Sewing management system

A management system and identification technology, applied in the field of sewing management system for custom-made garments, can solve problems such as time and labor, and achieve the effect of avoiding wrong parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

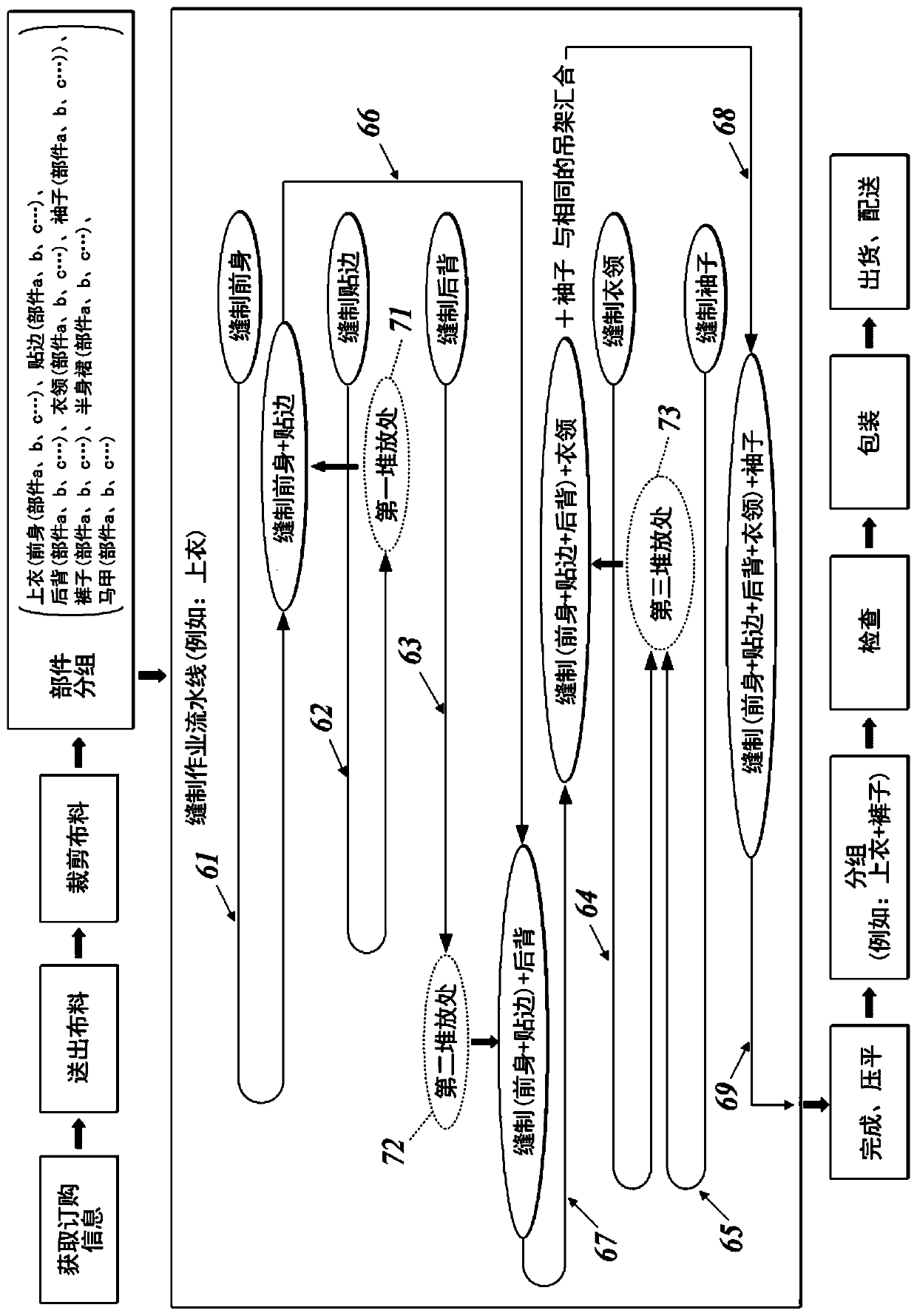

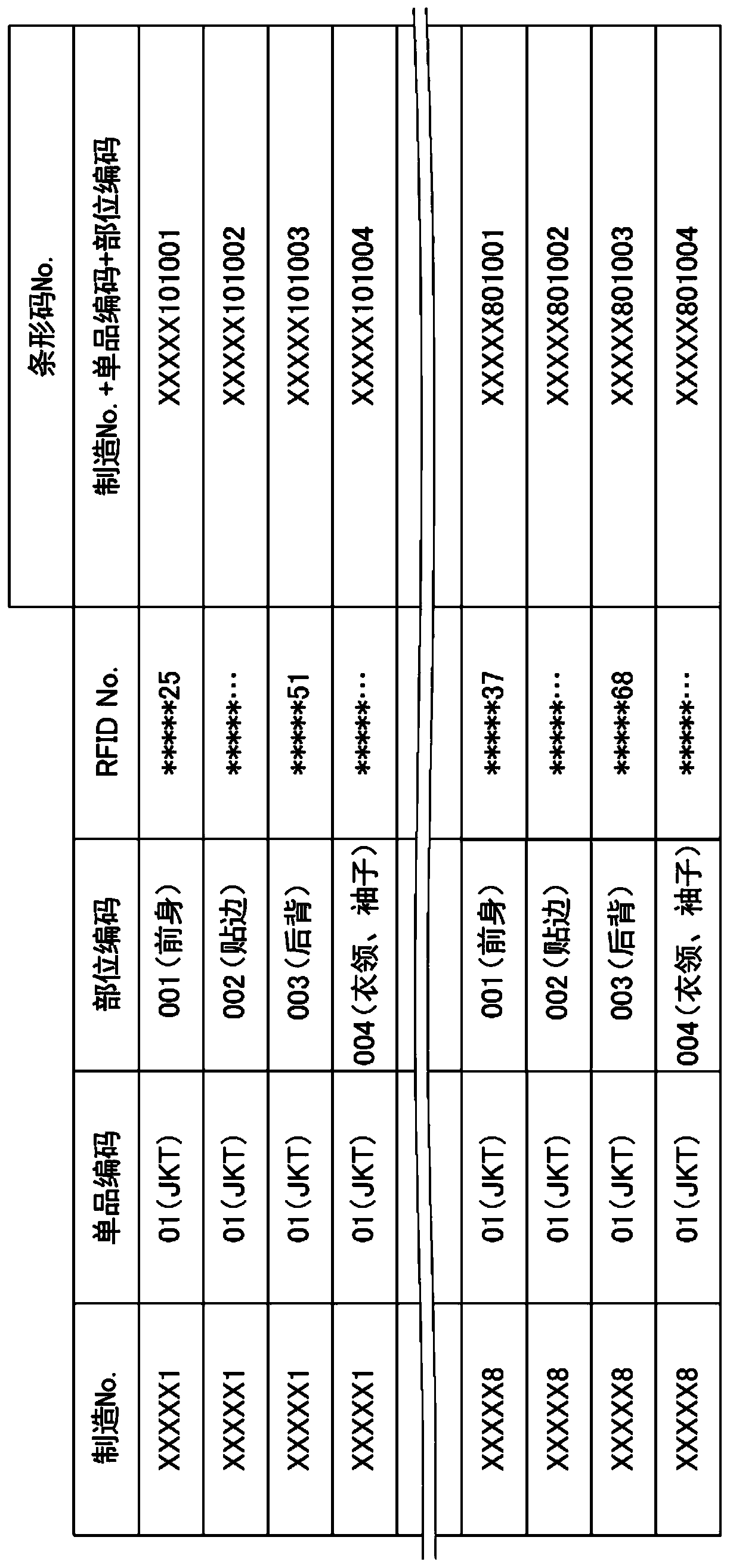

[0045] Below, refer to Figure 1 to Figure 6 One embodiment of the sewing management system according to the present invention will be described.

[0046] In addition, in the following embodiments, various limitations technically preferable for carrying out the present invention are added, but the scope of the present invention is not limited to the following embodiments and illustrated examples.

