Universal automatic coiling and unloading machine for pe and pert pipes

A fully automatic and unloading machine technology, which is applied in the direction of conveying filamentous materials, thin material processing, and parts of bundling machinery, and can solve problems such as coiled tube creases and folded tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

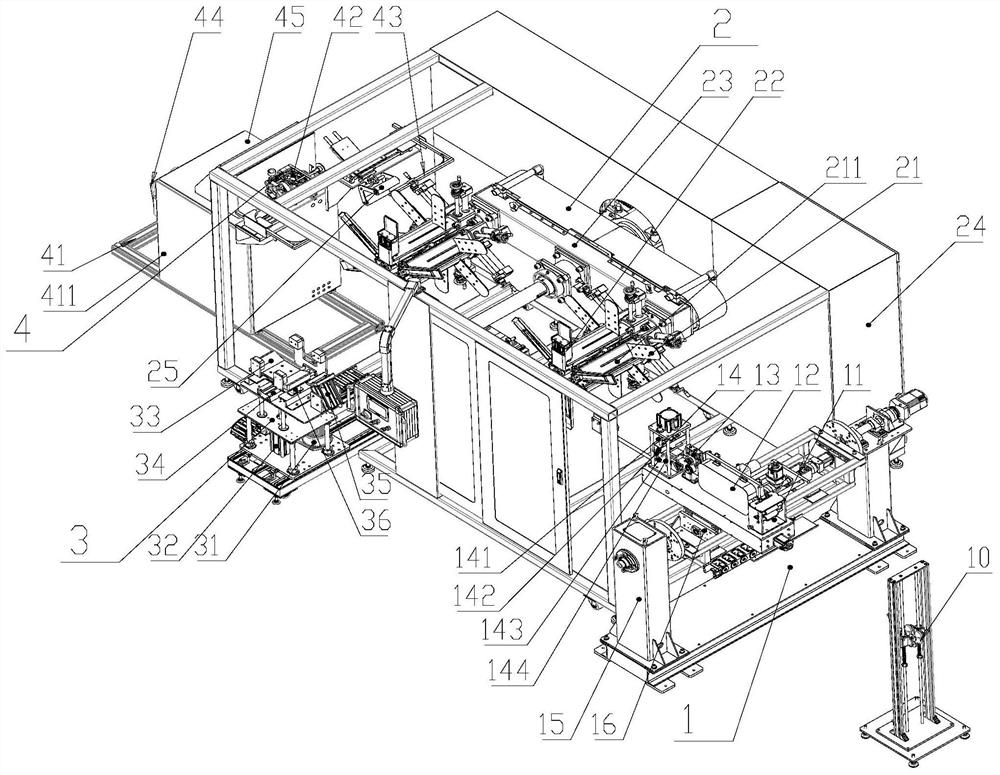

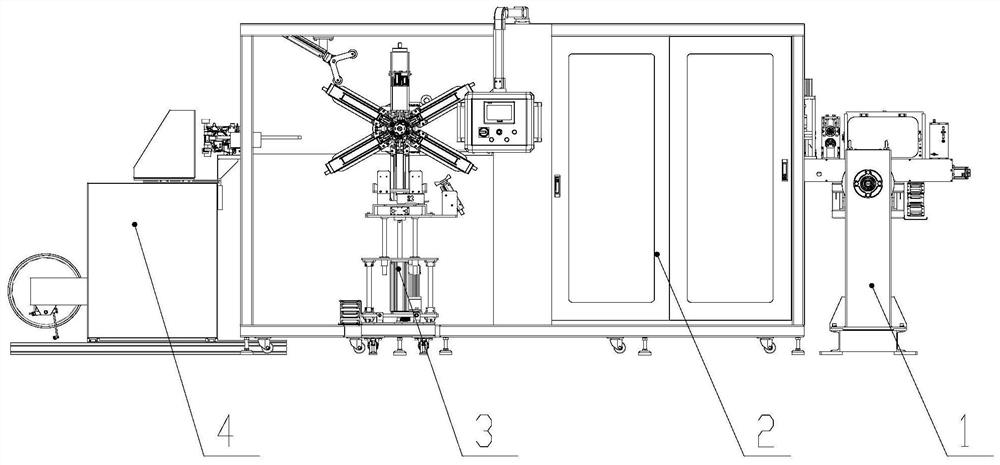

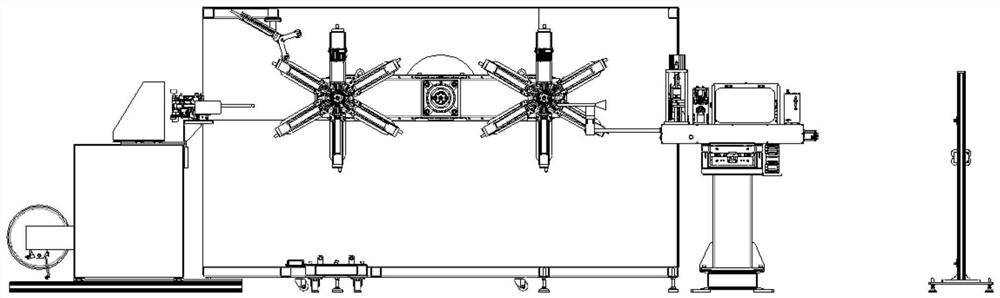

[0067] This embodiment discloses a general-purpose automatic coiling and unloading machine for PE and PERT pipes. For its structure, please refer to the attached Figure 1-19 As shown, it includes: a pipe introduction machine 1, a pipe coiler 2, an uncoiler 3 and a packing machine 4, and the pipe introduction machine 1, the pipe coiling machine 2 and the packing machine 4 are arranged in sequence.

[0068] The pipe introduction machine in this embodiment is suitable for small pipes with a pipe diameter of 16 to 32mm, and has higher precision and more neat and compact pipe arrangement. The following will combine Figure 6 to Figure 10 Specifically explain the various components and working principles of the pipe introduction machine.

[0069] as attached Figure 6 As shown, the pipe introduction machine of this embodiment includes: a tension controller 10, a guide mechanism 11, a traction mechanism 12, a speed measuring mechanism 13, a pipe cutting mechanism 14, a displacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com