Static pressure-variable pickling system

A control system and static technology, applied in food forming, food science, application, etc., can solve the problems of difficult hardware facilities in the production workshop, unsatisfactory production process, and reduced operating safety, so as to facilitate readjustment and reuse, The effect of preventing material extrusion and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

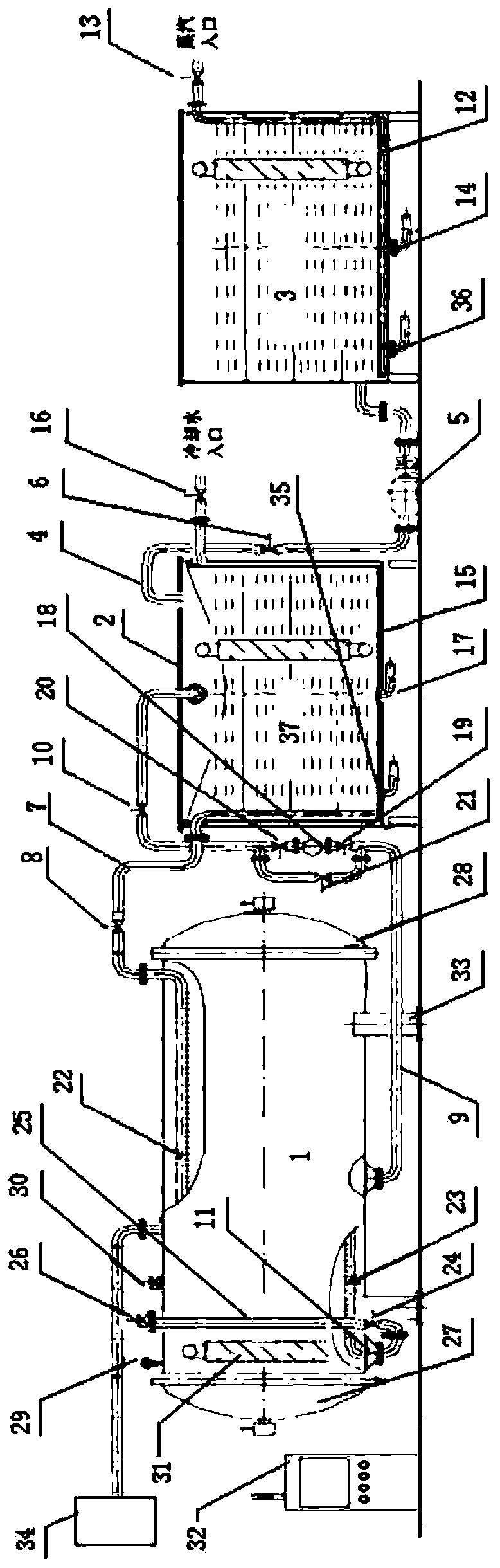

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0042] Such as figure 1 As shown, the invention provides a kind of static pressure-changing salting system, comprising:

[0043] Pickling solution boiling pool 3, which includes a heating device for heating and boiling the pickling solution;

[0044] Pickling tank 1, which is used to pickle the material to be pickled; wherein, the pickling system also includes: a control system 32, and a cooling storage pool 2 for cooling the pickling liquid; wherein, the The pickling solution boiling pool 3, the cooling storage pool 2 and the pickling tank 1 are sequentially connected through the infusion pipeline;

[0045] A pressure regulating device 34 for pumping and inflating the tank body is connected to the top of the pickling tank, the pressure regulating device is electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com