Patents

Literature

115results about How to "Safe and reliable clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

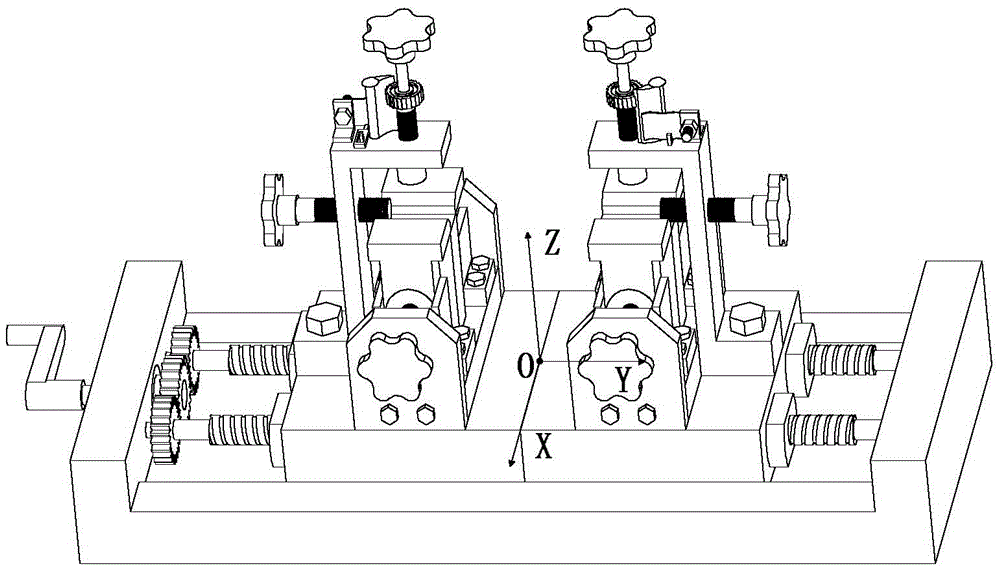

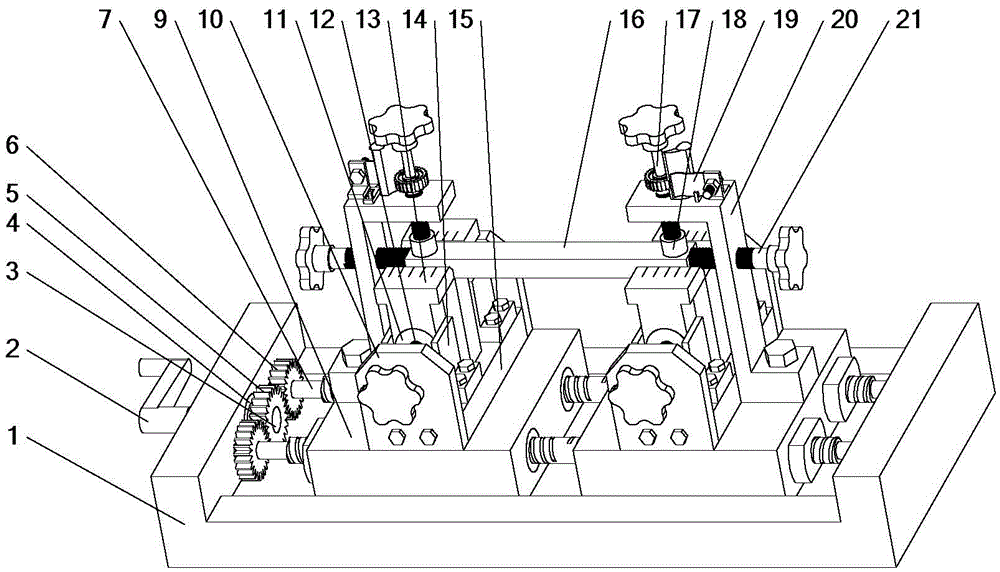

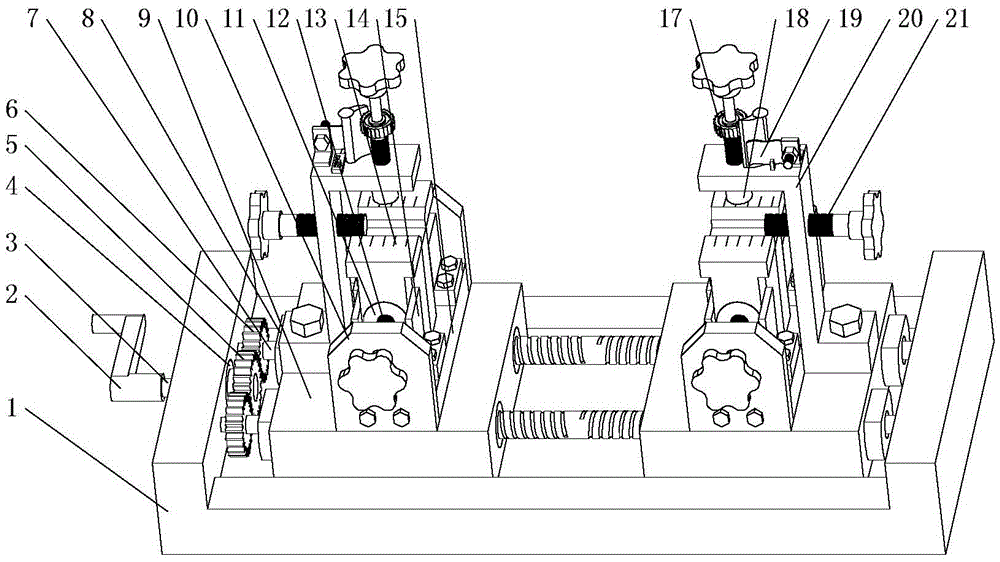

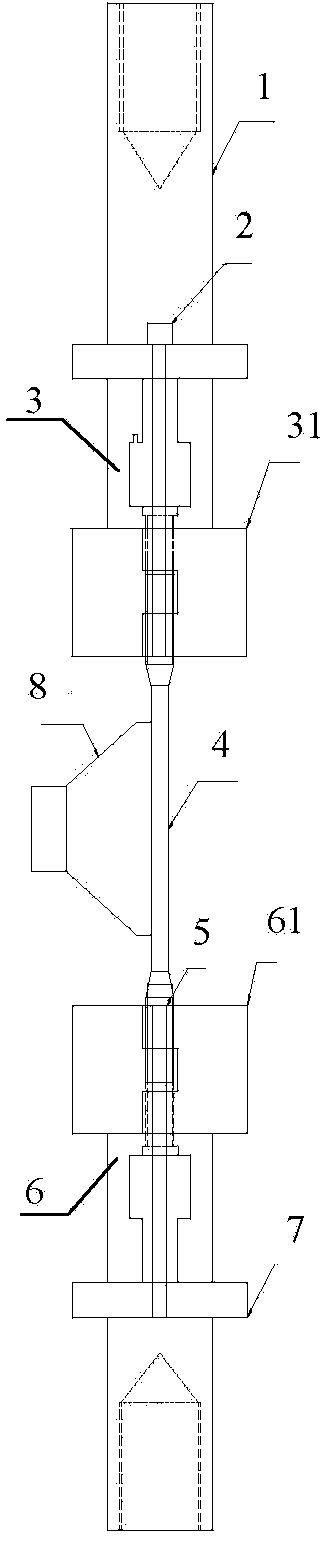

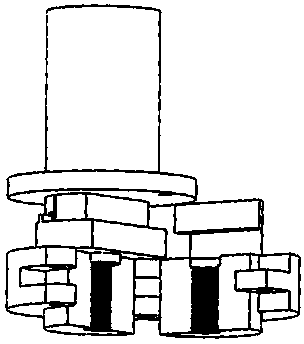

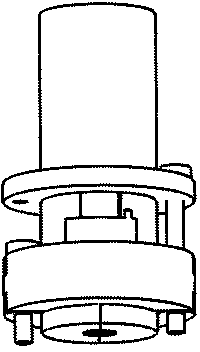

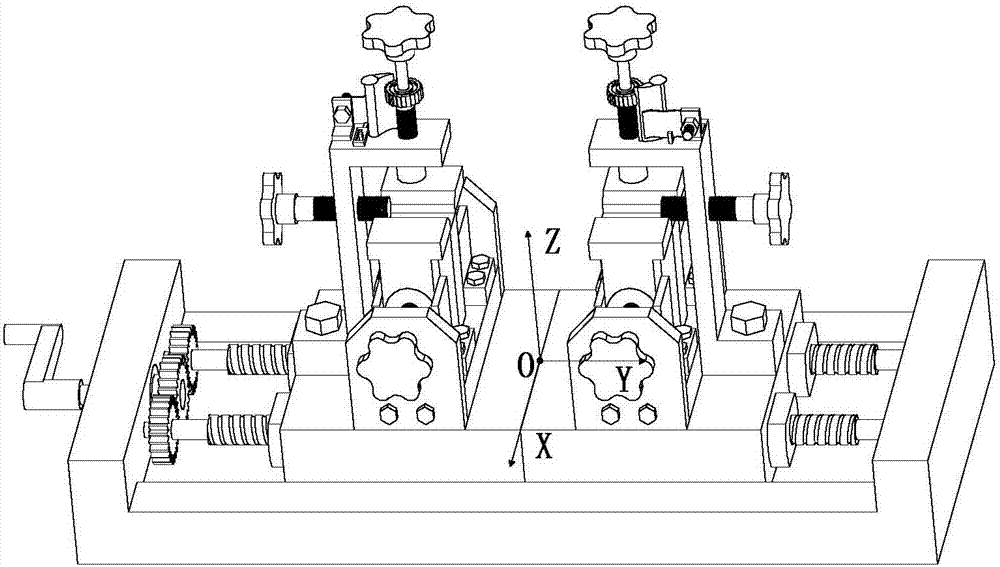

