Core mould vibrating bar for core mould vibrating machine

A vibrating machine and vibrating rod technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of deteriorating motor working conditions, high maintenance difficulty, and increased maintenance difficulty, so as to reduce the incidence of accidents and maintenance, and achieve good working conditions. The effect of reducing the number of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

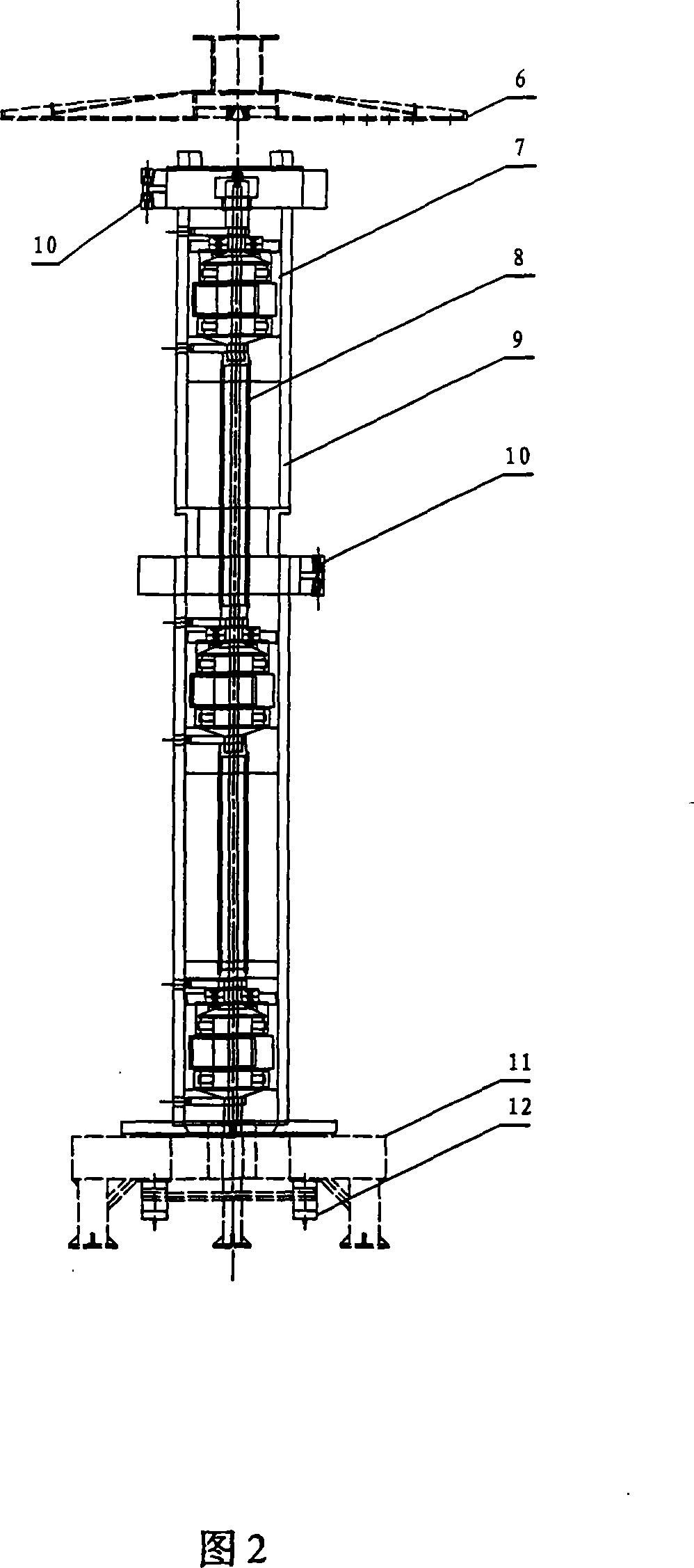

[0022] As shown in Figure 2, it is a schematic structural diagram of a core mold vibrating rod used for a core mold vibrating machine. The core mold vibrating rod used for a core mold vibrating machine is composed of an indenter cap 6, an eccentric block device 7, Central shaft 8, sleeve pipe 9, locking block 10, frame 11 and motor 12 are formed.

