Automatic paste mixing machine control system and method for preparing lead paste

A control system and lead paste technology, applied in chemical instruments and methods, mixing methods, mixers, etc., can solve the problems of inconvenient use, difficult control of stirring temperature, and influence on the quality of paste, so as to facilitate judgment and improve production. Quality and production efficiency, the effect of avoiding deviations in temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

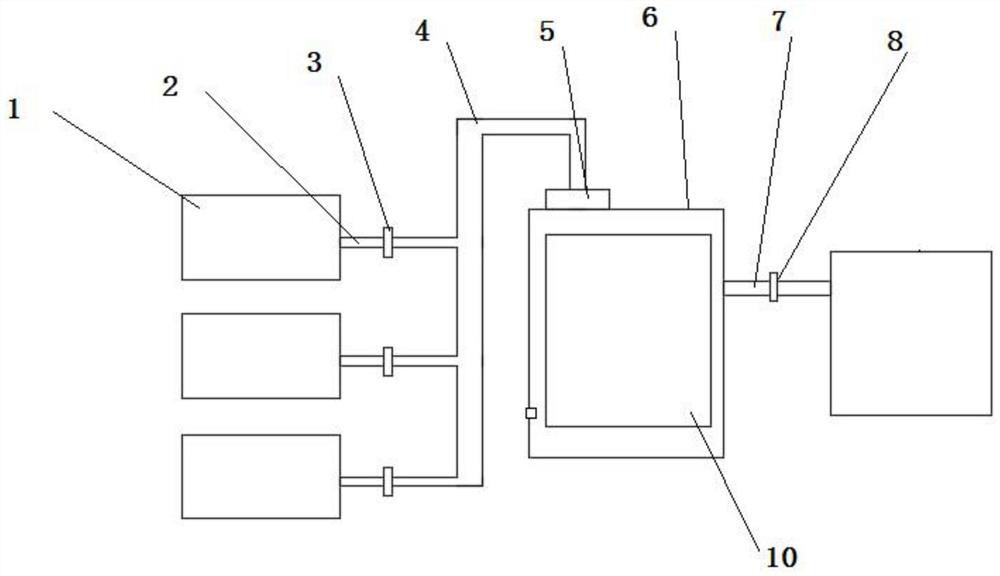

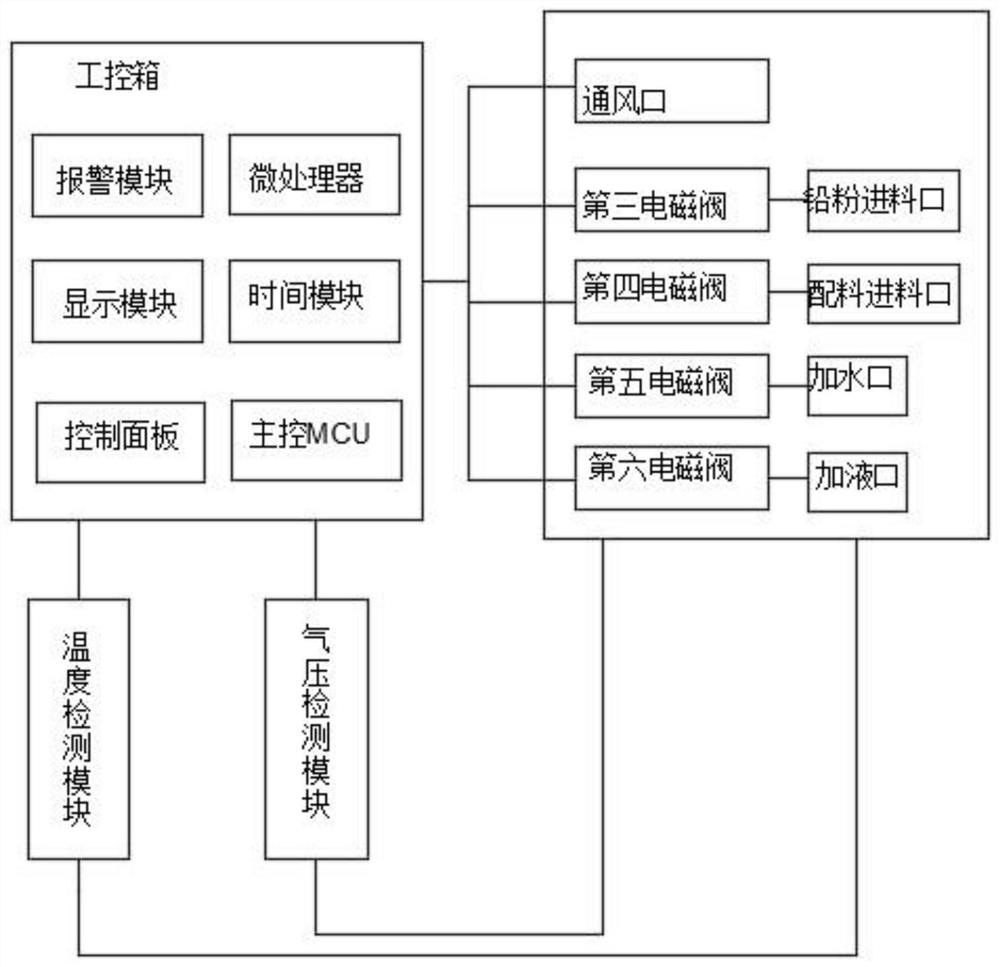

[0040] Such as Figure 1-4 As shown, an automation and paste machine control system for the preparation of lead paste includes three air coolers 1, a temperature detection module and an air pressure detection module; any air cooler 1 communicates with the main air pipe 4 through the cold air pipe 2; any The cold air pipe 2 is provided with a first electromagnetic valve 3; the main air pipe 4 communicates with the blowing box 6; an industrial control box 10 is installed on the side of the blowing box 6; an air pressure sensor and a temperature sensor are respectively installed on the bottom of the inner side of the blowing box 6 The blowing box 6 communicates with the paste machine through the blowing pipe 7; the blowing pipe 7 is provided with a second electromagnetic valve 8;

[0041] The surfaces of the cold air pipe 2 and the main air pipe 4 are covered with a heat insulation layer to avoid the temperature of the cold air from rising too fast; the industrial control box 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com