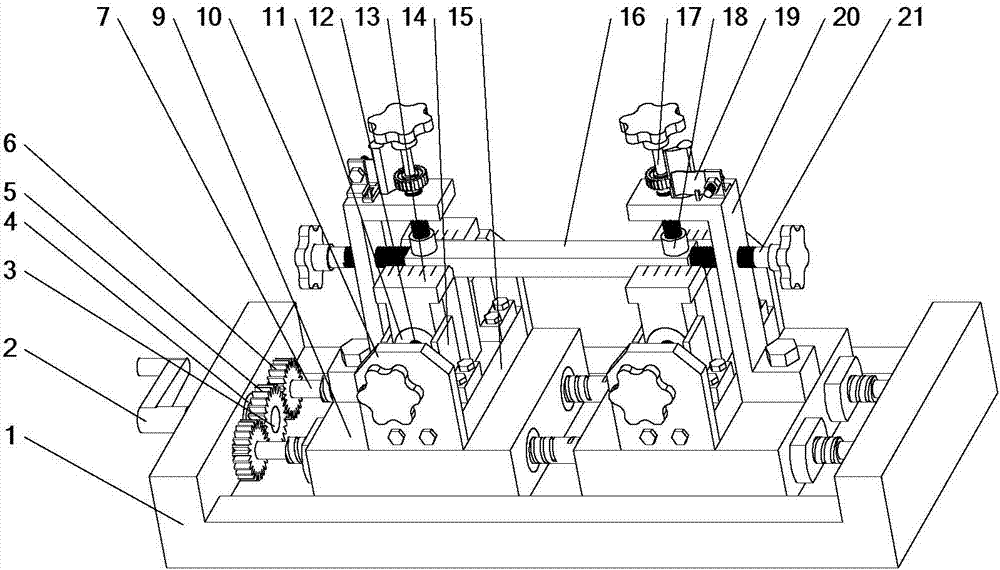

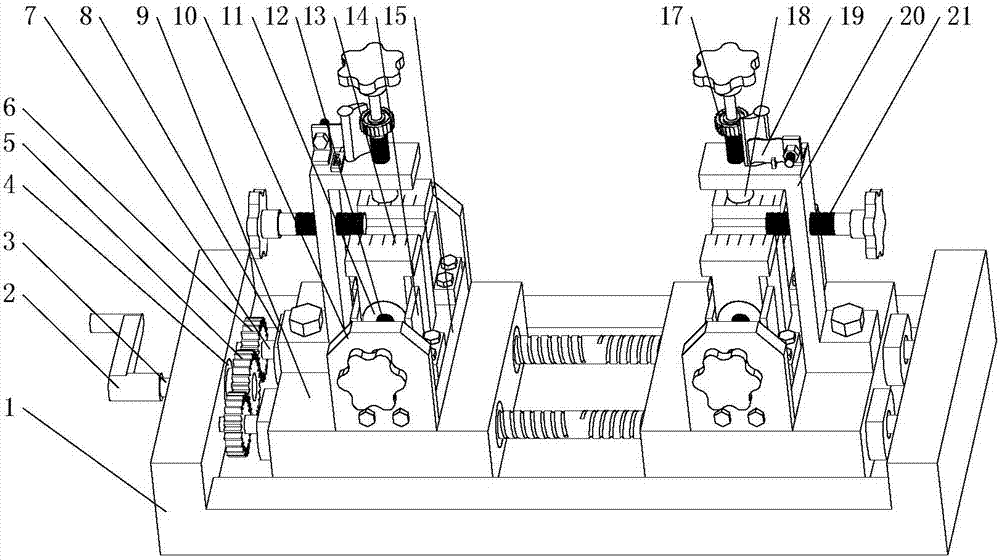

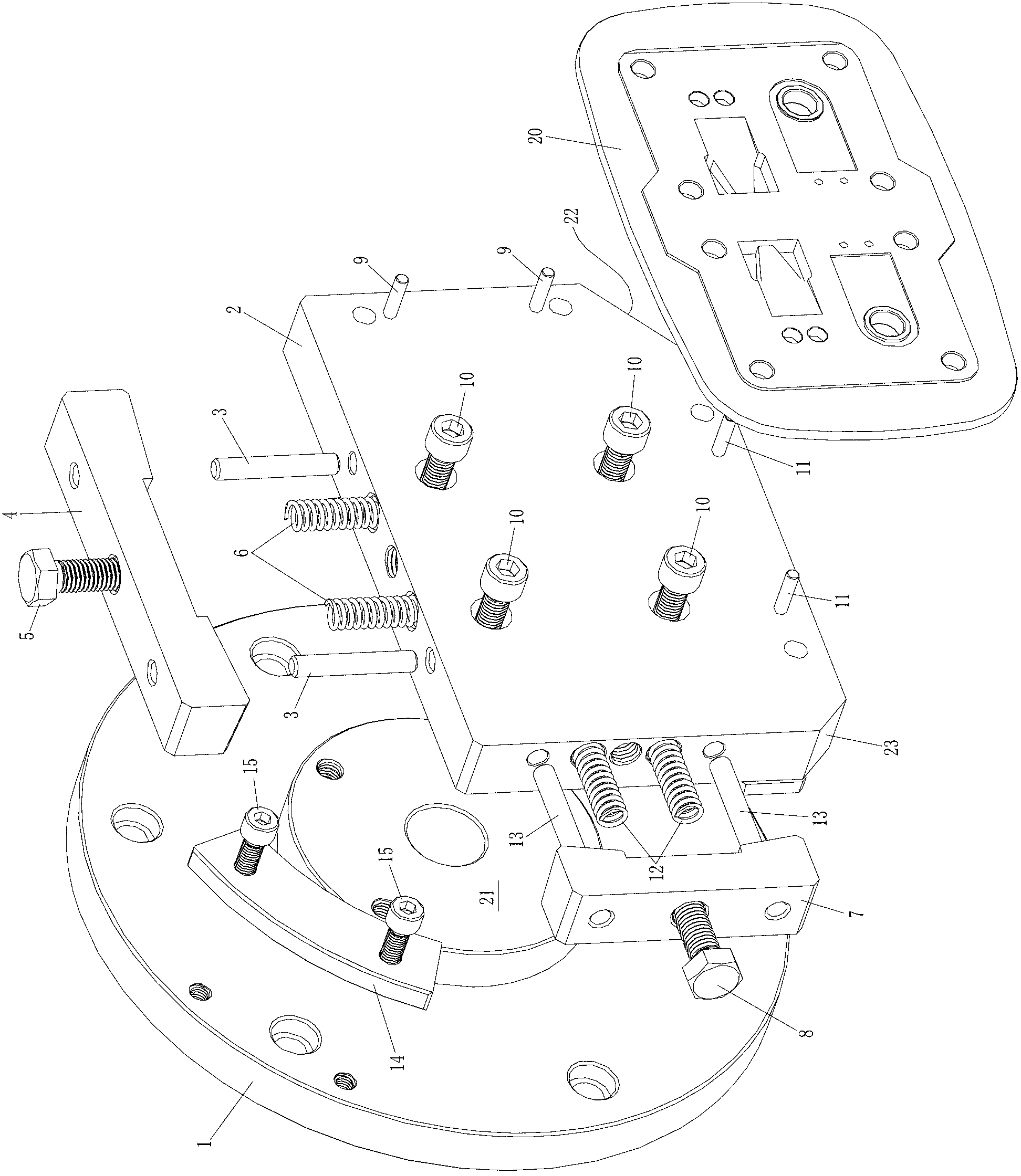

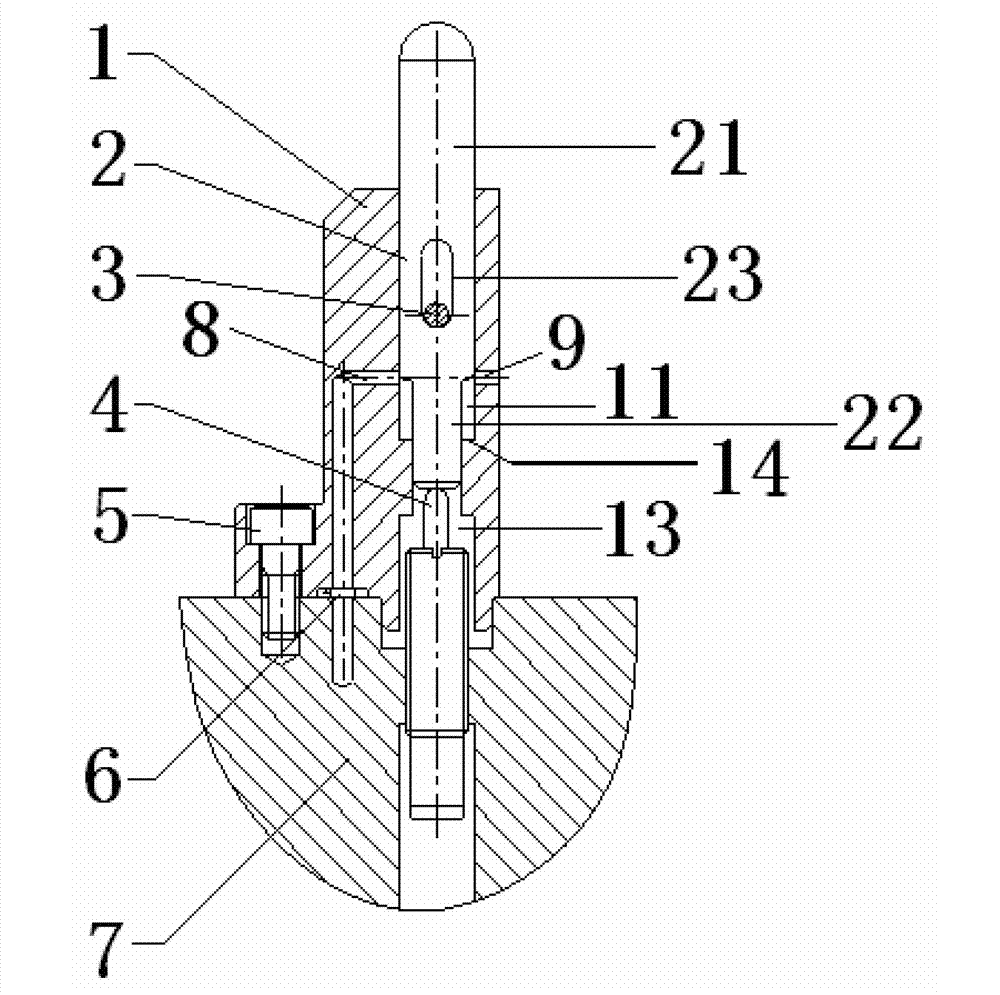

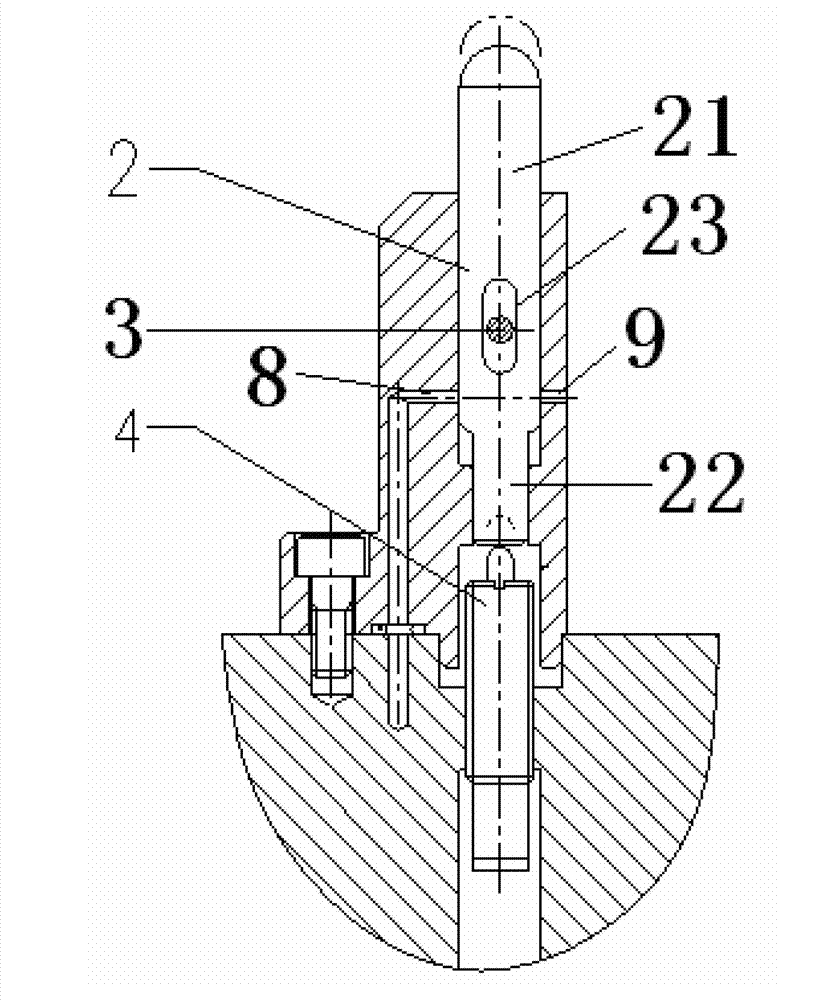

Clamp with all-freedom constraints for impact fatigue testing machine

ActiveCN105571808AReliable specimen clampingLow costShock testingStrength propertiesFatigue testingEngineering

