Fiber rope pre-drawing device and pre-drawing method

A pre-drafting and rope technology, applied in the field of fiber ropes, can solve the problems of difficulty in accurate control of drafting force, complicated operation, contamination, etc., and achieves the effect of good practical value and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

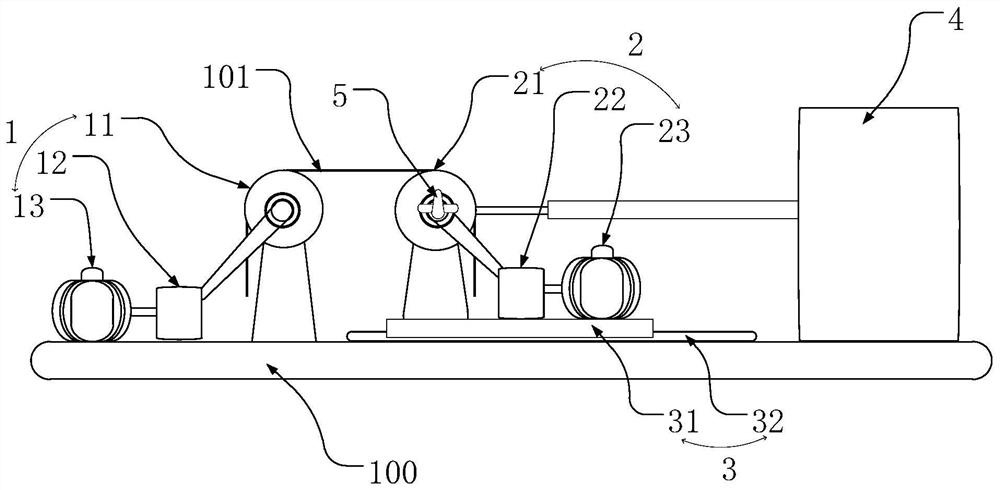

[0088] figure 1 It is a schematic diagram of the composition of the fiber rope pre-drawing device disclosed in Example 1.

[0089] In Embodiment 1, the device platform 100 is arranged horizontally, including a horizontally arranged plane for setting other components, wherein the first drafting assembly 1 is arranged on the left plane of the device platform 100, and on the right side of the first drafting assembly 1 The second drafting assembly 2 is provided, and the second drafting assembly 2 is set and installed on the movable assembly 3, and the movable assembly 3 is arranged on the device platform 100, and can move freely on the device platform 100; On the right side of the component 2, a drive component 4 is provided, and the tension detection component 5 is a torque sensor, which is adapted to be arranged on the rotating shaft of the second rotating component to detect the tension on the fiber rope;

[0090] Wherein, the first drafting assembly 1 includes a first rotatin...

