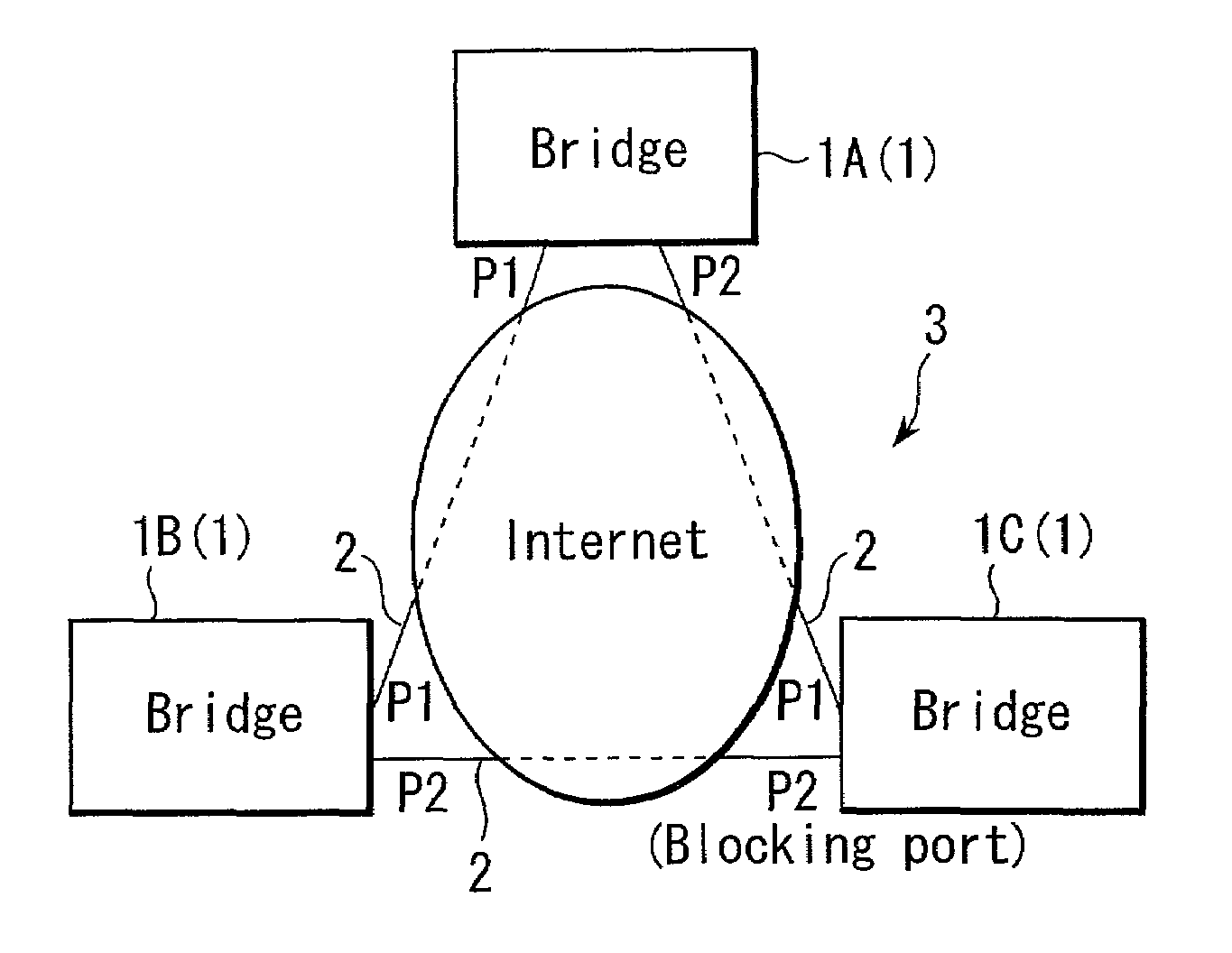

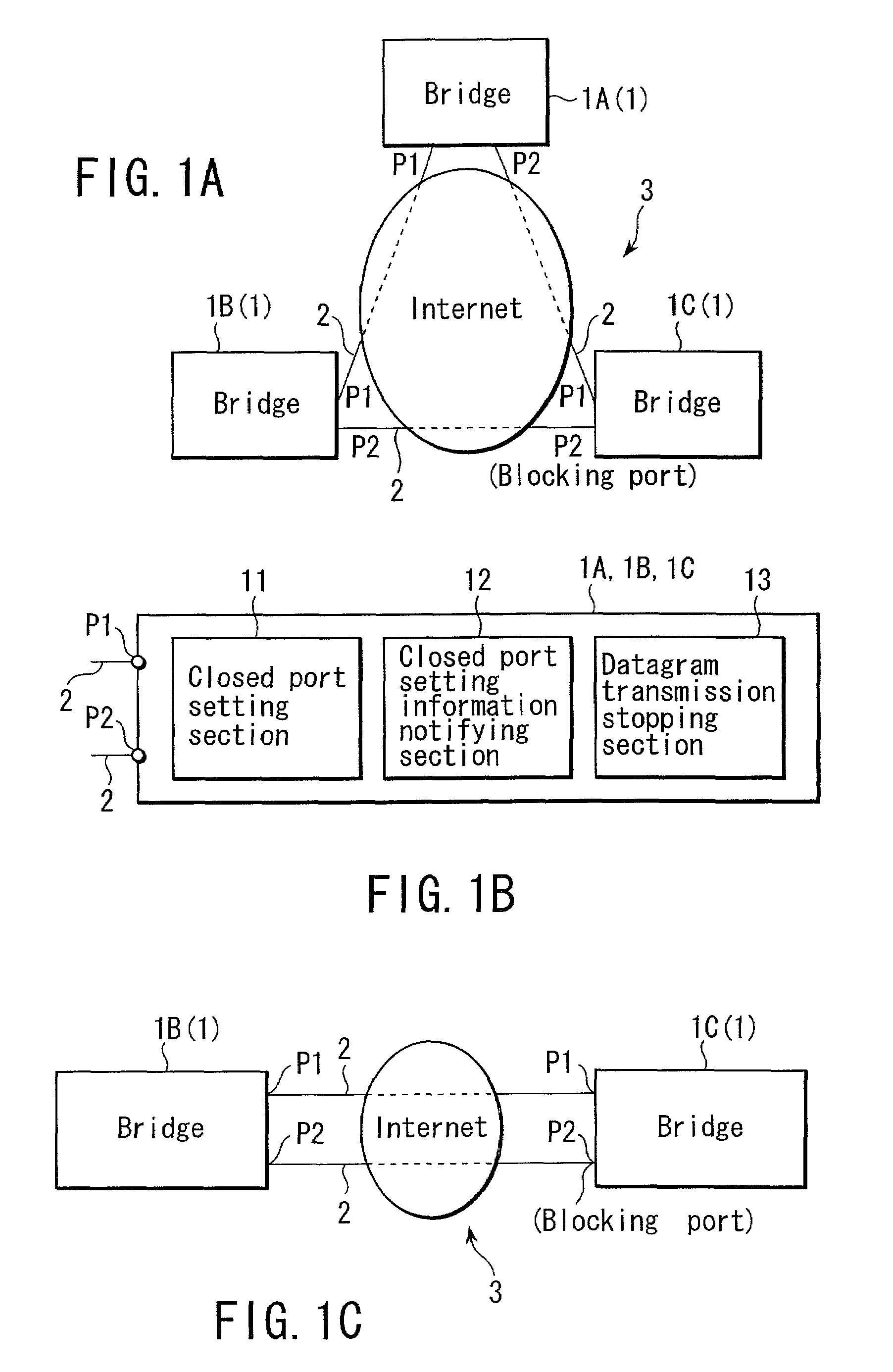

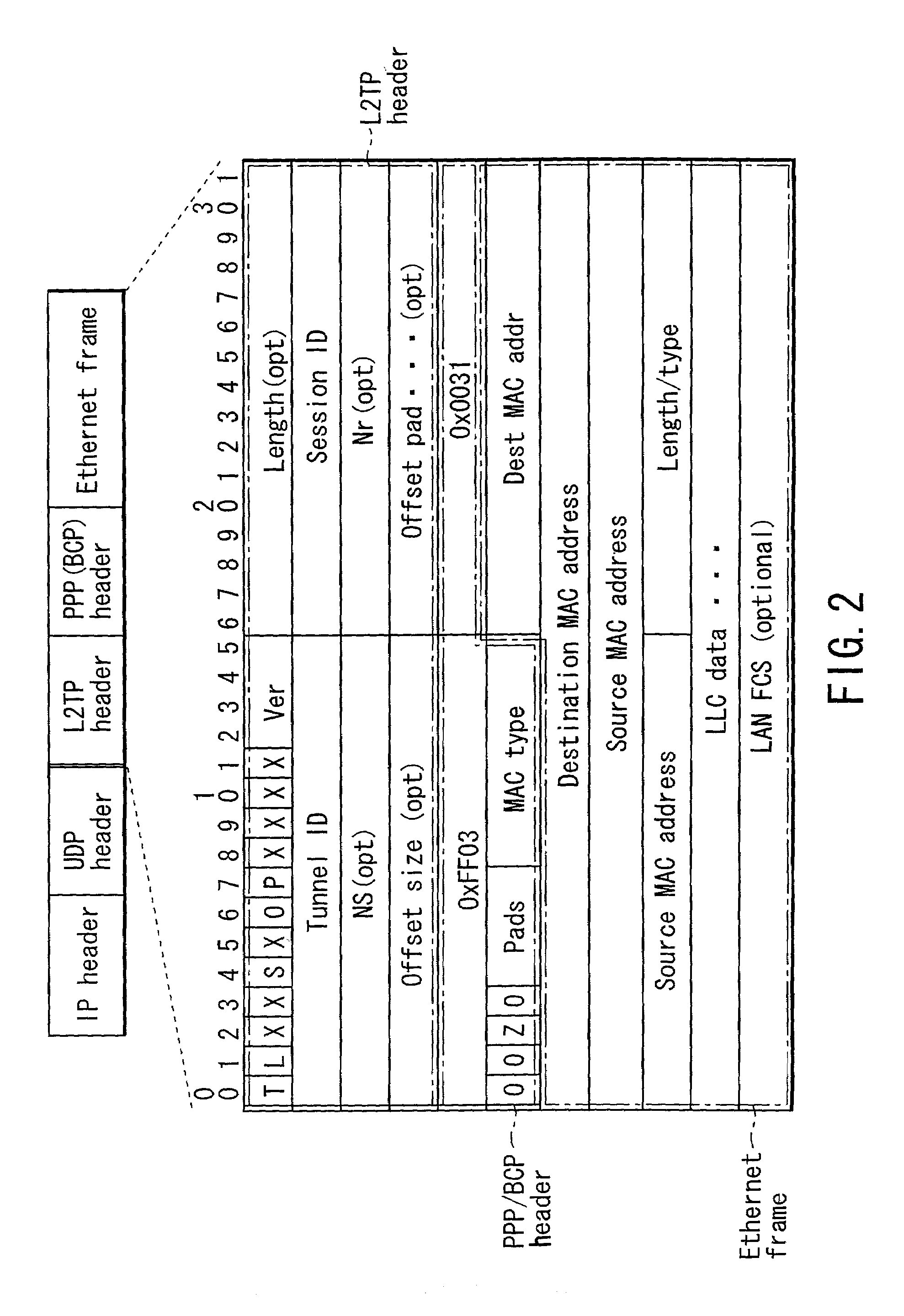

Communication relay device with redundancy function for line in network in accordance with WAN environment and communication system using the same

InactiveUS7440414B2Reduce outflowImprove production line efficiencyError preventionFrequency-division multiplex detailsCommunications systemEngineering

A communication relay device with a redundancy function for a line in a network under a WAN environment is connected to another, having a one-to-one relationship at both ends of each line by first and second ports to configure a redundancy channel between lines. A closed port setting section sets one of the ports as a closed port, thereby configuring a network free of a loop between the respective lines. A closed port setting information notifying section notifies a counterpart communication relay device connected to the one port, via the one port, of closed port setting notifying information for notifying that one of the ports has been set as a closed port. A datagram transmission stopping section stops transmission of a datagram from a port of its own connected to the one port set as the closed port when receiving the closed port setting notification information as the counterpart communication relay device.

