Carbon black and production method therefor, and electricity storage device and conductive resin composition

A manufacturing method and technology of carbon black, which are applied in the direction of carbon silicon compound conductors, battery electrodes, conductive materials dispersed in non-conductive inorganic materials, etc. Effects of undesirable phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

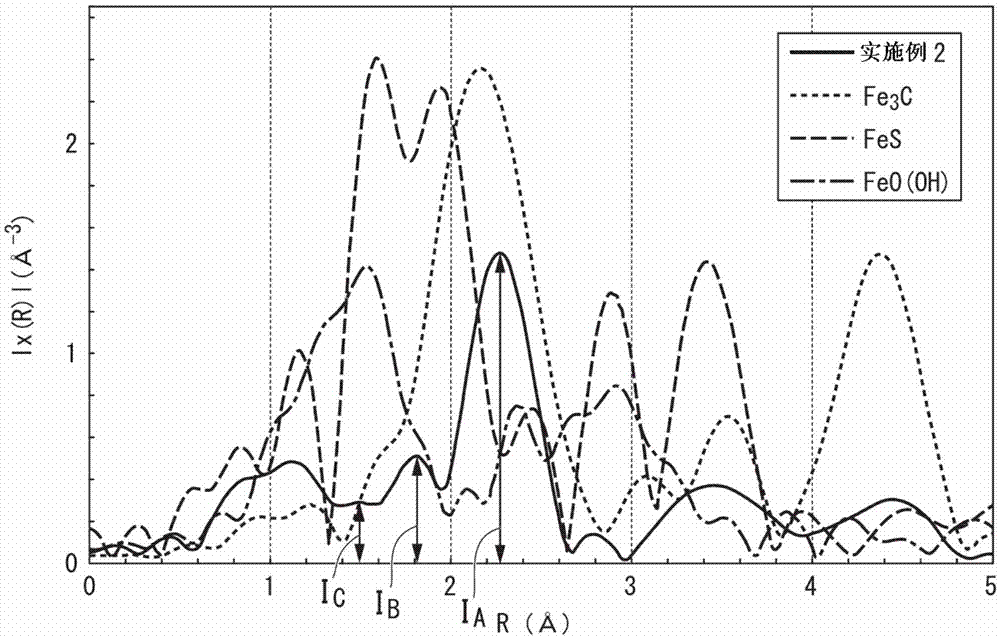

[0155] As raw carbon black, 50 g (dry mass) of CB-1 powder was placed in the center of the furnace tube, while chlorine gas as a halogen-containing gas was flowed at 10 L / min, and argon gas was flowed at 1 L / min at the same time. Heat at 900°C for 30 minutes. Then, by starting the oil pressure diffusion pump, the vacuum degree is decompressed to 1.33×10 -1 ~1.33×10 -2 After maintaining Pa or below for 30 minutes, it cooled to 30 degreeC and obtained the evaluation sample.

Embodiment 2 and 3

[0157] Except having changed heating temperature as shown in Table 1, it carried out similarly to Example 1, and obtained the evaluation sample.

Embodiment 4~17

[0159] As shown in Table 1 and Table 2, except having changed the raw material carbon black used, heating temperature, and the gas containing a halogen element, it carried out similarly to Example 1, and obtained the evaluation sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com