Cotton pressing and conveying mechanism and antiperspirant pad forming equipment

A conveying mechanism and cotton pressing technology, which is applied in the direction of conveyors, laminations, lamination devices, etc., can solve the problems of limited conveying effect of the conveyor belt on the cotton belt, loose cotton belt, and large change in the thickness of the cotton belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

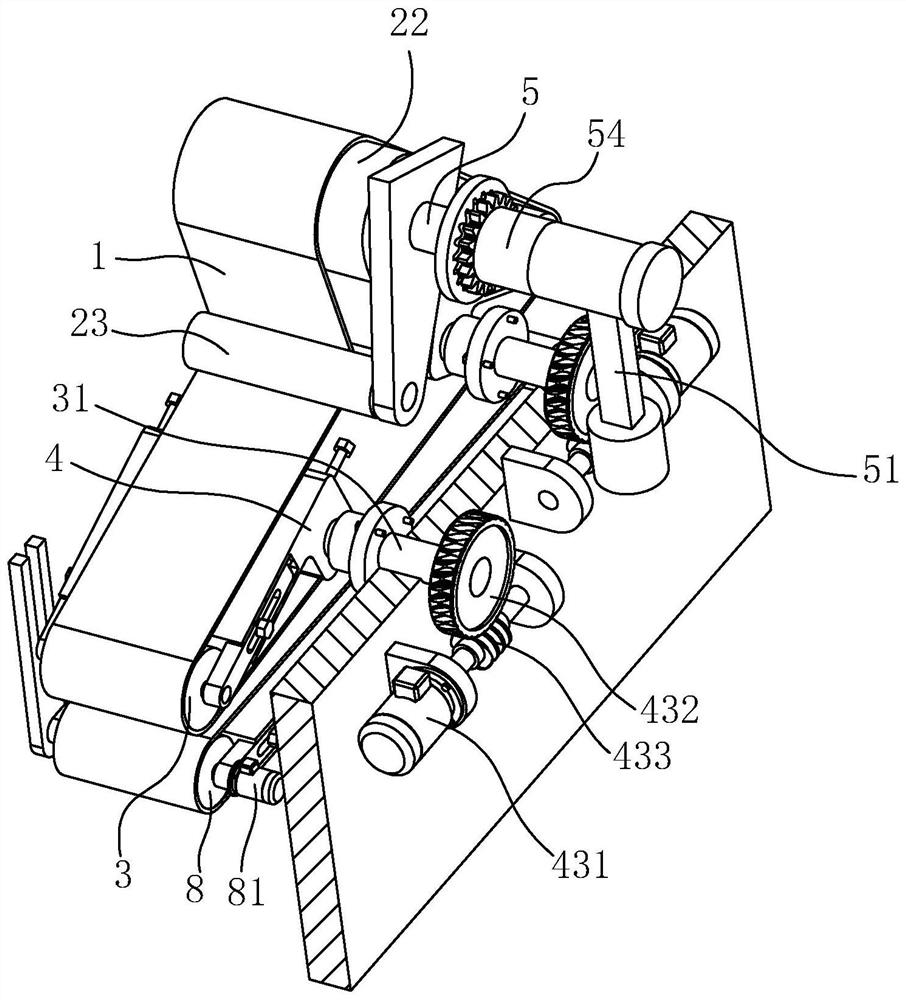

Method used

Image

Examples

Embodiment 2

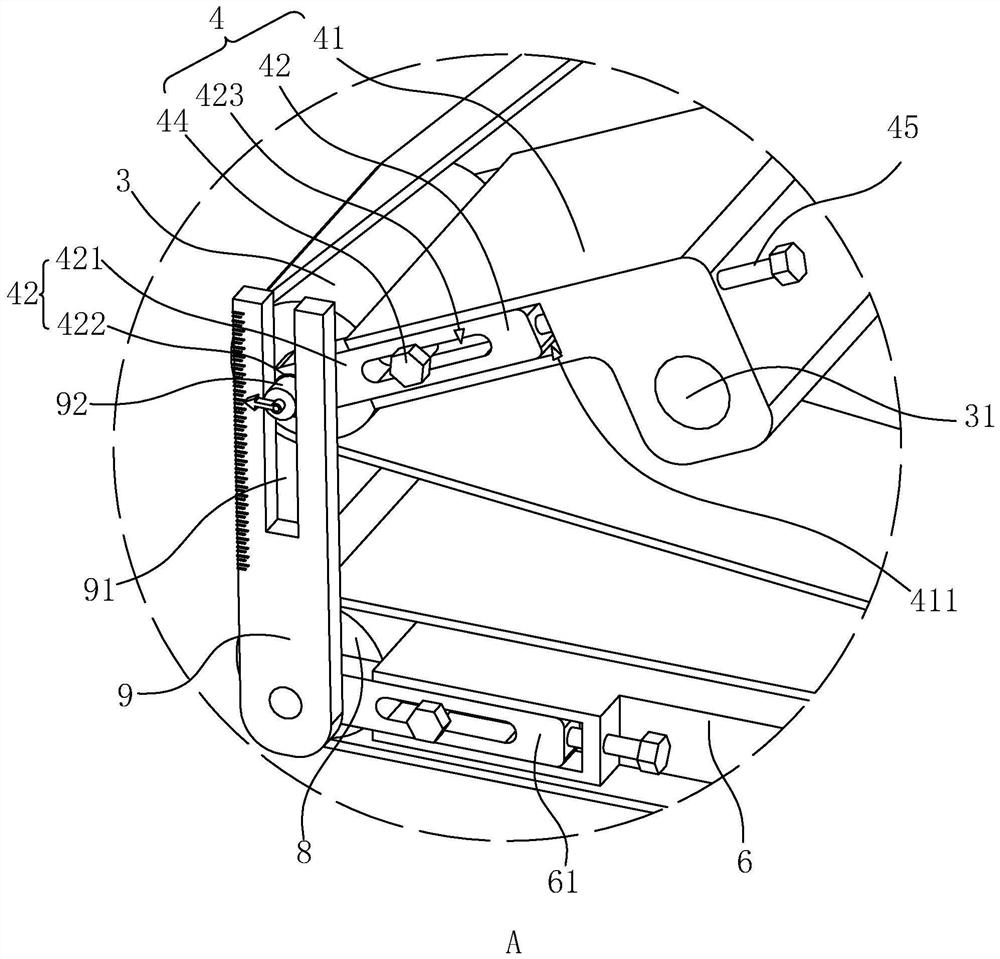

[0067] Embodiment 2, with reference to Figure 6 , the difference from Embodiment 1 is that the movable seat 42 is attached to both sides of the fixed seat 41, and each side of the fixed seat 41 connected with the movable seat 42 is provided with a first stopper that is threadedly connected with the fixed seat 41 44 , the first limiting