Aluminum bar length measurement hot-shear device having double-shearing function and application thereof

A technology of aluminum bar and length measurement, which is applied in the direction of shearing machine equipment, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of labor and production equipment time consumption, poor system adaptability, and poor measurement accuracy, so as to save raw materials Utilization rate, improvement of utilization rate, labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing, invention is described in further detail.

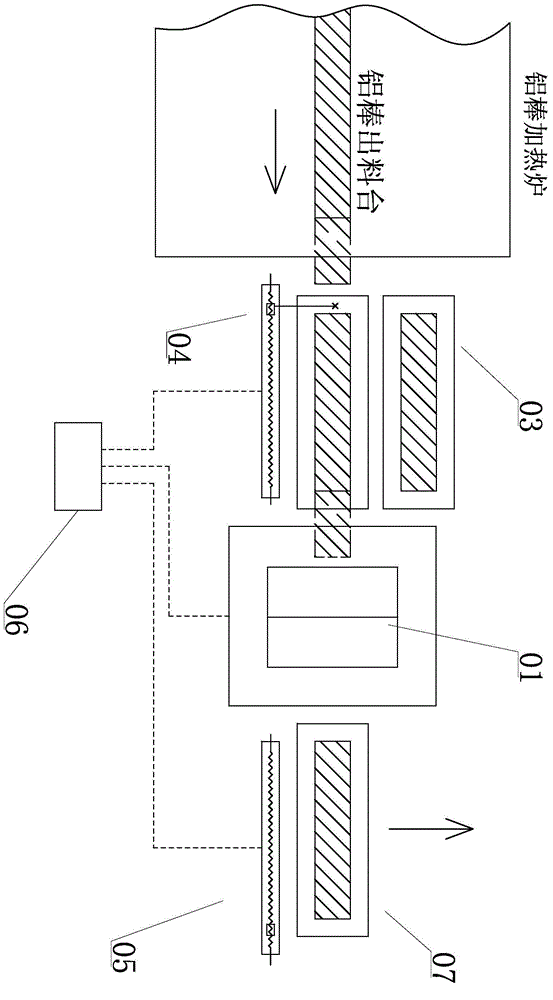

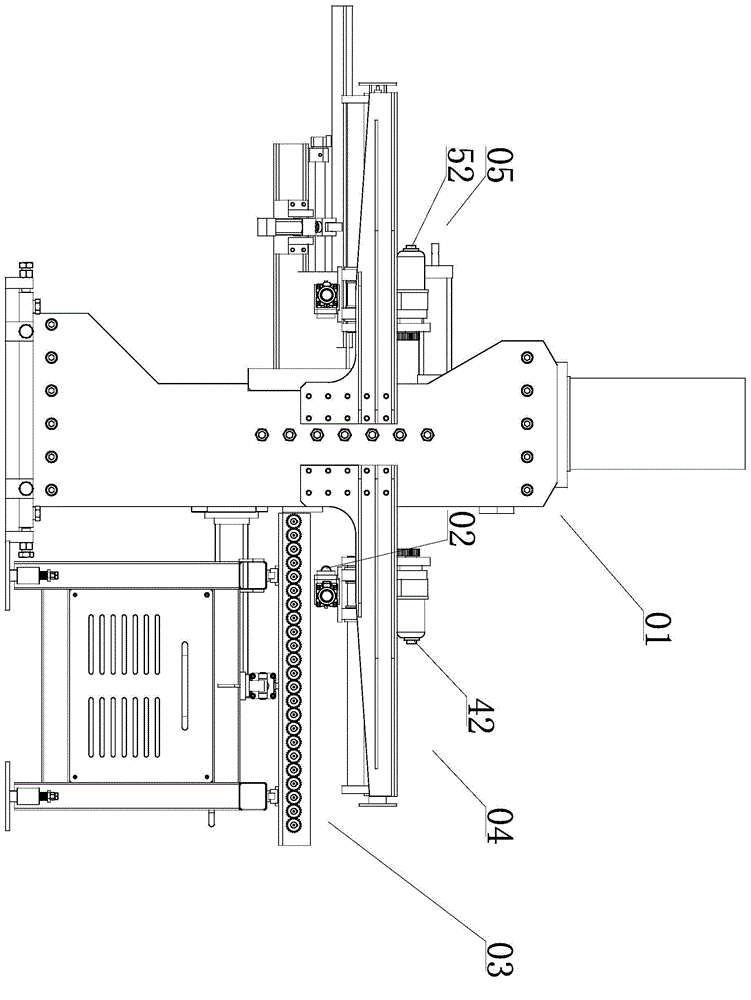

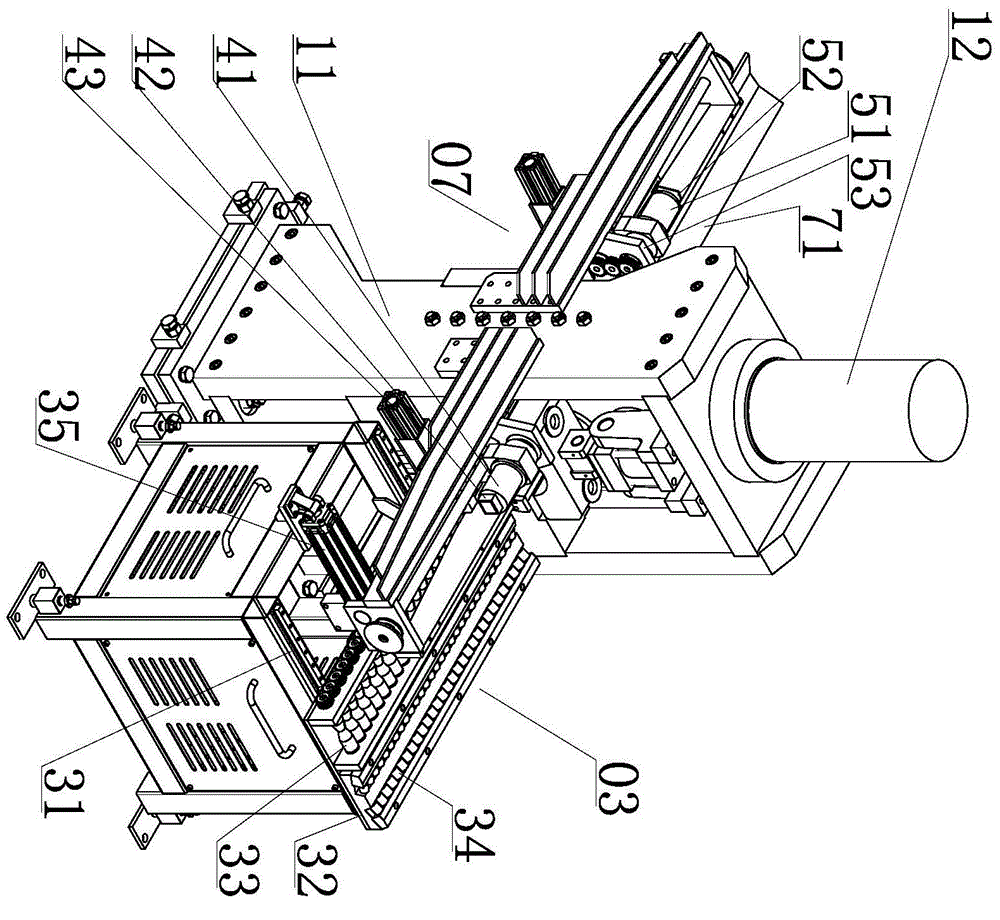

[0043] Such as Figure 1-10 As shown, the aluminum rod length measurement and thermal shearing equipment with double shearing function include thermal shearing machine 01 provided on the discharge table side of the aluminum rod heating furnace, photoelectric switch 02 provided on the thermal shearing machine 01, and The short rod storage platform 03 that is provided with on the hot shear machine 01, the first measuring device 04 that is provided with on one side between the hot shear machine 01 and the discharge platform and the second that is provided with on the other side of the hot shear machine 01 Two measuring devices 05, and a PLC controller 06 respectively connected to the hot shear machine 01, the photoelectric switch 02, the first measuring device 04 and the second measuring device 05. The above-mentioned PLC controller 06 is composed of a CPU and a signal module. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com