Transmission aligning device and butt joint equipment

A technology of alignment device and equipment, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of inflexible layout of PCB board production line, low degree of automation, and difficult control of the board body, and achieve simplified control requirements and structure Reduction of design and operation precision requirements, reduction of manpower and design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

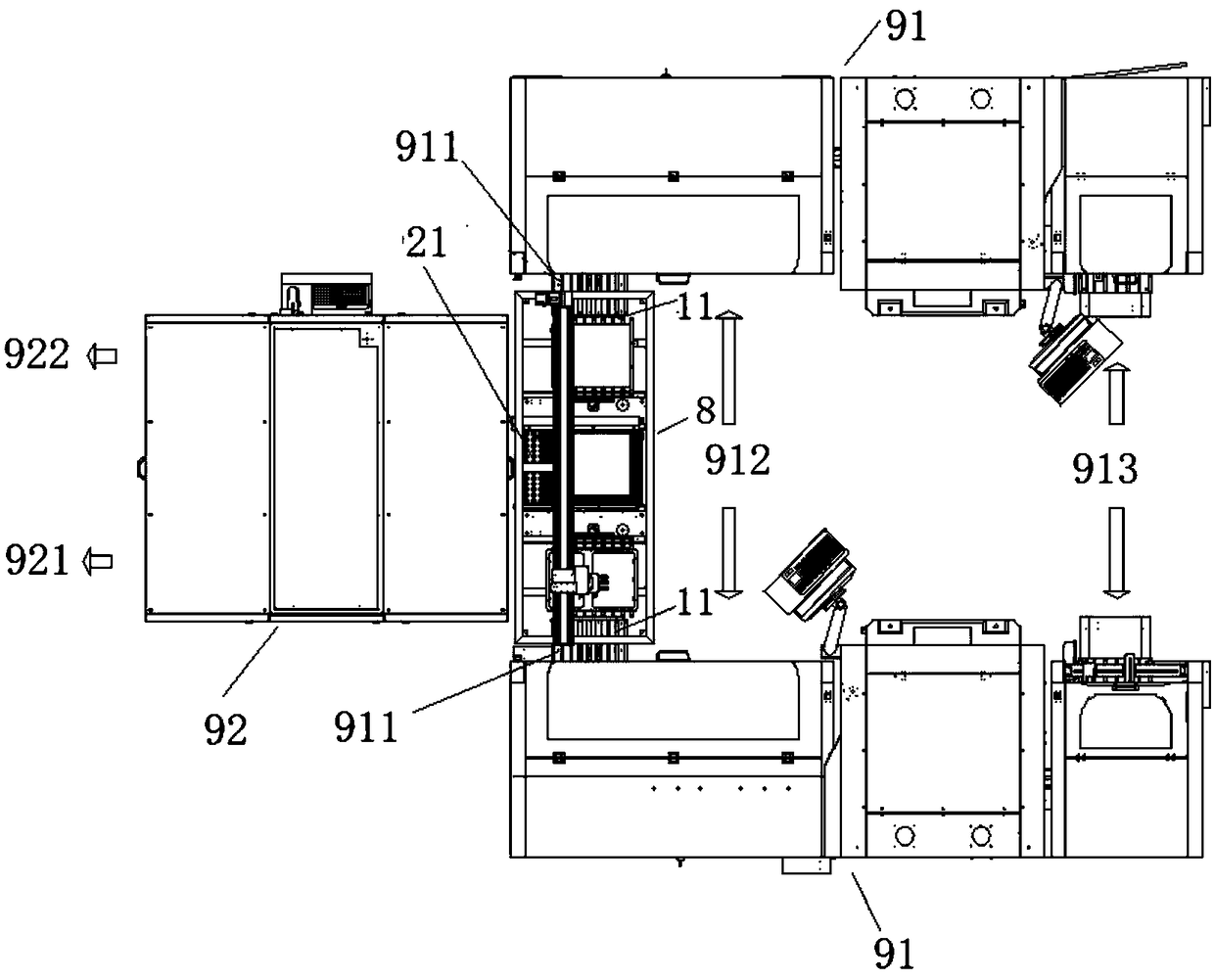

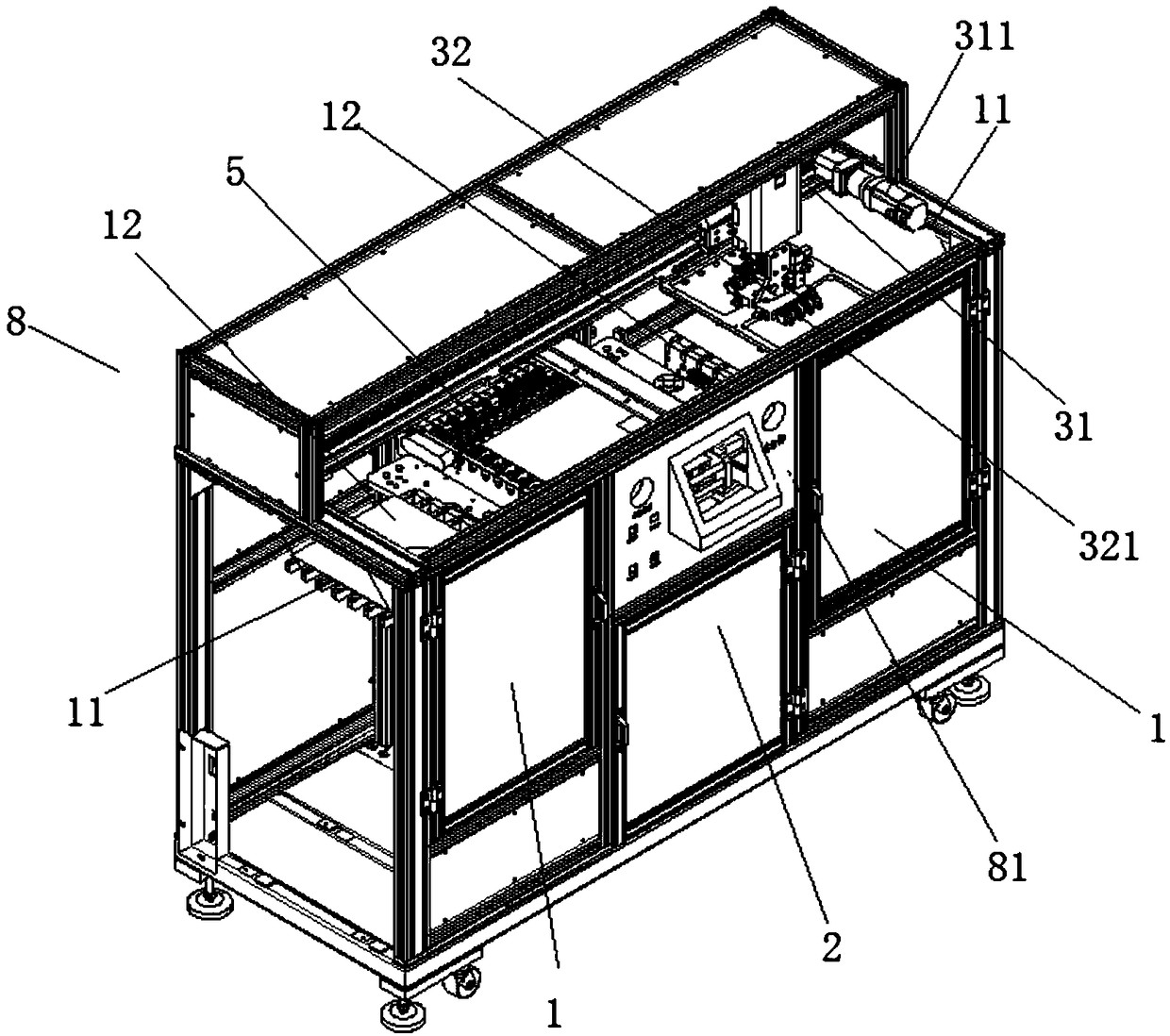

