Small-rolling-diameter full-automatic winding device

A winding device, fully automatic technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of inability to process small rolls, long roll changing time, low production efficiency, etc., and achieve difficult stretching , improve efficiency and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

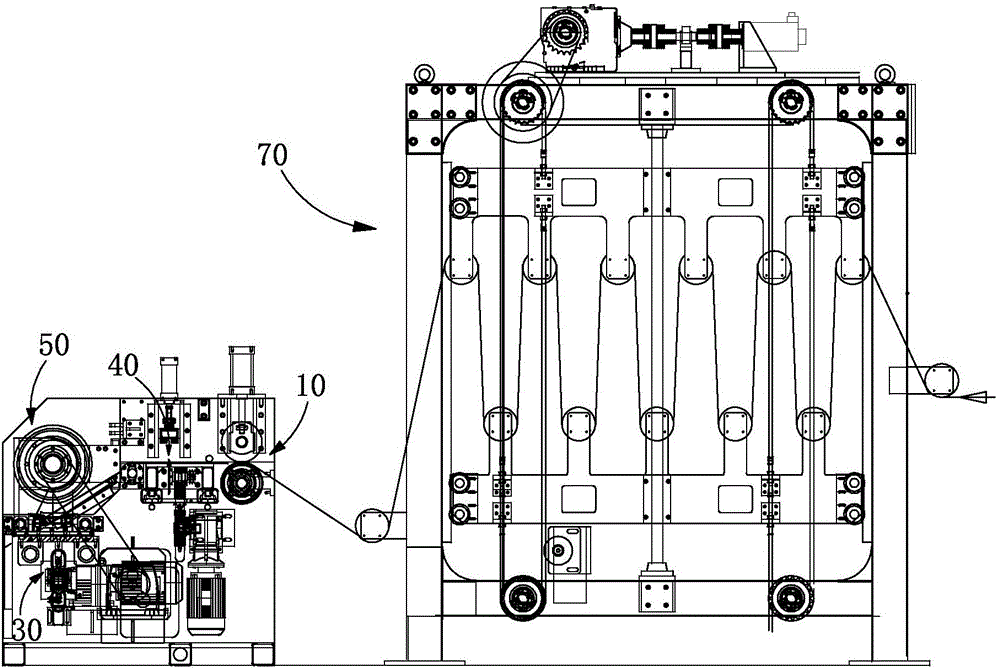

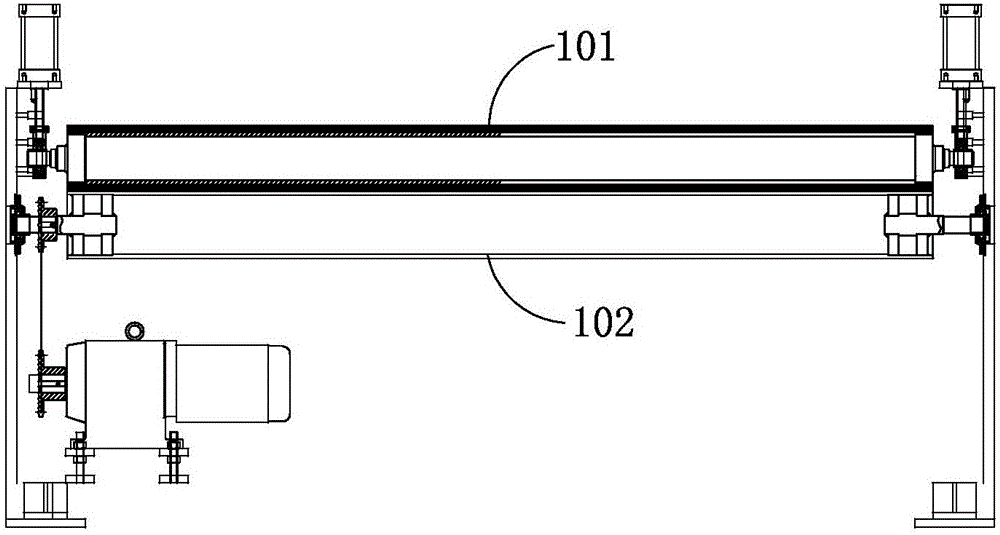

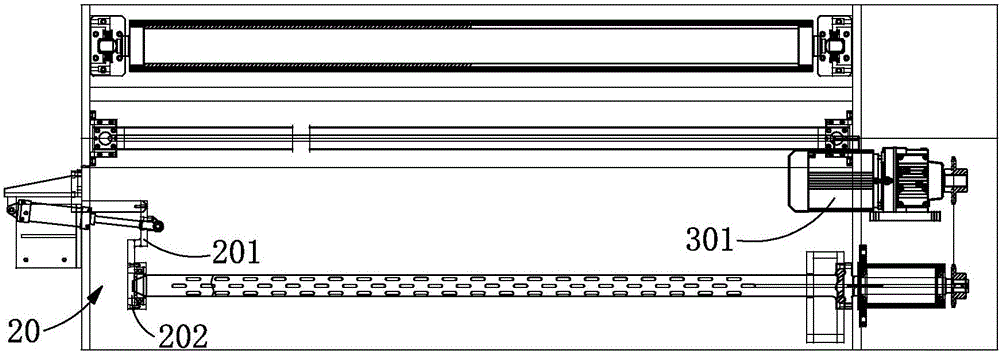

[0021] as attached figure 1 Shown, a kind of small roll diameter fully automatic winding device, comprises the traction mechanism 10 that is arranged on the frame successively (see attached figure 2 ), air shaft auxiliary jacking mechanism 20 (see attached image 3 ), winding mechanism 30 (see attached image 3 ), automatic cutting mechanism 40 (see attached Figure 4 ), automatic unloading mechanism 50 (see attached Figure 5 ), automatic conveying weighing mechanism 60 (see attached Figure 6 ) and storage mechanism 70 (see attached Figure 7 ); the sheet is wound around the traction mechanism 10 on the current winding shaft; the traction mechanism 10 includes a lower rubber roller 101 driven by a motor and an upper rubber roller 102 driven by an air cylinder that can be pressed together to pull the sheet material movement; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com