Owner:ANRITSU CORP

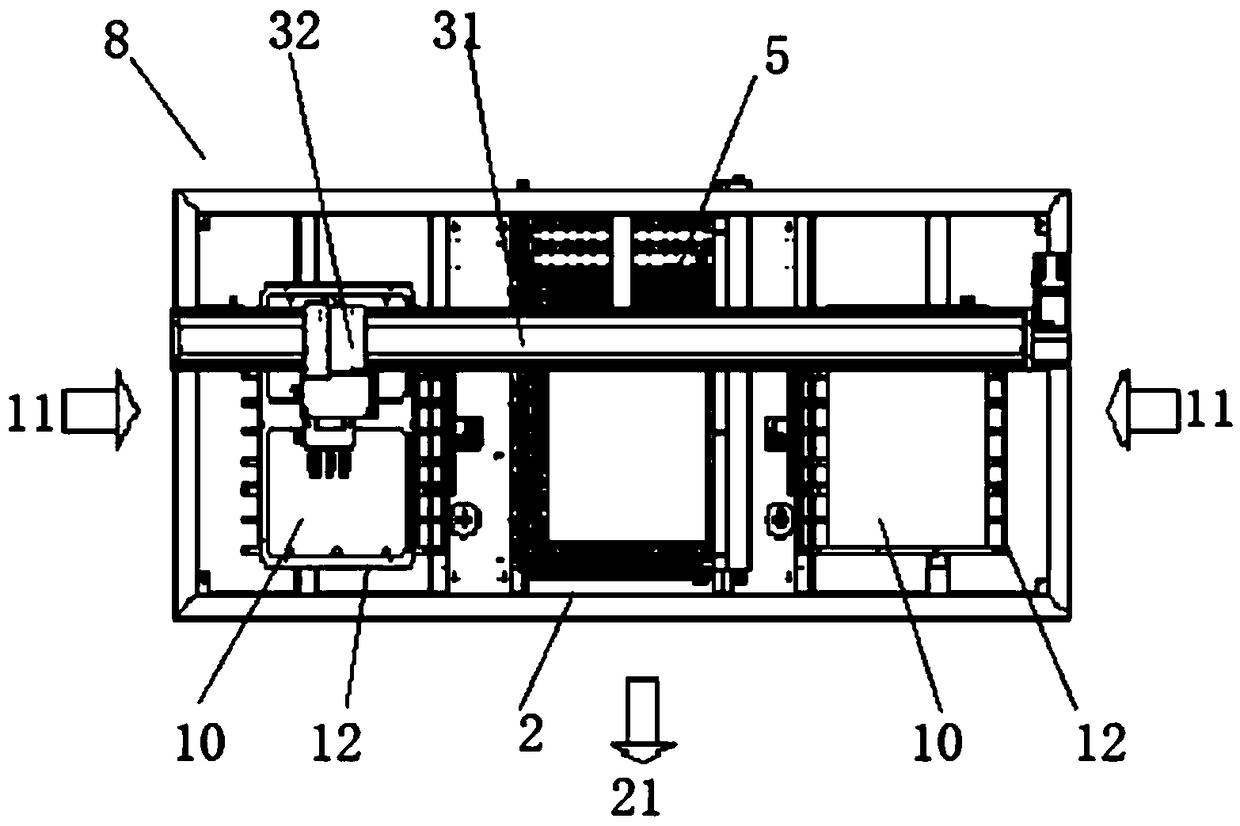

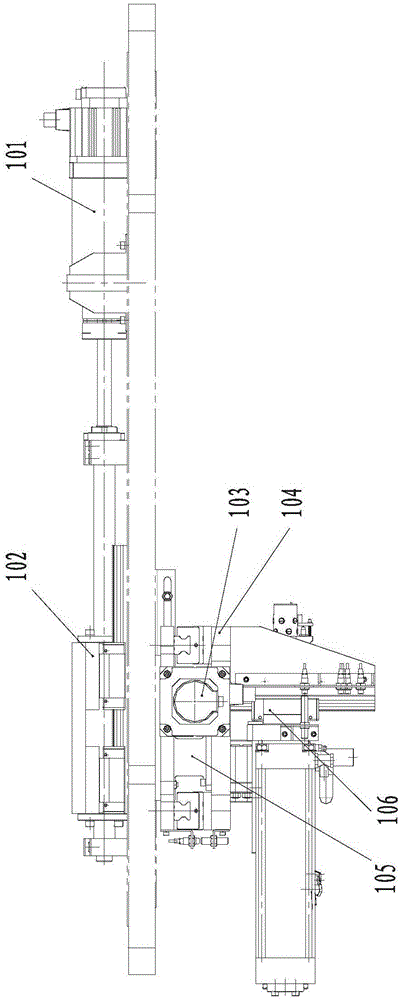

Integrated three-axis linked compound automatic pressing machine for adapter tubes

ActiveCN105583604ASolve mechanical effectsSolve take timeMetal working apparatusEngineeringPositioning system

The invention belongs to the technical field of automobile engine manufacturing, and particularly relates to an integrated three-axis linked compound automatic pressing machine for adapter tubes. The integrated three-axis linked compound automatic pressing machine comprises a machine body, and a horizontal positioning system and a vertical positioning system arranged on the machine body. The horizontal positioning system comprises an integrated three-axis positioning structure and a reverse thrust executing structure arranged on two sides of the machine body respectively. A pressing executing structure, corresponding to the reverse thrust executing structure, is arranged on the integrated three-axis positioning structure. The vertical positioning system comprises an upper limiting structure and a line body lifting structure, which are arranged at the top and bottom of the machine body respectively and correspond to each other. A workpiece to be pressed is placed on the line body lifting structure, and is lifted up by the line body lifting structure to be in contact with the upper limiting structure. The workpiece to be pressed is horizontally positioned by the integrated three-axis lined positioning structure and the reverse thrust executing structure. The integrated three-axis linked compound automatic pressing machine, provided by the invention, is a complete machine of which an integrated X, Y and Z space coordinates positioning device and a pressing mechanism work synchronously, is applicable to two straight adapter tubes and two special-shaped adapter tubes, and can complete compound pressing quickly and effectively.

