Edible chitosan-collagen antibacterial film and preparation method thereof

A collagen and ‐collagen technology, which is applied in the field of green food processing, can solve the problems of film-forming properties that have not yet been applied, and achieve the effects of improving mechanical properties and water resistance, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

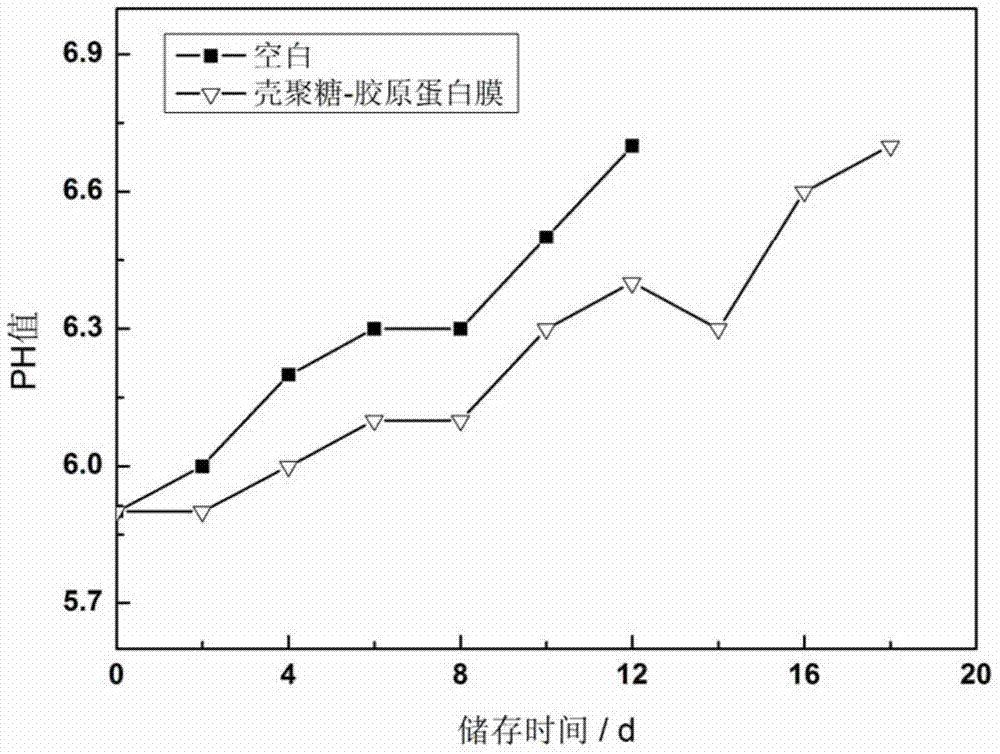

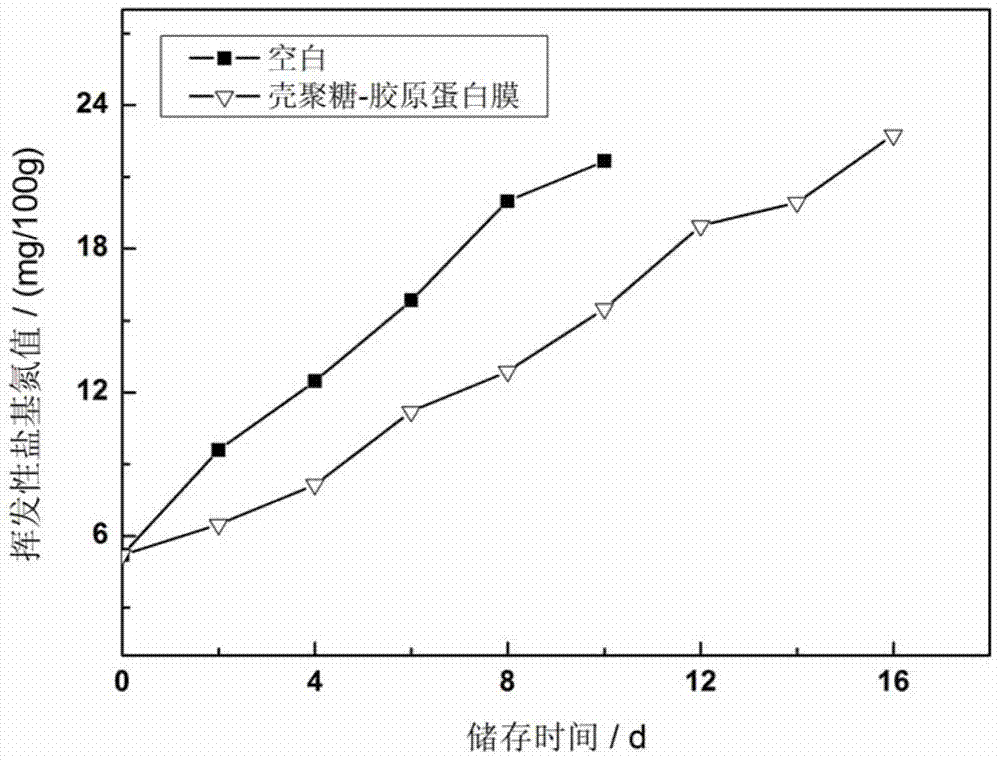

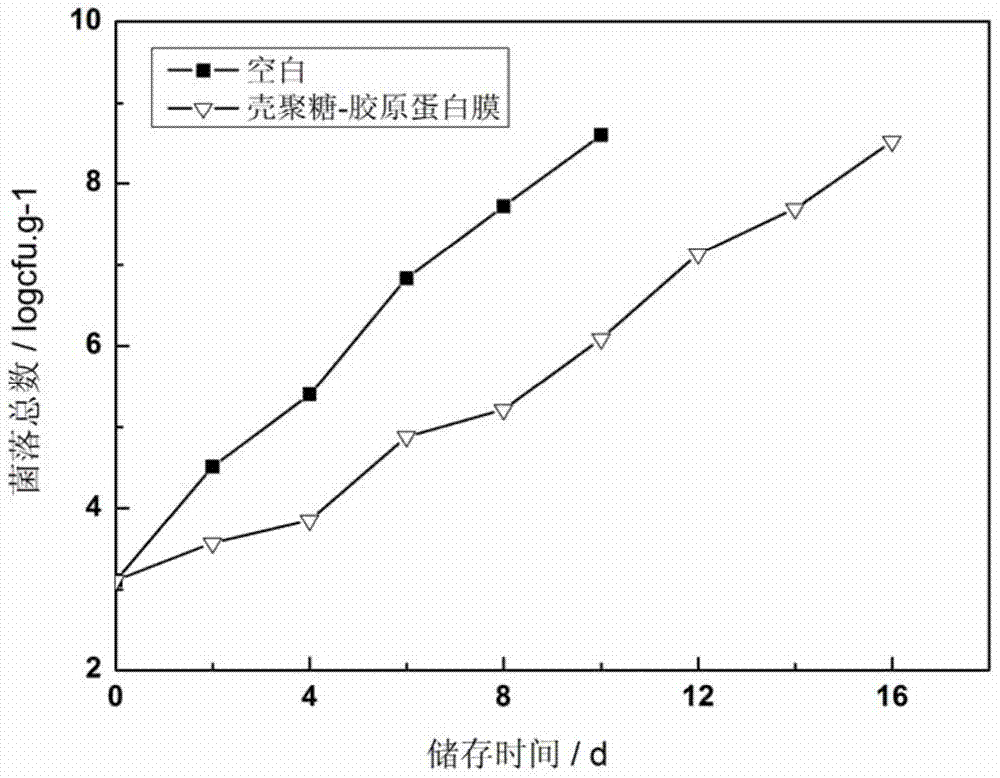

[0029] A method for preparing a chitosan-collagen antibacterial film: adding collagen to water, stirring and dissolving at a heat treatment temperature of 60°C to 70°C, adding glycerin, dialdehyde starch and chitosan in sequence to dissolve in the solution The mass concentration meter, collagen-chitosan concentration is 6%, glycerin is 0.78%, dialdehyde starch is 0.48%; The mass ratio of collagen protein and chitosan is 6:4, then adds the PH value of acetic acid control solution to be 5; Heat treatment at 60°C for 15 minutes, place in a stirring defoamer to remove air bubbles for 20 minutes, then cast on a glass plate, after the film-forming liquid is cooled, bake in an oven at 60°C for 5 hours, and cool at room temperature. Then peel off the film to obtain a chitosan-collagen film. The thickness of the formed film was 0.21 mm. An evaluation team of 5 people was set up, and the sensory testing of the formed film is shown in Table 1 under a non-interfering environment. As sho...

Embodiment 2

[0046] A preparation method of chitosan-collagen film: adding collagen into water, stirring and dissolving at a heat treatment temperature of 70°C, adding glycerin, dialdehyde starch and chitosan in sequence, based on the mass concentration in the solution , the