member 44 passes through the first waist hole 423 and presses the movable seat 42 to the fixed seat 41 . The moving seat 42 is provided with an arc-shaped hole 425 at one end of the first waist hole 423, and the middle part of the fixed seat 41 is provided with a cavity 426, and the side wall of the fixed seat 41 is provided with a second waist hole communicating with the cavity 426. 427, the movable seat 42 is provided with a second stopper 46, and the second stopper 46 includes a second bolt 461 and a second nut 462, wherein the second bolt 461 passes through the second waist hole 427 and the arc hole 425 , the nut of the second bolt 461 and...

Embodiment 3

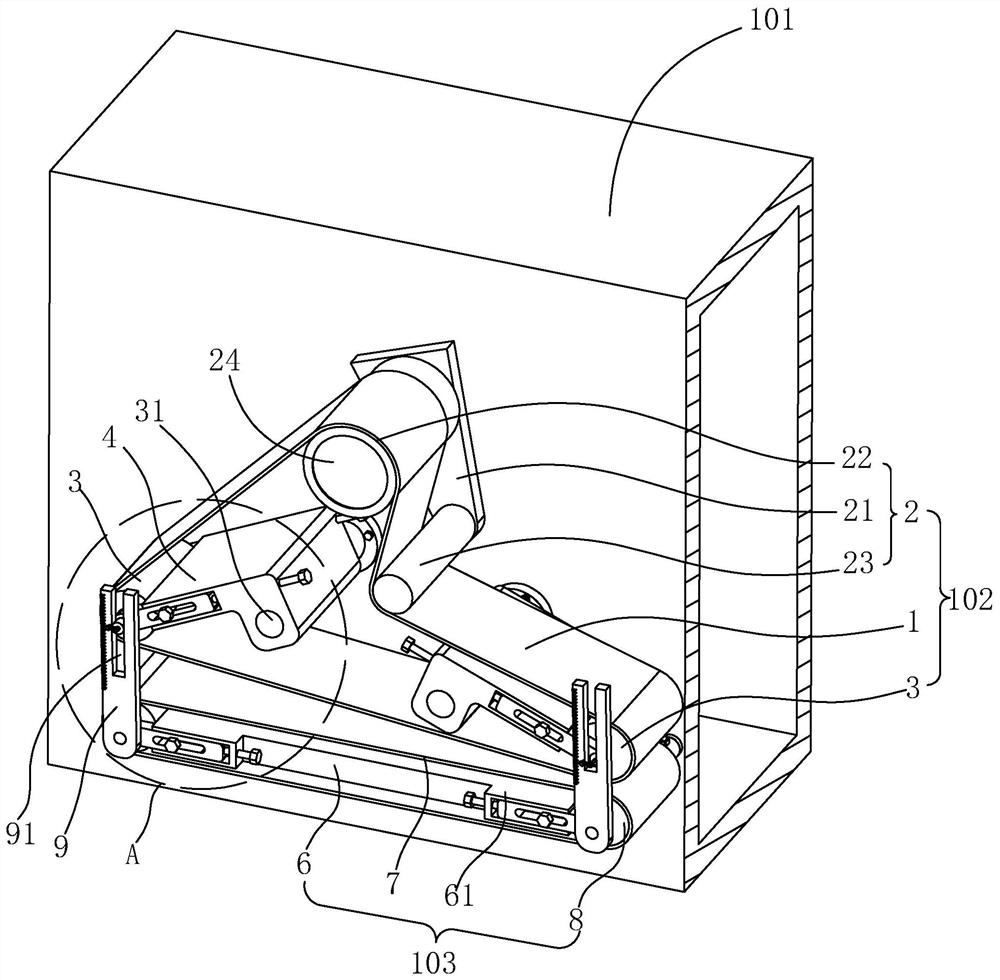

[0071] Embodiment 3, an antiperspirant pad forming equipment, which uses the pressing cotton conveying mechanism of the above-mentioned embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com