[0047] >

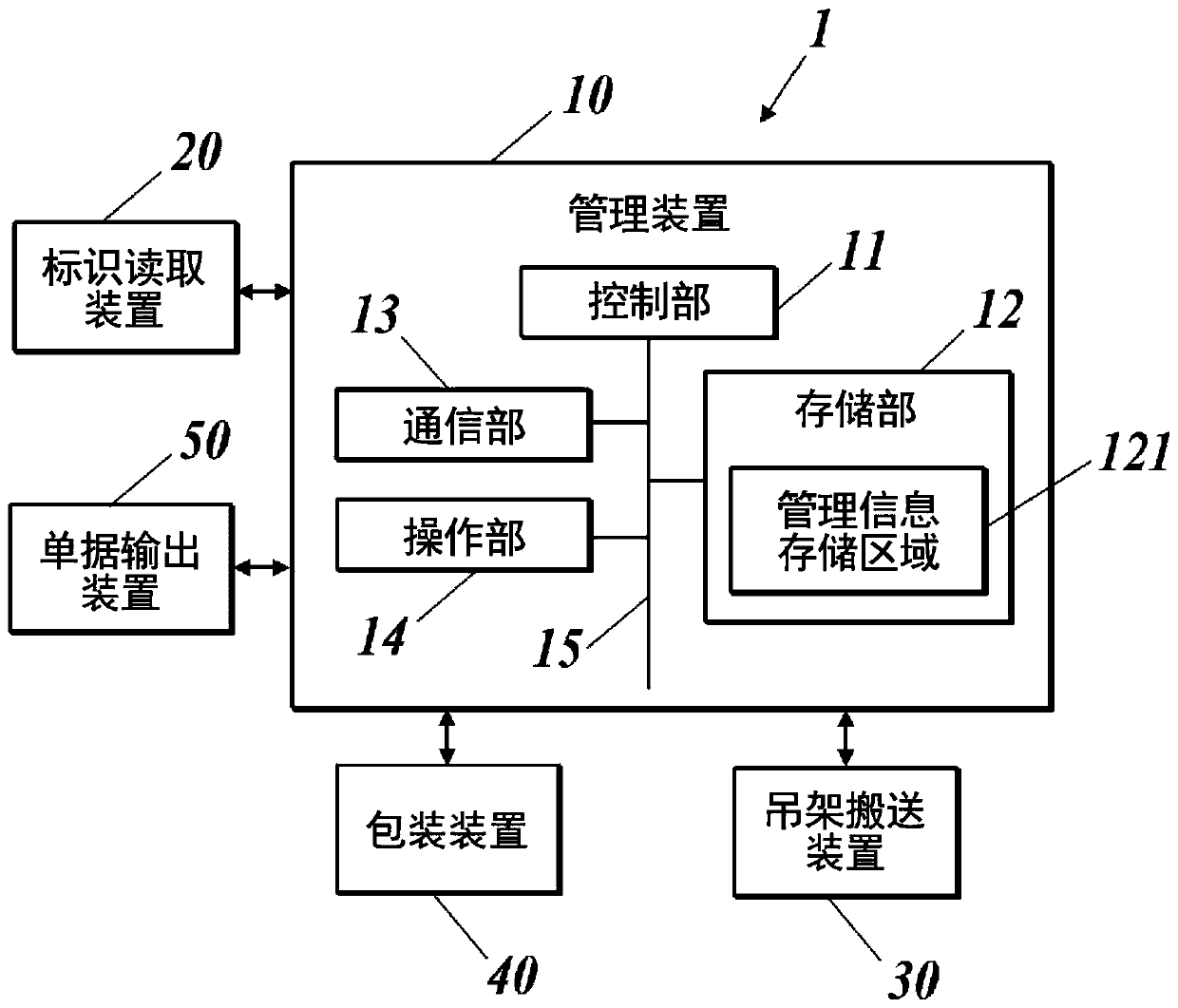

[0048] figure 1 It is a conceptual diagram showing the overall flow of one embodiment of the sewing management system according to the present invention, figure 2It is a main part block diagram which shows the main part structure of one embodiment of a sewing management system. In addition, the "sewing management system" of this embodiment is also called "this system" below.

[0049] Sewing management system (this system) 1 (refer to figure 2 ) is a sewing management system as follows: obtain order information from customers, sew customized garments including one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com