[0023] The three eccentric block devices 7 are connected and installed in the casing 9 through the central shaft 8, the two casings 9 are connected through the locking block 10, the pressure head cap 6 is set on the upper end of the casing 9, and the casing 9 is installed vertically on the frame 11, two motors 12 are installed at the bottom of the frame 11, and the motors 12 are connected with the central shaft 8.

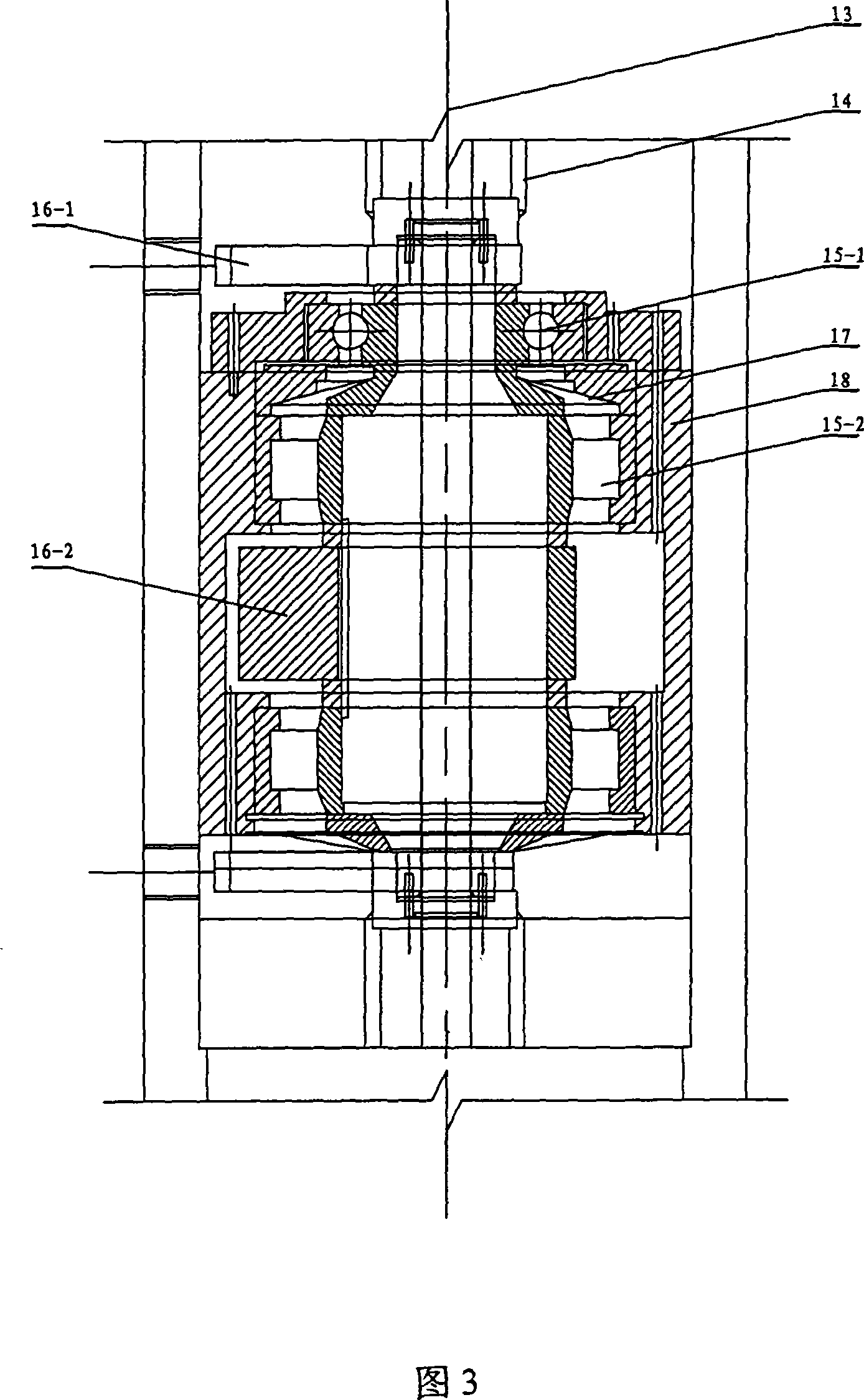

[0024] As shown in Figure 3, it is a schematic diagram of the structure of the eccentric block device, and the described eccentric block device 7 is composed of a pull rod 13, a connecting shaft 14, bearings 15-1, 15-2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com