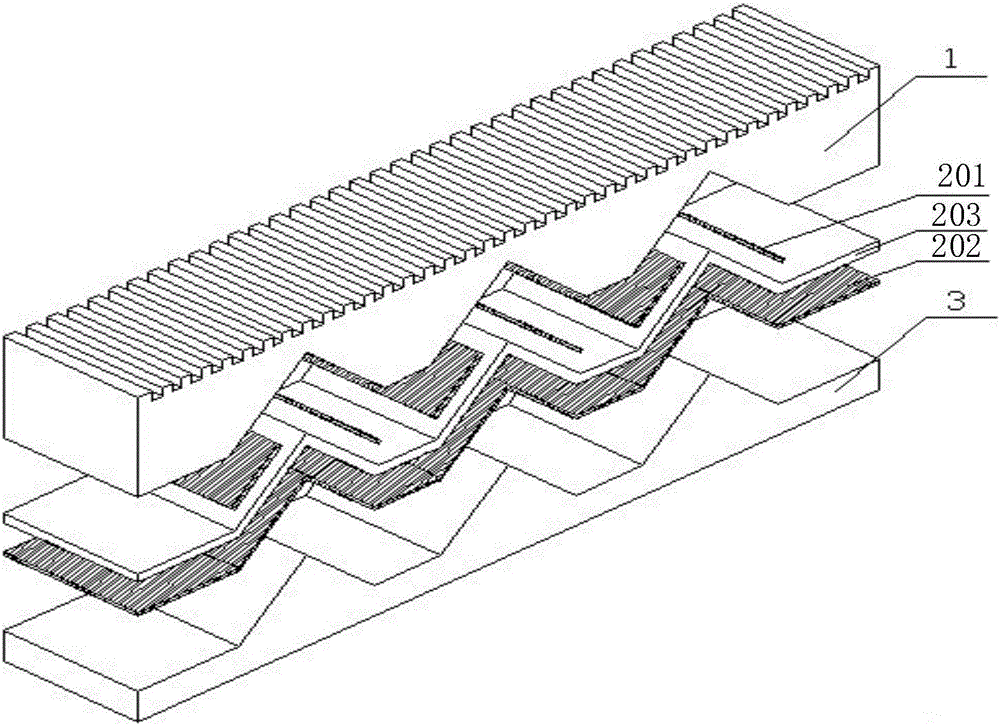

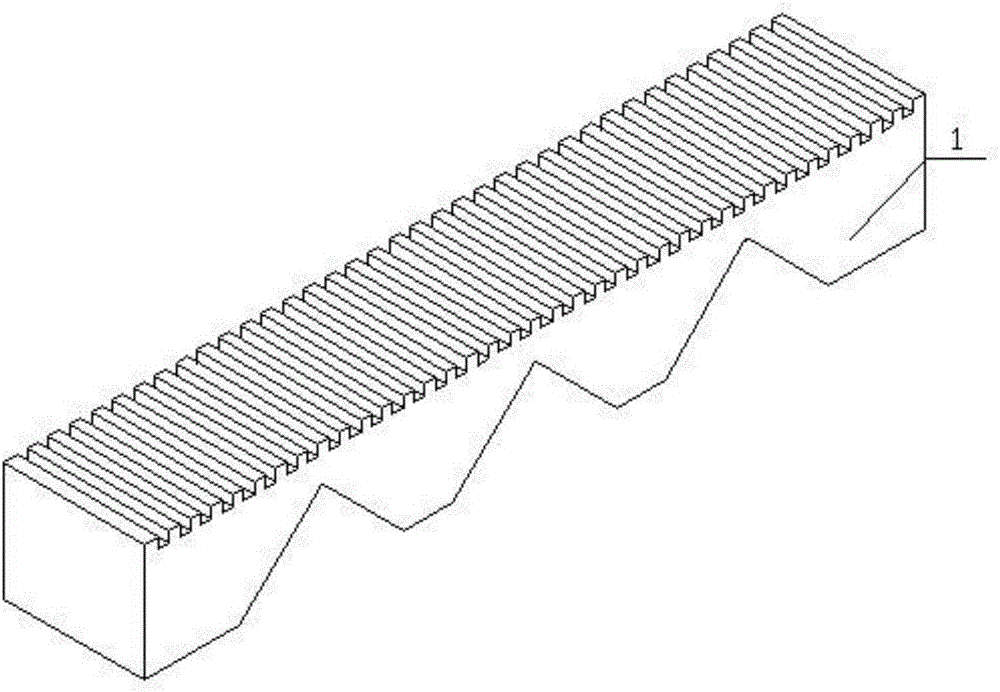

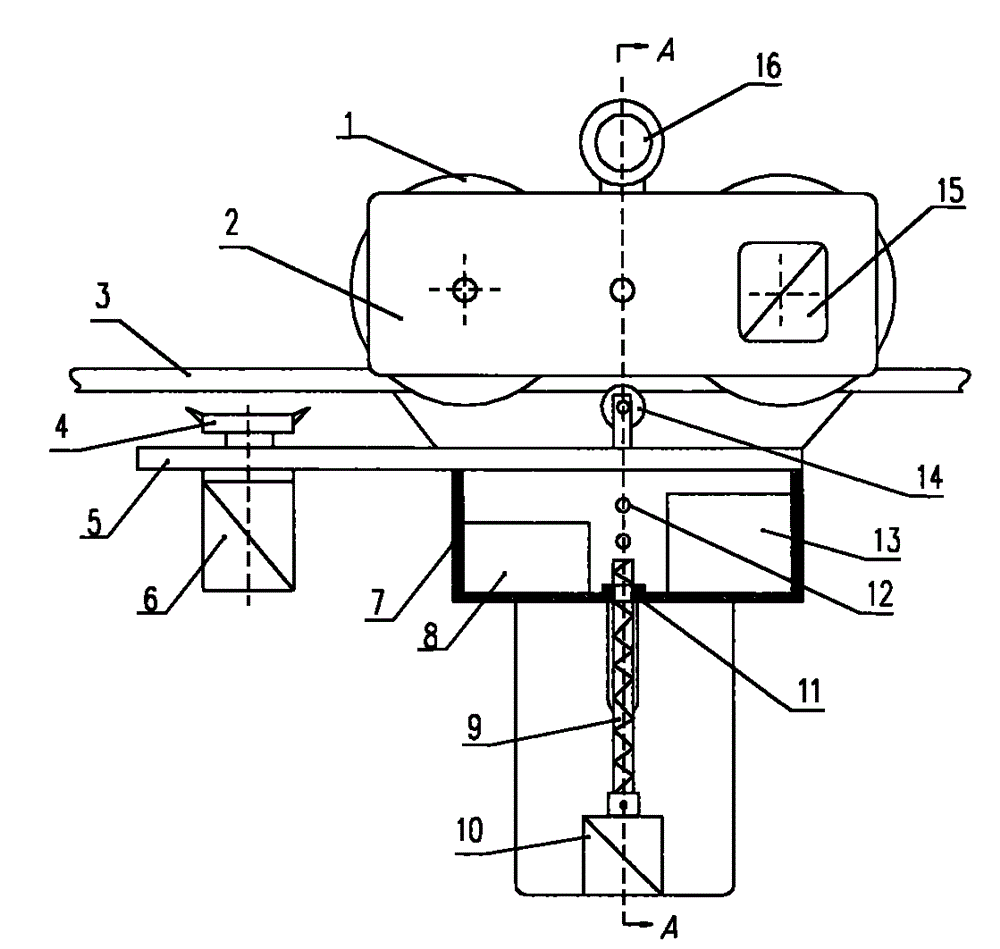

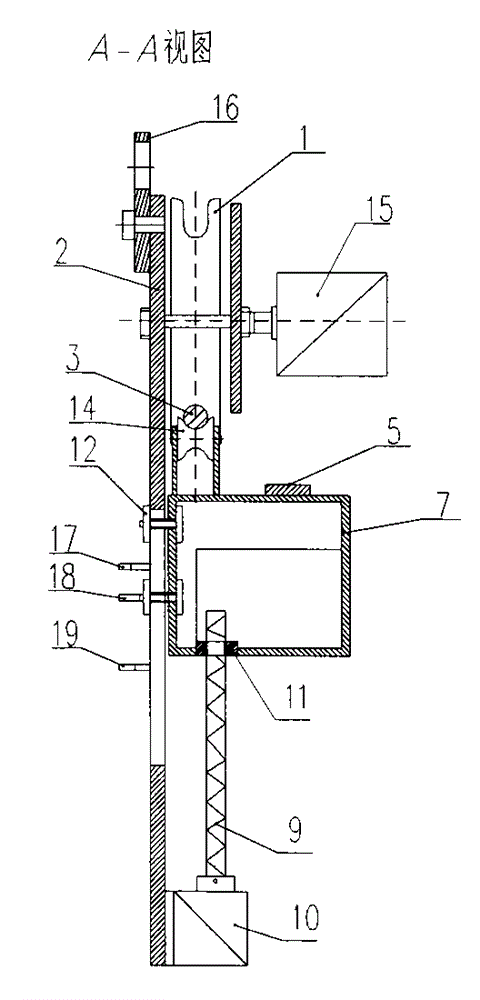

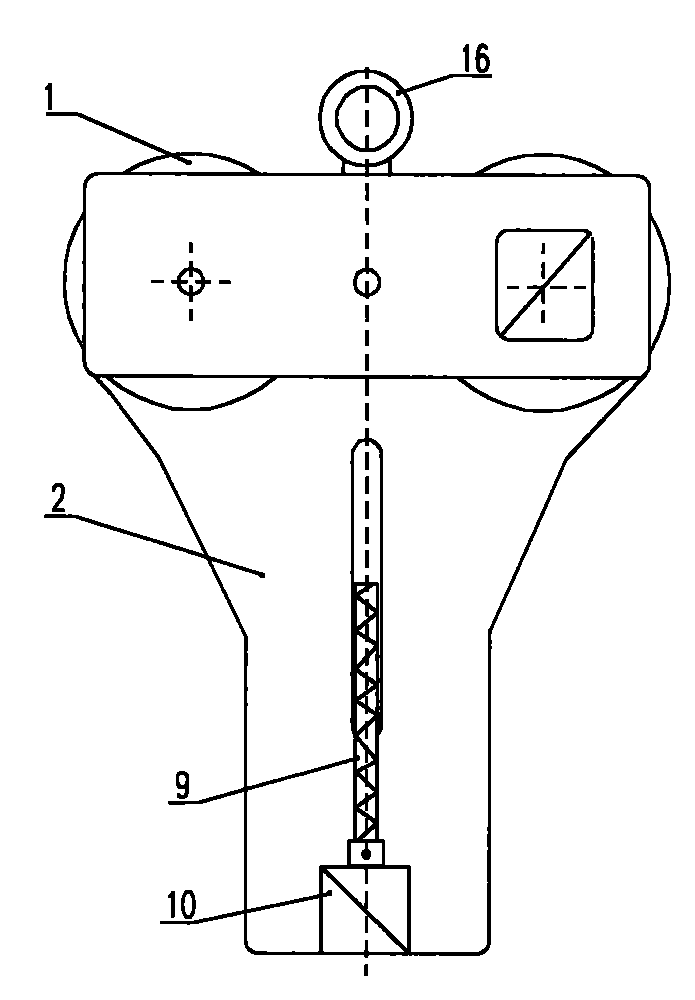

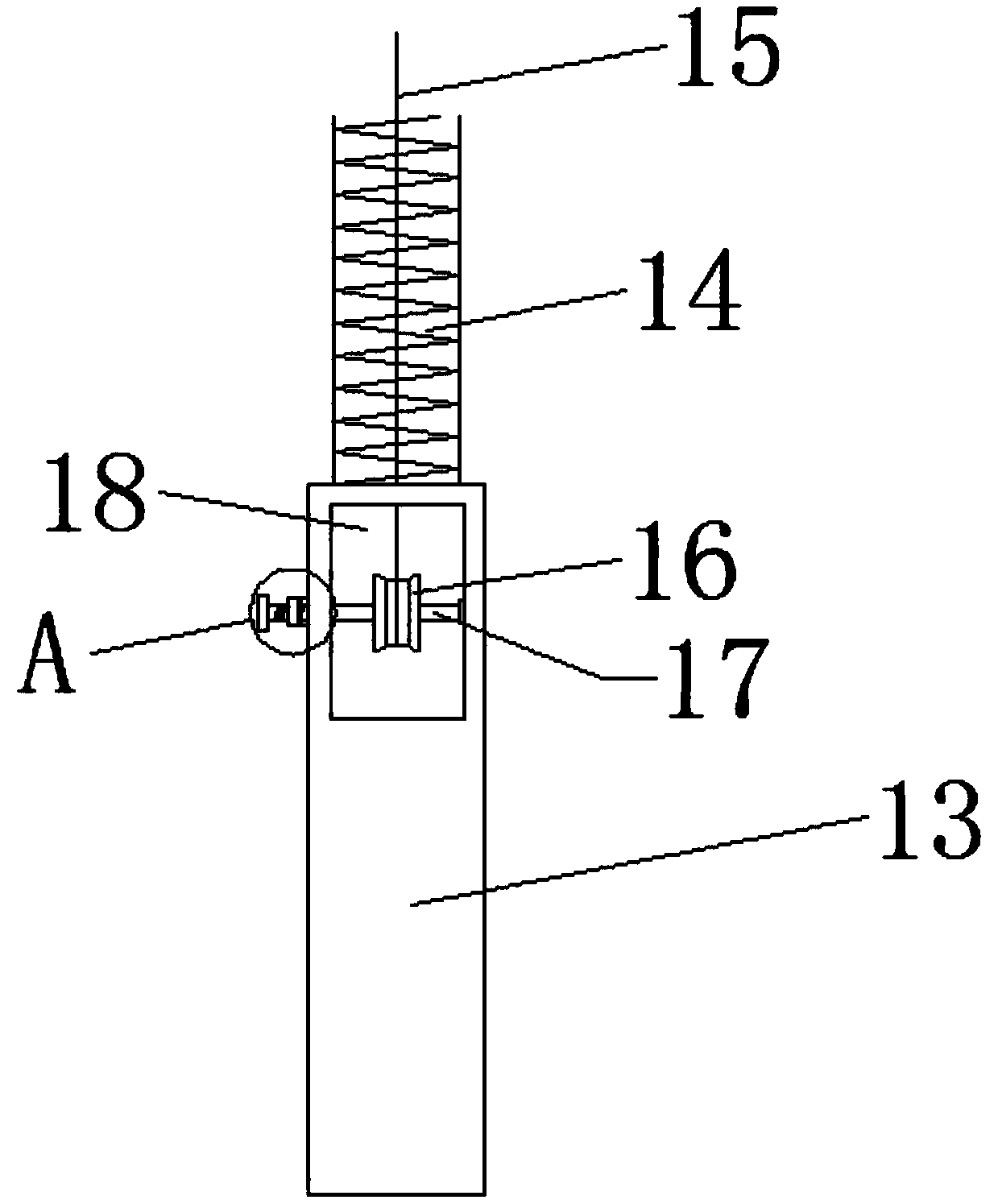

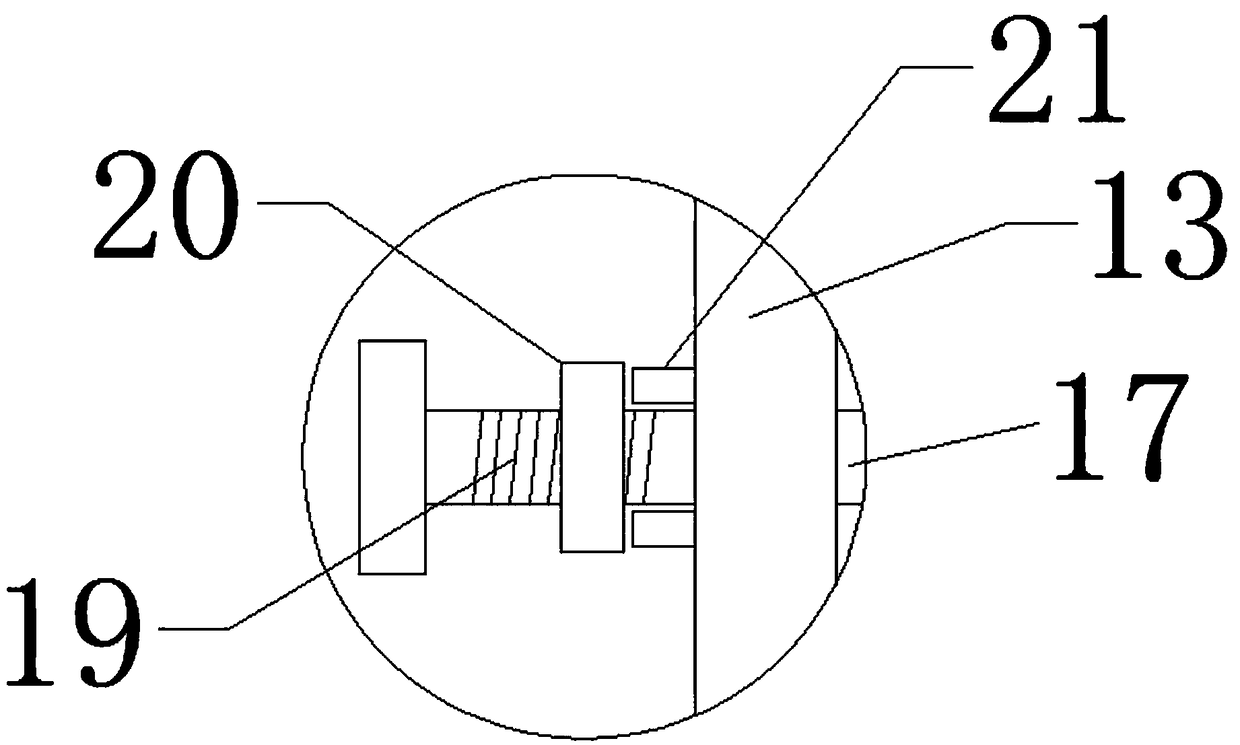

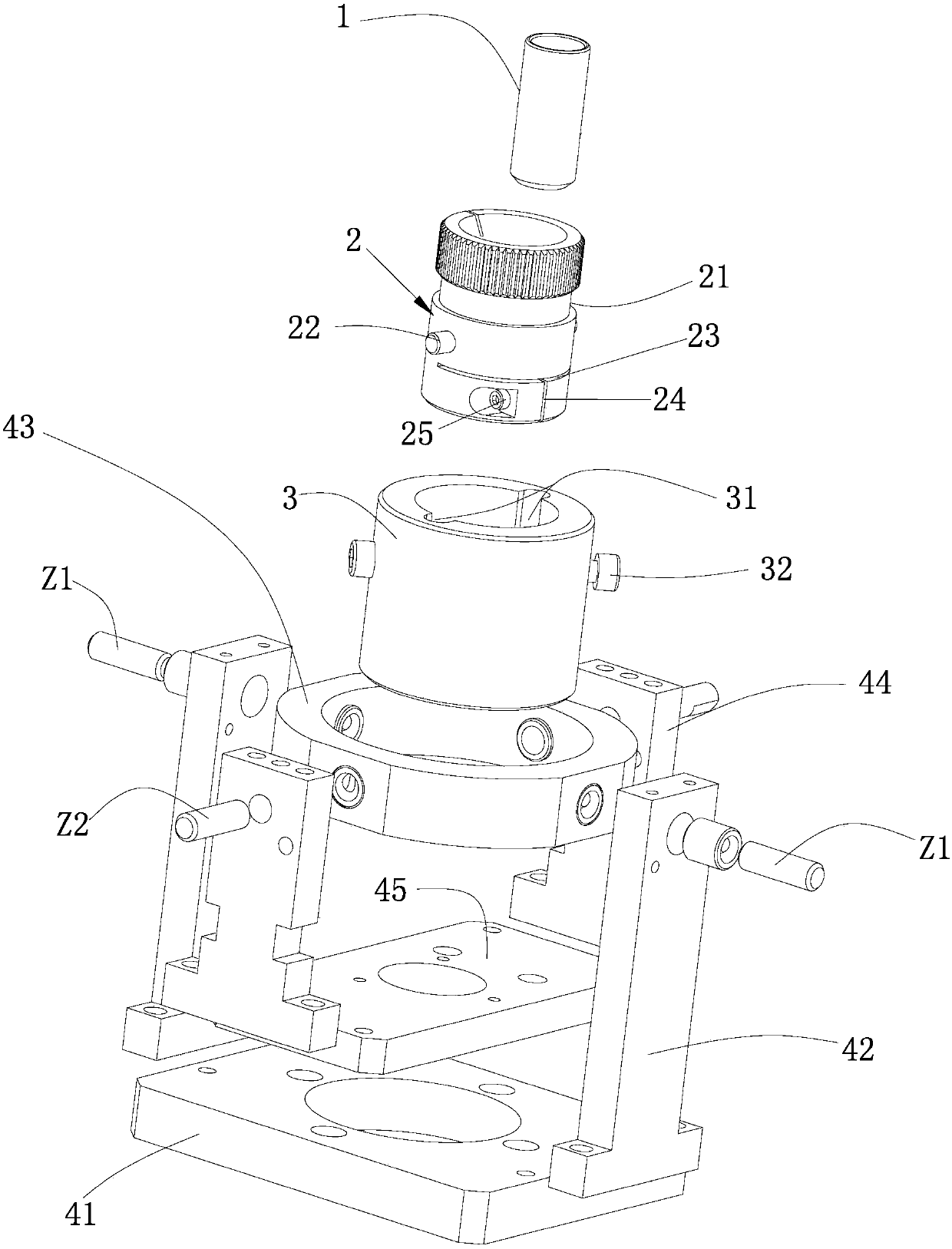

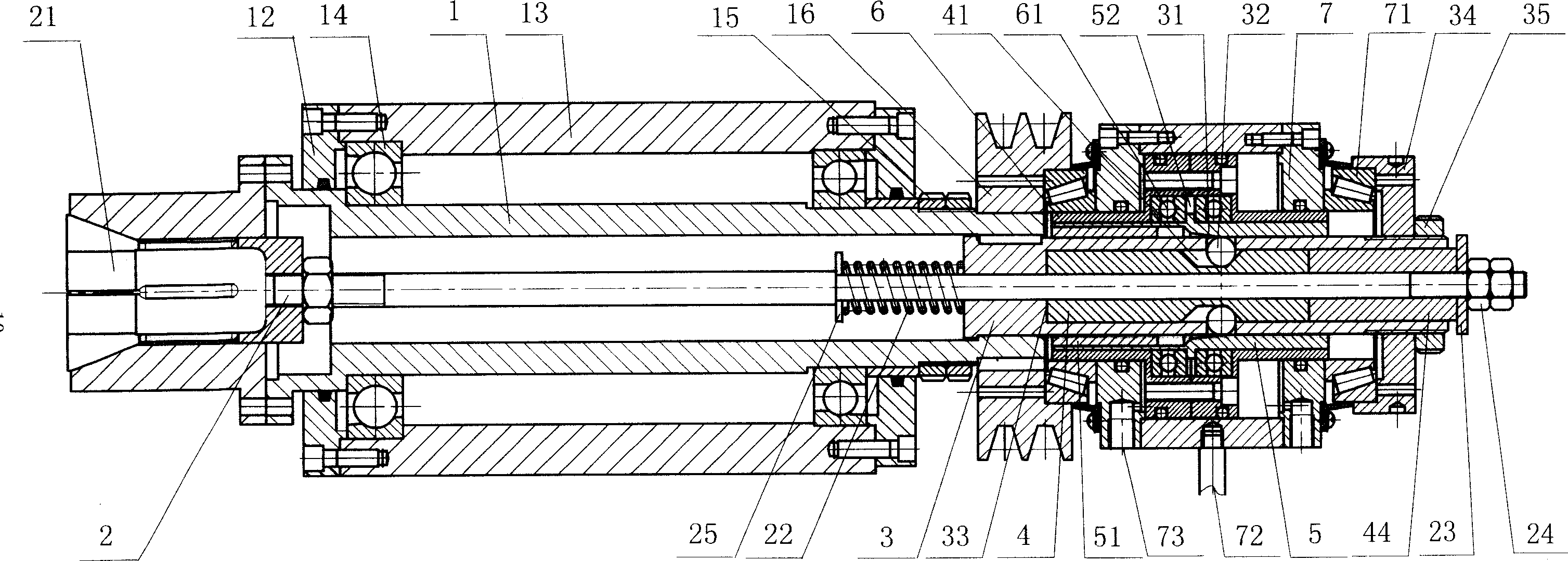

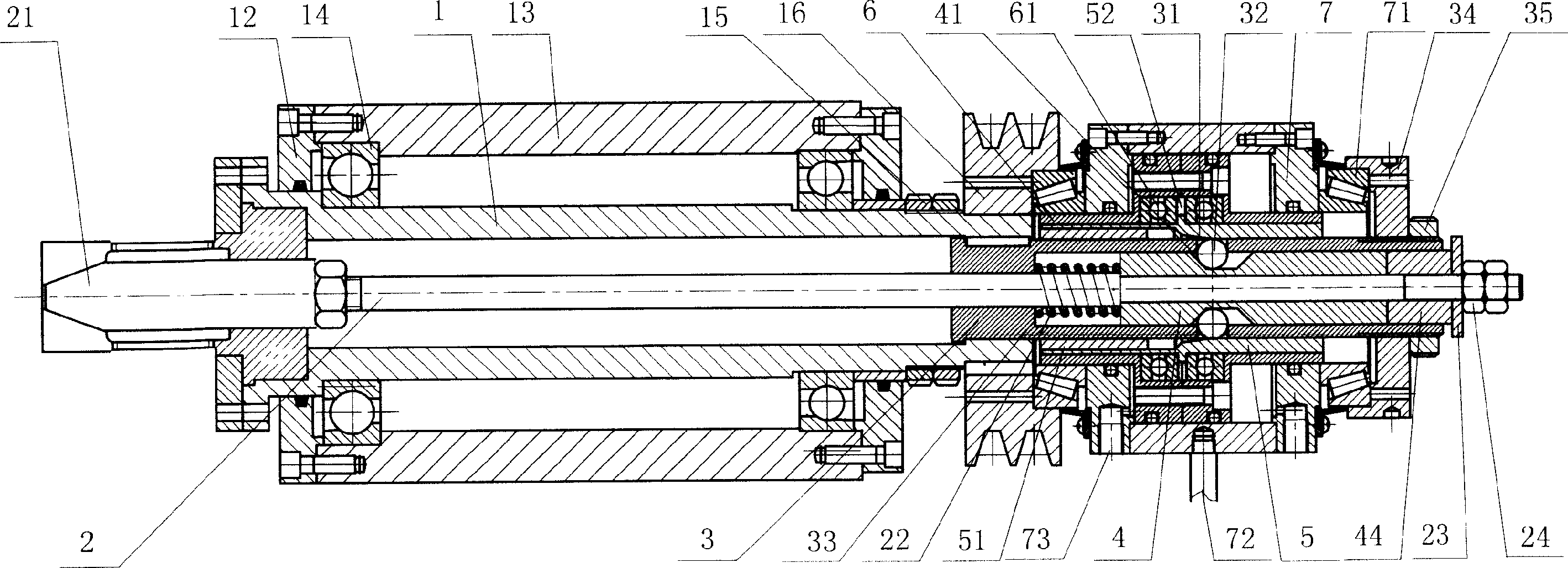

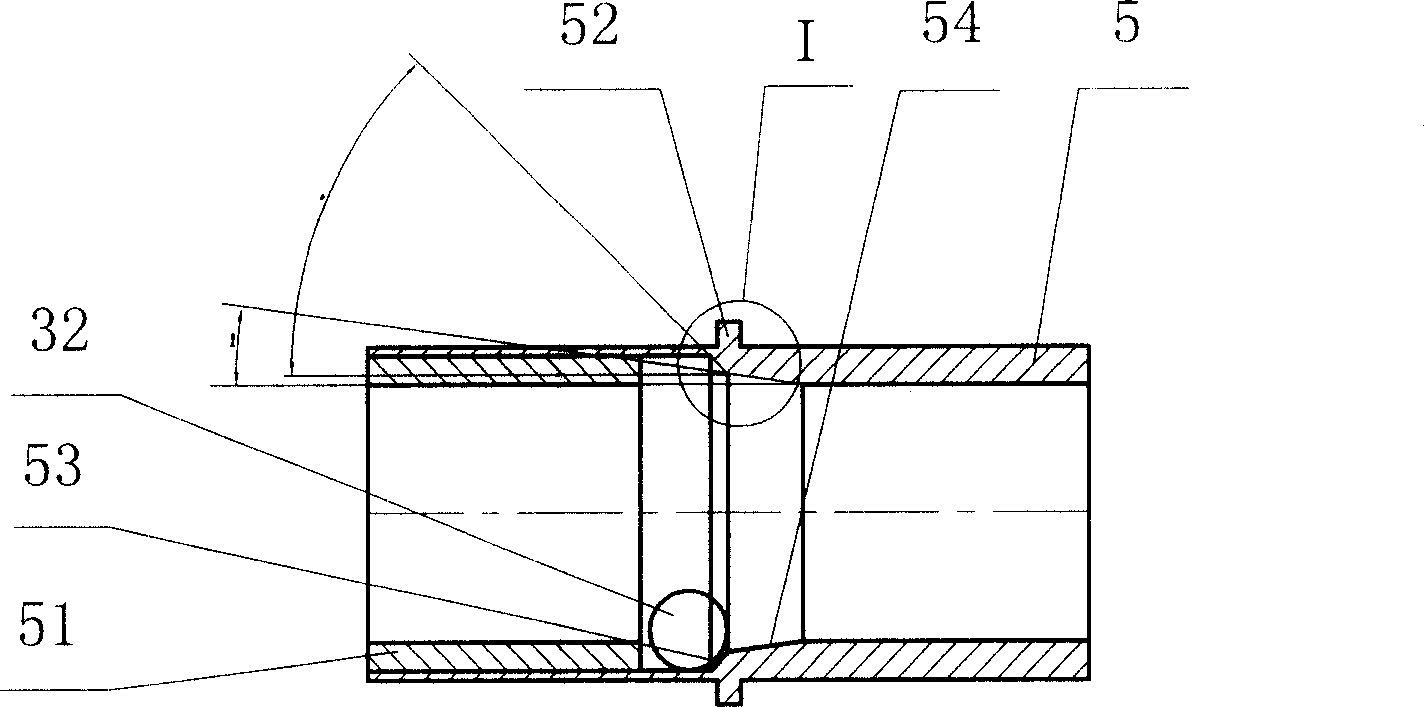

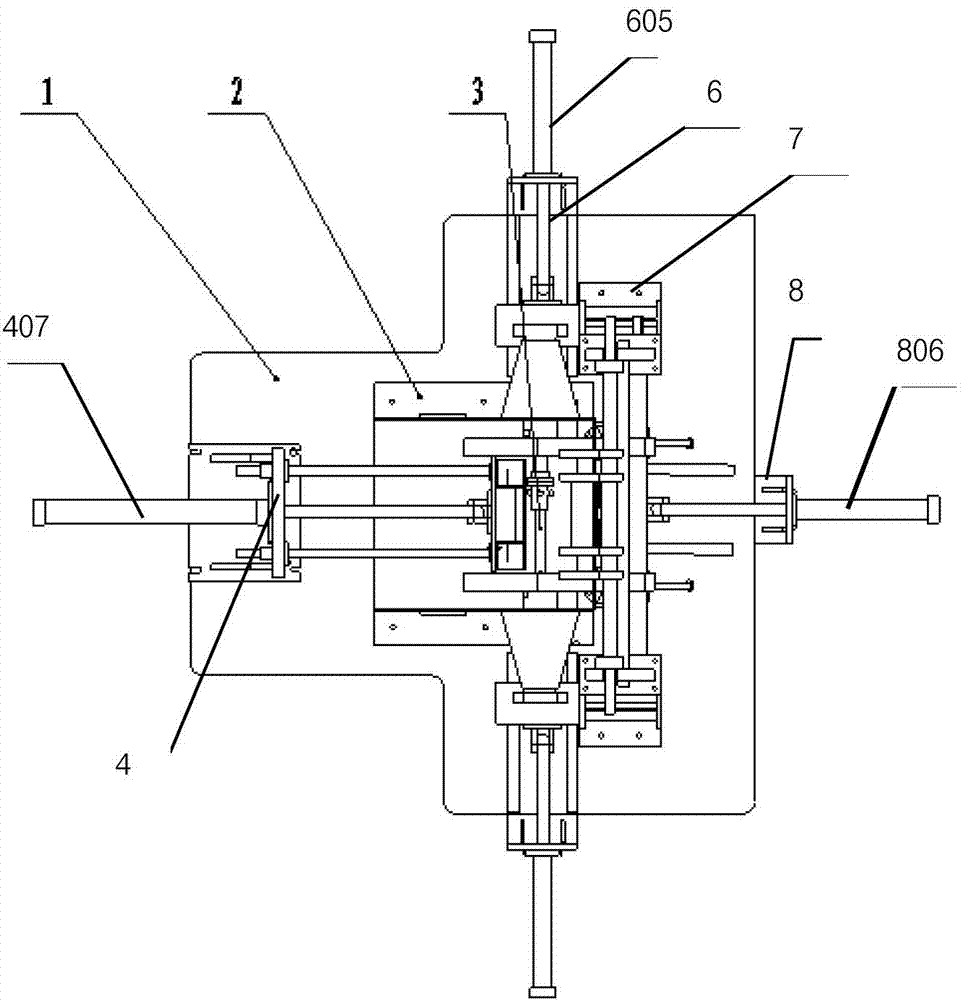

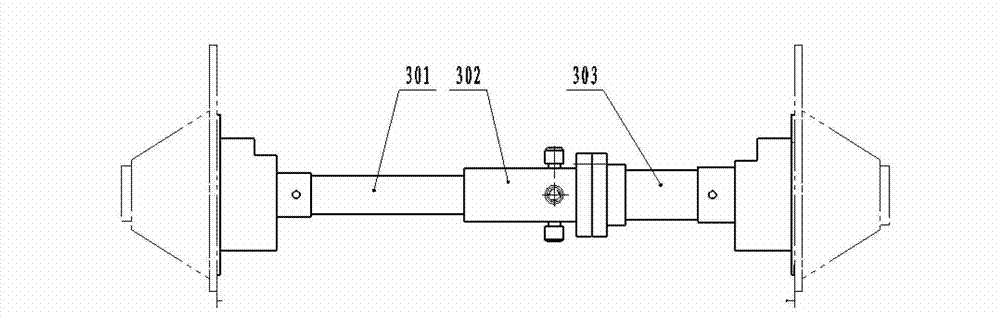

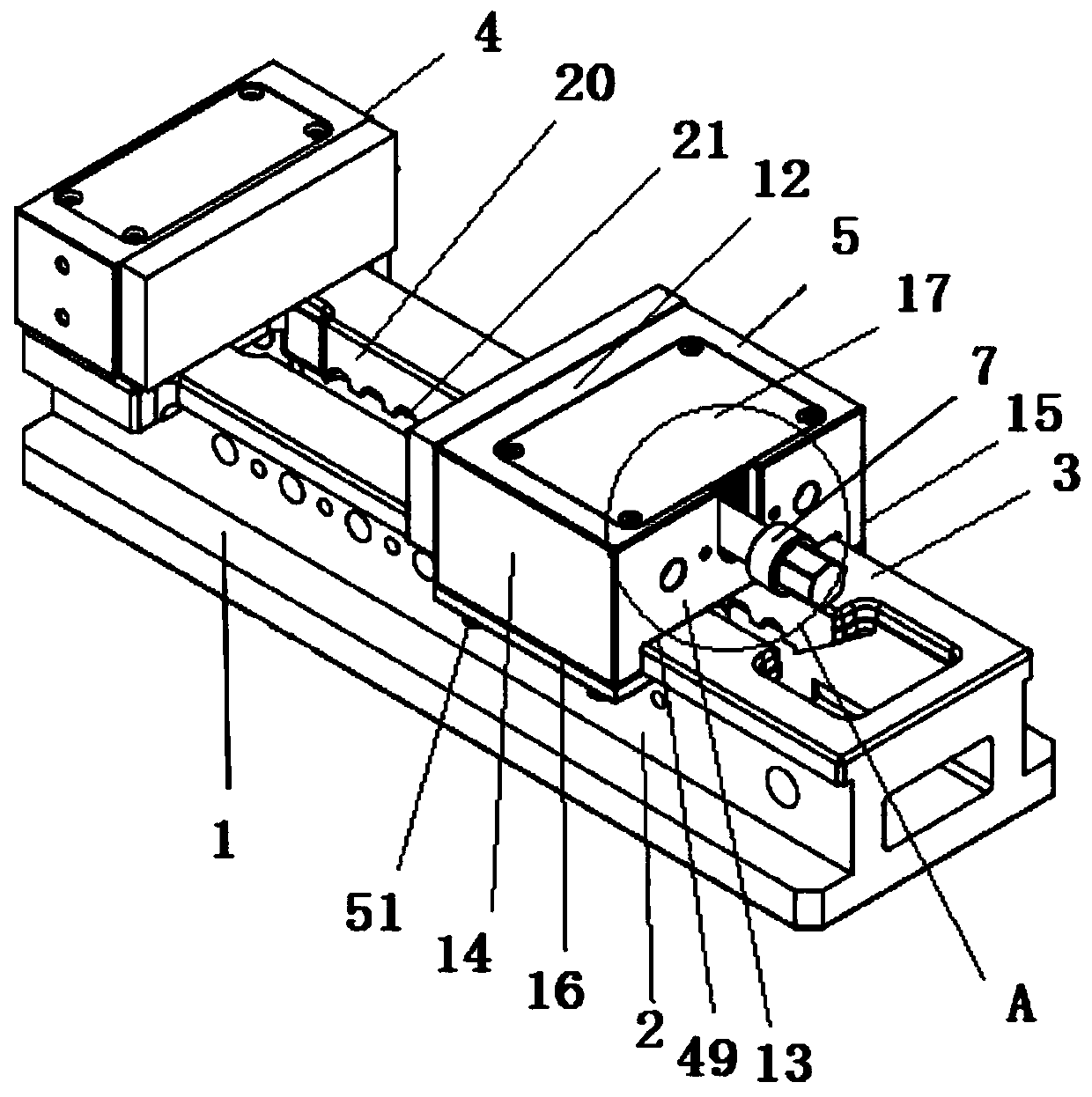

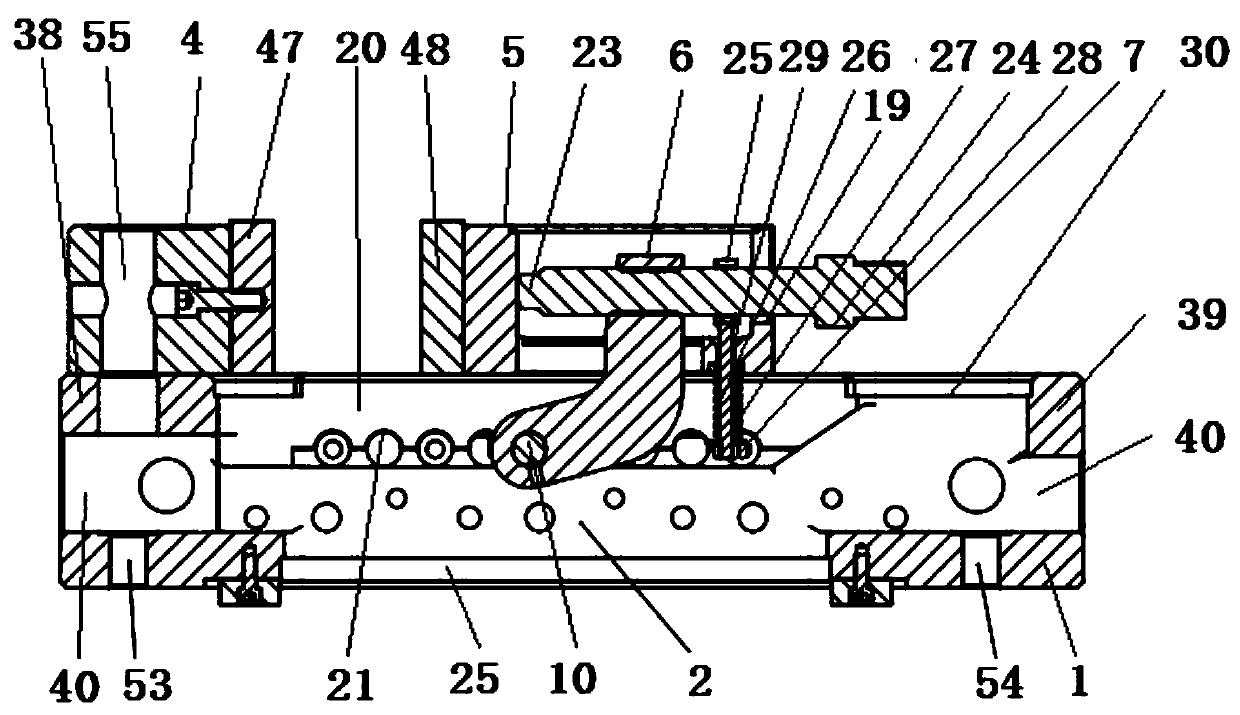

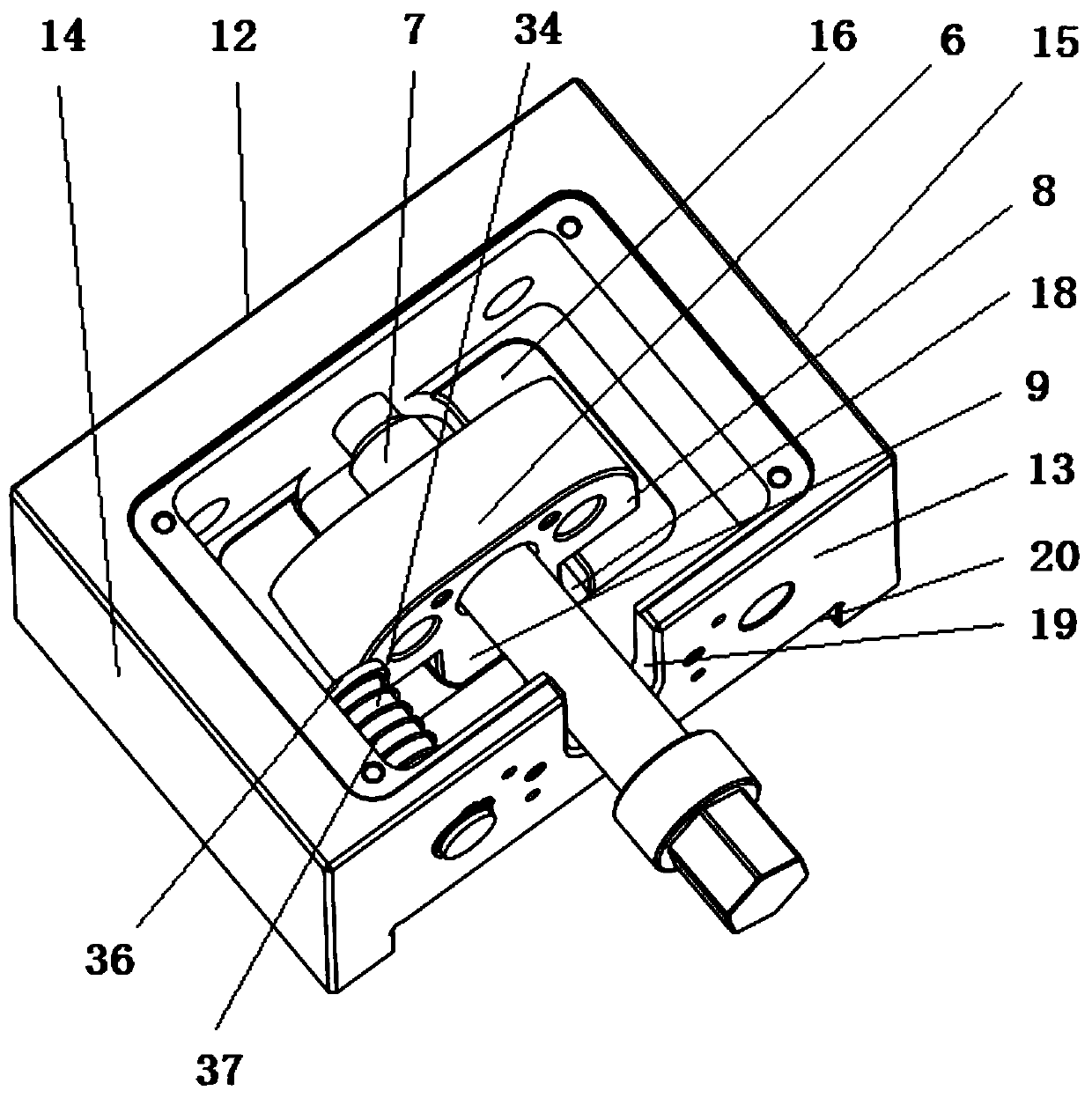

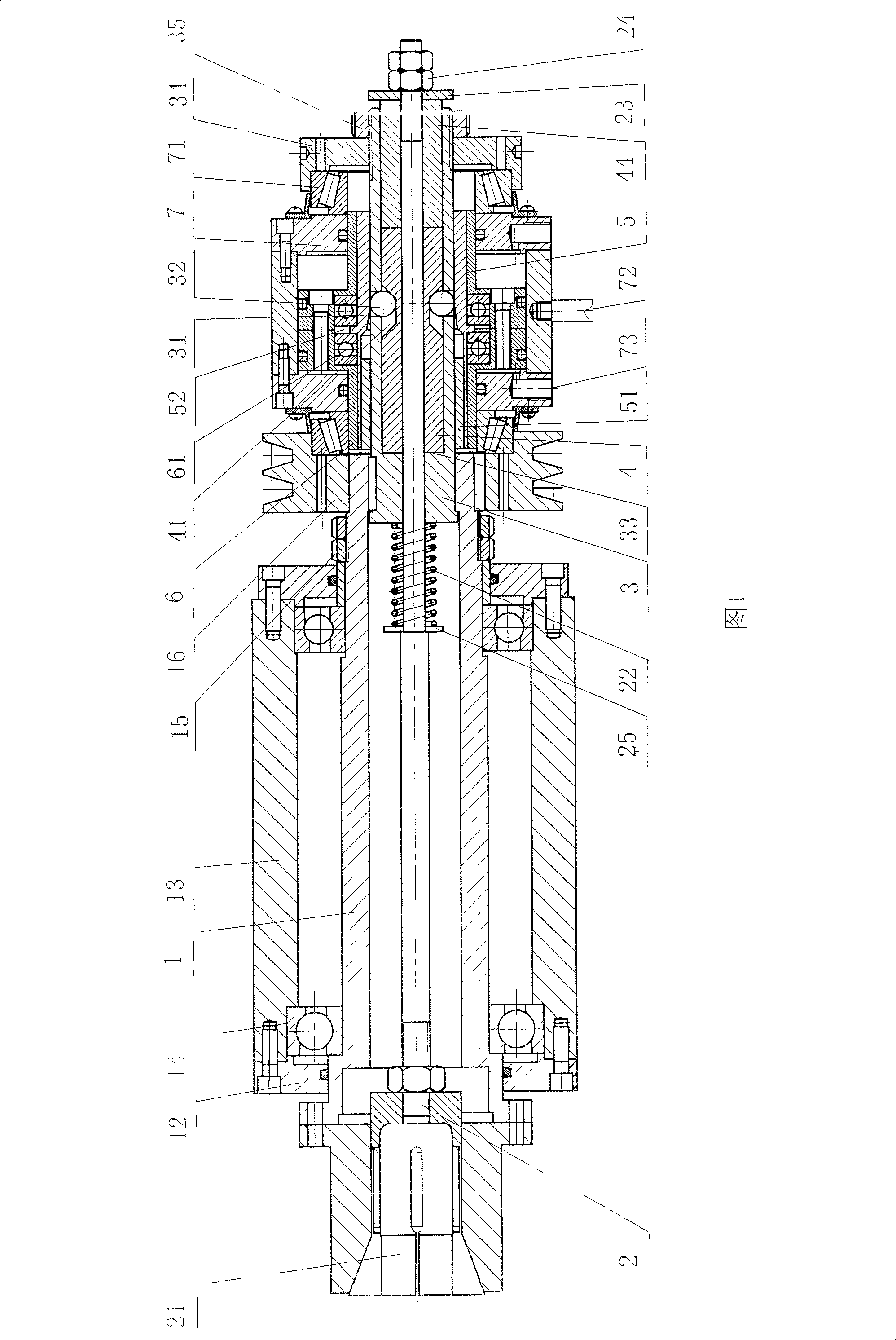

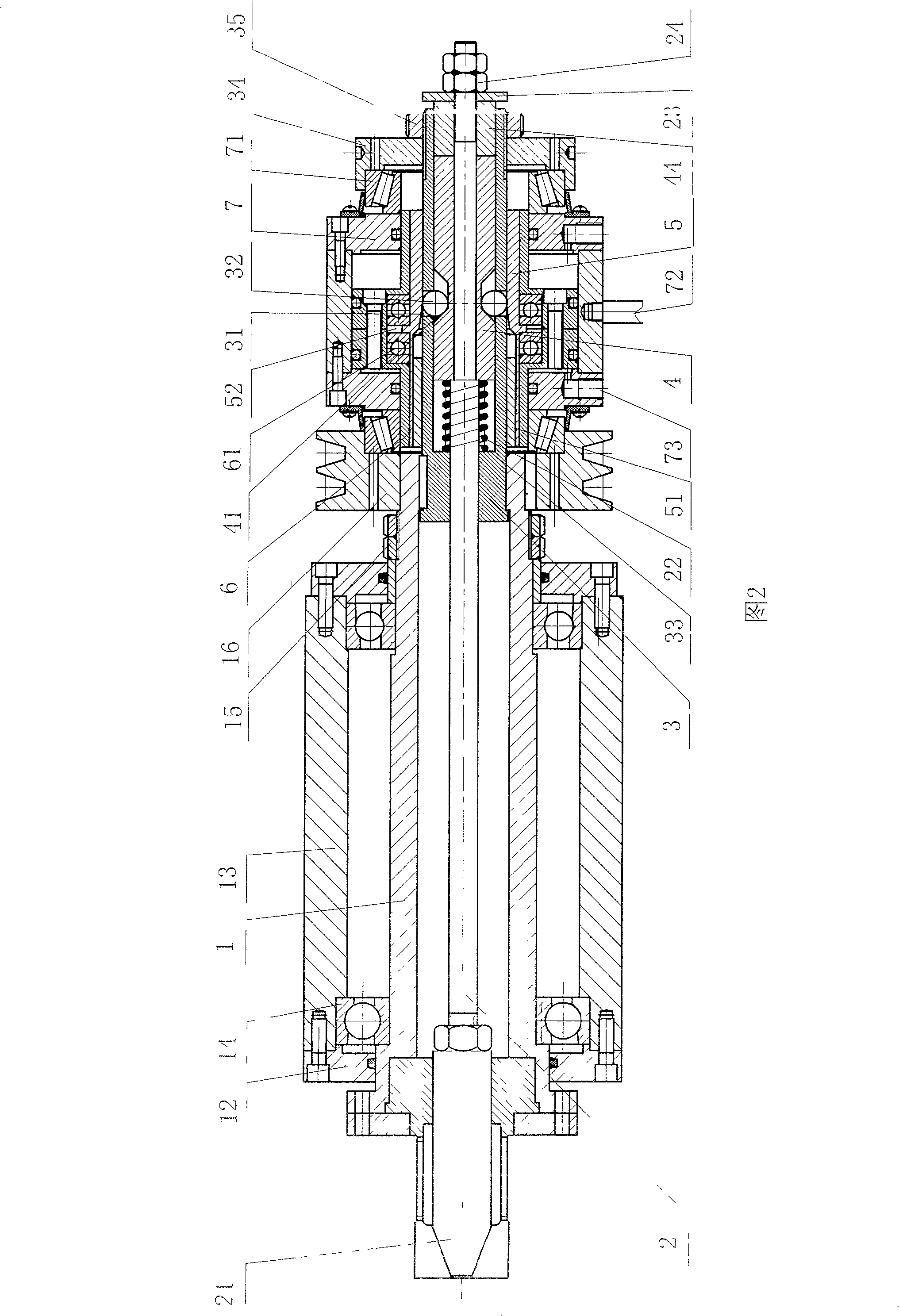

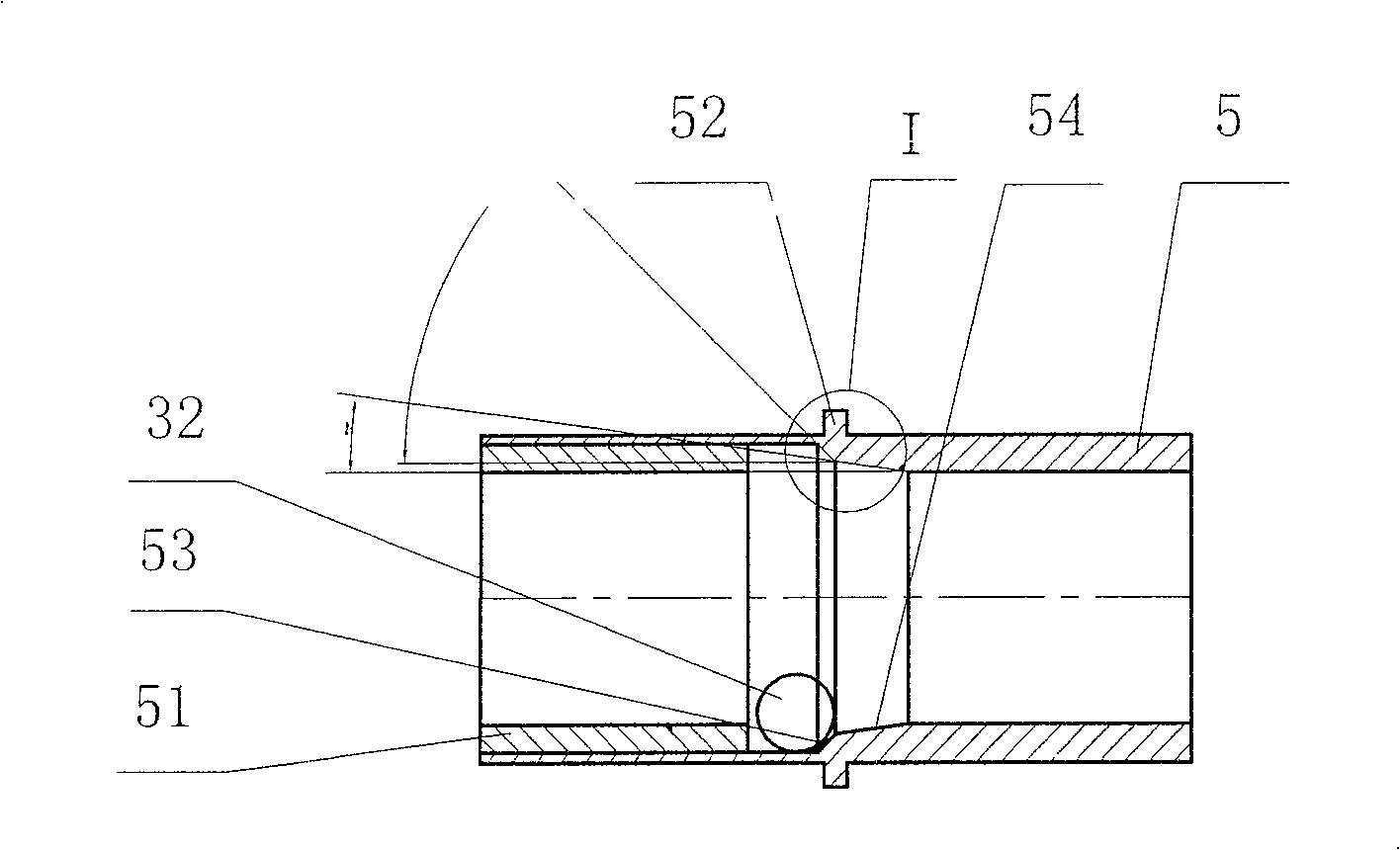

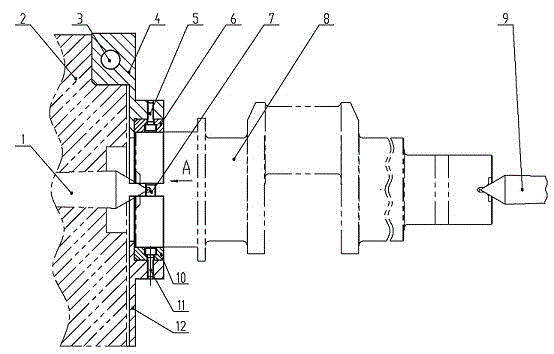

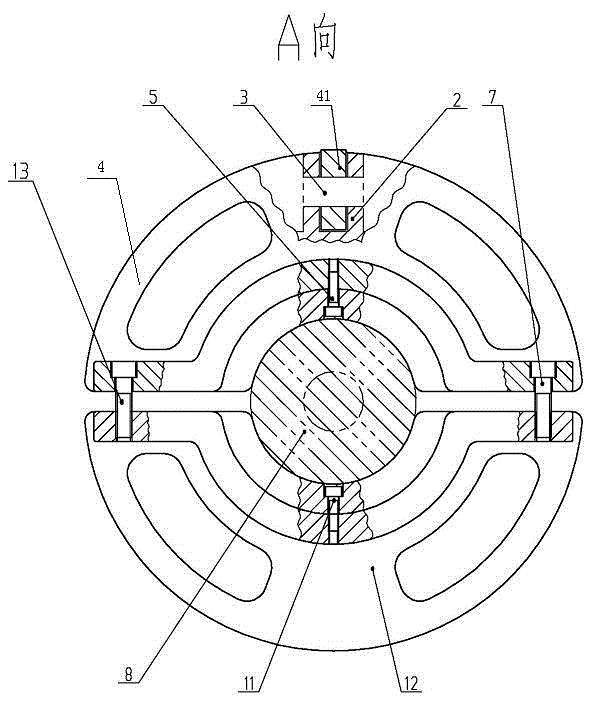

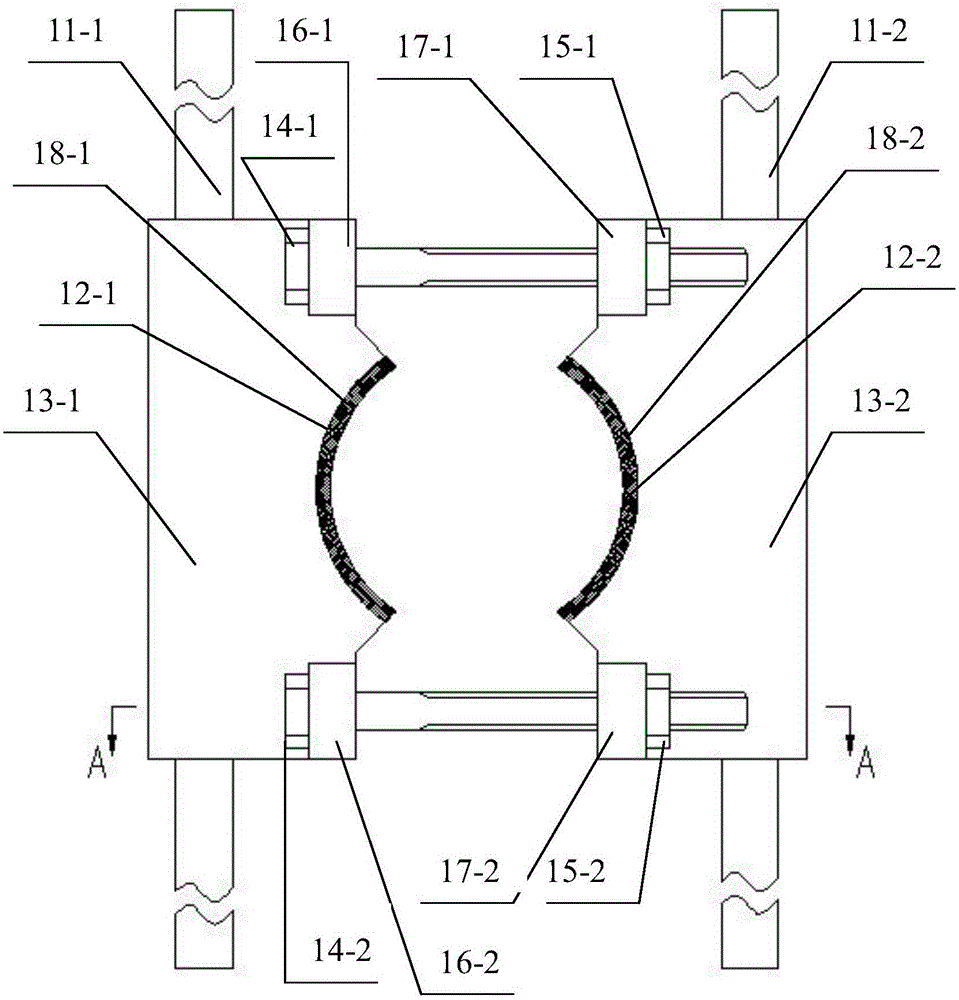

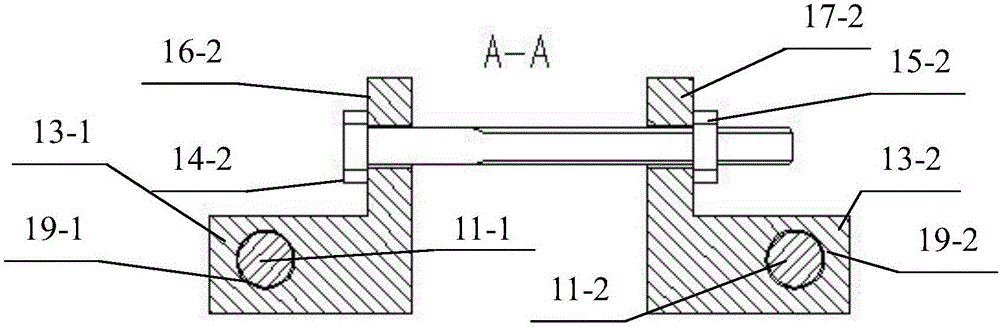

