Online full-automatic tempering equipment and technology for same-furnace multi-strip bimetal strip saw

A bimetal belt, fully automatic technology, applied to heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve problems such as equipment operation and maintenance difficulties, and achieve the goals of solving equipment operation and maintenance difficulties, reducing costs, and increasing heating and cooling speeds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

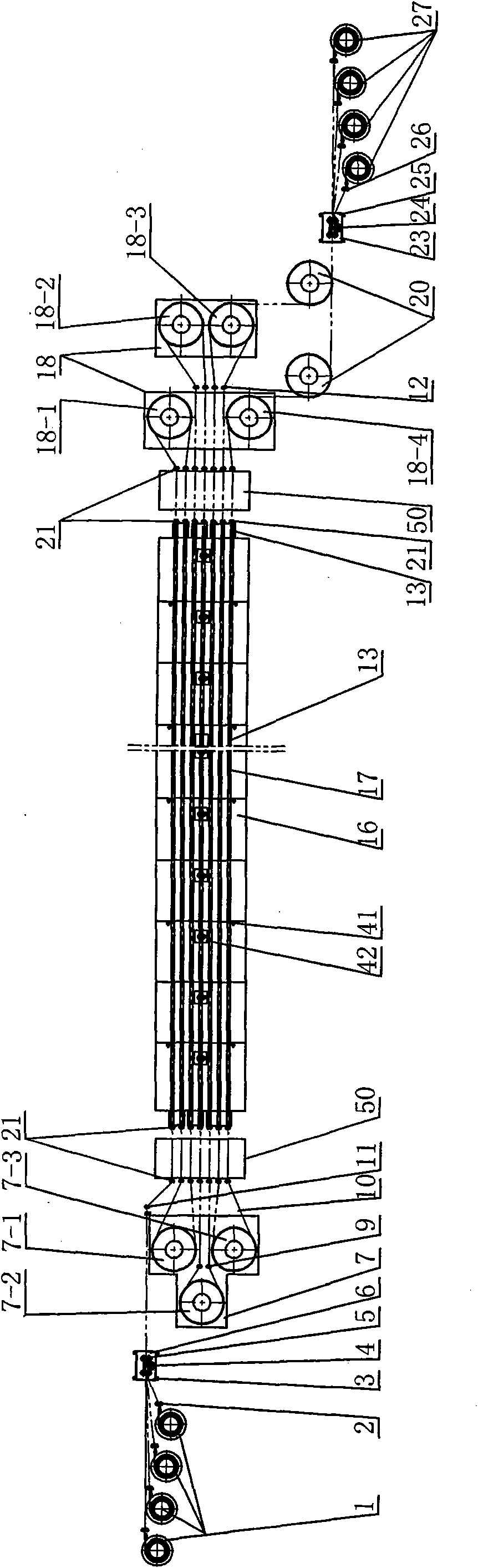

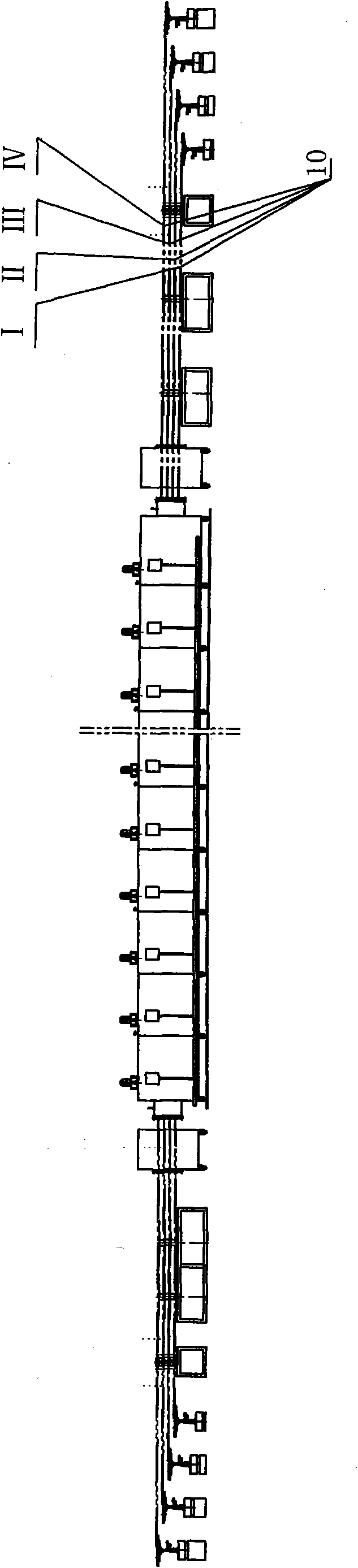

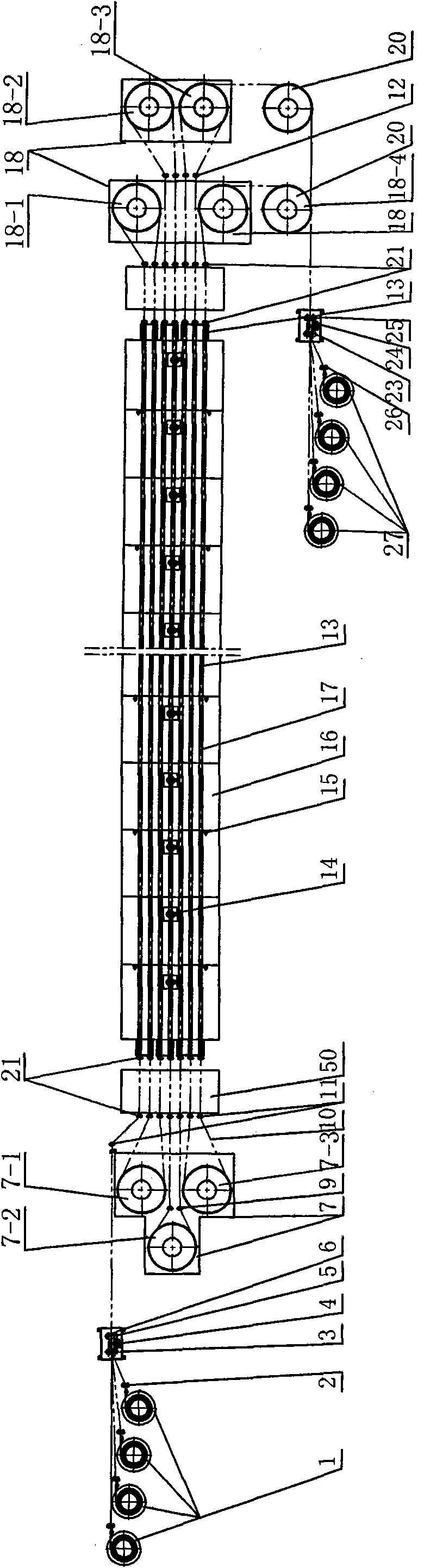

[0019] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6a~6b , Figure 7a~7d As shown, the online automatic tempering equipment for multi-band bimetallic band saw blades in the same furnace described in this embodiment includes N unwinding devices 1, tension damping devices 3, front rotary devices 7, Box-type tempering furnace 16, rear rotary device 18, output guide device 20, traction device 23 and N winding devices 27; box-type tempering furnace 16 is internally provided with multiple heating channels 17, and front rotary device 7 includes multiple front rotary devices. Runner, the rear rotary device 18 comprises a plurality of rear rotary wheels, and the layout of the front rotary wheel and the rear rotary wheel can make the saw blade 10 repeatedly turn back and run continuously along different heating passages in the box tempering furnace 16 .

[0020] The N unwinding devices 1 described in this embodiment incl...

specific Embodiment approach 2