Owner:中国科学院沈阳计算技术研究所有限公司

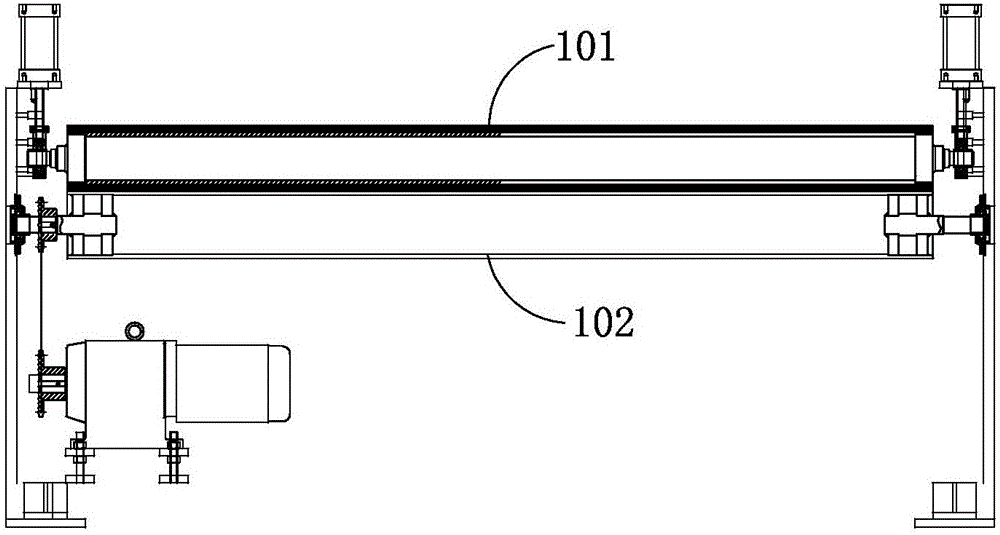

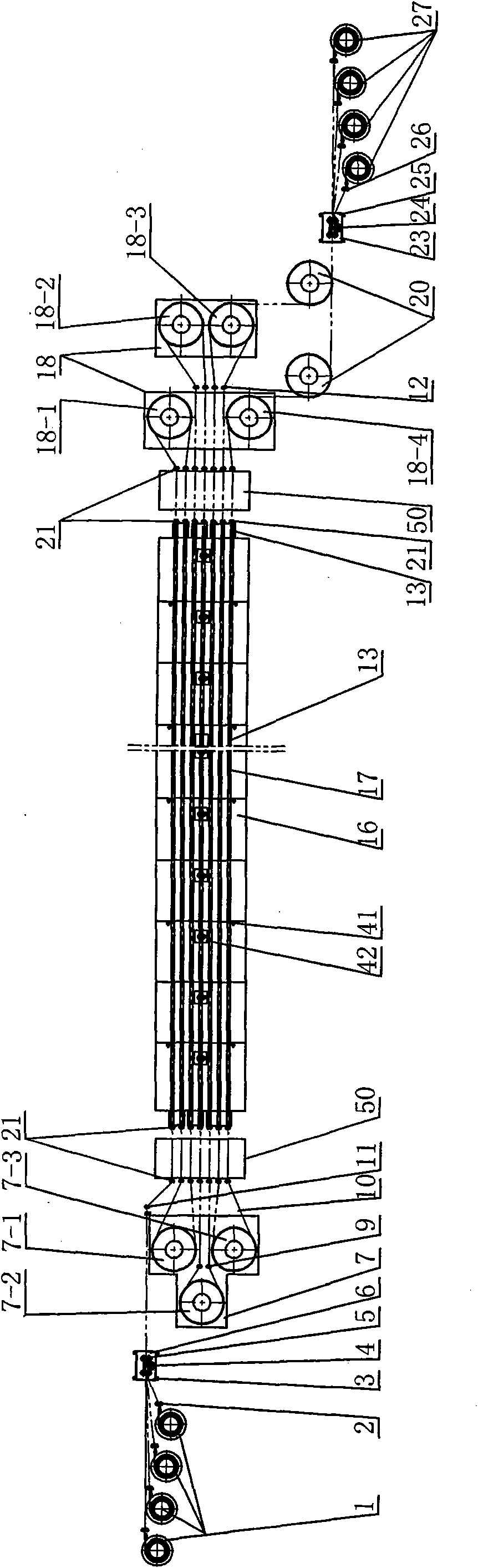

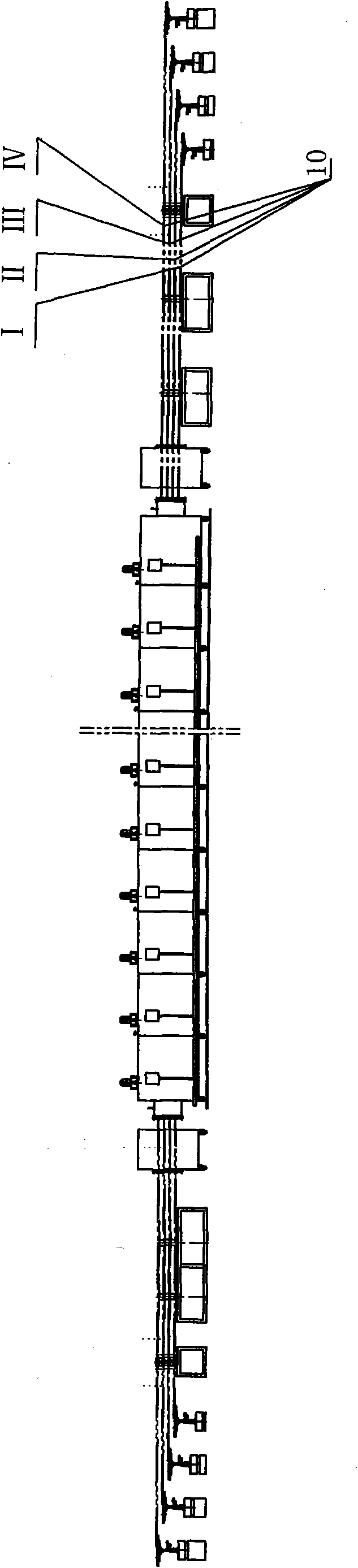

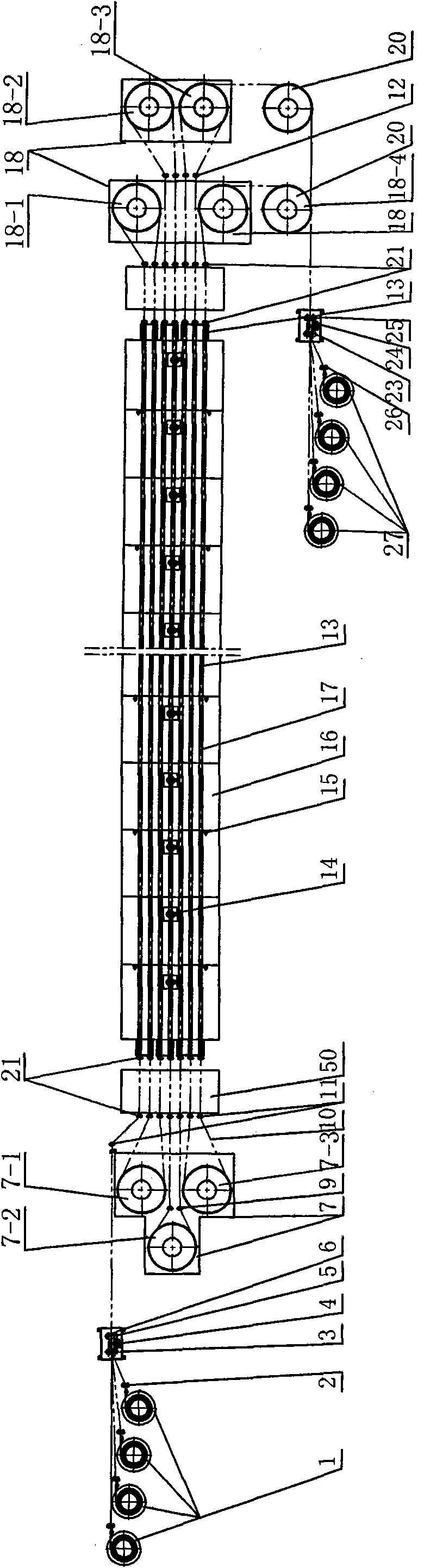

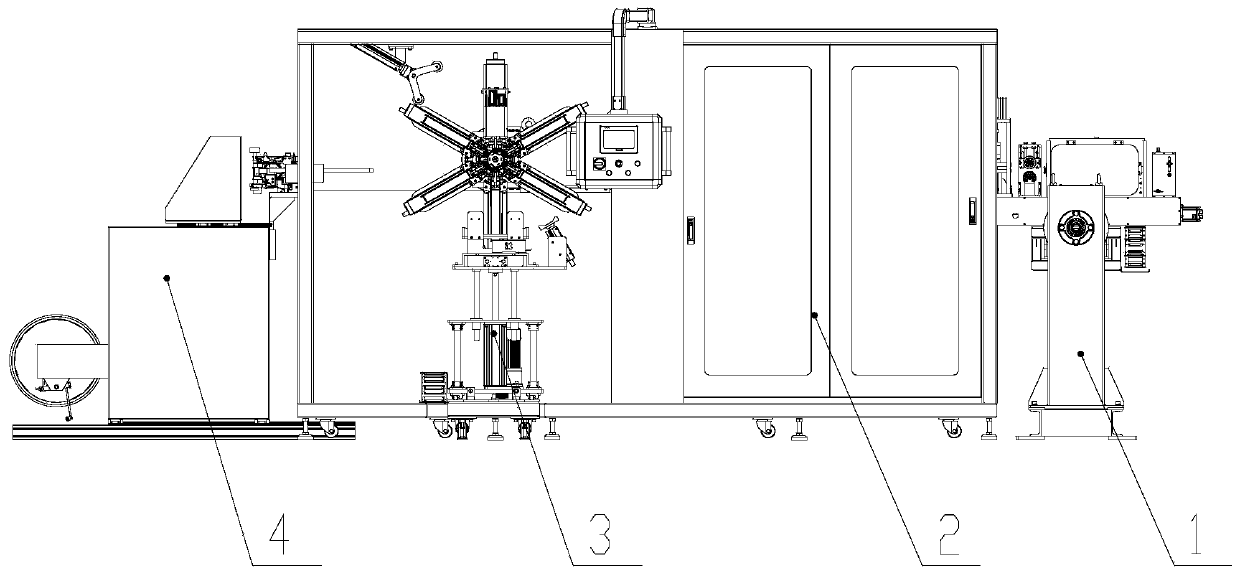

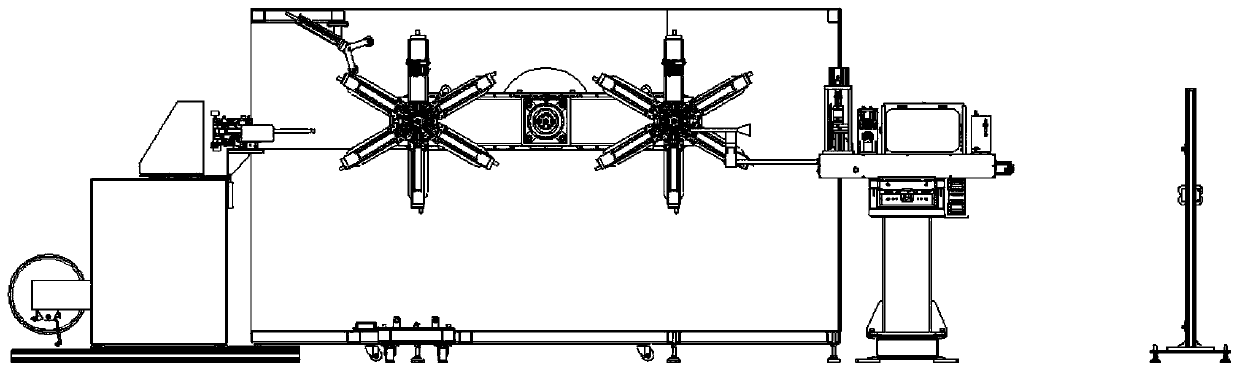

Online full-automatic tempering equipment and technology for same-furnace multi-strip bimetal strip saw

ActiveCN102002574ASolve the accuracy problemIncrease heating speedFurnace typesHeat treatment furnacesProduction lineHigh energy

The invention discloses online full-automatic tempering equipment and technology for a same-furnace multi-strip bimetal strip saw, and relates to tempering equipment and tempering technology. The invention solves the problems that the conventional tempering equipment and technology for the bimetal strip saw cannot finish the tempering technology on one production line at one time, the tempering technology has low production efficiency and high energy consumption and the like. The tempering equipment comprises a front rotating device, a box-type tempering furnace and a rear rotating device. The production efficiency of the saw is improved by 5 to 8 times, the energy consumption is greatly reduced, a great amount of energy is saved, the energy consumption of the box-type tempering furnace is reduced by over 60 percent compared with that of a bell-type tempering furnace or a well-type tempering furnace due to calculation, the occupancy area is reduced by over 90 percent, the problems that the bell-type tempering furnace or the well-type tempering furnace has non-uniform inner and outer temperature field and upper and lower temperature field, the bending stress of the saw is non-uniform, and the saw is easily upwarped are solved, repeated rewinding processes needed by the box-type tempering furnace or the well-type tempering furnace are canceled, and the problem of difficulty in controlling the saw tempering technology and quality and the problem of difficulty in maintaining the equipment are solved.

Owner:曹玉贵

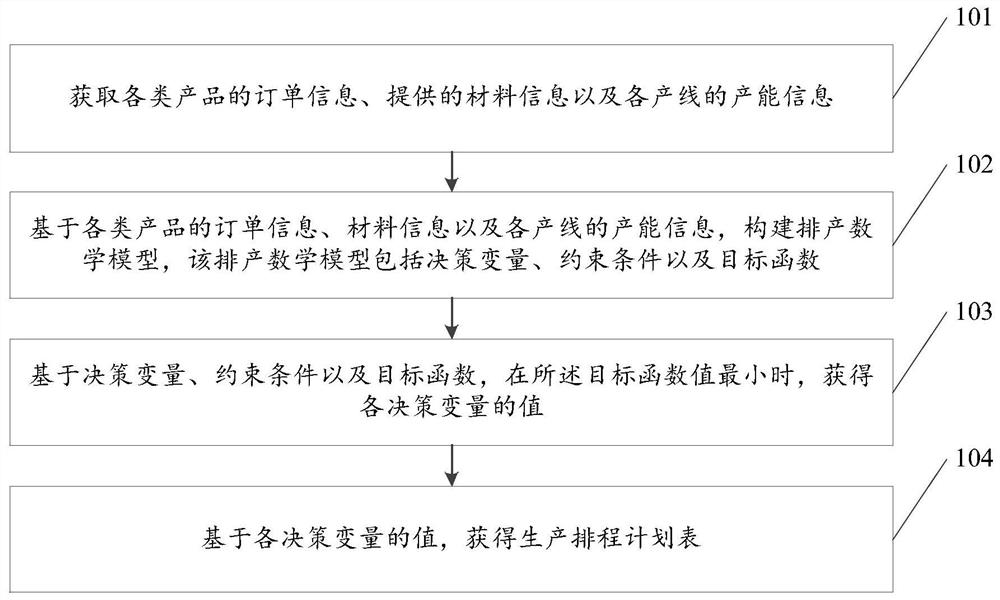

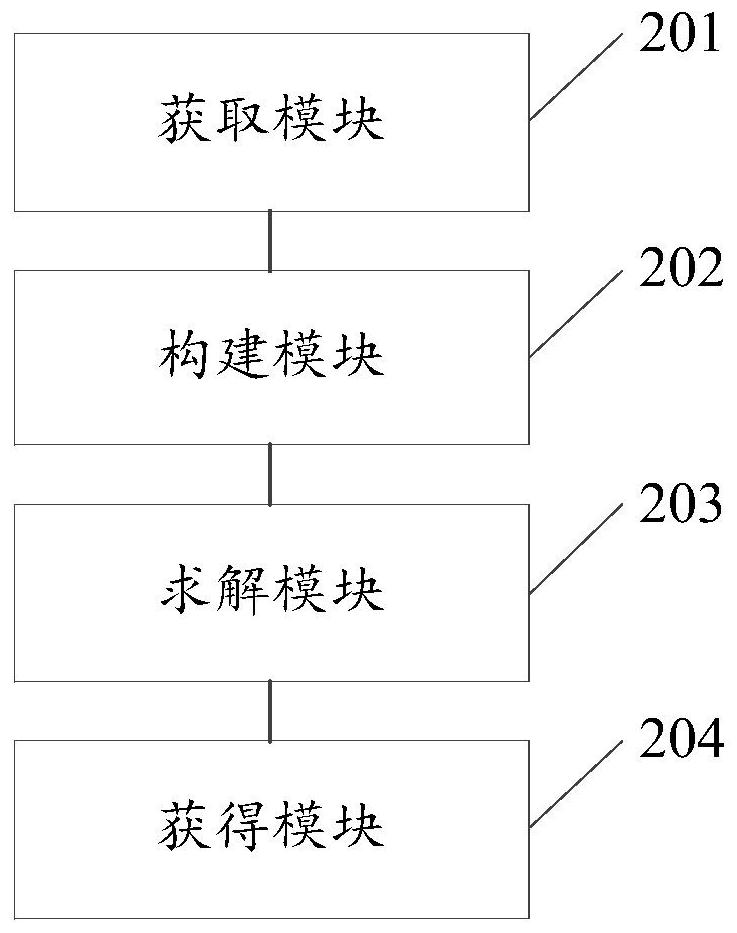

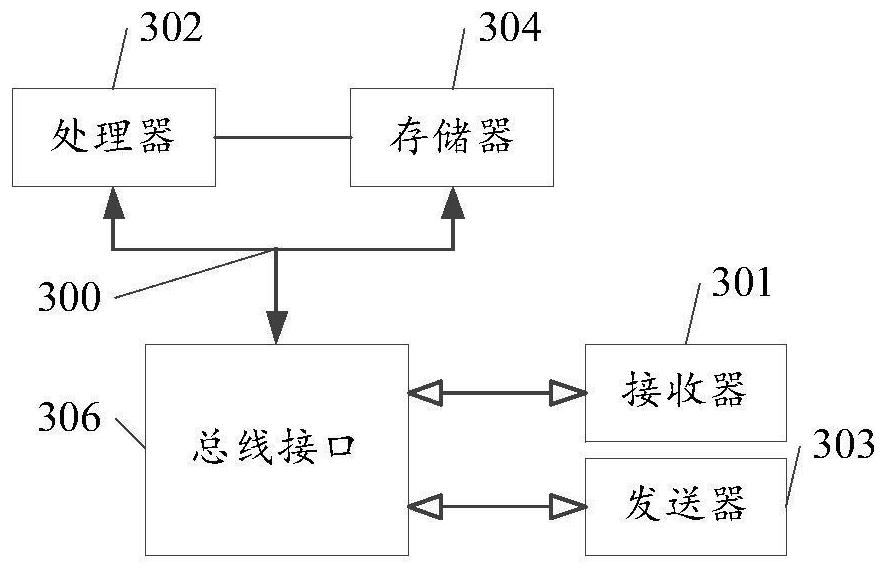

Method and device for scheduling production

InactiveCN112132546AImprove production line efficiencyForecastingOffice automationProduction scheduleProduction line

