Push rod device of annealing furnace shovel loader

A push rod device and push rod technology, applied in the direction of furnaces, conveyors, furnace components, etc., can solve problems such as prone to expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

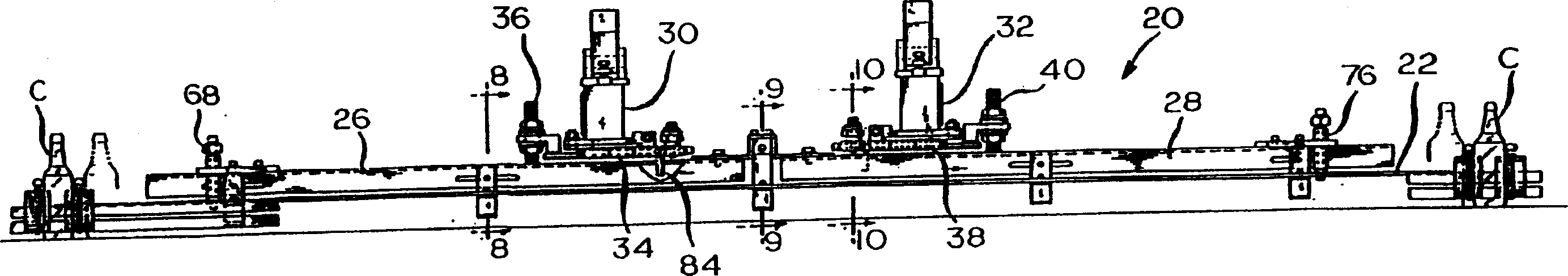

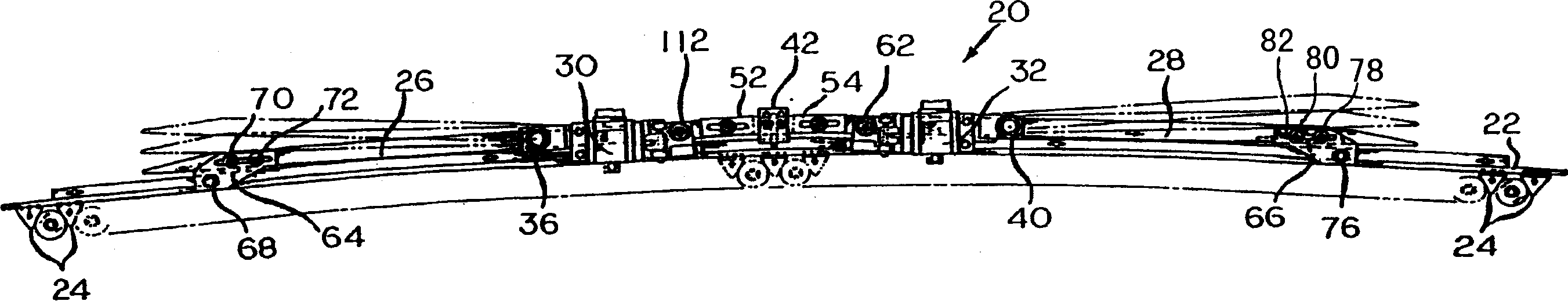

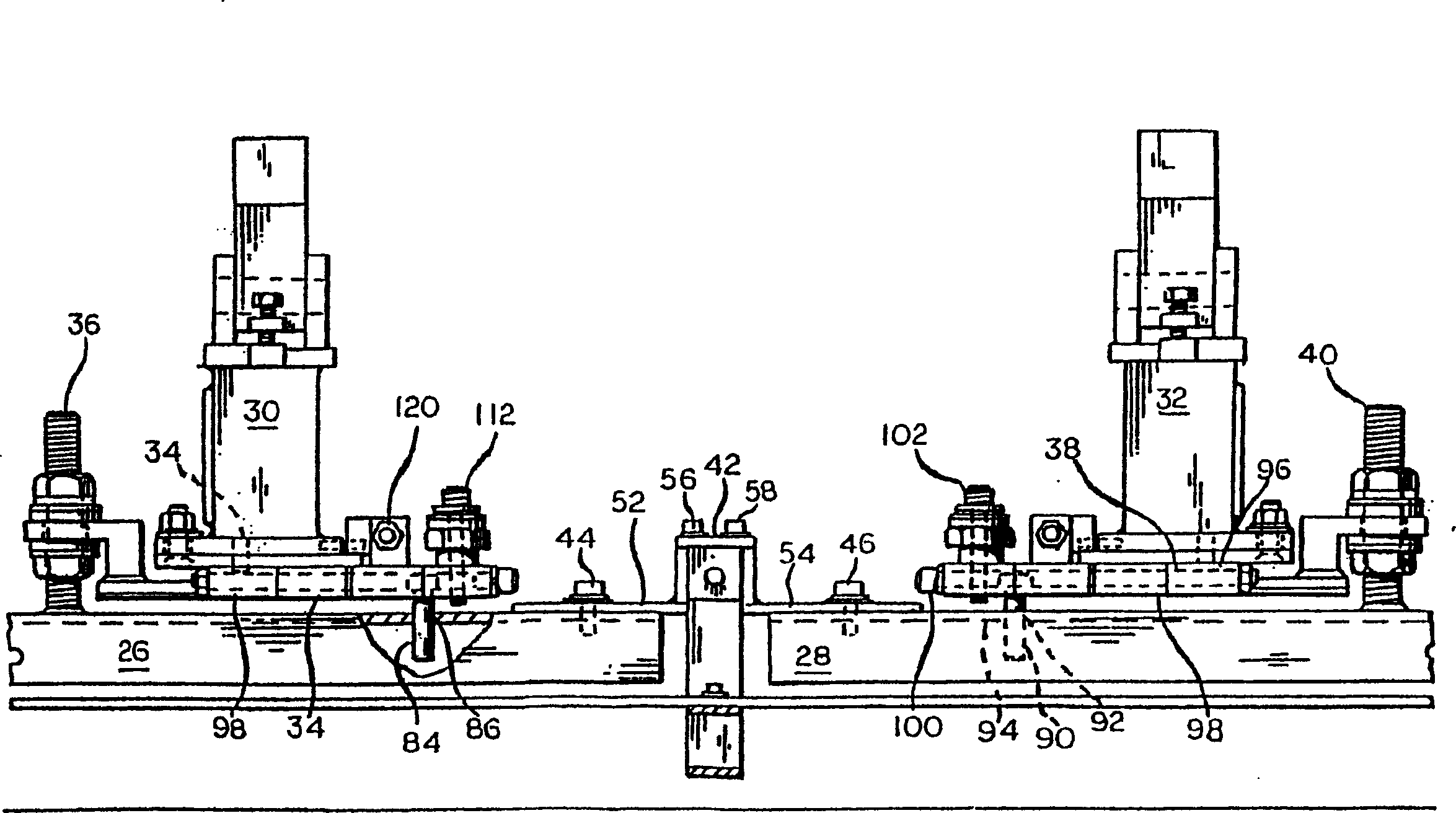

[0019] According to a preferred embodiment of the present invention, in figure 1 with figure 2 , reference numeral 20 generally denotes such a push rod device. This push rod arrangement 20 comprises a generally horizontally extending one-piece rod 22 which extends across the entire width of the interior of a lehr (not shown). This sleeve bar 22 is provided with a set of spaced apart generally triangular teeth 24 forming a sleeve for engagement with the newly formed glass container C to be annealed.

[0020] The sleeve rod 22 is supported on a set of generally horizontally extending push rods arranged end to end, shown as push rods 26 and 28 . Push rods 26 and 28 are connected to downwardly extending beams 30, 32, respectively, which are part of the uppermost carriage of a prior art three-axis annealing loader, but this uppermost carriage is not shown. The push rod 26 is suspended from a generally horizontally extending flange 34 secured to the bottom of the beam 30 by thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com