Grinding head replacing system and robot grinding system

A technology of grinding heads and robots, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve problems such as economic losses, achieve guaranteed efficiency, improve replacement efficiency, improve efficiency and The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

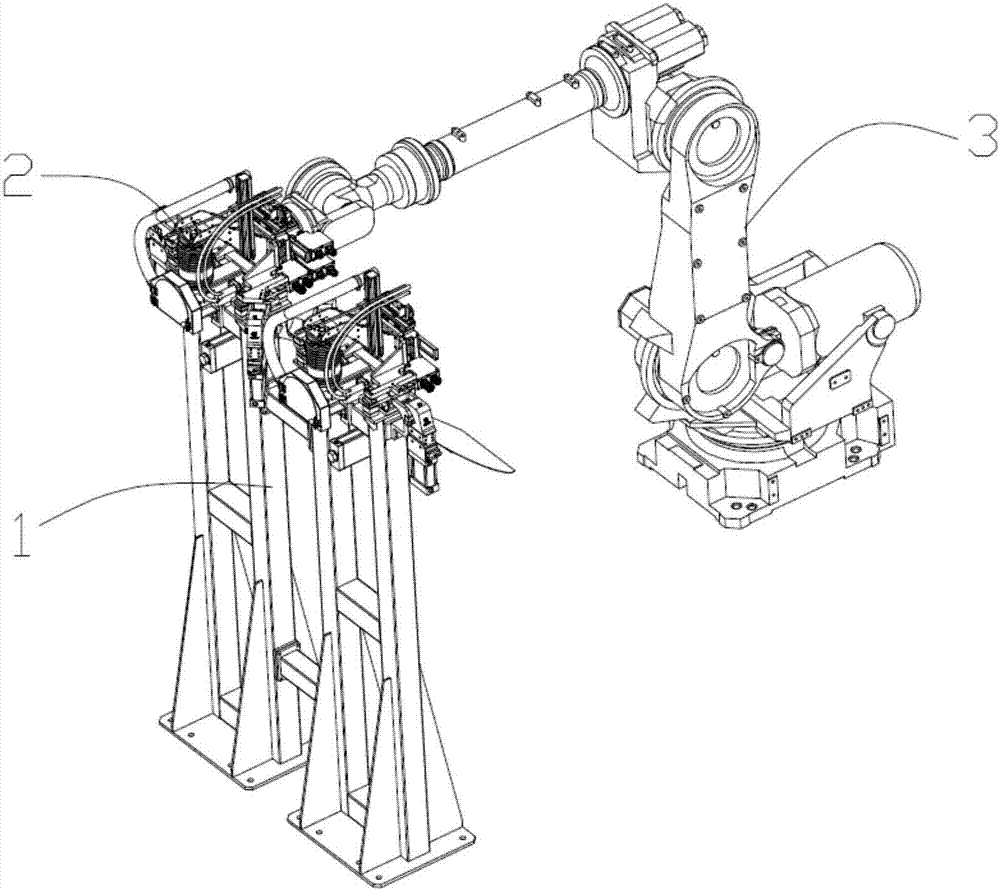

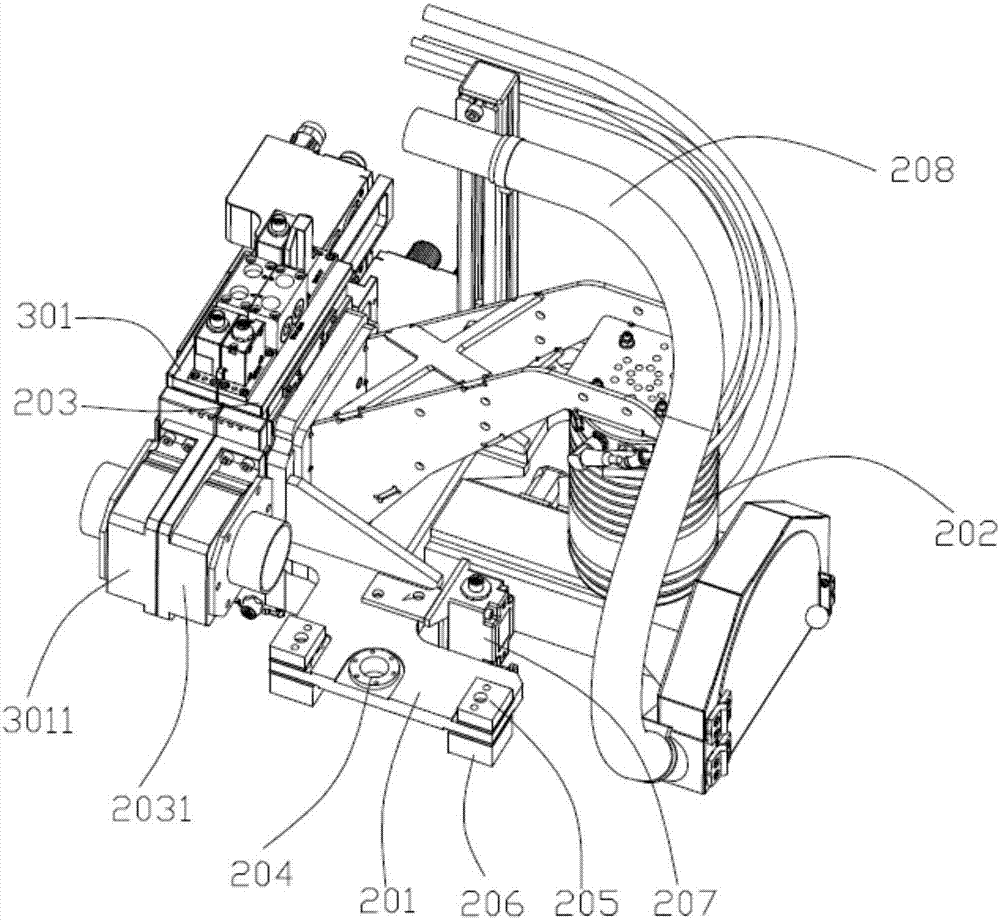

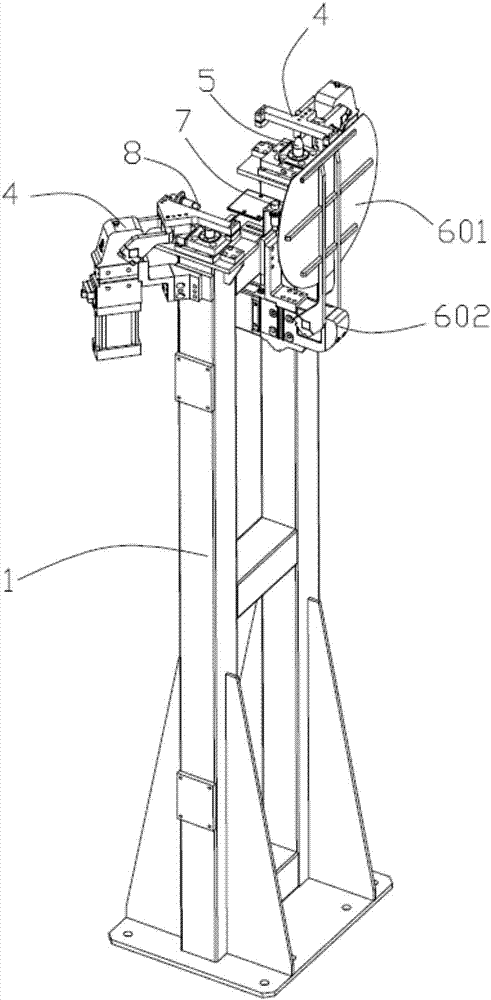

[0040] The embodiment of the present invention relates to a robot grinding system, which includes a grinding robot 3 and an online grinding head 2 installed at the free end of the grinding robot 3, which is further equipped with the grinding head replacement system provided in the first embodiment above, and the grinding robot 3 The free end is equipped with a quick-change male disc 301, and the quick-change male disc 301 is detachably connected to the quick-change master disc 203 of the online grinding head 2.

[0041] Among them, the separation operation of the quick-change male disk 301 and the quick-change master disk 203 of the grinding head 2 to be off-line, and the assembly operation of the quick-change male disk 301 and the quick-change master disk 203 of the online grinding head 2 are all signaled by the robot 3 It is done automatically, so the replacement efficiency of the grinding head 2 can be effectively improved, thereby ensuring the efficiency of the production l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com