The invention belongs to the technical field of production scheduling, and relates to a method and device for scheduling production. The method comprises the steps that: the order information of various types of products, the information of materials needed by the production of the various types of products, and the capacity information of each production line are obtained; based on the order information of the various products, the material information and the capacity information of the production lines, a production scheduling mathematical model is constructed, wherein the production scheduling mathematical model comprises decision variables, constraint conditions and an objective function; based on the decision variables, the constraint conditions and the objective function, the valueof each decision variable is obtained when the objective function value is minimum; and based on the value of each decision variable, a production scheduling plan table is obtained, so that a production scheduling scheme can be quickly obtained, and the production line efficiency is improved.

Owner:杉数科技(北京)有限公司 +3

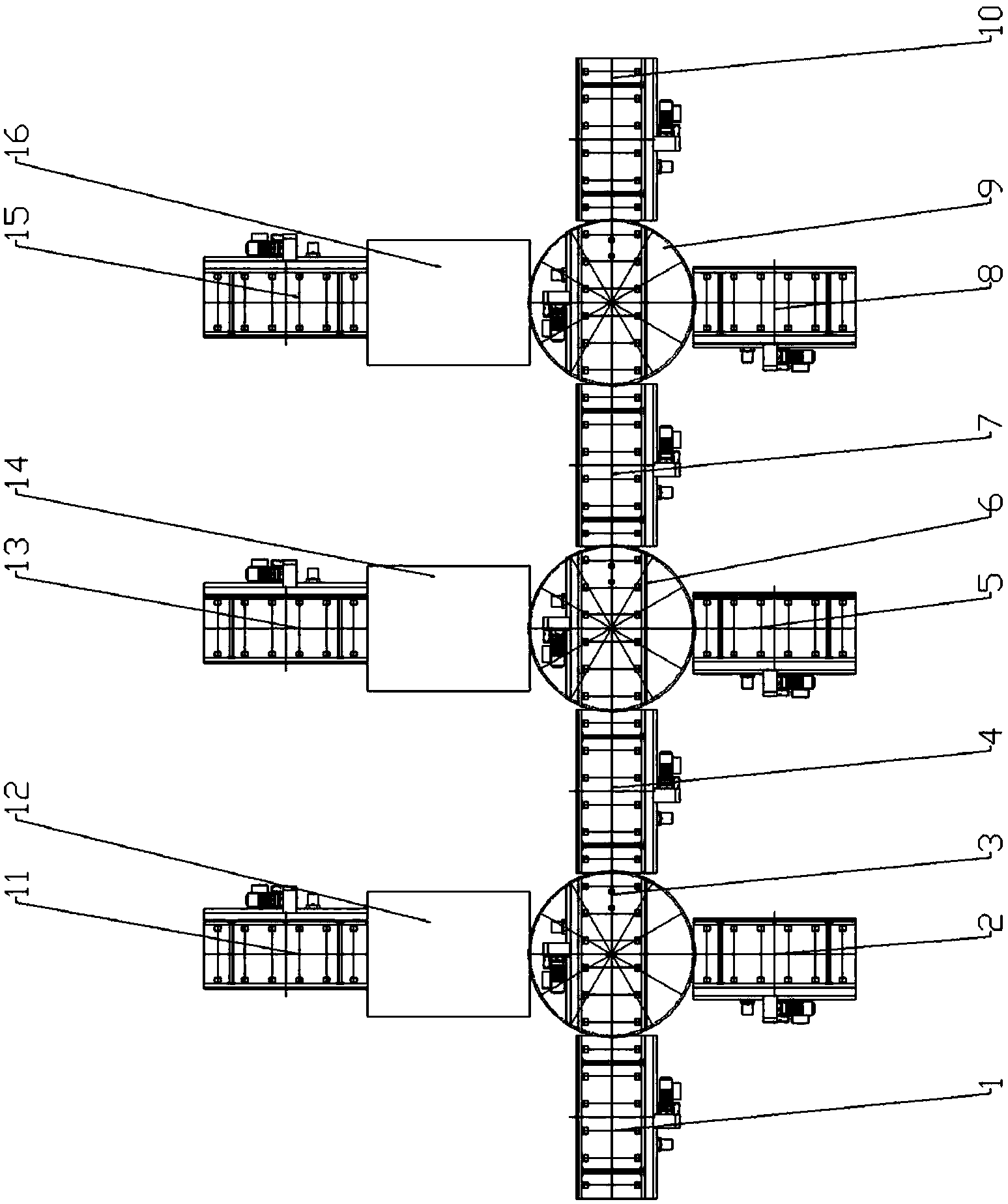

Complete machine leakage detection line for diesel engine

ActiveCN103935717ATimely online repairDoes not affect circulationMechanical conveyorsDiesel engineDiesel fuel

The invention relates to a detection line, in particular to a complete machine leakage detection line for a diesel engine and belongs to the technical field of engine assembly. The complete machine leakage detection line comprises a main line body, wherein a first rotary table, a second rotary table and a third rotary table are arranged on the main line body from left to right in sequence. A first storage section line body is arranged on one side of the first rotary table, and a first leakage detector and a first repair line body are arranged on the other side of the first rotary table. A second storage section line body is arranged on one side of the second rotary table, and a second leakage detector and a second repair line body are arranged on the other side of the second rotary table. A third storage section line body is arranged on one side of the third rotary table, and a third leakage detector and a third repair line body are arranged on the other side of the third rotary table. By means of the complete machine leakage detection line, takt requirements of complete machine leakage detection of the diesel engine can be met, production takt is not affected when online repair of the diesel engine can be performed, offline repair can be performed conveniently, and production efficiency and productivity are increased greatly.

