Sheet tension control system

A technology of tension control and bed sheets, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of paper stretching deformation, uneven sheets, wrinkled sheets, etc., and achieve the effect of smooth replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

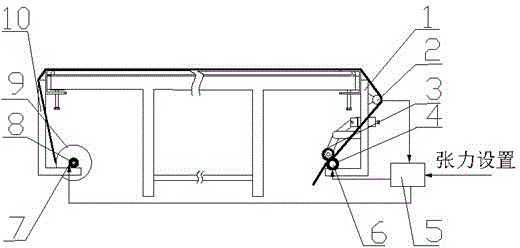

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] The invention aims at the bed sheet tension control system of the automatic bed sheet replacement equipment for the medical examination bed, realizes the stable replacement of the bed sheet (constant tension control), and can ensure the reliable and stable replacement operation of medical paper sheets of different materials and thicknesses. It includes paper sheet reel 9 , driving bracket 1 , roller bracket 10 , driven shaft 8 , motor 6 , first friction cylinder 3 , second friction cylinder 4 , electric clutch 7 , tension sensor 2 , and automatic tension controller 5 . One end of the electric clutch is fixedly connected with the bracket, and the other end is installed on the driven shaft; the paper sheet reel is sleeved on the driven shaft and fixed by a chuck; the paper sheet bypasses the bed surface and the tension sensor and is pressed between the friction cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com