The invention discloses a clamp with all-freedom constraints for an impact fatigue testing machine. A general clamp can not ensure reliable clamping under effects of reciprocating impacts of the impact fatigue testing machine, and even the clamp itself is damaged. The clamp of the invention is composed of a distance adjusting mechanism, an X-direction clamping mechanism, a Y-direction clamping mechanism, a Z-direction clamping mechanism and a Z-direction clamping and self locking mechanism, wherein the distance adjusting mechanism is used for adjusting the distance between two sample supporting seats to be applied to samples of different lengths; the X-direction clamping mechanism, the Y-direction clamping mechanism and the Z-direction clamping mechanism are used for clamping a sample to constrain all freedoms of the sample; and the Z-direction clamping and self locking mechanism is used for preventing the Z-direction clamping mechanism in the impact direction from getting loose. The clamp of the invention can be used for clamping a rectangular section sample for the impact fatigue testing machine, all freedoms of the sample can be constrained, and as the self locking device is arranged in the impact direction, the reliability and the safety of sample clamping can be ensured.

Owner:ZHEJIANG SCI-TECH UNIV

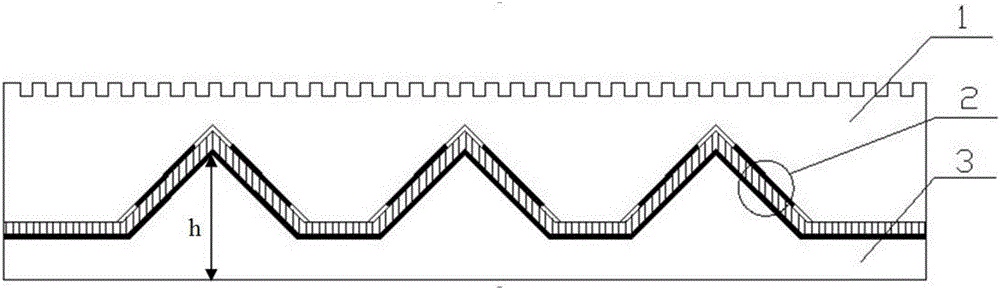

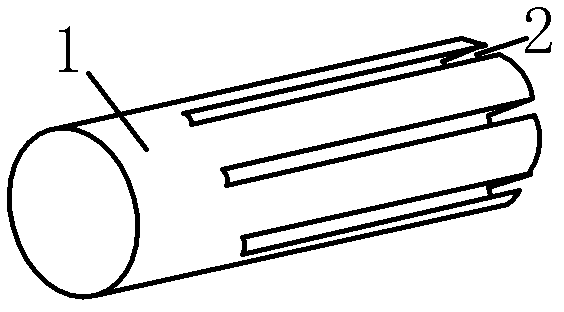

Flexible vector tactile and slip composite sensor

ActiveCN106802200AStable slip signal outputObtain mechanical information in real timeForce measurementConvex structurePositive pressure

The invention discloses a flexible vector tactile and slip composite sensor, and relates to the field of robot flexible tactile sensors and intelligent surgical instruments. The flexible vector tactile and slip composite sensor comprises an upper flexible substrate, a force sensitive structure layer and a lower flexible substrate which are closely fit from the top to the bottom. The force sensitive structure layer comprises an upper electrode layer, a flexible piezoresistive material layer and a bottom electrode layer which are arranged from the top to the bottom. The upper surface of the upper flexible substrate is provided with an