Owner:CHINA FIRST AUTOMOBILE

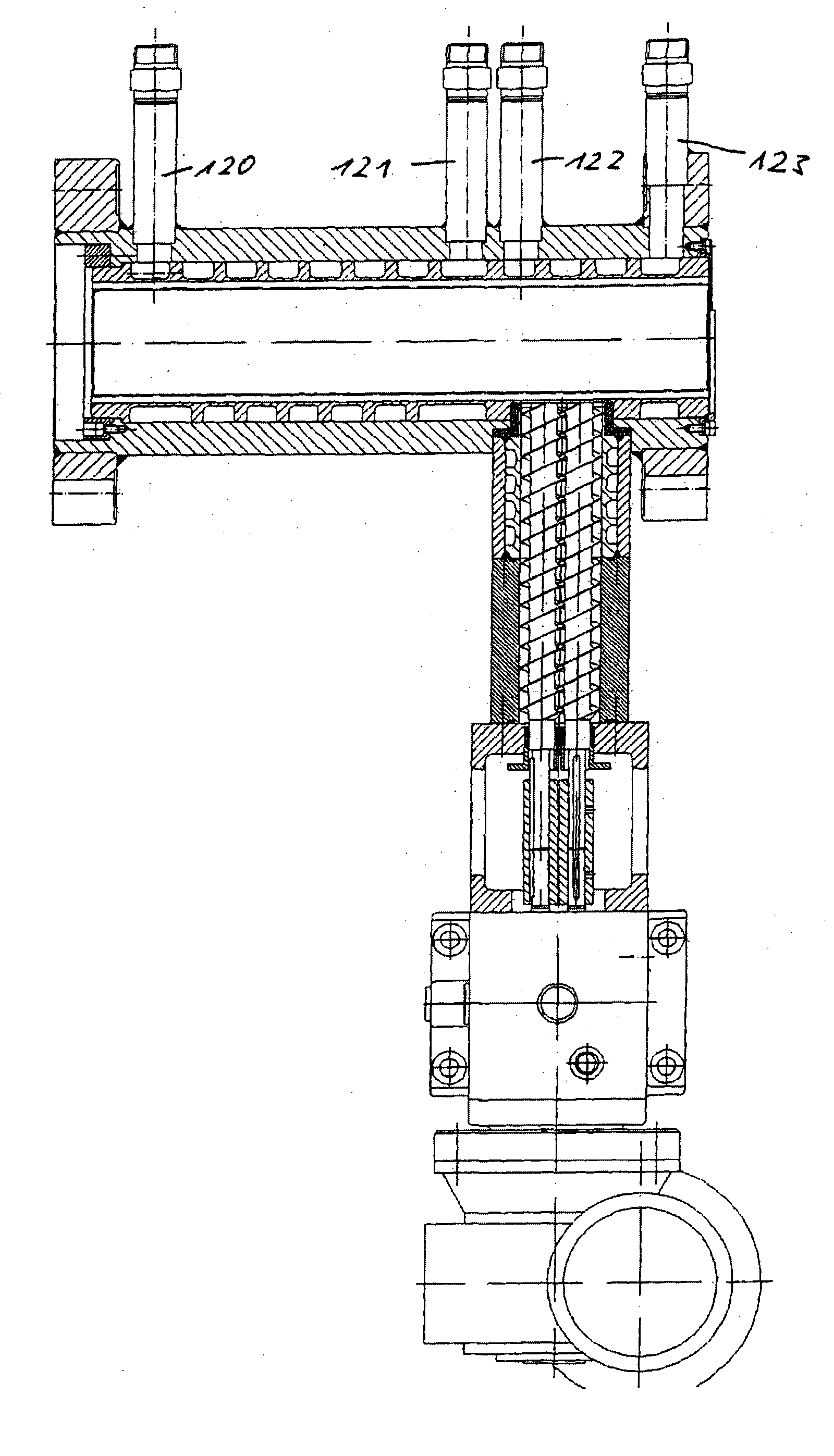

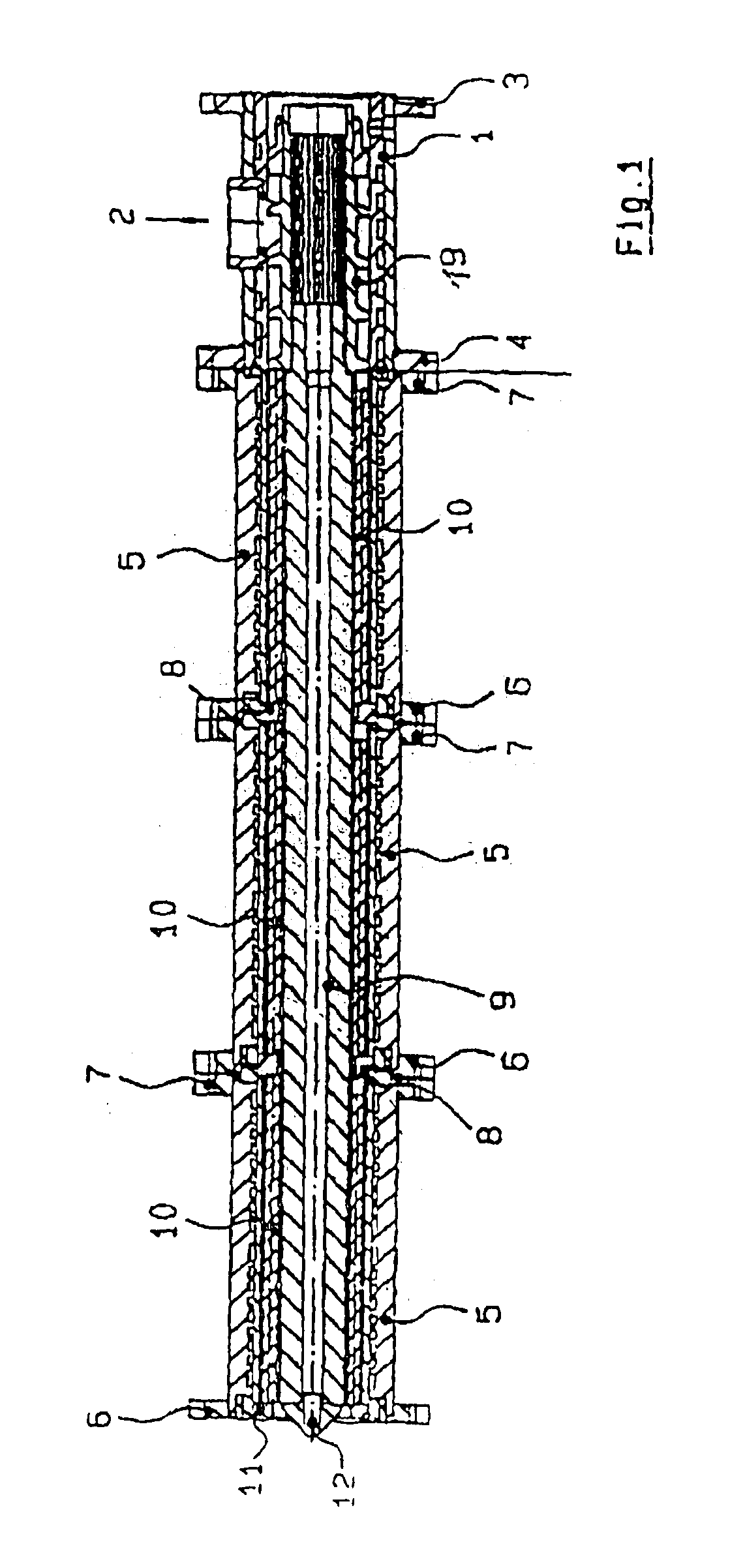

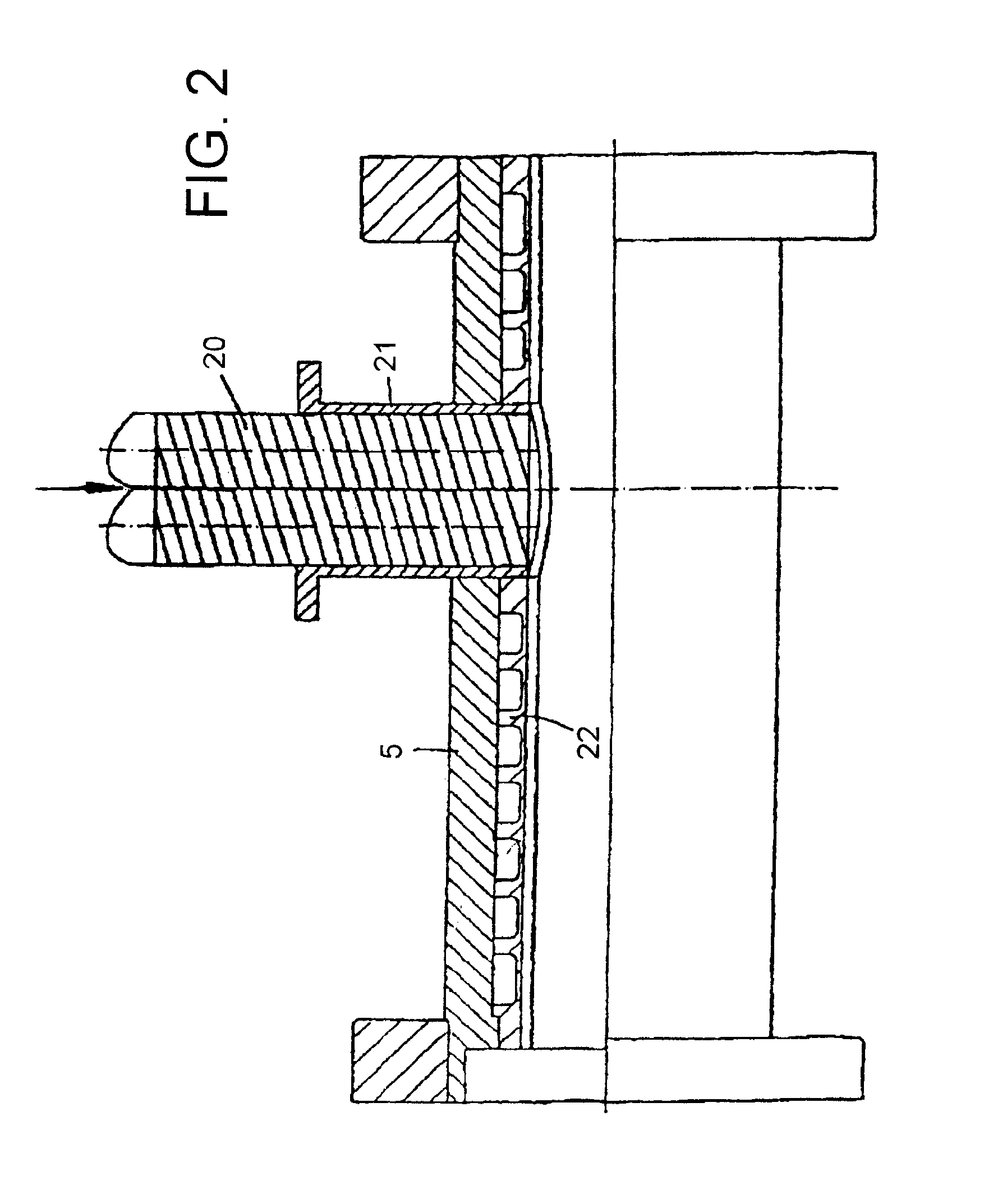

Blend of plastics with wood particles

Owner:ENTEX RUST & MITSCHKE +1

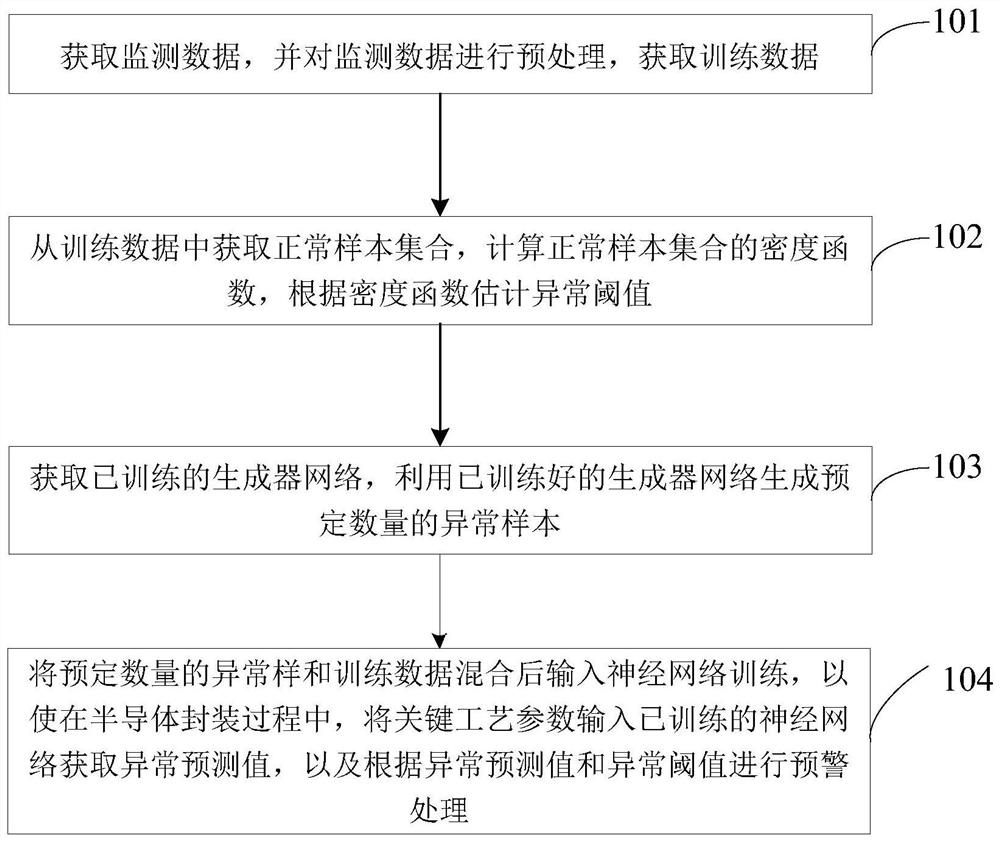

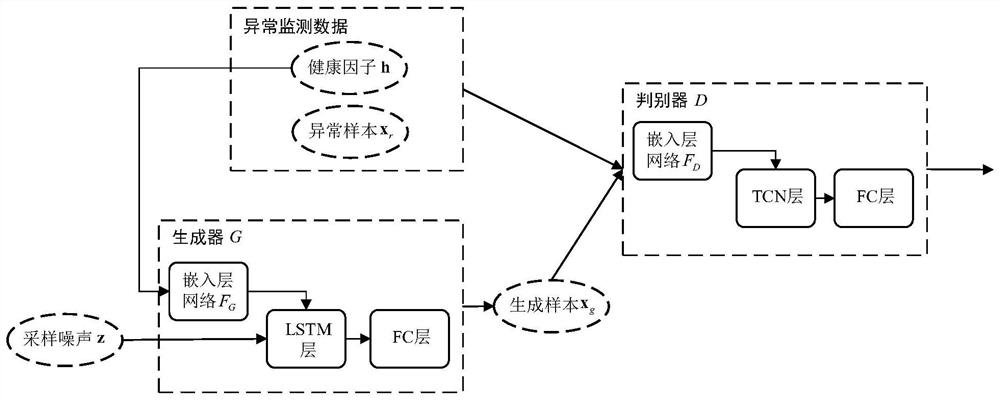

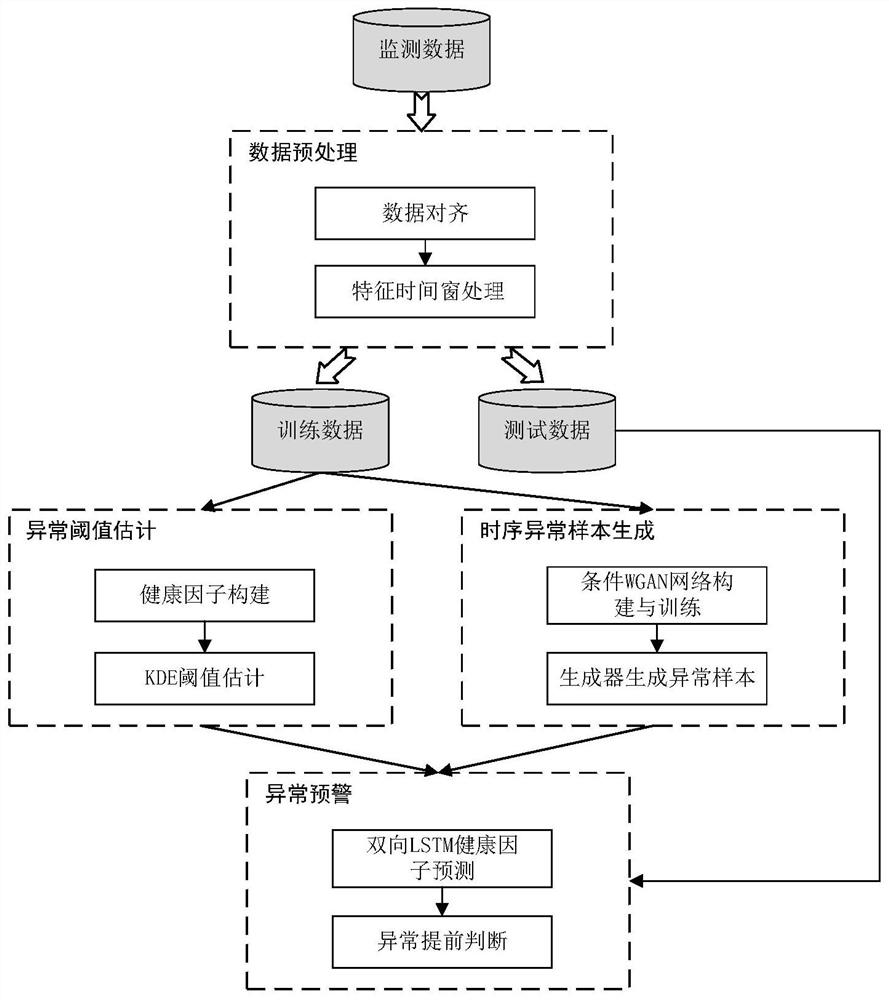

Semiconductor packaging process early warning method and device based on time sequence generative adversarial network

