Complete machine leakage detection line for diesel engine

A leak detection, diesel engine technology, applied in mechanical conveyors, conveyors, transportation and packaging, etc., can solve the problems of long test cycle, production capacity restriction of the whole line, and impact of process cycle, so as to improve efficiency, increase production capacity, and facilitate offline The effect of repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

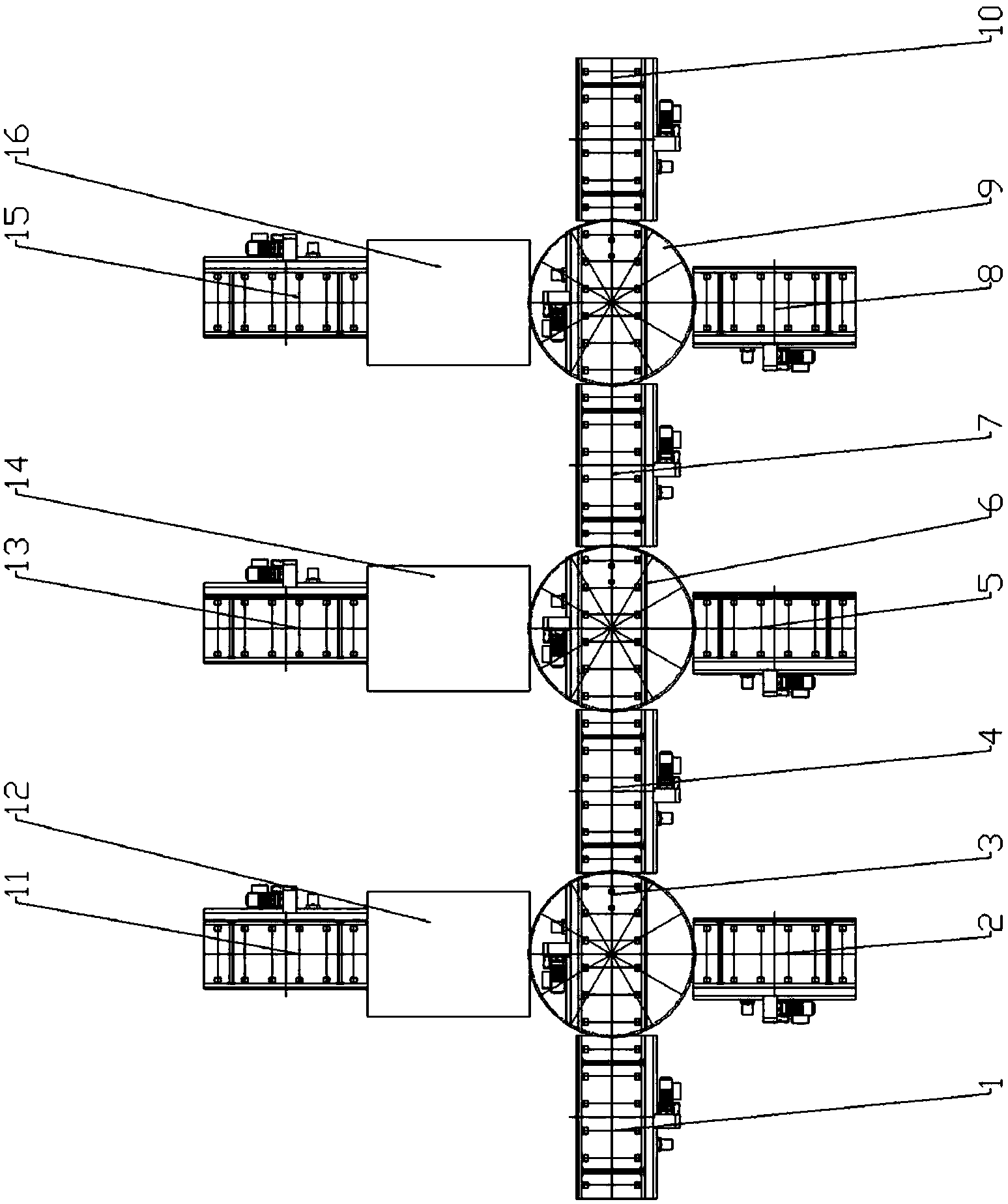

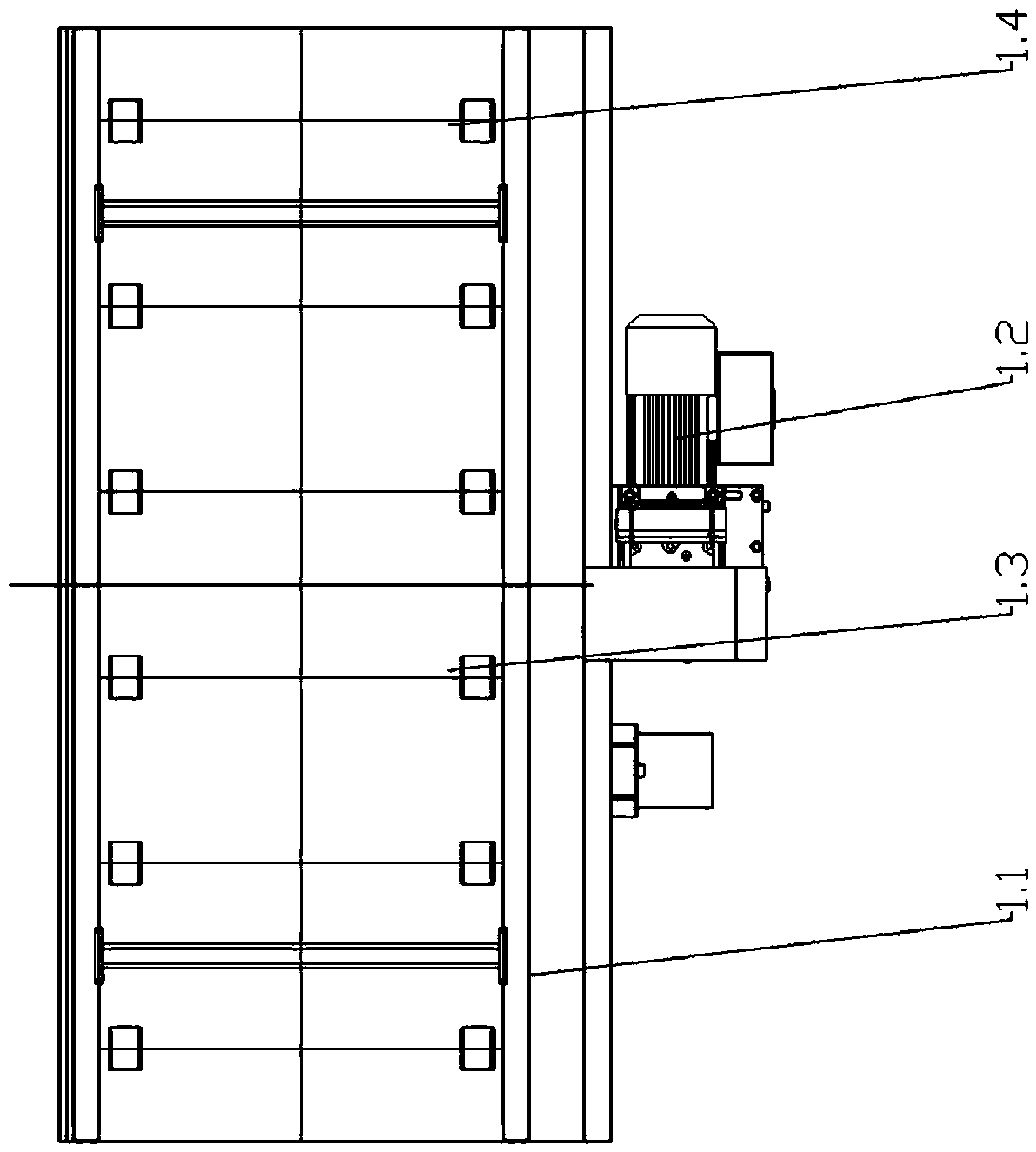

[0015] Such as figure 1 As shown, the present invention mainly includes a main line body, and the main line body is formed by connecting the first main transmission line body 1, the second main transmission line body 4, the third main transmission line body 7 and the fourth main transmission line body 10 sequentially end to end, A first turntable 3 , a second turntable 6 and a third turntable 9 are sequentially arranged on the main line body from left to right. The first turntable 3 is located between the first main transmission line body 1 and the second main transmission line body 4, the second turntable 6 is located between the second main transmission line body 4 and the third main transmission line body 7, and the third turntable 9 It is located between the third main transmission line body 7 and the fourth main transmission line body 10 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com