Bistable double-piezoelectric cantilever beam vibration energy collector

A vibration energy harvesting and cantilever beam technology, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of limited energy supply time or power, and reduce electromechanical energy conversion Efficiency, limiting the miniaturization of microsensors and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below with reference to the drawings and embodiments.

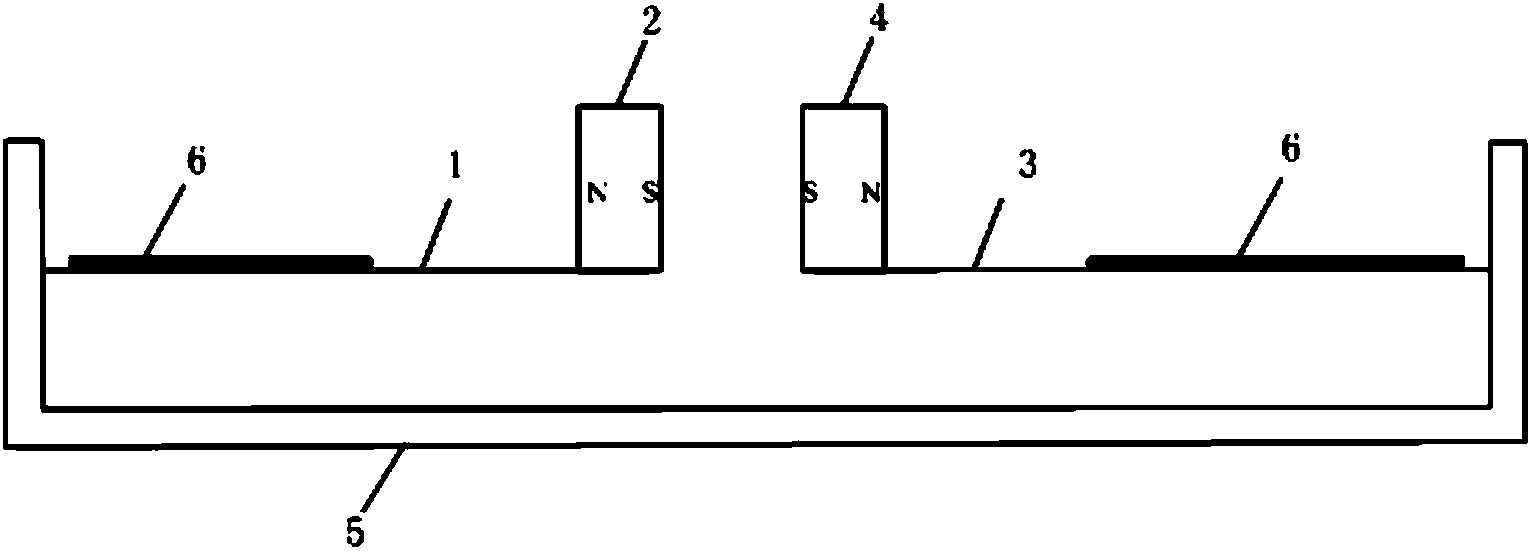

[0017] The structure of the bistable bi-stable piezoelectric cantilever beam vibration energy harvester is: two cantilever beams are placed on the same horizontal line and arranged left and right, the free end of the left cantilever beam 1 is equipped with an inner magnet 2, and the free end of the right cantilever beam 3 is installed There is an outer magnet 4, the fixed ends of the two cantilever beams are fixedly installed on the vertical surface of the right-angle base 5, and the magnetic polarities of the outer magnet and the inner magnet are oppositely arranged. Piezoelectric sheets 6 are respectively pasted on the fixed end of each cantilever beam at a position 2-3mm away from the vertical plane of the right-angle base. The vibration of the cantilever beam causes the piezoelectric sheet to generate electric energy, and the piezoelectric s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com