Trowelling machine

A troweling machine and walking mechanism technology, applied in the field of construction machinery, can solve the problems affecting the efficiency and quality of the cement board production line, the cement board is not easy to operate, time-consuming and labor-intensive, and achieve the effects of saving manpower, excellent performance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

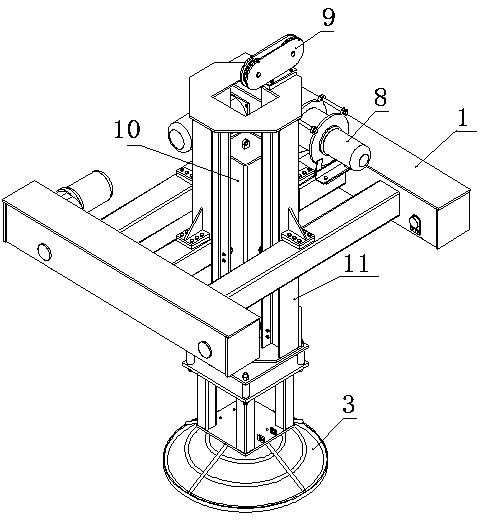

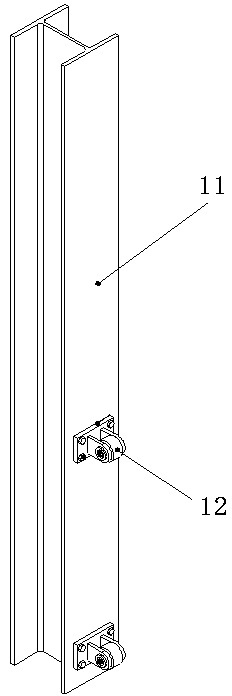

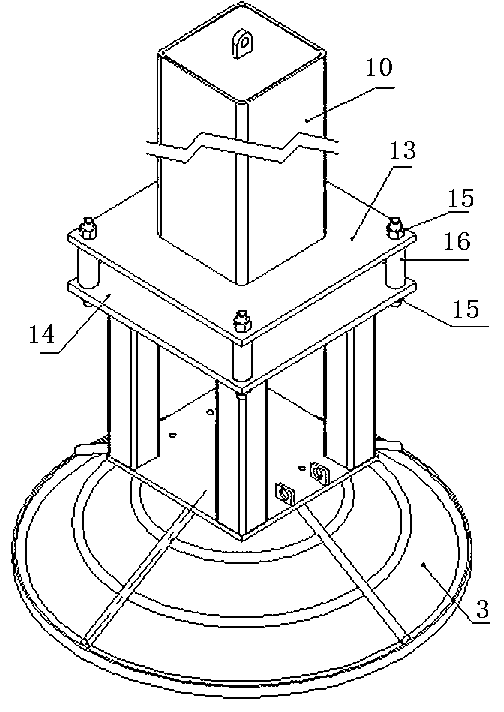

[0019] see figure 1 — Figure 4 , a troweling machine of the present invention, comprising a traverse vehicle 1, a traveling mechanism 2, a cutter head assembly 3, an electric control cabinet 4, a track 5 and an operating console 7, the track 5 is installed and fixed on the ground, and the traveling mechanism 2 is a bridge The double-flange traveling wheels of the traveling mechanism are installed at the bottom of the booms on both sides of the bridge-type structure, and the double-flange traveling wheels of the traveling mechanism travel longitudinally on the track on the ground. The bottom of the frame of the traversing car is equipped with double-flange road wheels, and the double-flange road wheels of the traversing car move laterally on the beam track. Installed on the traversing vehicle 1, the lifting device 8 adopts an electric hoist to connect with the wiping plate, and the guiding device adopts four guide frame columns 11 to install two needle bearings 12 on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com