[0021] Specific implementation mode two: as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, the front swivel device 7 in this embodiment includes a first front swivel wheel 7-1, a second front swivel wheel 7-2, a third front swivel wheel 7-3 and two front limiter wheels 9. Looking at the direction, the first front rotary wheel 7-1, the second front rotary wheel 7-2 and the third front rotary wheel 7-3 are arranged in a triangle, and the two front limit wheels 9 are arranged on the front of the first rotary wheel 7-3. 1. In the middle of the triangle formed by the second front rotary wheel 7-2 and the third front rotary wheel 7-3, there are N disks on each of the above three front rotary wheels; the rear rotary device 18 Comprise the first rear rotary wheel 18-1, the second rear rotary wheel 18-2, the third rear rotary wheel 18-3, the fourth rear rotary wheel 18-4 and four rear limit wheels 12, from Looking down on the direction, the first rear rotary wh...

specific Embodiment approach 3

[0022] Specific implementation mode three: as figure 1 As shown, the front rotary device 7 in this embodiment is composed of N saw blade rotary units at the inlet end, and the rear rotary device 18 is composed of N saw blade rotary units at the exit end, and each saw blade rotary unit at the inlet end includes a triangular Arranged first front rotary wheel 7-1, second front rotary wheel 7-2 and third front rotary wheel 7-3; each outlet end saw blade rotary unit includes first rear rotary wheel 18-1 in trapezoidal arrangement , the second rear rotary wheel 18-2, the third rear rotary wheel 18-3 and the fourth rear rotary wheel 18-4. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com