Regeneration cycle method of acidic etching solution

A technology of acid etching solution and acid etching waste solution, which is applied in photography process, instrument, photography auxiliary process, etc., can solve the problems of inability to meet the etching requirements, slow down the etching rate, etc., achieve simple and convenient system operation and maintenance, and avoid chlorine gas. The effect of leaking and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

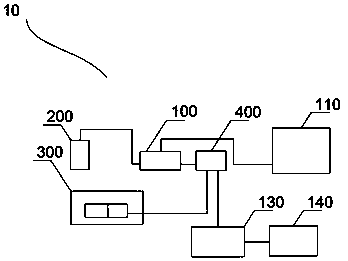

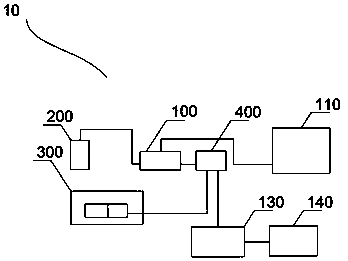

[0029] The regeneration cycle device and method for the acidic etching solution provided by the present invention will be described in detail below.

[0030] A recycling device 10 for acidic etching solution includes an acidic etching line (DES) 100 , an etching waste liquid tank 200 and an electrolytic tank 300 connected in sequence, and the acidic etching line communicates with an acid mist absorption cylinder 400 . The etching waste liquid tank 200 collects the waste liquid generated by the acid etching line (DES) 100, and transports it to the electrolytic cell 300, and the electrolytic cell 300 electrolyzes the waste liquid, and converts copper ions in the waste liquid into electrolyzed Copper plate, while oxidizing the chlorine ions in the waste liquid to chlorine gas. The acid mist absorption cylinder 400 collects the waste liquid in the electrolytic cell 300 and reacts with chlorine gas to obtain a regenerated etching liquid.

[0031] The chlorine gas is produced in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com