equidistant microstructure array. The force sensitive structure layer is closely fit with the upper surface of the lower flexible substrate. The lower flexible substrate is provided with periodic symmetrical convex structures along the thickness direction of the sensor. Symmetrical force sensitive units are respectively arranged at the two sides of the symmetrical convex structures. The slip situation can be judged and the positive pressure, the frictional force and the slip speed can be measured through the simple internal symmetrical convex structures; and the microstructure array is arranged on the upper surface of the sensor so as to enhance the clamping stability and safety.

Owner:BEIHANG UNIV

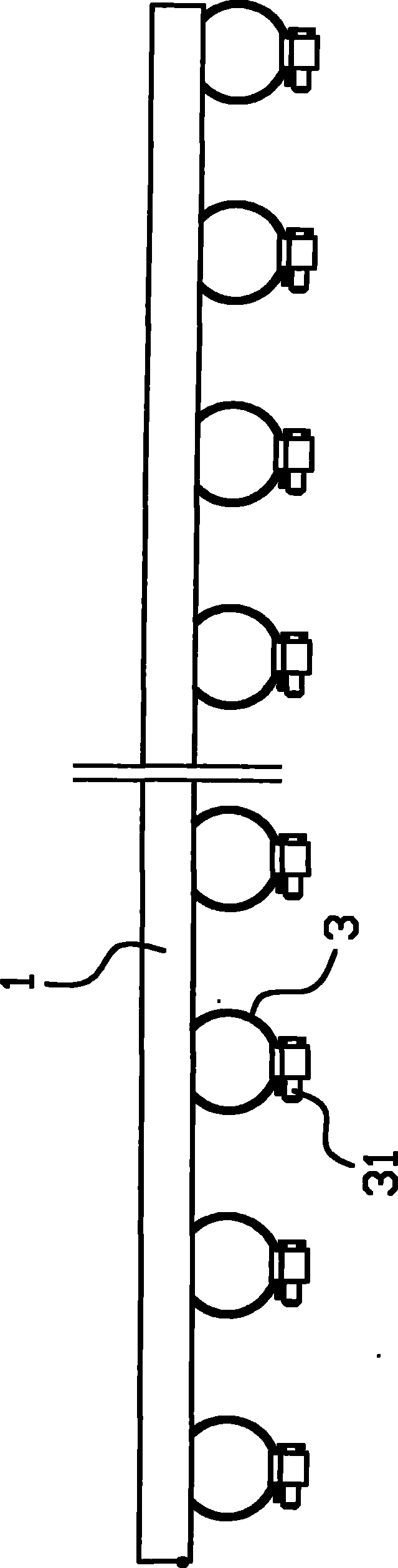

Foreign matter cleaner for electric transmission line lead

InactiveCN104795764ASafe and reliable clampingSimple structureApparatus for overhead lines/cablesElectric energyTransmission line

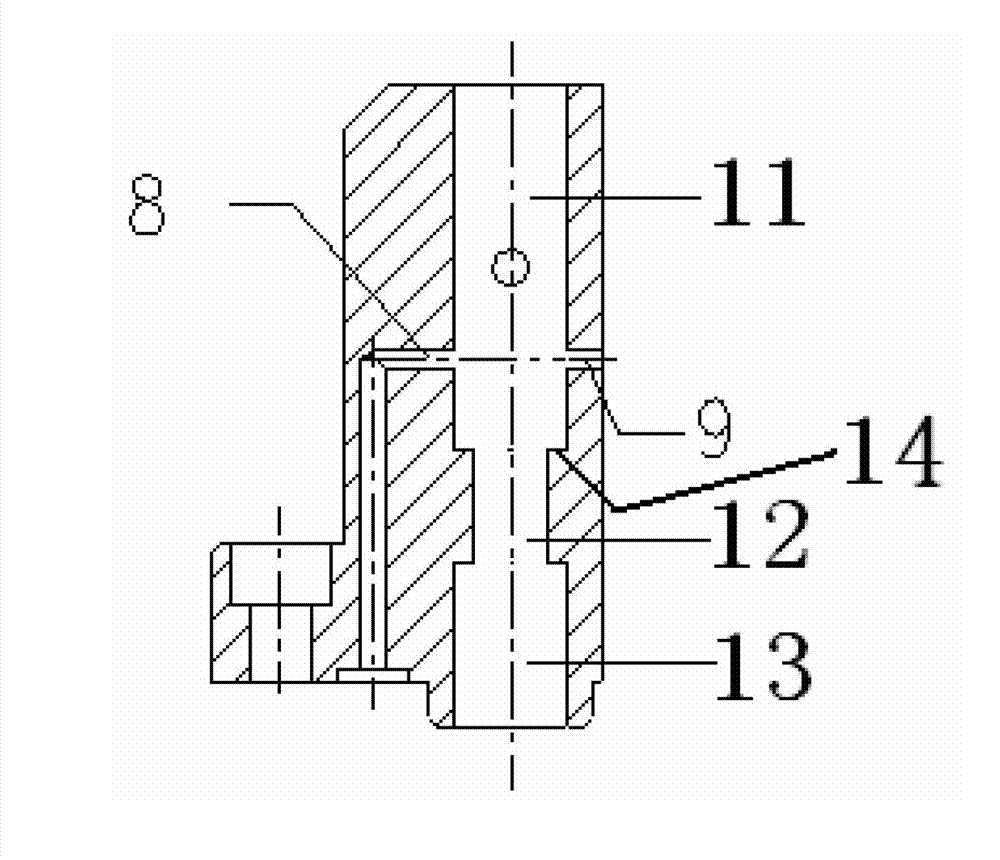

The invention discloses a foreign matter cleaner for an electric transmission line lead. The foreign matter cleaner comprises a rack walking mechanism, a foreign matter cutting mechanism and a lead clamping and blocking mechanism, wherein a controller (8) and a power supply (13) are arranged in a box body (7); a wireless receiver is arranged on the controller (8), and is used for receiving an operation instruction sent out by an over-ground remote controller and controlling various motors to run according to an operation instruction from the ground; the lead clamping and blocking mechanism clamps the lead (3) and then the lead is blocked, so that the clamping is safe and reliable; the distance from a rotating cutter wheel (4) to the lead (3) is short; positioning is accurate; almost all foreign matters can be cut off; walking control of the cleaner on the lead (3), lead clamping and locking, and foreign matter cleaning can be realized when a person stands on the ground; the foreign matter cleaner is simple in structure, light in weight, convenient to carry and use, and high in cutting efficiency, and electric energy of equipment is saved.

