Universal fully-automatic pipe reeling and unloading machine for PE and PERT pipes

A fully automatic, unloader technology, applied in the direction of conveying filamentous materials, thin material handling, parts of bundling machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

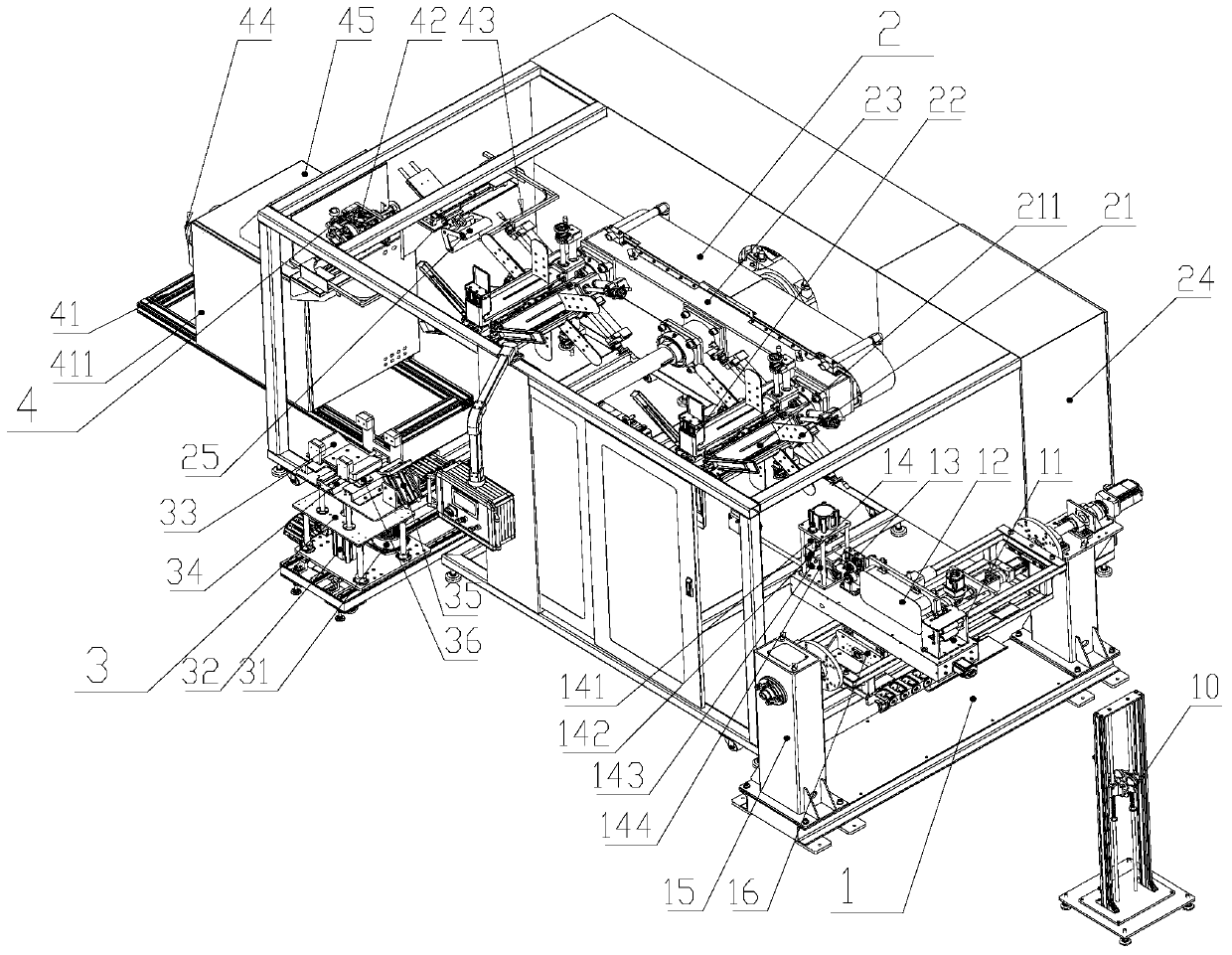

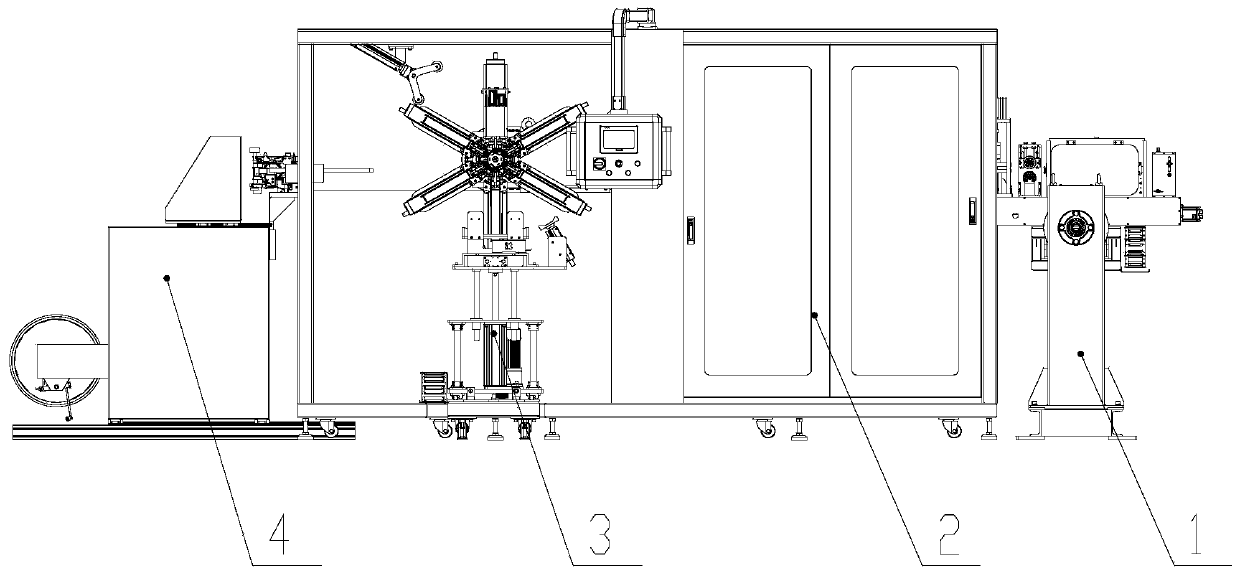

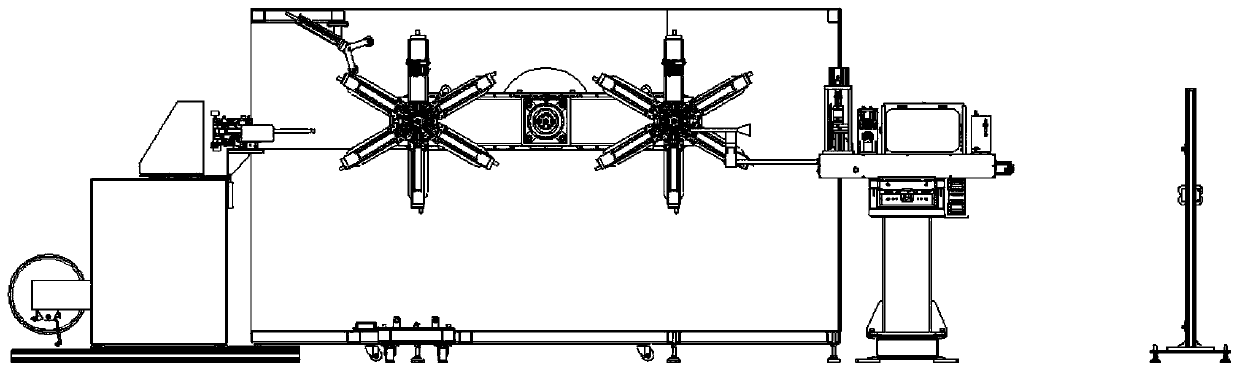

[0067] This embodiment discloses a general-purpose automatic coiling and unloading machine for PE and PERT pipes. For its structure, please refer to the attached Figure 1-19 As shown, it includes: a pipe introduction machine 1, a pipe coiler 2, an uncoiler 3 and a packing machine 4, and the pipe introduction machine 1, the pipe coiling machine 2 and the packing machine 4 are arranged in sequence.

[0068] The pipe introduction machine in this embodiment is suitable for small pipes with a pipe diameter of 16 to 32mm, and has higher precision and more neat and compact pipe arrangement. The following will combine Figure 6 to Figure 10 Specifically explain the various components and working principles of the pipe introduction machine.

[0069] as attached Figure 6 As shown, the pipe introduction machine of this embodiment includes: a tension controller 10, a guide mechanism 11, a traction mechanism 12, a speed measuring mechanism 13, a pipe cutting mechanism 14, a displacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com