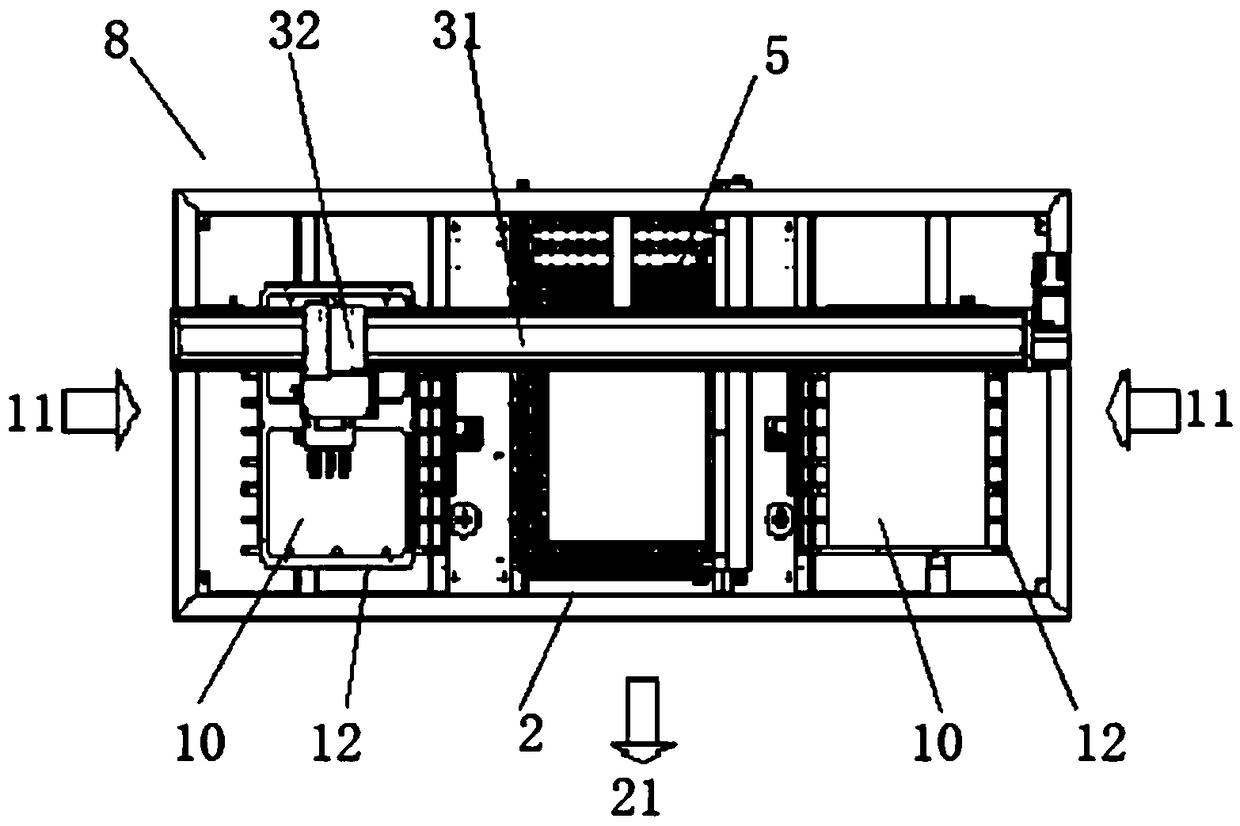

[0057] Such as Figure 1-2 As shown, the present invention records a docking device that includes: an input platform 1, an output platform 2, and a handling mechanism 3. The input platform 1 receives the output material from the upstream device, and the discharge end 21 of the output platform 2 faces the downstream The device outputs materials; the handling mechanism 3 transports the materials from the input platform 1 to the output platform 2, wherein the input platform 1 and / or the output platform 2 are provided with transmission alignment devices. The material in this embodiment refers to the circuit board 10, of course, it can also be other plate-shaped materials or non-plate-shaped materials with flat surfaces.

[0058] The input platform 1 is provided with at least two, the material output direction of the output platform 2 is different from the material input direction of the input platform 1, and the input end 11 of the input platform 1 and the output end 21 of the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com