Netting strength supporting construction method based on fence breeding facility

A construction method and netting technology, which can be used in fences, fish farming, mechanical equipment, etc., can solve the problems of netting tearing, and achieve the effect of not being easy to stretch, prolonging the service life, and being easy to manufacture and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

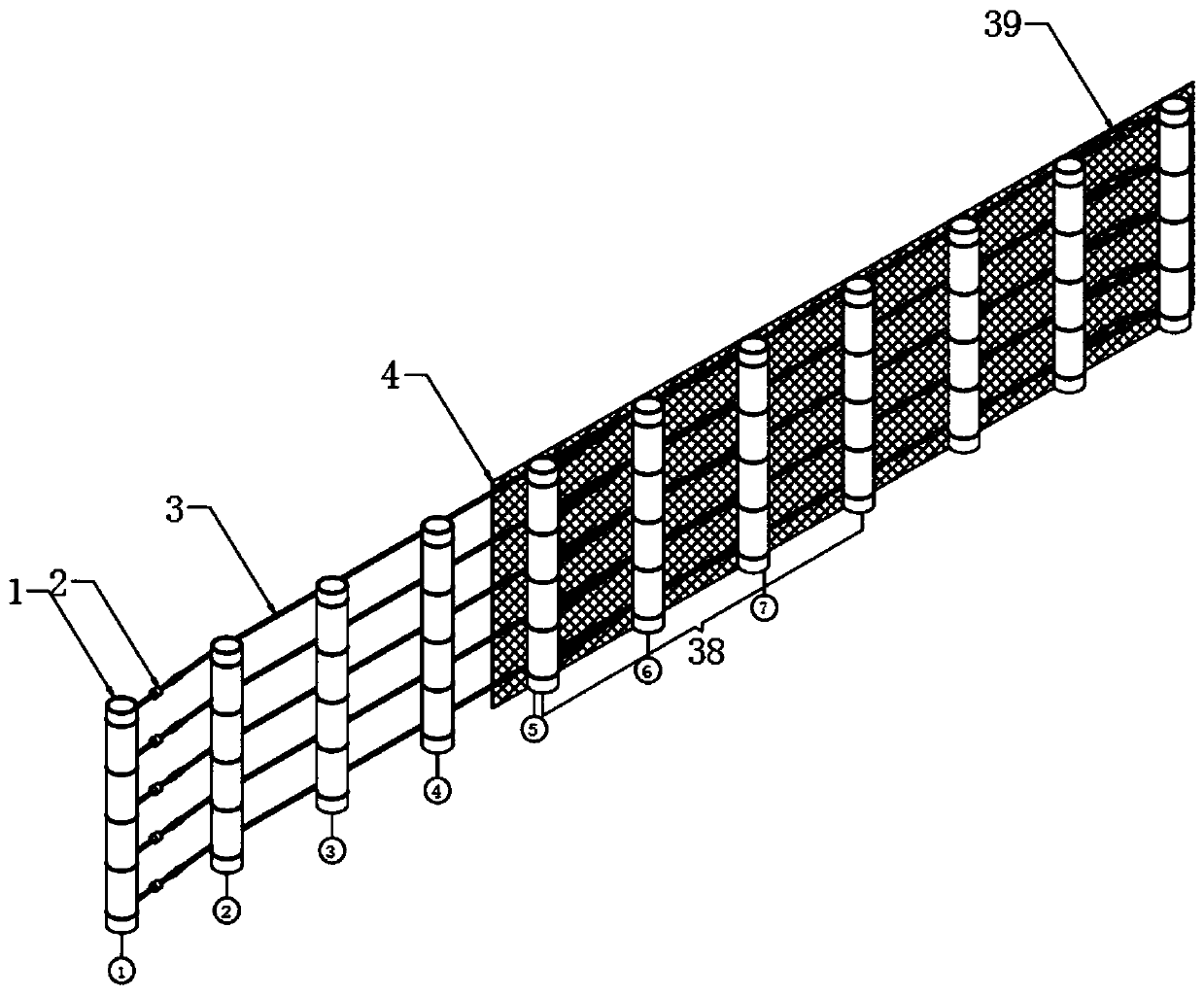

[0035] 1. Net strength support construction method, such as figure 1 :

[0036] a. Select 4 net supports between the piles 1 as a group, number the piles 1 ①②③④⑤⑥⑦, the distance between the piles 1 is 5m, and the length of the net 4 that can be supported is 20m, that is, the net 4 between ②③④⑤⑥;

