Fan guide cylinder positioning device

A positioning device and guide tube technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of large product deformation, low efficiency, low concentricity of the guide tube, etc., to avoid damage, uniform force, ensure The effect of roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

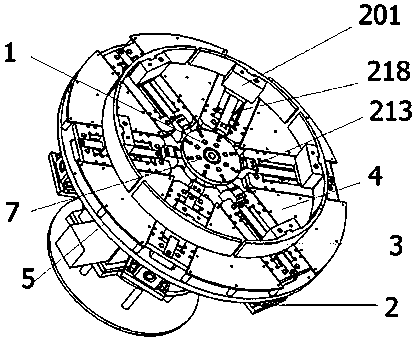

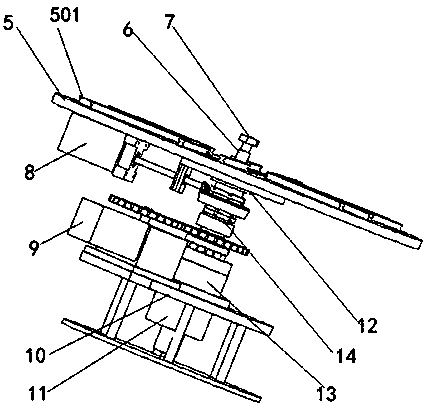

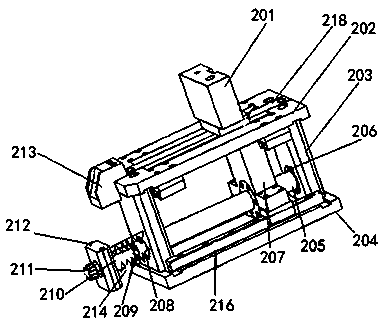

[0029] Such as Figure 1-6 As shown, a positioning device for a fan guide tube mainly includes a main shaft part 14 and a table bottom plate 5. The bottom plate of the table top 5 is a circular plate with 6 mounting holes arranged on the upper surface. The mounting holes extend radially and are evenly arranged around the center of the bottom plate 5 of the table top. A tensioning arc 3 is correspondingly provided on the outside of each mounting hole. All the tensioning arcs 3 are surrounded by circular arcs, and the extension lines of adjacent tensioning arcs are connected to form a tensioning circle. A diameter adjustment mechanism 2 is installed at the position of the installation hole on the bottom plate of the table top 5, and the diameter adjustment mechanism 2 is connected with the tensioning arc 3 in cooperation. The tensioning arc 3 is arc-shaped, and there are projections on the inner wall, and the projections and the slots cooperate to complete the connection betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com