ActiveCN112581719ARealize intelligent maintenanceImprove yieldAlarmsNeural architecturesProduction lineNetwork generation

The invention provides a semiconductor packaging process early warning method and device based on a time sequence generative adversarial network, and relates to the technical field of data processing,and the method comprises the steps: obtaining monitoring data, carrying out the preprocessing of the monitoring data, and obtaining training data; obtaining a normal sample set from the training data, calculating a density function of the normal sample set, and estimating an abnormal threshold according to the density function; obtaining a trained generator network, and generating a predeterminednumber of abnormal samples by using the trained generator network; and mixing a predetermined number of abnormal samples and the training data and then inputting the mixed abnormal samples and the training data into a neural network for training, so that in the semiconductor packaging process, the key process parameters are input into the trained neural network to obtain an abnormal prediction value, and early warning processing is carried out according to the abnormal prediction value and an abnormal threshold value. Therefore, the abnormal samples are generated and mixed to the training data for training, the abnormal threshold value is determined to realize early warning of production abnormality in advance, and the product yield and the production line efficiency are improved.

Owner:TSINGHUA UNIV +1

Robot grinding system and grinding clamp thereof

PendingCN113183027AFast replacementAvoid waiting in lineGrinding wheel securing apparatusGrinding machinesProduction lineEconomic benefits

The invention discloses a robot grinding system and a grinding clamp thereof, and belongs to the technical field of grinding. The robot grinding system comprises a grinding table, and the top of the grinding table is connected with a mechanical arm and the grinding clamp; the end, away from the grinding table, of the mechanical arm is connected with a rotating plate, and the outer wall of the rotating plate is connected with a working plate; the two sides of the outer wall of the working plate are connected with a first side plate and a second side plate separately, and the outer wall of the working plate is connected with a stroke plate through a connecting rod; a rail slot is formed in the outer wall of the stroke plate, and a movable rod is connected with the inner wall of the rail slot movably; a connecting plate is connected to the outer wall of the movable rod; a fixing rod is connected to the outer wall of the connecting plate; a fixing base is connected to one end, far away from the connecting plate, of the fixing rod; and a motor is connected to the outer wall of the fixing base. According to the robot grinding system, the replacement speed between grinding wheels can be increased, and it is ensured that normal grinding operation cannot be affected by the replacement operation of the grinding wheels; and the situation that an assembly line stops for waiting due to replacement of the grinding wheels is avoided, and the efficiency and economic benefits of a production line can be improved.