concentration of collagen-chitosan is 3%, glycerol is 0.45%, and dialdehyde starch is 0.15%; the mass ratio of collagen to chitosan is 5:4, and then acetic acid is added to control the pH value of the solution to 6; at 50°C Heat treatment for 20 minutes, put it in a stirring defoamer to remove air bubbles for 18 minutes, then cast on a glass plate, after the film-forming liquid is cooled, put it in an oven at 60°C and bake for 6 hours, cool at room temperature, and then peel off the film. Prepare chitosan-collagen film. The thickness of the formed film was controlled to be 0.21mm. Referring to the method in pumpkin-soybean protein isolate composite edible film by Xiao et al. (Journal of Zhongkai College of Agricultura...

Embodiment 3

[0048] A method for preparing a chitosan-collagen film: adding collagen to water, stirring and dissolving at a heat treatment temperature of 60°C to 70°C, adding glycerin, dialdehyde starch and chitosan in sequence to obtain the Mass concentration meter, collagen-chitosan concentration is 7%, glycerin is 0.35%, dialdehyde starch is 0.70%; The mass ratio of collagen protein and chitosan is 6:4, then adds the pH value of acetic acid control solution to be 5.5; Heat treatment at 60°C for 15 minutes, place in a stirring defoamer to remove air bubbles for 20 minutes, then cast on a glass plate, after the film-forming liquid is cooled, bake in an oven at 70°C for 4 hours, cool at room temperature, and then Remove the film to obtain a chitosan-collagen film. The thickness of the formed film was controlled to be 0.21mm. Referring to Xiao et al. pumpkin-soybean protein isolate composite edible film (Journal of Zhongkai College of Agricultural Engineering, Volume 25, Issue 3), the mois...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com