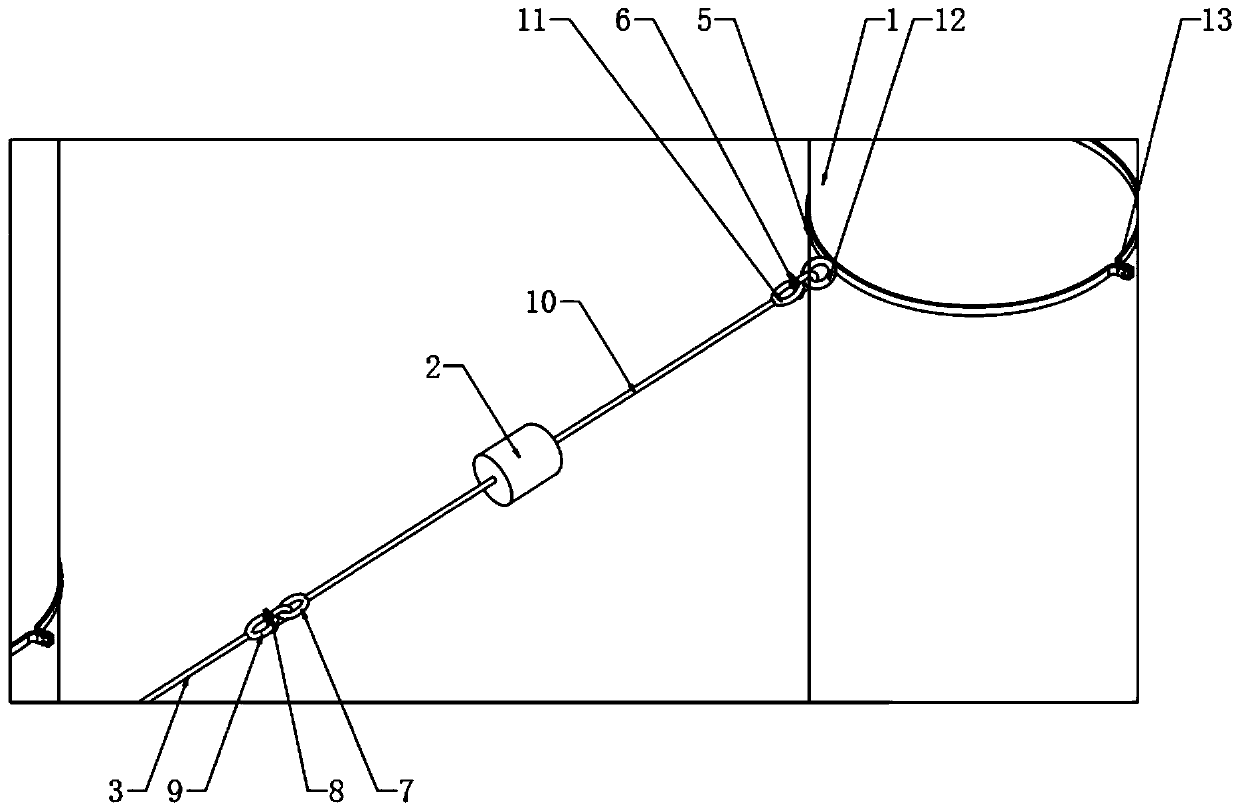

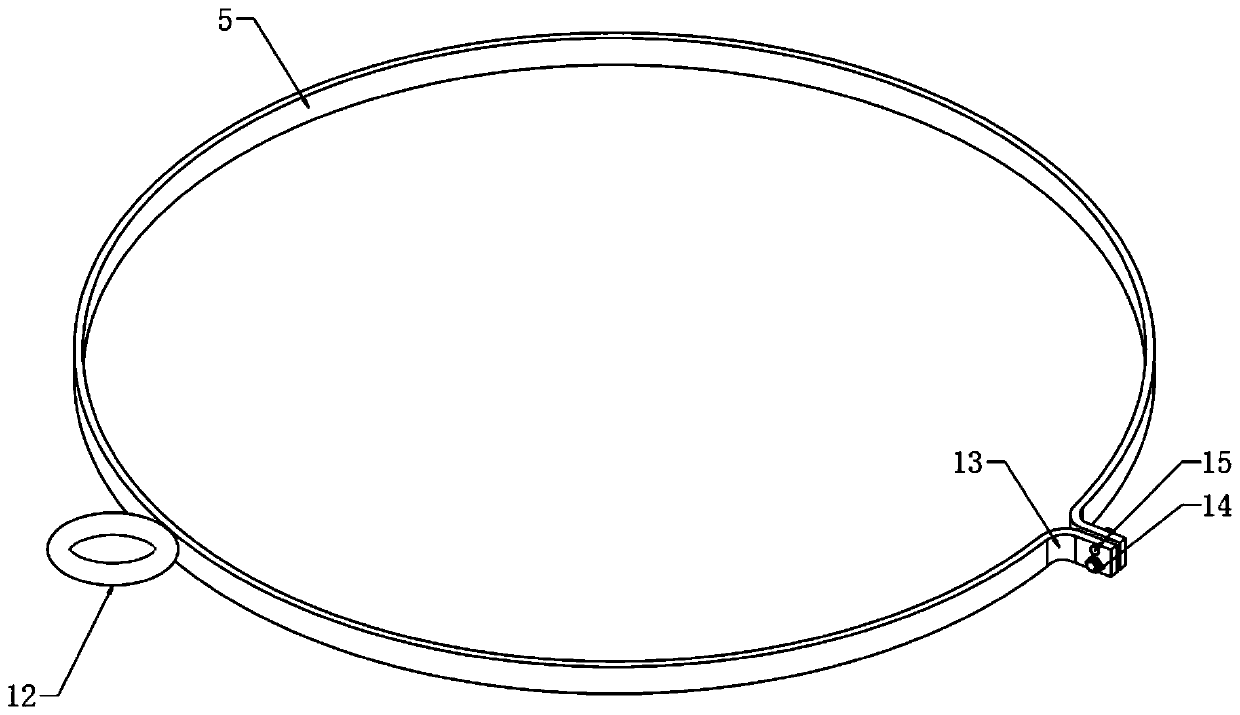

[0037] b. Install the connecting ring 16 on the column pile 1②③④⑤⑥, the connecting pipe 18 is located on the same horizontal line on the side of the net 4, the solid ring 5 is installed on the pile ①⑦, and the pull ring 12 is opposite to the same horizontal line ;

[0038] c. The length of the steel wire rope 3 is determined as 22m, and after the steel wire rope 3 passes through 4 connecting steel pipes 18, the two ends are respectively fixed on the pull ring 12 by adjusting the steel rope 10;

[0039] d. The wire tensioner 2 connected in series in the middle of the adjustment guide 10 is the adjustment section, the initial length of the adjustment section is about 4.5m, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com