Laminate

A laminated body and laminated structure technology, applied in the direction of layered products, layered product processing, synthetic resin layered products, etc., can solve problems such as difficult operation, and achieve the effect of not being easy to self-adhesive and excellent safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0207] Hereinafter, the present invention will be described in further detail based on examples and the like, but the present invention is not limited by these examples.

[0208] [Evaluation method]

[0209] (Physical property evaluation of thermoplastic resin)

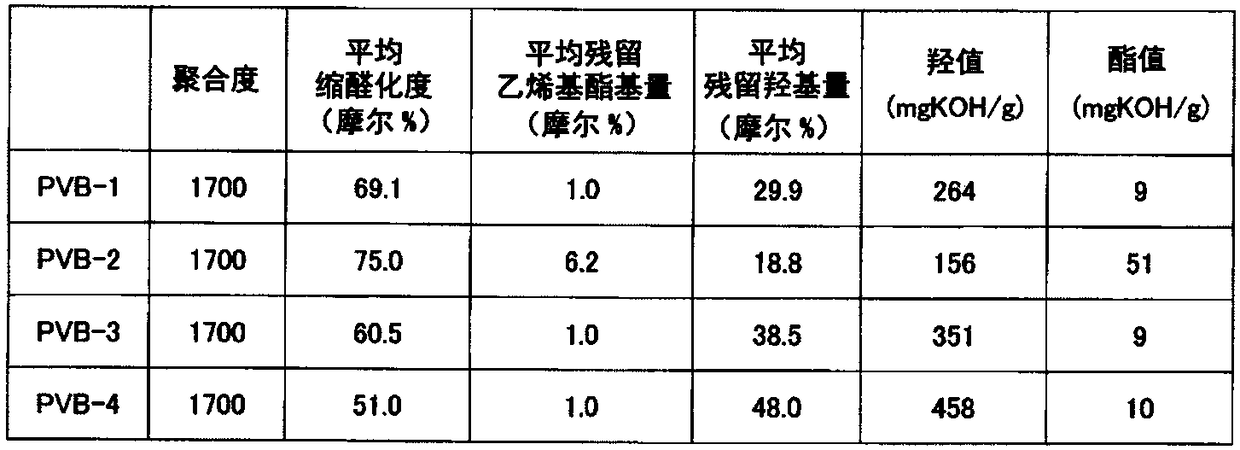

[0210] The average acetalization degree, average residual vinyl ester group amount, and average residual hydroxyl group amount of PVB-1 - PVB-4 obtained in manufacture examples 1-4 were measured based on JISK6728:1977.

[0211] The hydroxyl values of PVB-1 to PVB-4 obtained in Production Examples 1 to 4 were measured in accordance with JIS K1557:2007.

[0212] The ester values of PVB-1 to PVB-4 obtained in Production Examples 1 to 4 were measured in accordance with JIS K0070:1992. Table 1 shows the measurement results of the average degree of acetalization, the average amount of residual vinyl ester groups, the average amount of residual hydroxyl groups, the hydroxyl value, and the ester value.

[0213] (Flexib...

manufacture example 1

[0243] In a 5-liter glass container equipped with a reflux cooler, a thermometer, and an IKARI-type stirring blade, 4050 g of ion-exchanged water and 330 g of polyvinyl alcohol (PVA-1: degree of polymerization 1700, degree of saponification 99 mol%) were put in, and the temperature was raised to 95°C. Allow polyvinyl alcohol to dissolve completely. The resulting solution was slowly cooled to 10° C. at 160 rpm with stirring for about 30 minutes, then 189 g of n-butyraldehyde and 200 mL of 20% aqueous hydrochloric acid were added, and a butyralization reaction was carried out for 50 minutes. Thereafter, the temperature was raised to 65° C. over 60 minutes, maintained at 65° C. for 120 minutes, and then cooled to room temperature. After the obtained resin was washed with ion-exchanged water, an aqueous sodium hydroxide solution was added to neutralize the remaining acid, and then it was washed with excess ion-exchanged water and dried to obtain polyvinyl butyral (PVB-1).

manufacture example 2

[0245] 330 g of polyvinyl alcohol (PVA-2: polymerization degree 1700, saponification degree 92 mol %) was added instead of PVA-1, and the consumption of n-butyraldehyde was changed to 195 g, except that PVB-2 was obtained in the same manner as in Production Example 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com