Corrugated paper production line control system

A control system and production line technology, applied in the field of corrugated cardboard processing, can solve the problems of not being able to achieve unified management, stay, and impact on the quality and quantity of corrugated cardboard production, so as to improve convenience and effectiveness, and improve production efficiency and production quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

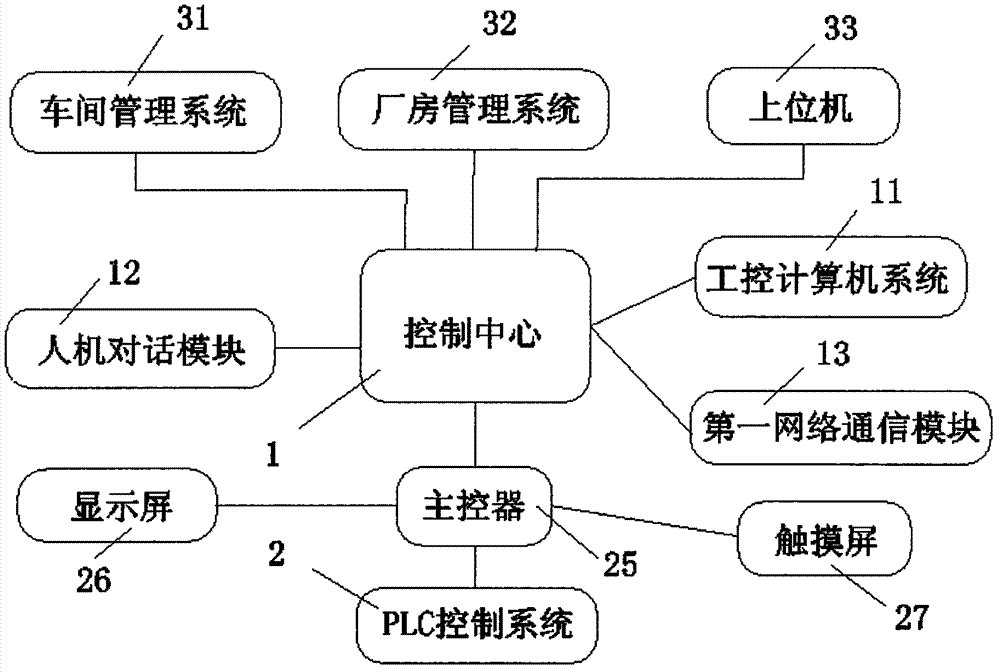

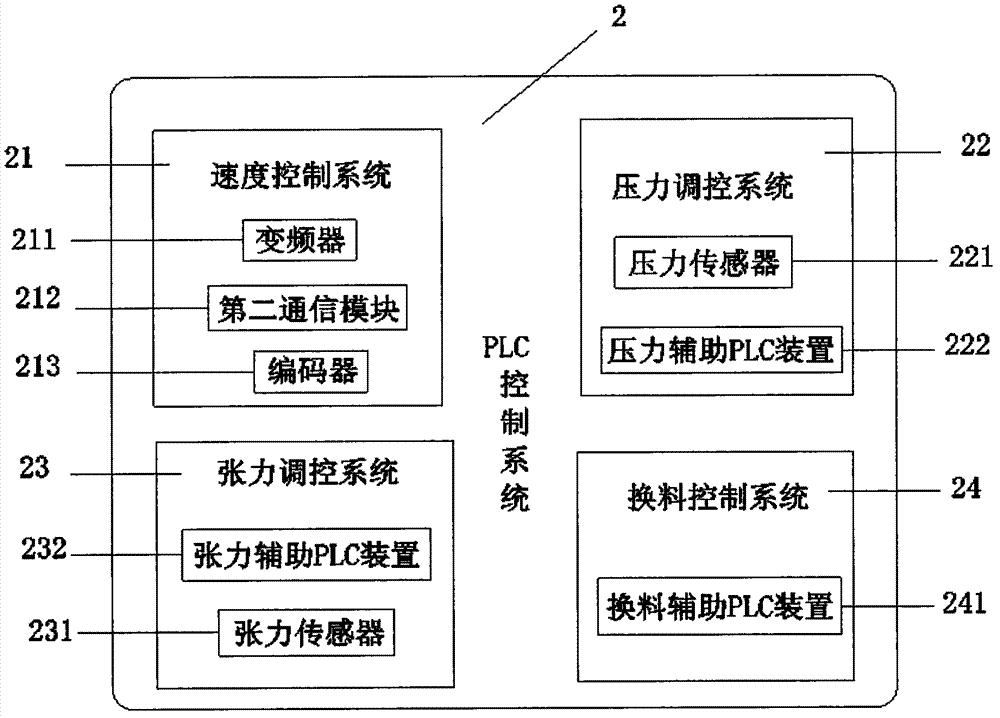

[0022] The following will be combined with figure 1 And attached figure 2 The present invention is further described, but it should not be used to limit the protection scope of the present invention.

[0023] A control system for a corrugated paper production line of the present invention, which includes: several management systems, the management systems are used to operate and manage the corrugated paper production line; a control center 1, which is connected to the management system through Ethernet; PLC control system 2, the PLC control system 2 communicates with the control center 1, and the PLC control system 2 includes a speed control system 21, a tension control system 22, a pressure control system 23 and a refueling control system 24, through The speed control system 21 realizes the regulation and control of the running speed of the production line, realizes the tension control of the paper of the production line through the tension regulation system 22, realizes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com