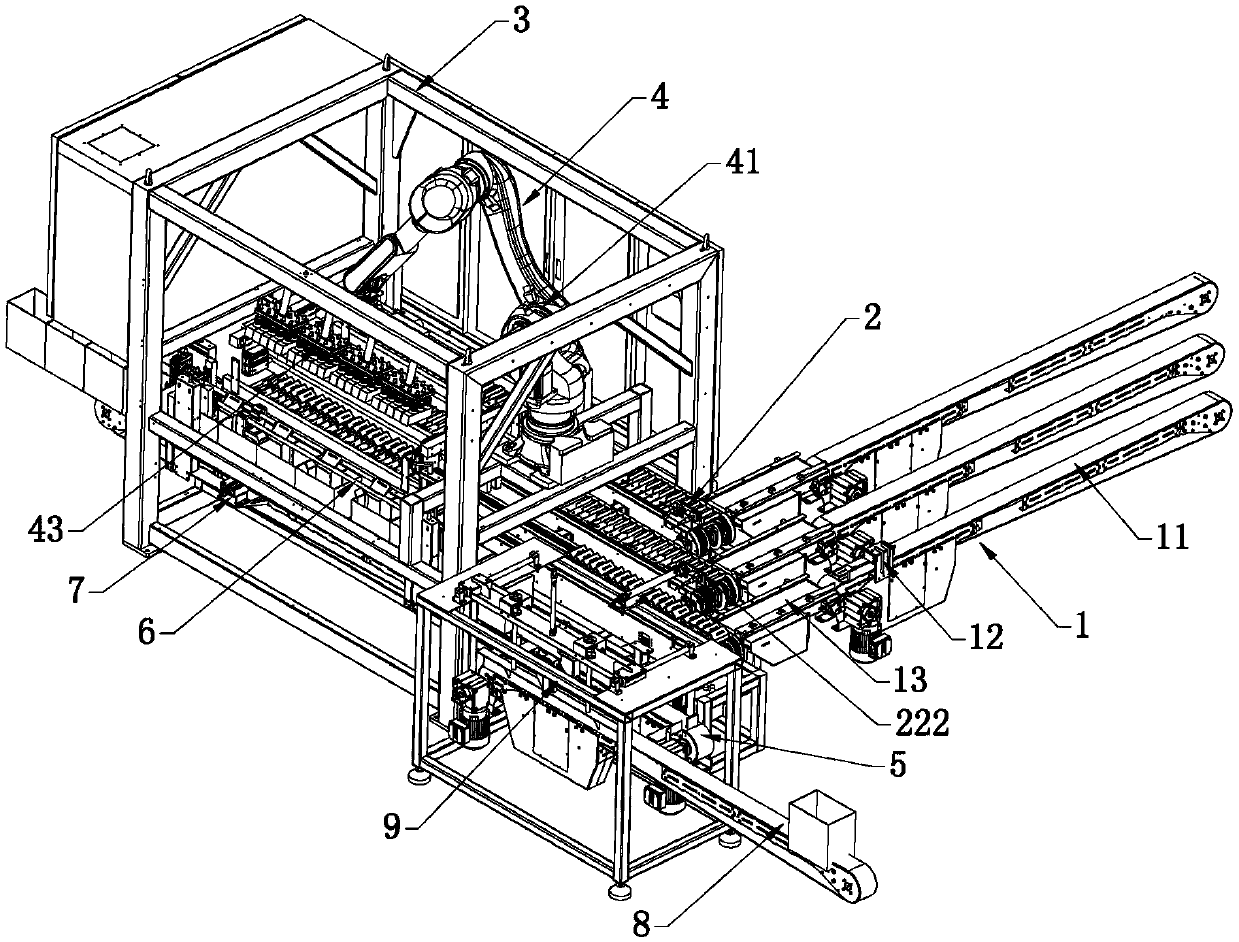

Automatic ice cream packaging system

An automatic packaging and ice cream technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of time-consuming, labor-intensive, and low work efficiency, and achieve high efficiency, high packing efficiency, and fast integration speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