Owner:安徽精翔自动化科技有限公司

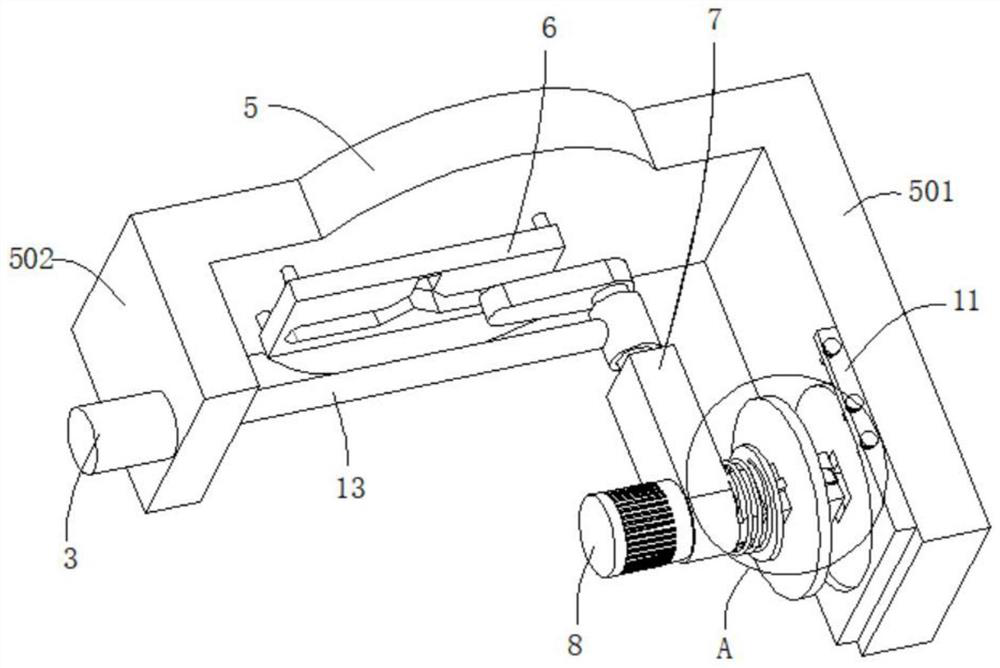

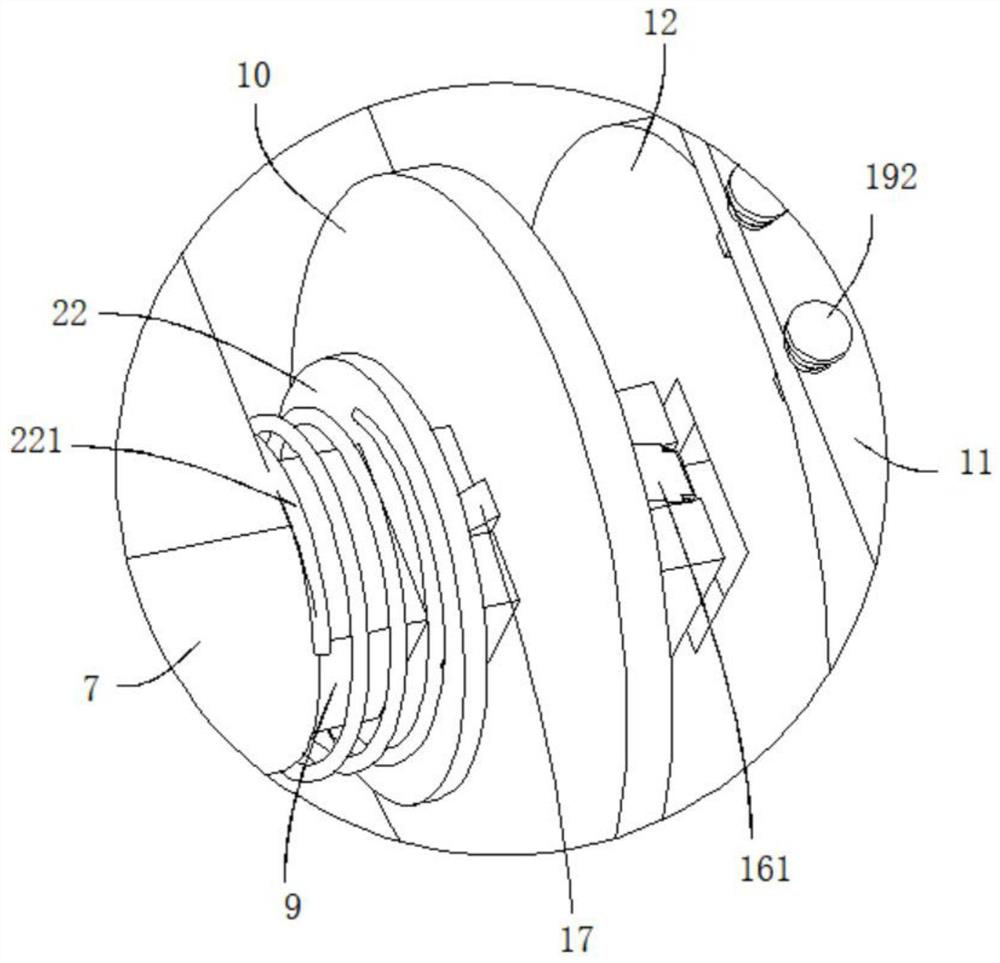

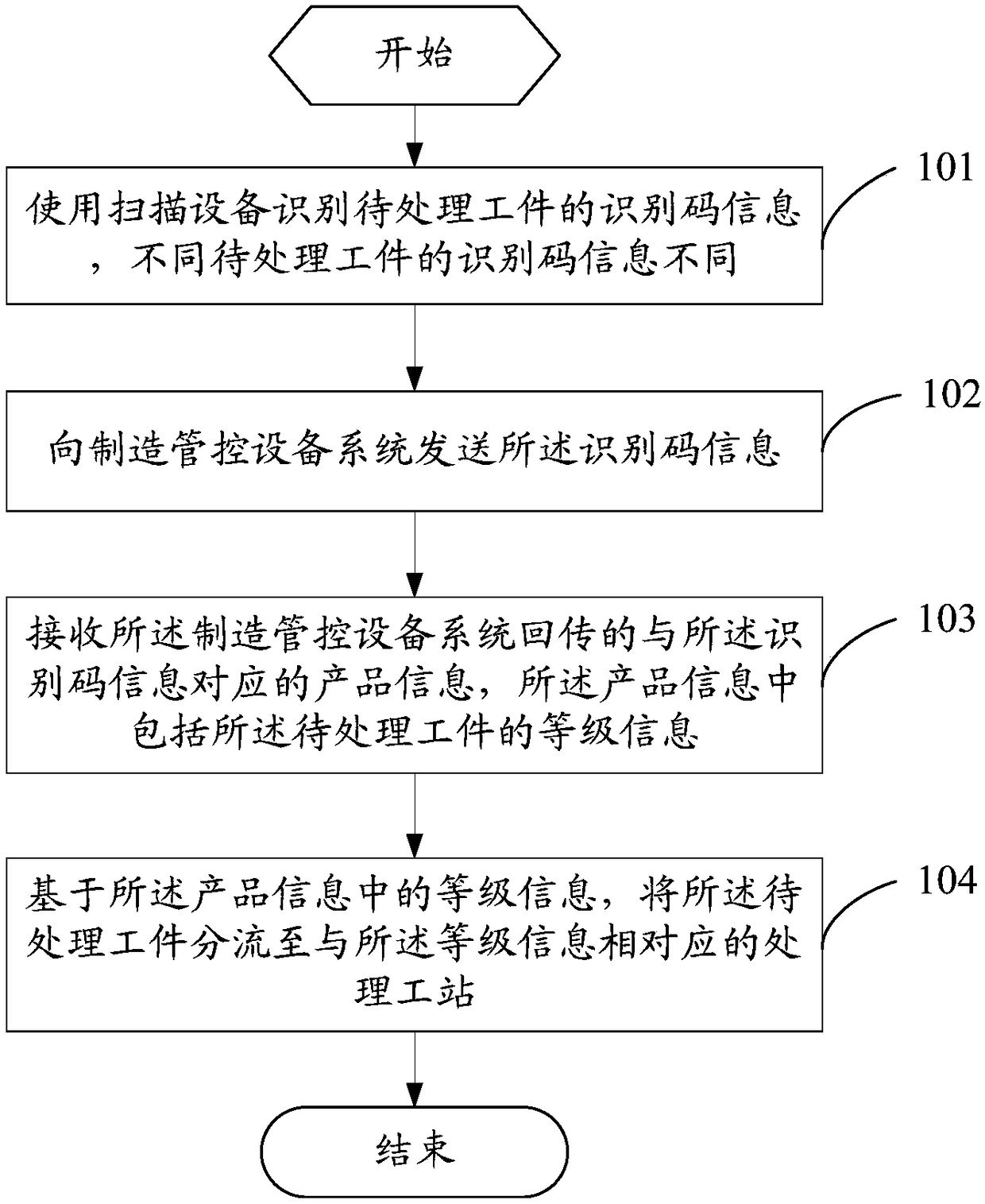

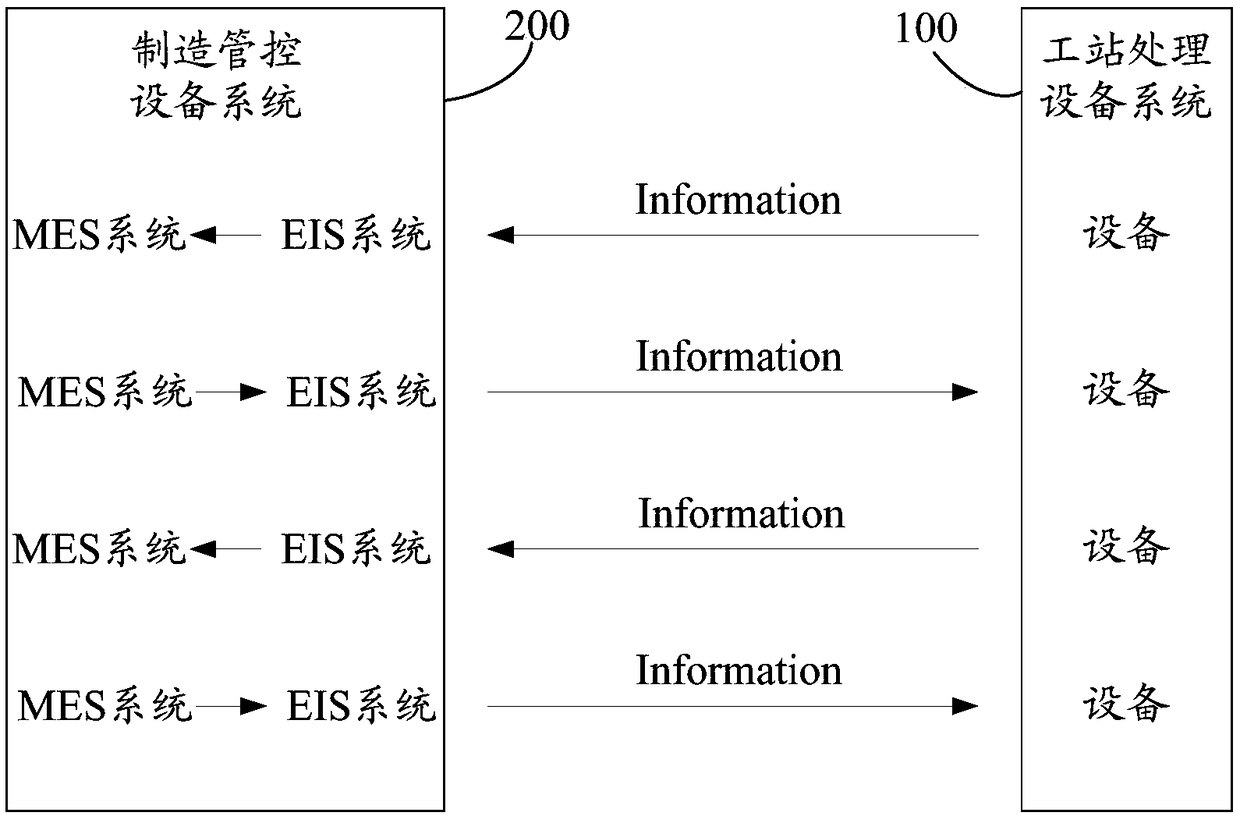

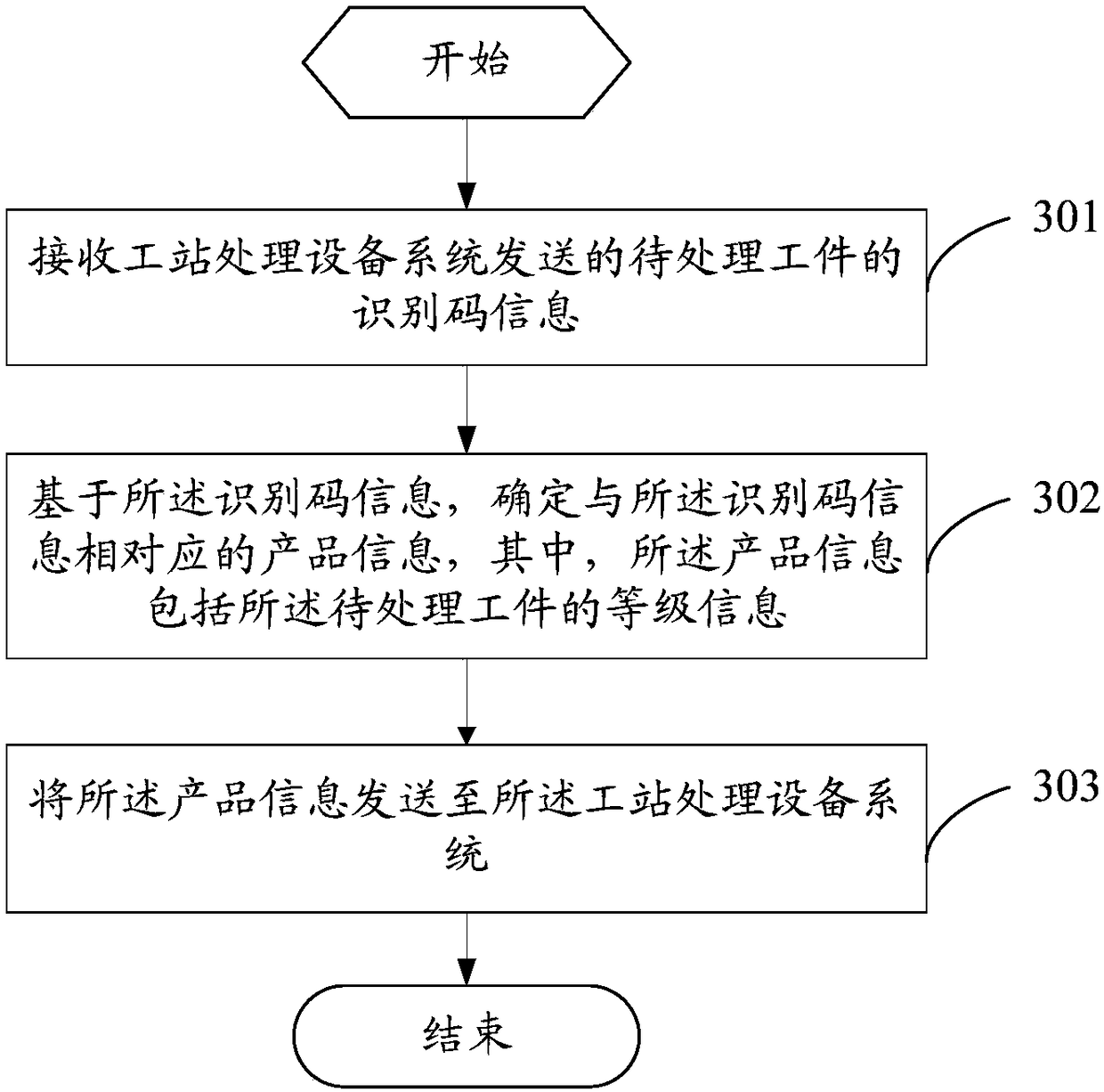

Production management and control method, workstation processing equipment system, and manufacture management and control equipment system

PendingCN108171448ASave human effortImprove production line efficiencyCo-operative working arrangementsResourcesAutomatic processingControl equipment

The invention provides a production management and control method, a workstation processing equipment system, and a manufacture management and control equipment system. The production management and control method, the workstation processing equipment system, and the manufacture management and control equipment system are characterized in that through automatic communication between the workstation processing equipment system and the manufacture management and control equipment system, detection, identification, packaging or piling and other processing processes of an automatic processing production line can be realized; a lot of labor can be saved; the production line efficiency can be effectively improved; automatic identification processing can be realized; the probability of making errors by manual operation can be reduced; and improvement of the product yield rate can be improved.

Owner:BOE TECH GRP CO LTD +1

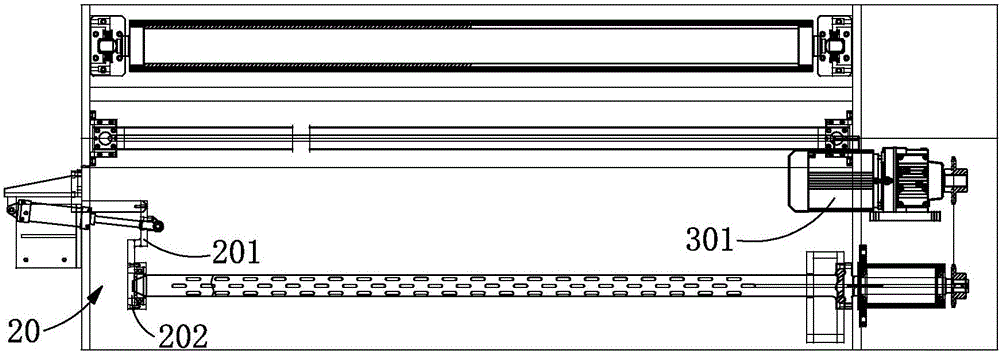

Universal fully-automatic pipe reeling and unloading machine for PE and PERT pipes

ActiveCN110980429AAvoid bending tube deformationHigh speedFilament handlingBundling machine detailsControl engineeringElectric machinery

The invention provides a universal fully-automatic pipe reeling and unloading machine for PE and PERT pipes. The universal fully-automatic pipe reeling and unloading machine comprises a pipe guiding machine, a pipe reeling machine and an unreeling machine; the pipe guiding machine can convey the pipes to the pipe reeling machine; the pipe reeling machine comprises a first pipe reeling disc, a second pipe reeling disc, a pipe reeling machine main transmission mechanism for driving the first pipe reeling disc and the second pipe reeling disc, and a reel pressing assembly; the unreeling machine comprises an unreeling vehicle, a driving travelling motor, a longitudinal air cylinder, an unreeling supporting V-shaped block, a transverse air cylinder and a lateral air cylinder, the unreeling vehicle is driven by the driving traveling motor, the longitudinal air cylinder can jack the unreeling supporting V-shaped block and then jacks a material coil on the pipe reeling machine, the transverseair cylinder can clamp the material coil, and the lateral air cylinder can push the material coil out; and the unreeling vehicle retreats to achieve automatic unreeling. The pipe reeling and unloadingmachine has the functions of automatic pipe arranging, double-station pipe coiling, accurate pipe guiding, wrapping through a wrapping machine and automatic uncoiling, and the problem of reeled pipecreases existing in an existing pipe reeling machine for the pipes can further be effectively solved by adopting the machine.

