Bottle cap dedusting conveying device

A conveying device and bottle cap technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of waste of floor space, inability to integrate settings, complex structure of dust removal devices, etc., and achieve simple structure and floor space. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention, but it should not be understood as a limitation on the protection scope of the present invention.

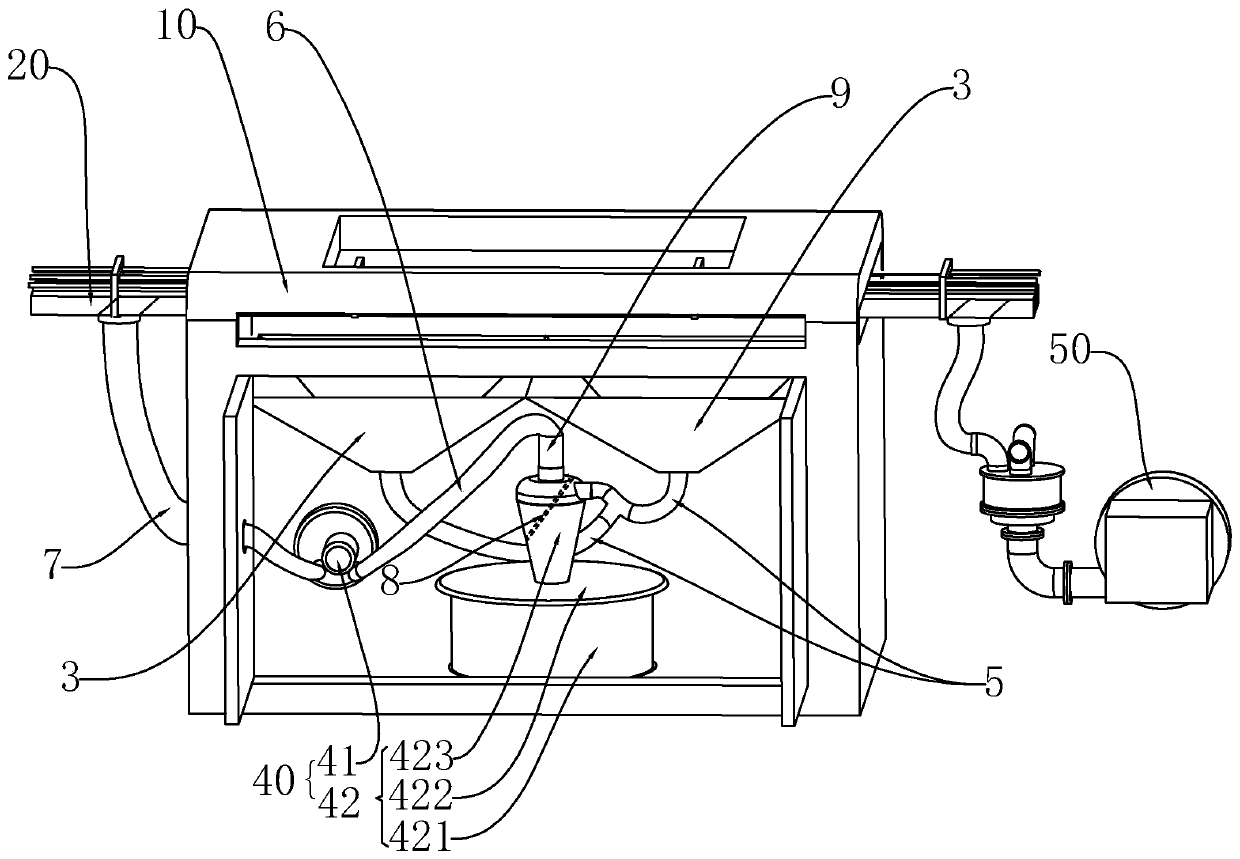

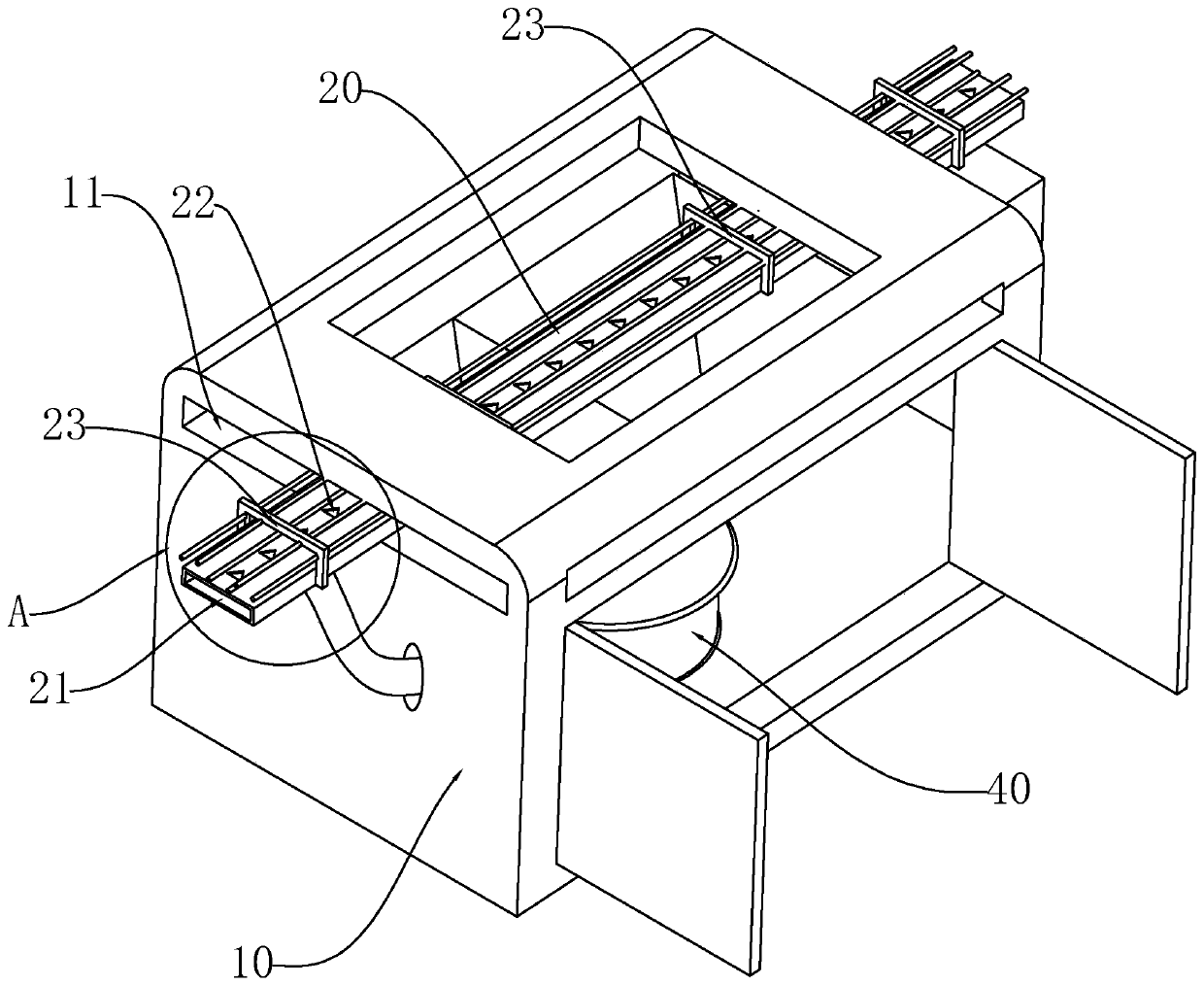

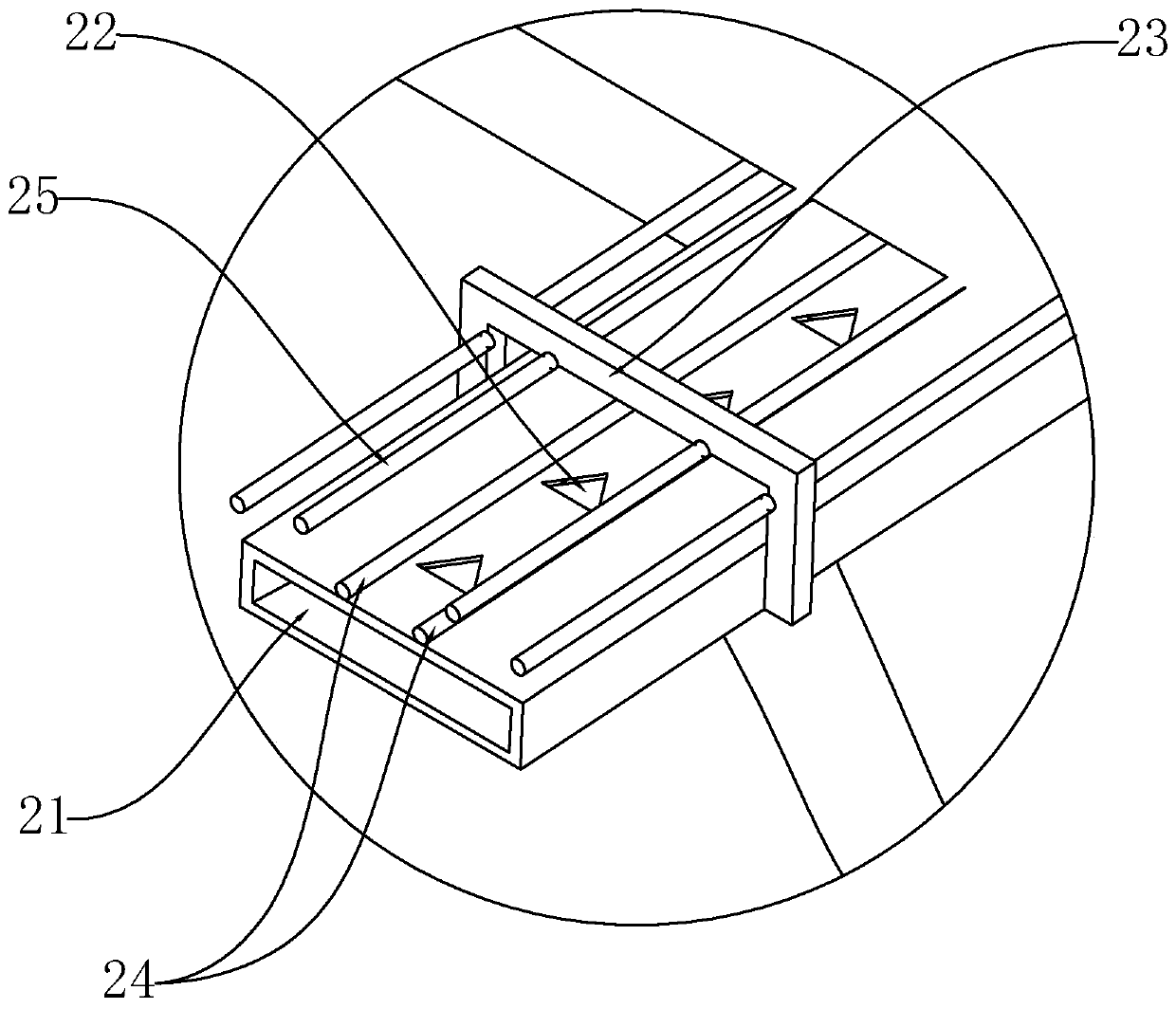

[0020] refer to figure 1 with figure 2 , a bottle cap dedusting and conveying device of the present invention, comprising: a box body 10, which has a cavity inside, and the box body 10 is provided with track passages 11 running through its left and right sides; the delivery track 20, from the track passage 11, for conveying the bottle cap along its length; at least one hopper 3 is arranged inside the cavity, the opening of the hopper 3 is located below the conveying track 20, and the lower end of the hopper 3 communicates with There is a dust suction mechanism 40, and the dust suction mechanism 40 is used to suck the particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com