Winding device of wire drawing machine

A technology of a wire take-up device and a wire drawing machine is applied in the field of wire drawing machines, which can solve the problems of low production efficiency and product quality qualification rate, scratches on the surface of the stranded wire, disordered arrangement of wires, etc. Quality, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

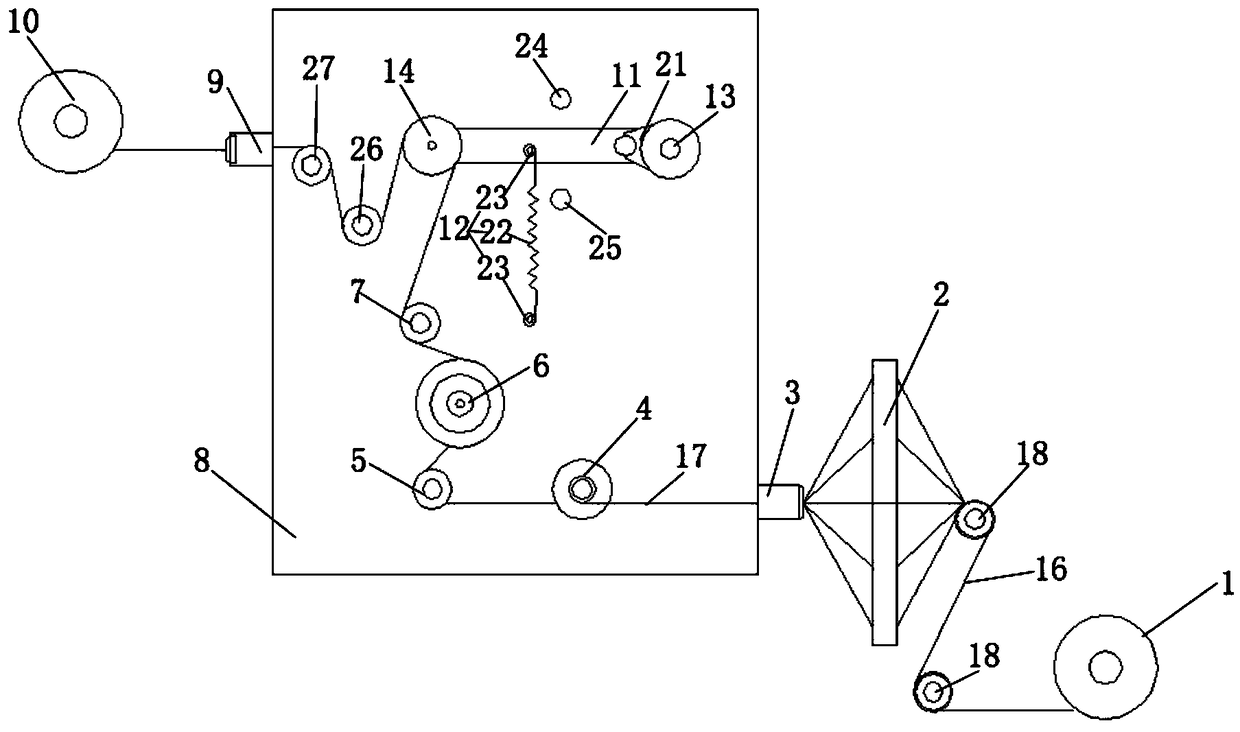

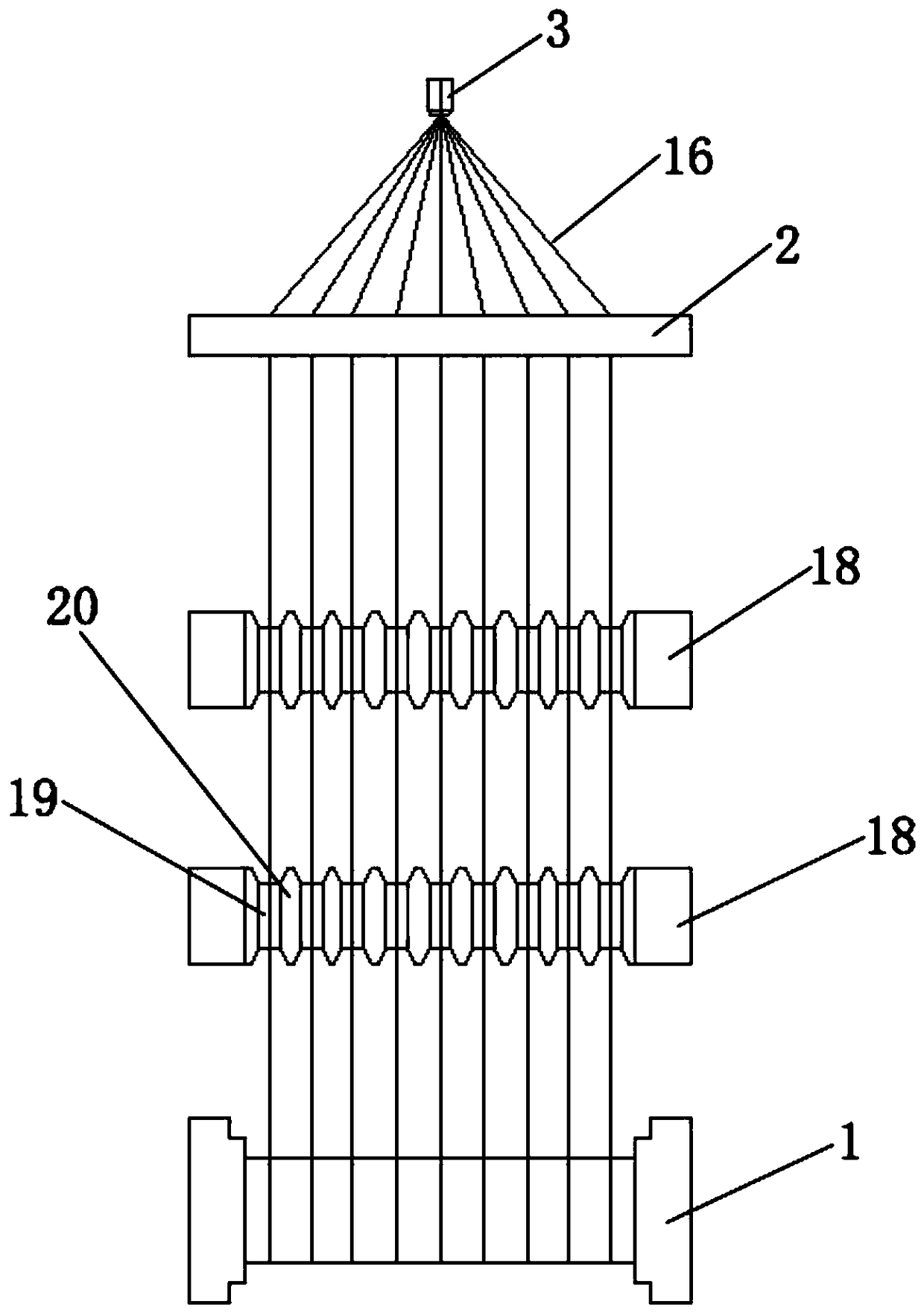

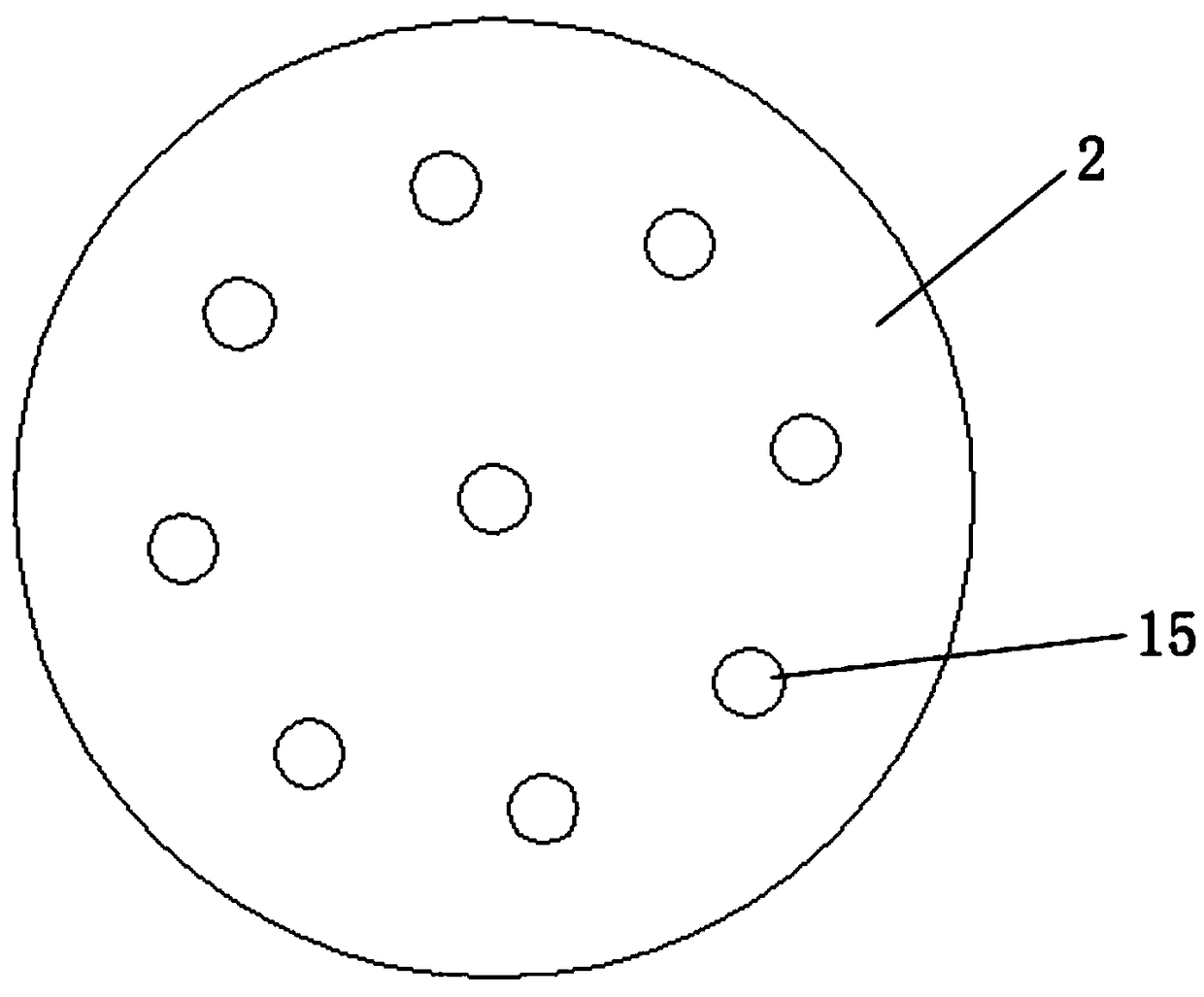

[0023] In order to facilitate the understanding of the present invention, the present invention will be described in detail below in conjunction with the preferred embodiments of the present invention given in the accompanying drawings.

[0024] like Figure 1 to Figure 3 As shown, the wire drawing machine wire take-up device of the embodiment of the present invention includes a single-wire wire take-up roller 1, a wire roller shaft group, a wire plate 2, a stranded wire die 3, a tension regulator, a stranded wire porcelain eye 9 and a stranded wire take-up Roller 10. The tension controller includes a felt clip 4 integrally assembled on a mounting plate 8, a first wire pulley 5, a tension pulley 6, a second wire pulley 7, a tension adjustment plate 11, a spring assembly 12, a fixed axis rotary wheel 13 and a floating Lead wheel 14. The tension wheel 6 is controlled by a tension regulating motor and is provided with an angular displacement encoder. The fulcrum end of the ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com