Owner:大连春禾智能科技有限公司

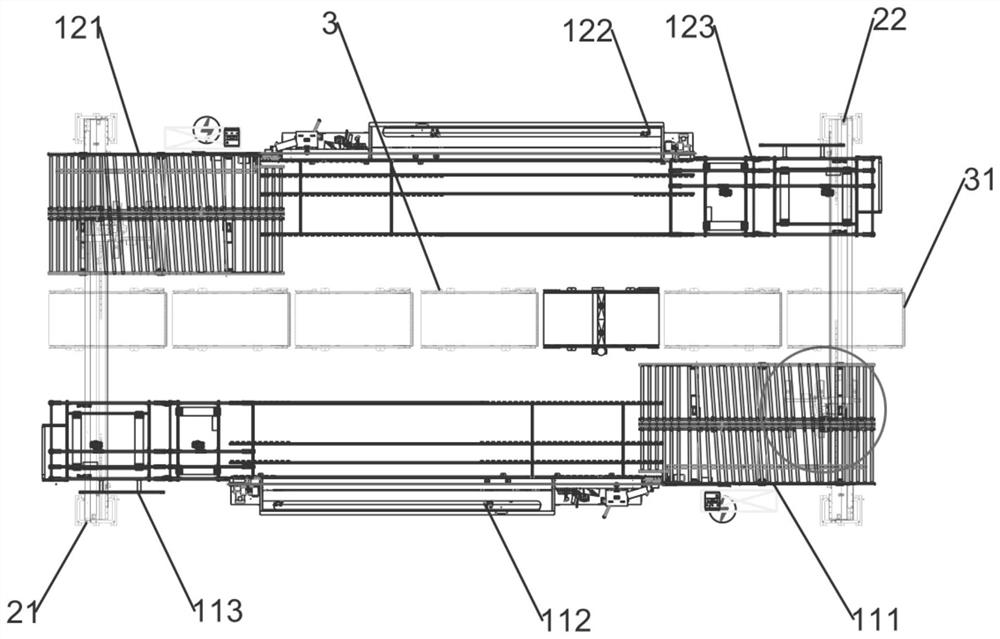

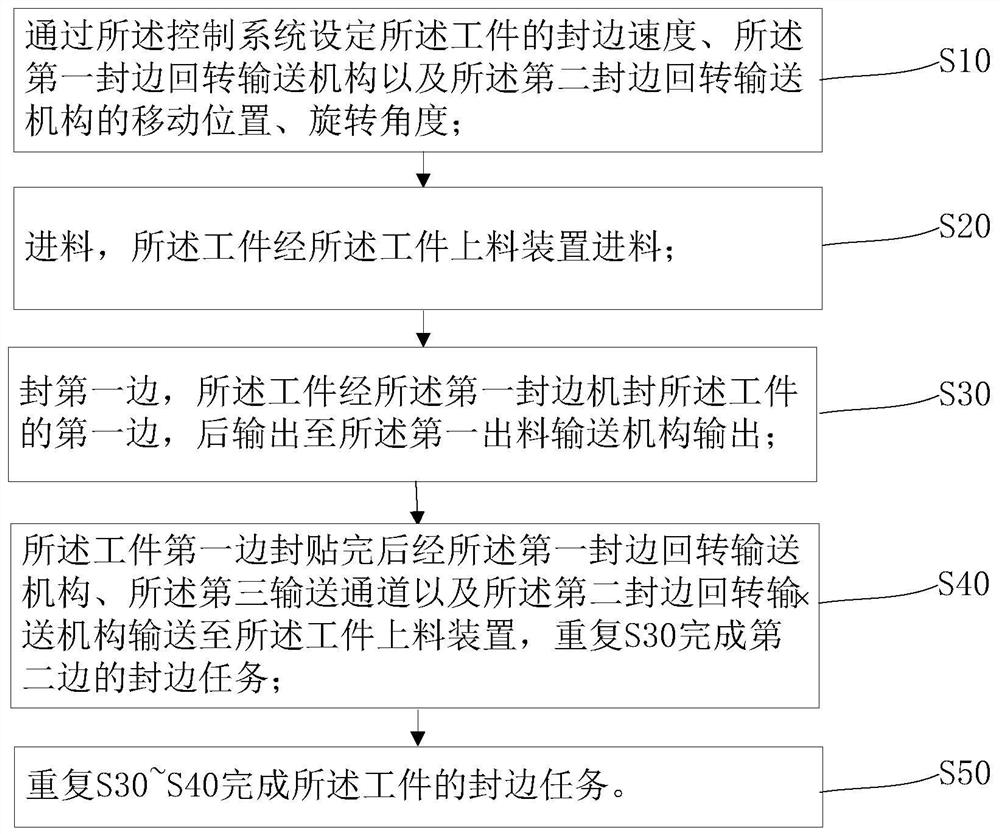

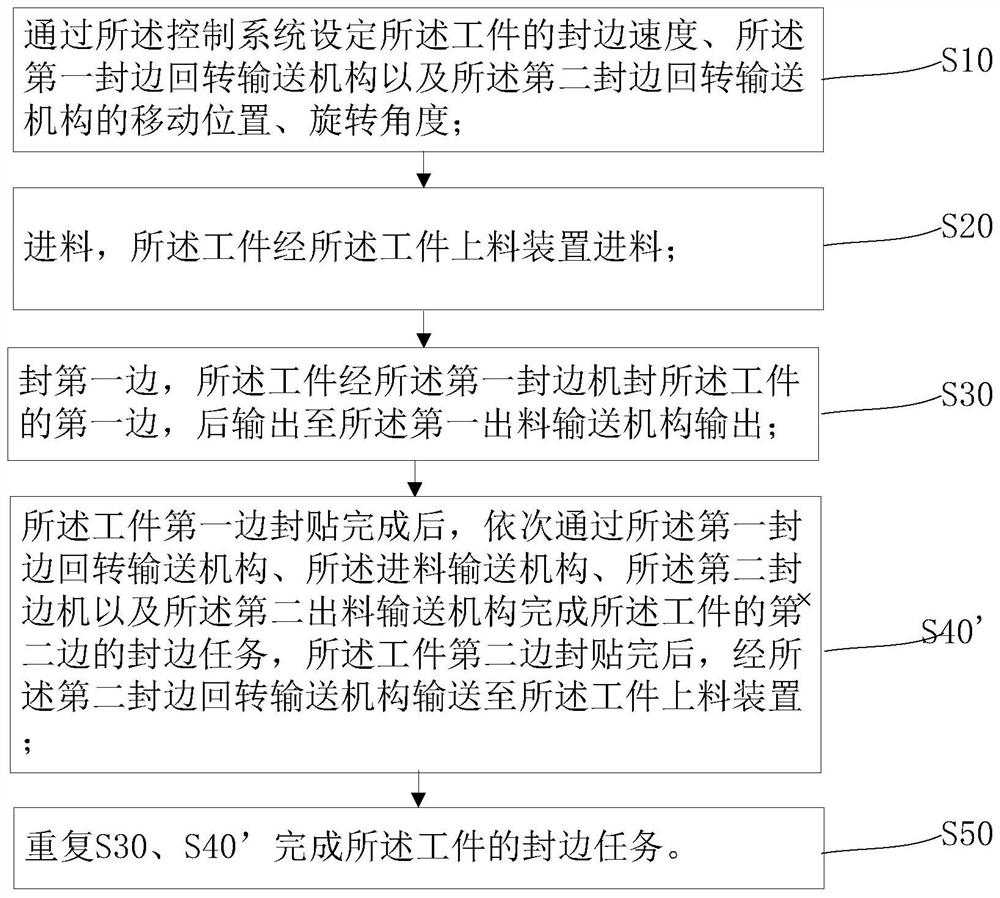

Alternately complementary edge sealing cycle device and edge sealing method based on same

ActiveCN111941583AReduce the number of revolutionsIncrease flexibilityWood working apparatusDomestic articlesStructural engineeringMechanical engineering

The invention provides an alternately complementary edge sealing cycle device and an edge sealing method based on the same. The device comprises edge sealing channels, a first edge sealing rotary conveying mechanism, a second edge sealing rotary conveying mechanism and a third conveying channel, wherein the edge sealing channels comprise a first edge sealing channel and a second edge sealing channel, the output end of the first edge sealing channel is connected to the input end of the second edge sealing channel, the output end of the second edge sealing channel is connected to the input channel of a first edge sealing machine, the third conveying channel is arranged between the first edge sealing channel and the second edge sealing channel, and the third conveying channel is parallel to the first edge sealing channel and the second edge sealing channel. According to the double-channel rapid edge sealing cycle device and the edge sealing method, the double-channel rapid edge sealing cycle device is formed by splicing two independent workpiece edge sealing machines, the third conveying channel is arranged between the two edge sealing machines to form a series-parallel connection structure of the two edge sealing machines, so that the two independent edge sealing machines can be independently used and can also be connected in series for cyclic use, and an edge sealing scheme is added.

Owner:NANTONG YUETONG CNC EQUIP CO LTD

Electroluminescence display device

ActiveUS7742023B2Optimizes the layout of linesImprove production line efficiencyElectroluminescent light sourcesSolid-state devicesDriver circuitDriving current

In an electroluminescence display device having, on a display panel, a display portion in which pixels are arranged in matrix, an external connection terminal is placed along a lateral side of the display panel and a vertical scan driver circuit is placed on a lateral side of the display panel which opposes the lateral side on which the external connection terminal is placed. Lines for a horizontal scan driver circuit and for the vertical scan driver circuit can be provided only on three sides of the display panel including the side on which the external connection terminal is provided, a side opposing this side, and another side. By not placing the line for the driver circuits on the remaining side, spaces can be secured on this side for a drive current line which supplies power to an electroluminescence element. With this structure, a size of a frame portion can be reduced while securing sufficient width for the drive current common line.

Owner:SANYO ELECTRIC CO LTD

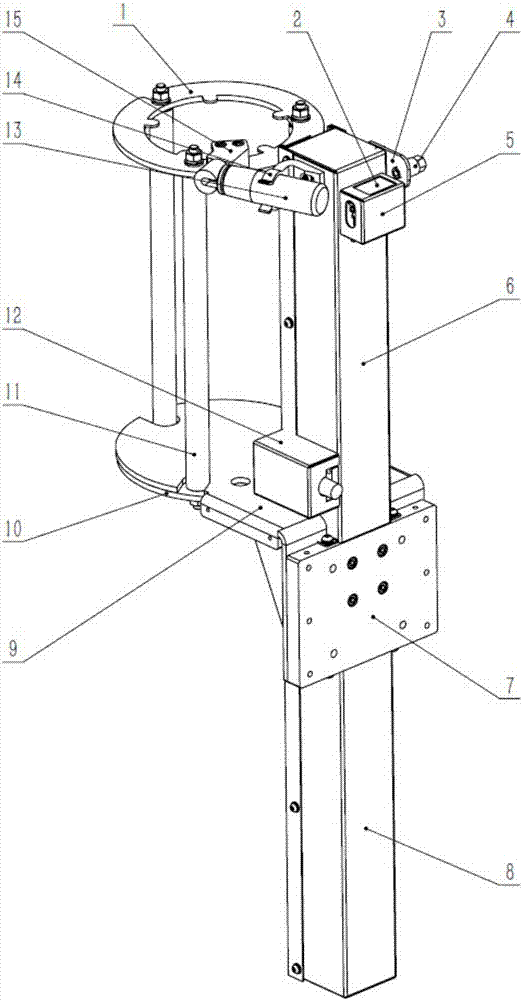

Solar panel observation station

InactiveCN104009115AMeet ergonomic requirementsReduce labor intensityPhotovoltaic supportsPhotovoltaic monitoringProduction lineTurnover time

A solar panel observation station relates to the technical field of solar panel visual inspection. Synchronous belt assemblies are symmetrically arranged on the two sides of the upper part of a body, and the synchronous belt assembly on one side is connected with a motor. A turnover mechanism is arranged between the two synchronous belt assemblies. The lower end of the turnover mechanism is uniformly equipped with a plurality of vacuum chucks. The bottom of the body is equipped with a vacuum pump and an electric control box. The vacuum pump is respectively connected with the electric control box and the vacuum chucks. The electric control box is connected with the motor. The design structure is more in line with the requirements of ergonomics, the requirement of an entire assembly line for the production cycle can be met, a panel can be turned to a position and an angle for easy observation by inspectors, the labor intensity is reduced, the turnover time can be effectively controlled, the production cycle is shortened, and the efficiency of the production line can be improved.

Owner:REIS ROBOTICS KUSN

White oil production line

ActiveCN107267210AImprove production line efficiencyReasonable structural designTreatment with hydrotreatment processesProduction lineHydrogenation reaction

The invention discloses a white oil production line. The white oil production line comprises a filtering storage tank and a hydrogenation reaction vessel; the filtering storage tank comprises a filtering storage tank body (21), a double-layer tapered filter screen (22), a filter screen support (23), and a filter screen lifting device; the top of the filtering storage tank body (21) is provided with an oil inlet, and the bottom is provided with an oil outlet; a hollow guide rod (24) is vertically arranged in the filtering storage tank body (21); the rod wall of the hollow guide rod is provided with a pair of slot holes symmetrically; and the hollow guide rod (4) is sleeved with a telescopic pipe (25). The advantages are that: structure design is reasonable; slow filtering of white oil can be realized in storage process; filtering is fine; filtering in applications of white oil is avoided; working efficiency is increased; the adding amount of a catalyst is controlled automatically and accurately using a flow valve; the catalyst is added in a manner of uniform distribution on the top, so that full contact of the catalyst with tail oil and hydrogen is realized, and tail oil reaction fission process is accelerated.

Owner:湖北维佳科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com