Continuous shearing system suitable for elastic lace fabric

A continuous type fabric technology, which is applied in the cutting of textile materials, textiles and papermaking, metal processing, etc., can solve the problems of poor continuity of cutting, fabric runaway, high work intensity, etc., and achieves prevention of runnage and high straightness , high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

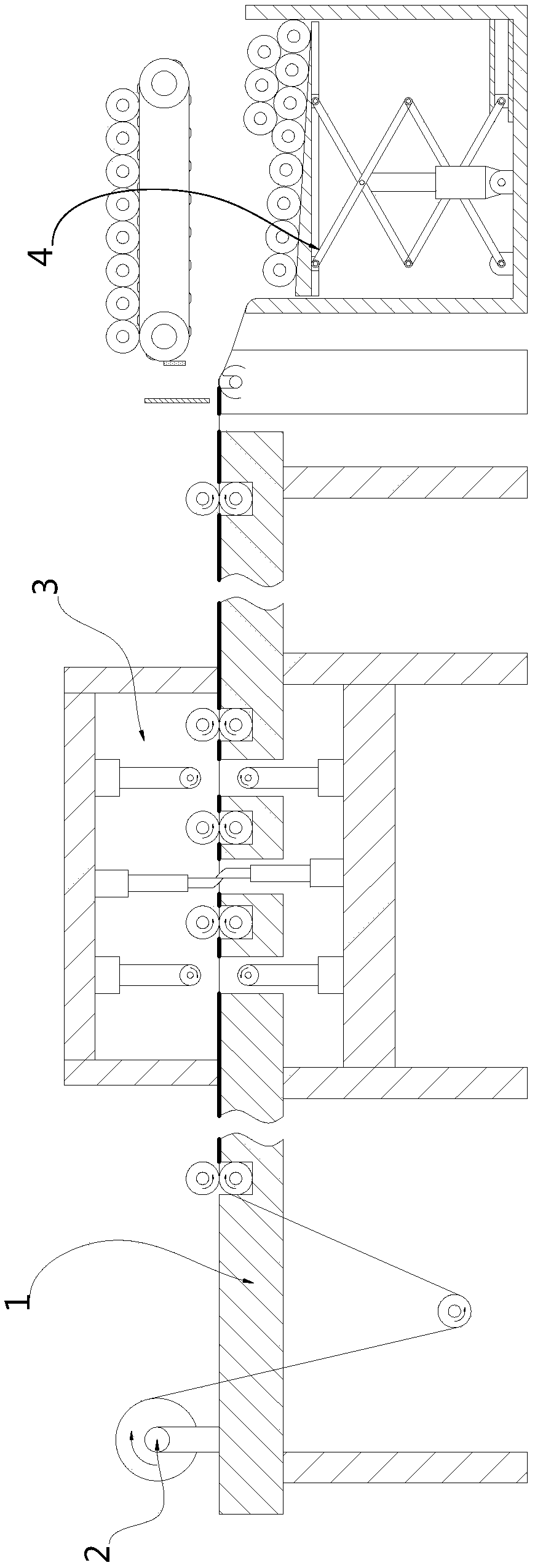

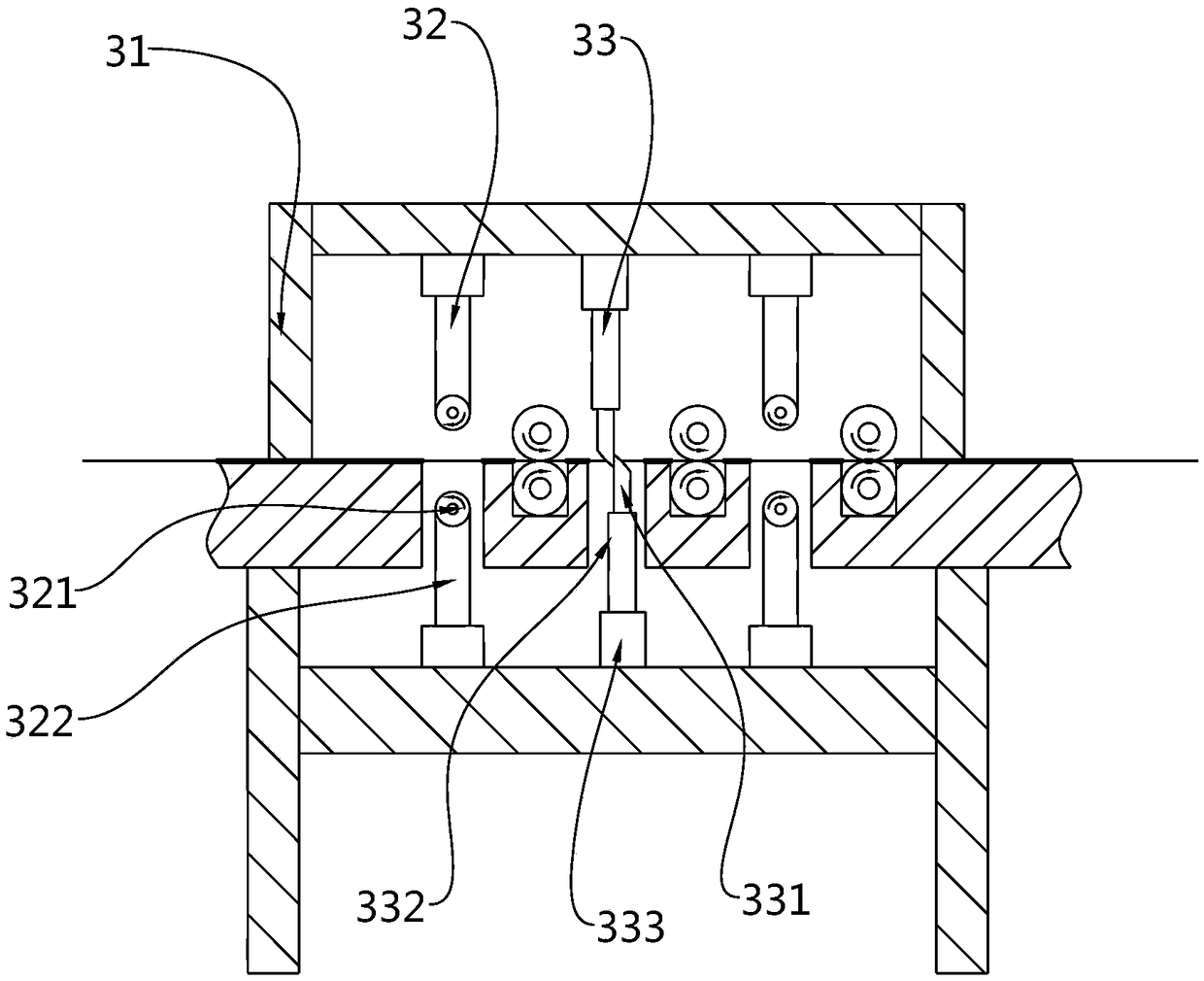

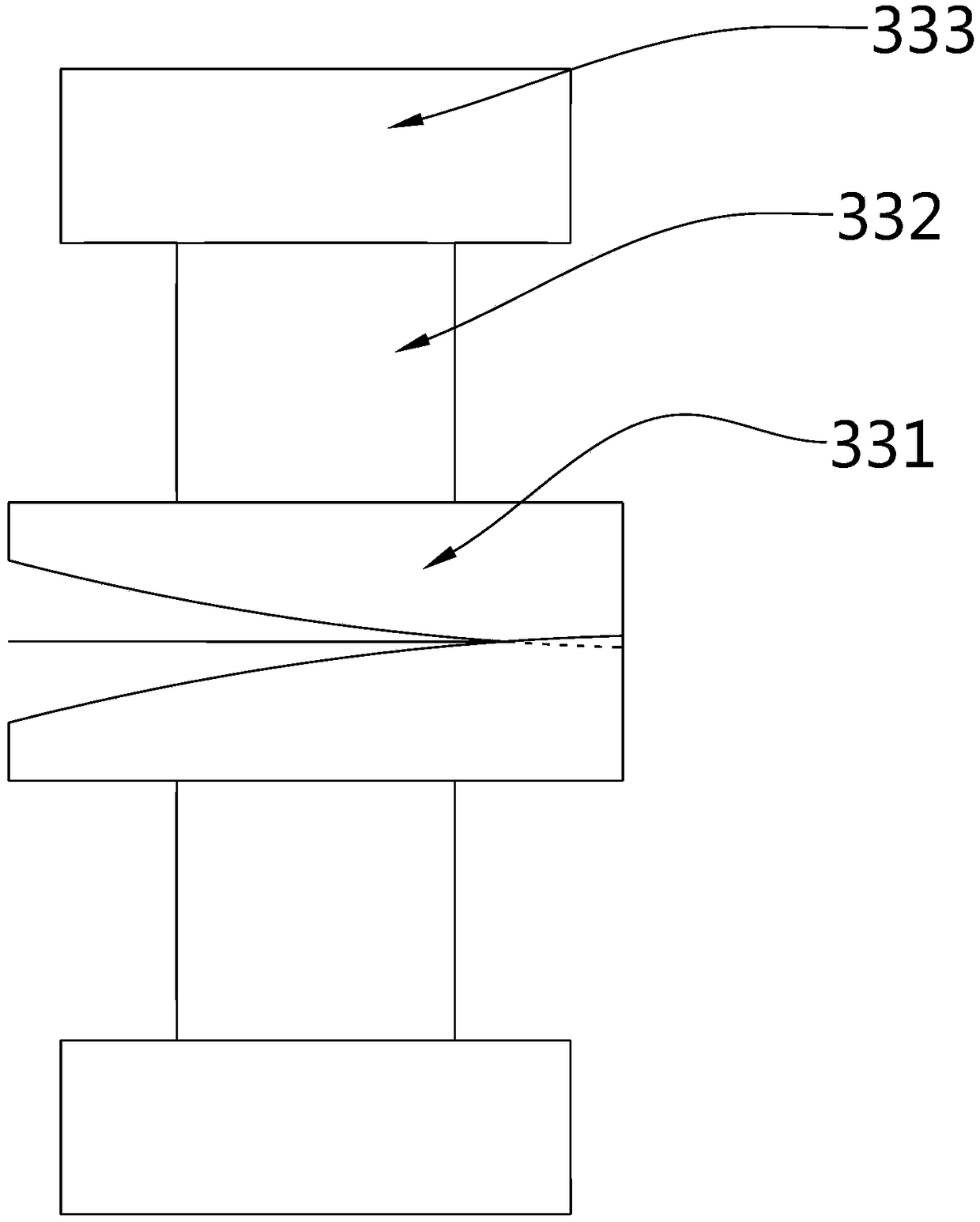

[0029] Embodiment: a kind of continuous type cutting system that is applicable to elastic lace fabric, structure such as Figure 1 to Figure 7 As shown, the main frame 1 is included, the end of the main frame 1 is provided with a total roller 2, the main frame 1 is provided with a plurality of pairs of transmission rollers along the fabric transmission direction, the middle part of the main frame 1 is provided with a cutting device 3, and the main frame 1 discharges a Side is provided with recovering device 4; Described cutting device 3 comprises the sub-frame 31 that is connected with main frame 1, and sub-frame 31 is provided with two pairs of fabric tensioning mechanisms 32, is provided between two pairs of fabric tensioning mechanisms 32 The scissors mechanism 33, the scissors mechanism 33 comprises a pair of shearing cutters 331 that are cross-fitted up and down; the recovery device 4 comprises a rewinding mechanism 41, and the top of the rewinding mechanism 41 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com