Solar panel observation station

A solar panel and observation station technology, applied in the field of visual inspection of solar panels, can solve the problems of long time required for flipping both sides and large impact on production line production tempo, so as to shorten production cycle, improve production line efficiency, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

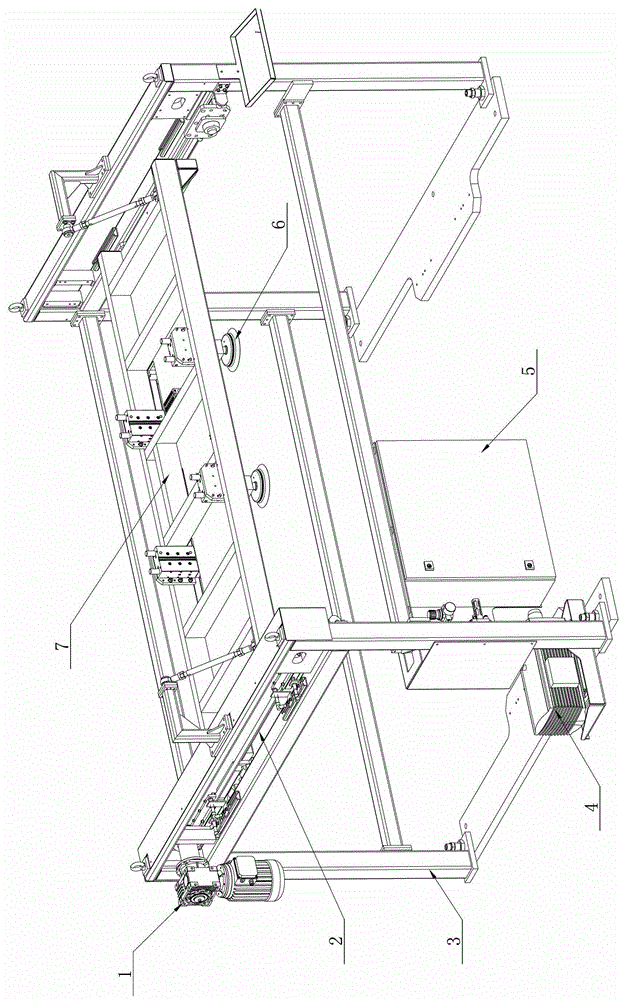

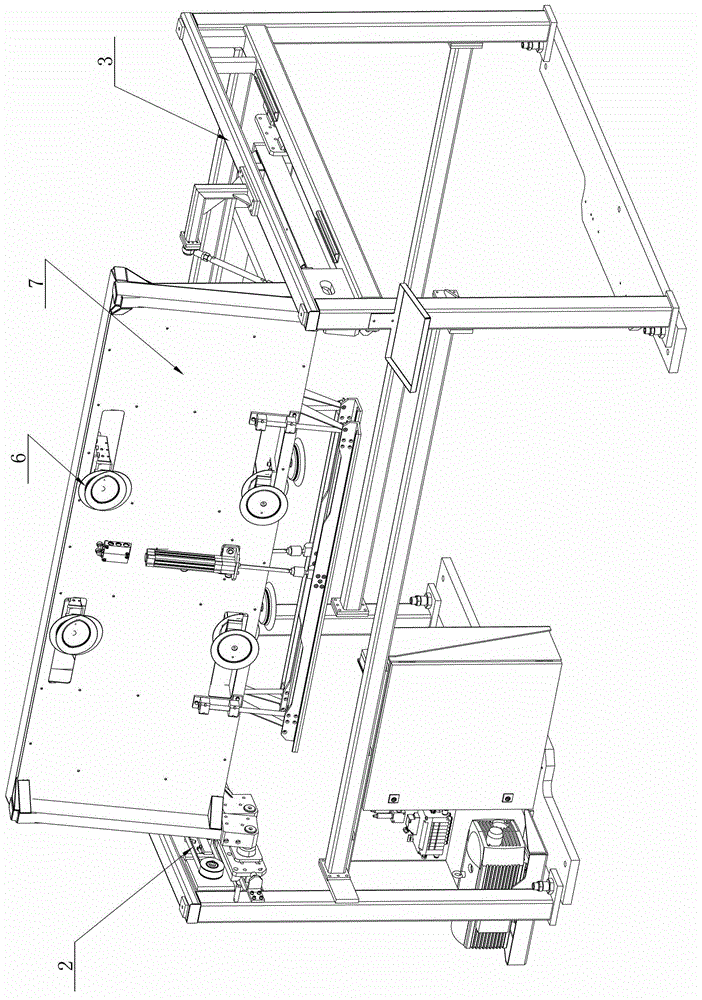

[0017] refer to Figure 1-Figure 2 , the specific embodiment adopts the following technical solutions: it includes a motor 1, a synchronous belt assembly 2, a main body 3, a vacuum pump 4, an electric control box 5, a vacuum chuck 6 and a turning mechanism 7, and synchronous belts are symmetrically arranged on both sides of the upper part of the main body 3 Component 2, and the synchronous belt component 2 on one side is connected to the motor 1, a turning mechanism 7 is set between the two timing belt components 2, and several vacuum suction cups 6 are uniformly set on the lower end of the turning mechanism 7, and a vacuum pump 4 is set on the bottom of the main body 3 And electric control box 5, vacuum pump 4 is connected with electric control box 5 and vacuum sucker 6 respectively, and electric control box 5 is connected with motor 1.

[0018] The synchronous belt assembly 2 includes a synchronous belt and a slide rail link mechanism, the timing belt is arranged on the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com