Embodiment 2

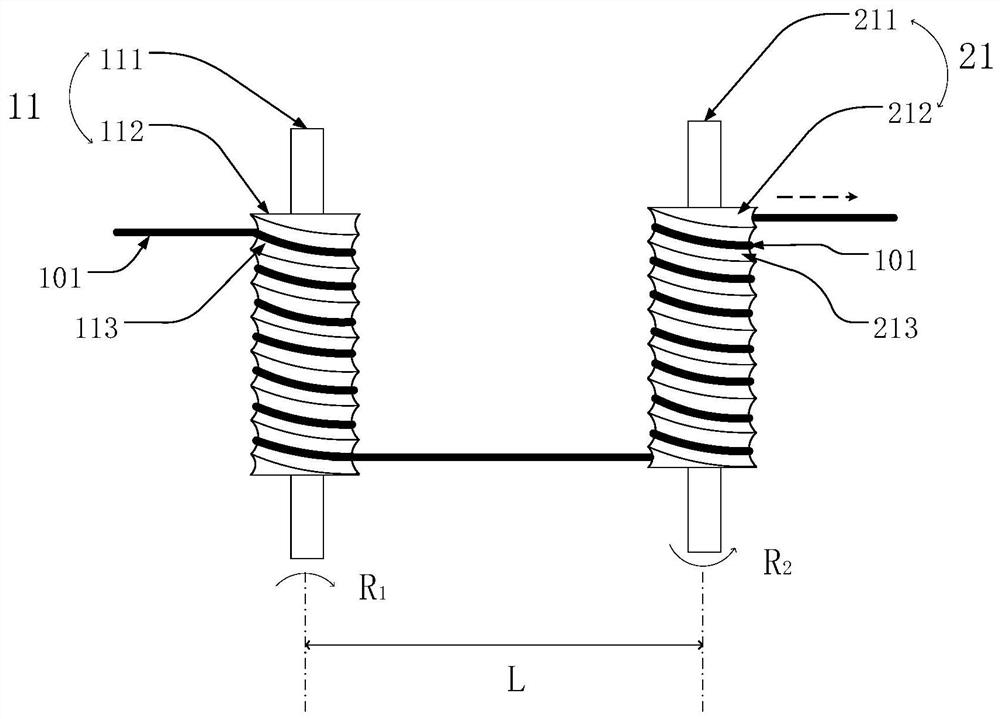

[0095] figure 2 It is a schematic diagram of the arrangement of the first rotating part and the second rotating part disclosed in the second embodiment.

[0096] In Embodiment 2, the first rotating part 11 includes a first rotating shaft 111 and a cylindrical first guide roller 112 fixedly connected to it. The surface of the first guide roller 112 is provided with a first continuous groove 113. The first continuous groove 113 is distributed on the surface of the first guide roller 112 in a spiral shape; the first rotating part 11 is set to rotate clockwise, as shown in the figure R 1 the first direction of rotation shown;

[0097] The second rotating part 21 includes a second rotating shaft 211 and a cylindrical second guide roller 212 fixedly connected to it. The surface of the second guide roller 112 is provided with a second continuous groove 213, and the second continuous groove 213 is distributed in a spiral shape. On the surface of the second guide roller 212; the sec...

Embodiment 3

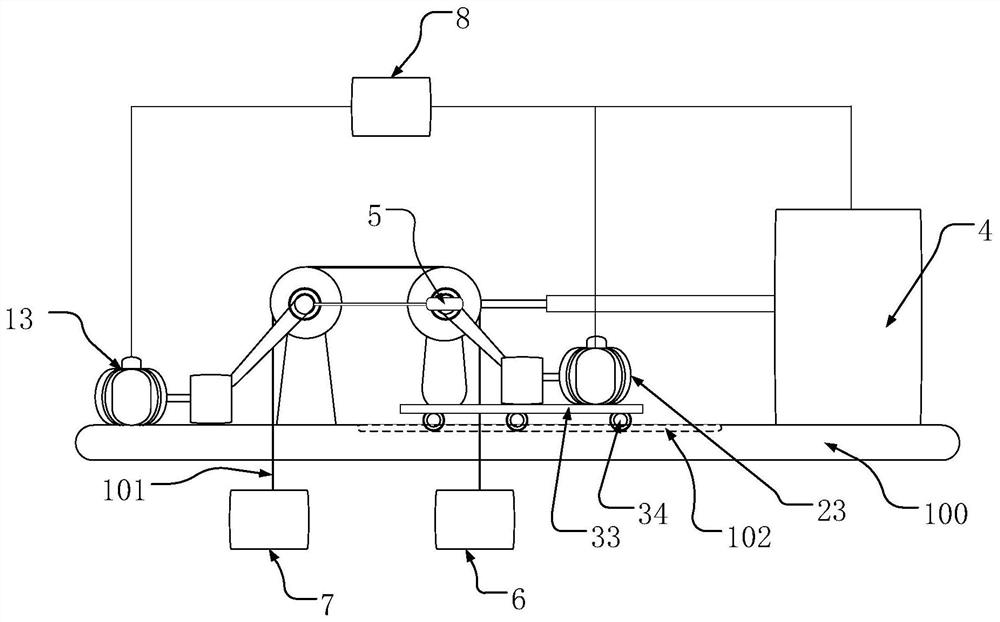

[0102] image 3 It is a schematic diagram of the composition of the fiber rope pre-drawing device disclosed in Example 3.

[0103] In Embodiment 3, the device platform 100 is arranged horizontally, including a horizontally arranged plane so as to arrange other components, wherein the first drafting assembly is arranged on the left plane of the device platform 100, and the right side of the first drafting assembly is provided with The second drafting assembly, the second drafting assembly is installed on the movable assembly, the movable assembly is arranged on the device platform 100, and can move freely on the device platform 100; on the right side of the second drafting assembly, A drive assembly 4 is provided, and the tension detection assembly 5 is a tension sensor, adapted to be arranged on the rotation shaft of the first rotating part and the rotating shaft of the second rotating part, so as to detect the tension on the fiber rope;

[0104] Wherein, the first drafting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com