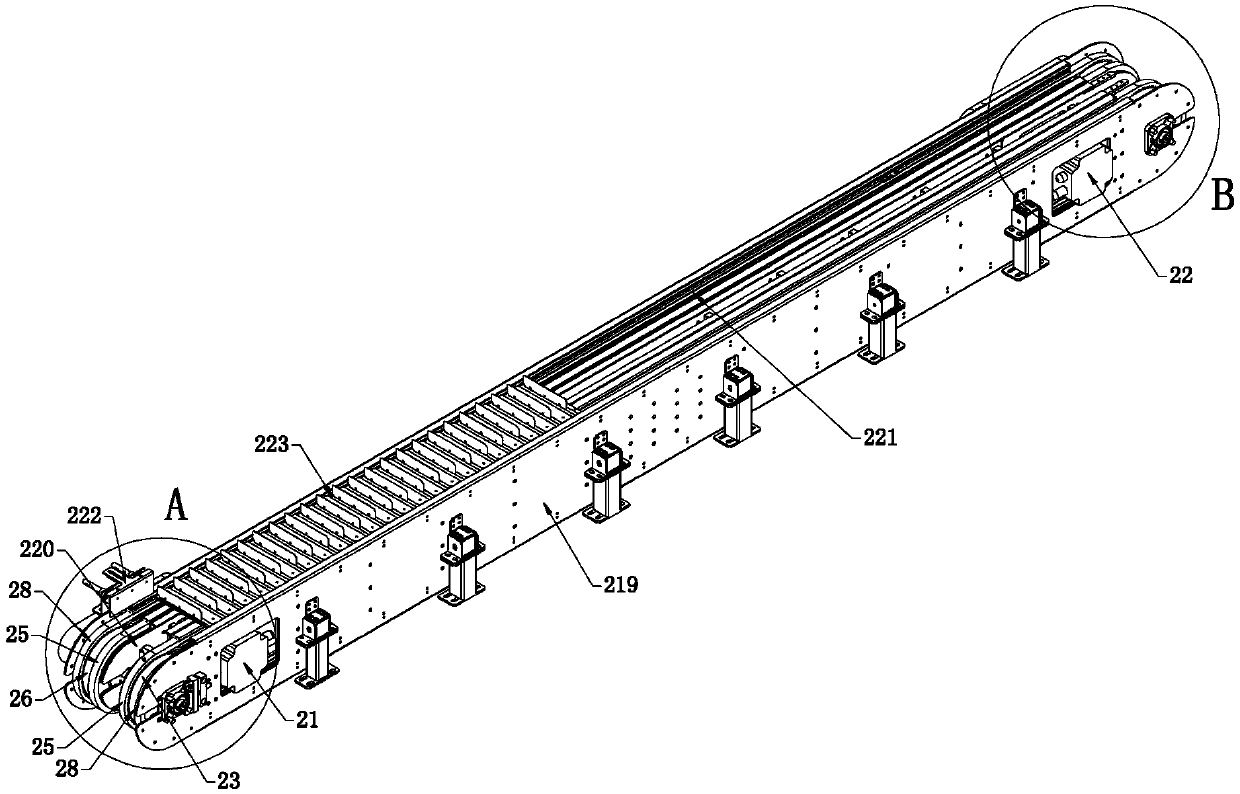

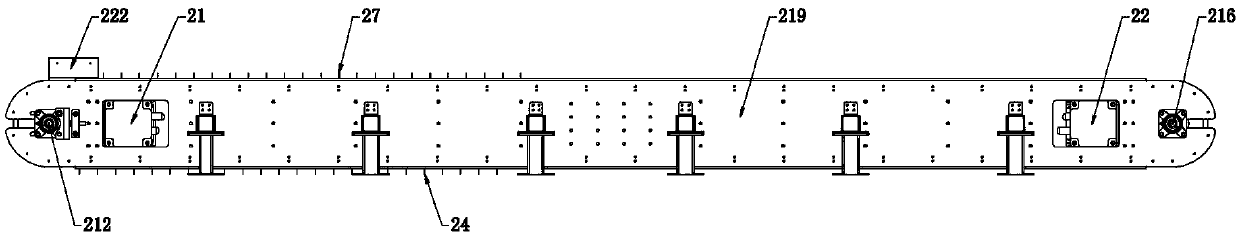

[0064] Below to be provided with three mutually corresponding ice cream feeding mechanism 1 and integrated conveying mechanism 2; One end that has ice cream baffle plate 222 in integrated conveying mechanism 2 is provided with tension servo motor 21, tension sprocket wheel 23 and is positioned between thrust sprocket wheel 24, Tens of ice cream grooves are respectively arranged on the tension integrated conveyor belt 24 and the thrust integrated conveyor belt 27; a robot 41 of each robot grasping mechanism 4 drives four tool fixtures 43 at the same time, and each tool fixture 43 is provided with five Three suction cups 433, three suction cup flexible joints 434 are all provided on the cavity cover plate 4317 of each suction cup 433; and the specific setting that the box support positioning mechanism 6 and the box lifting plate 7 simultaneously lift four packing boxes and position the box support To further illustrate the technical solution of the present invention.

[0065] li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com