Automatic mold grinding method based on complex curved surface feature division

A technology of complex curved surfaces and molds, applied in grinding machines, manufacturing tools, grinding workpiece supports, etc., can solve the problems of affecting the manufacturing level, too small grinding tools, harsh working environment, etc., to improve production quality and production efficiency, and reduce costs. time and cost, the effect of improving the level of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

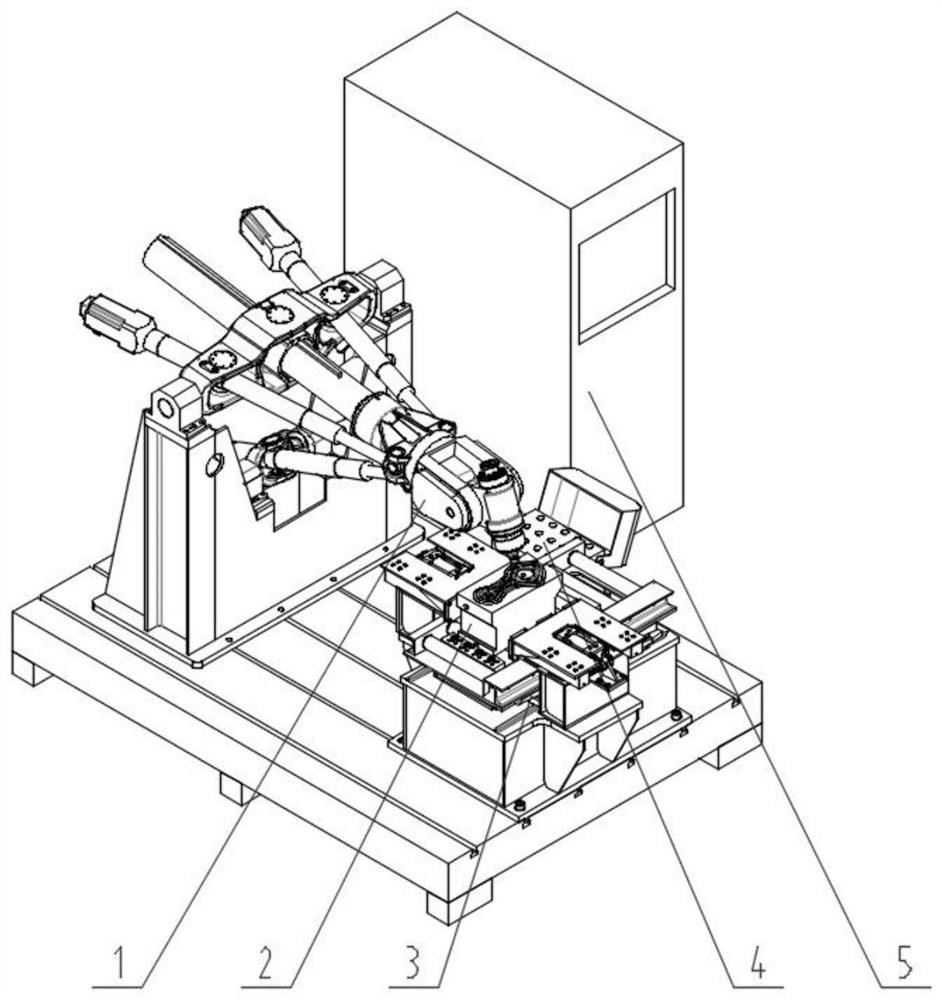

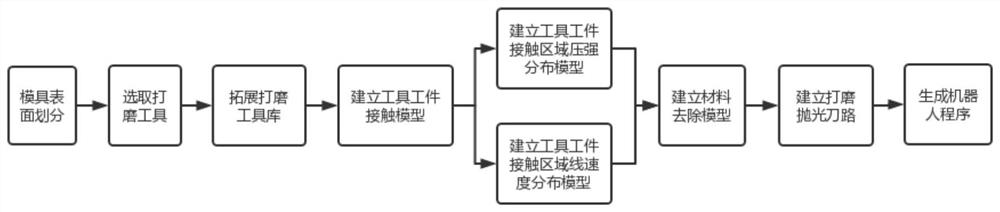

[0029] See Figure 1 to Figure 2 , an automatic mold grinding method based on the division of complex surface features, set the curvature of the concave surface to be negative, and the curvature of the convex surface to be positive, and divide the mold surface into multiple surface categories according to the main curvature value; match the grinding tool by the mold surface category, to Build the tool library of the grinding robot; formulate the grinding path according to the surface shape of the mold, the tool library and the grinding process; compile the automatic grinding program according to the grinding path, tool library and grinding process; download the automatic grinding program to the grinding robot and start the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com