Owner:石岩龙

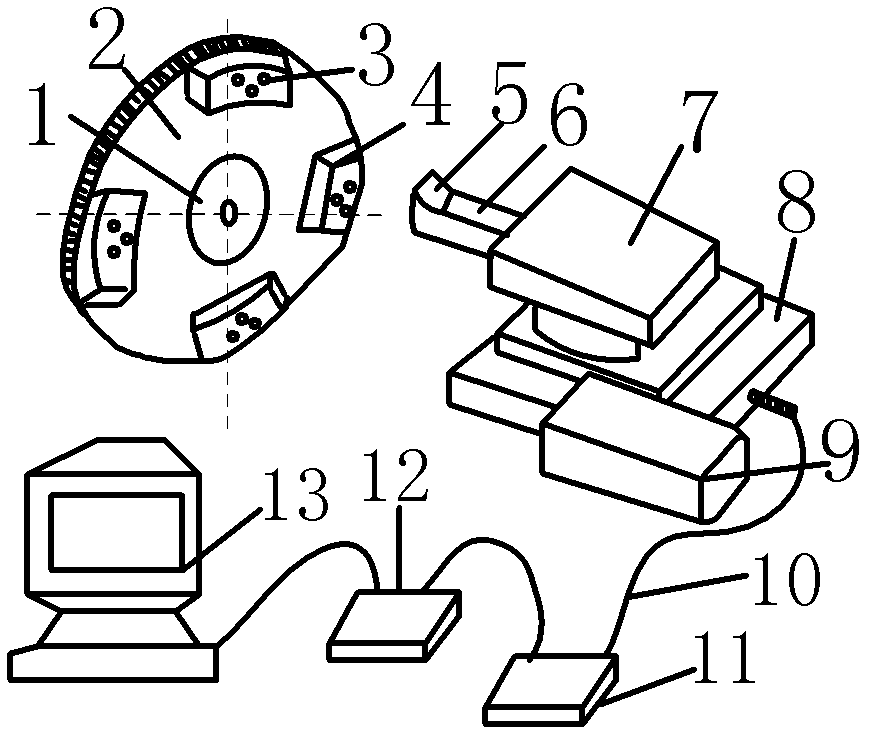

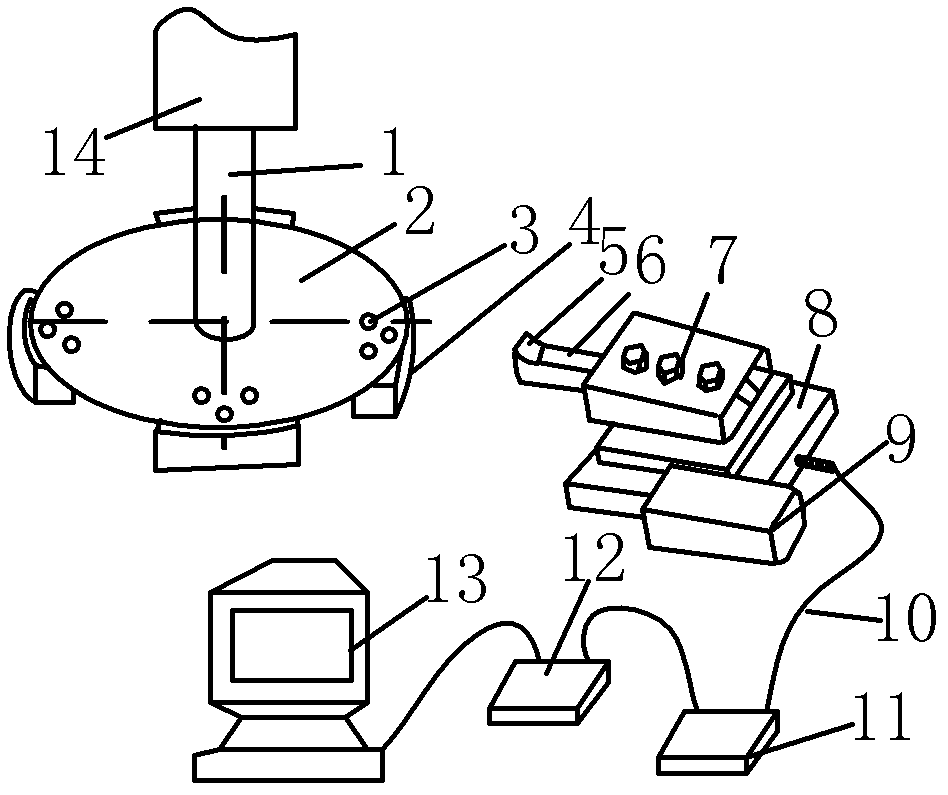

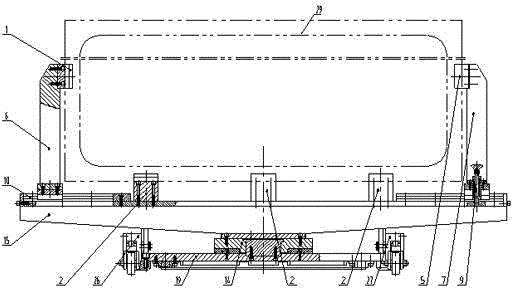

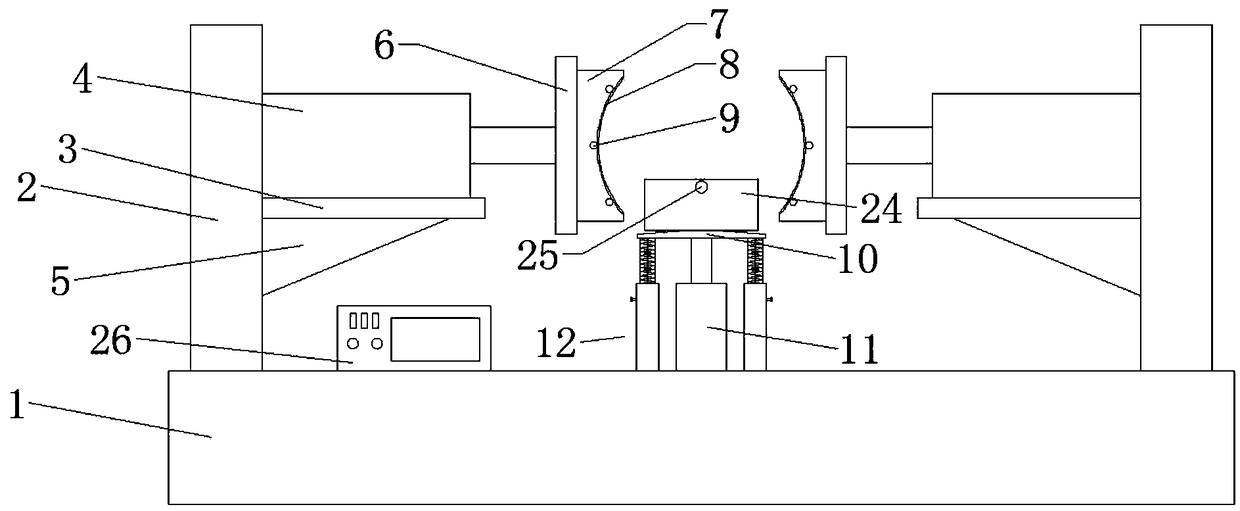

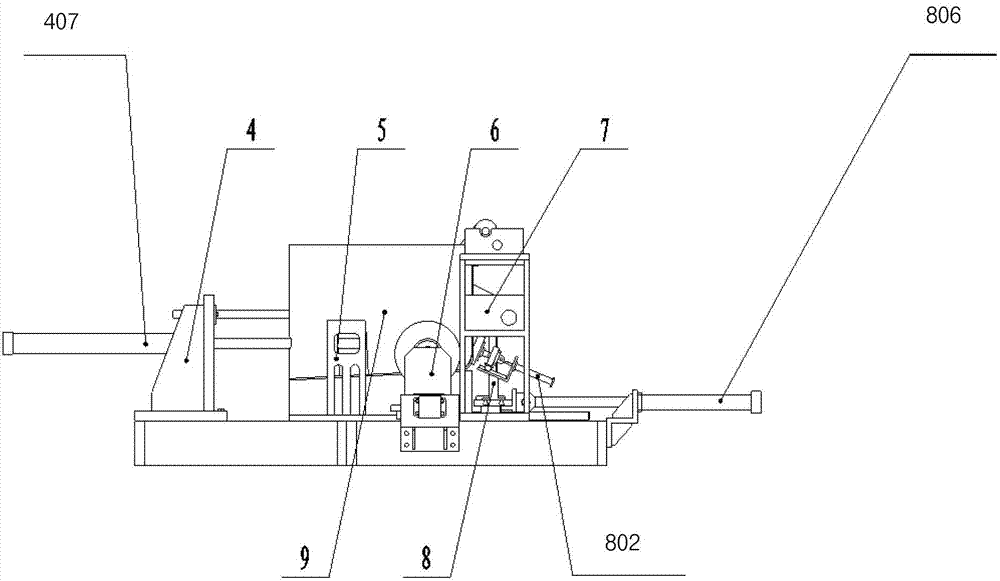

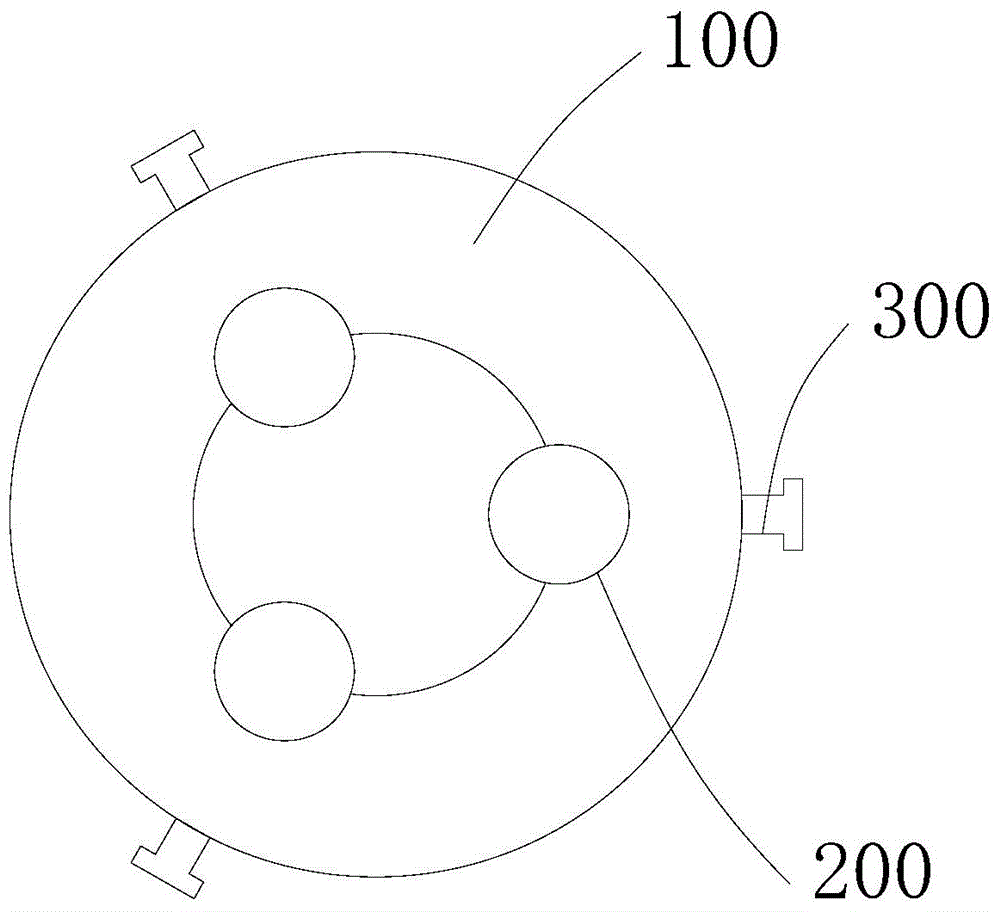

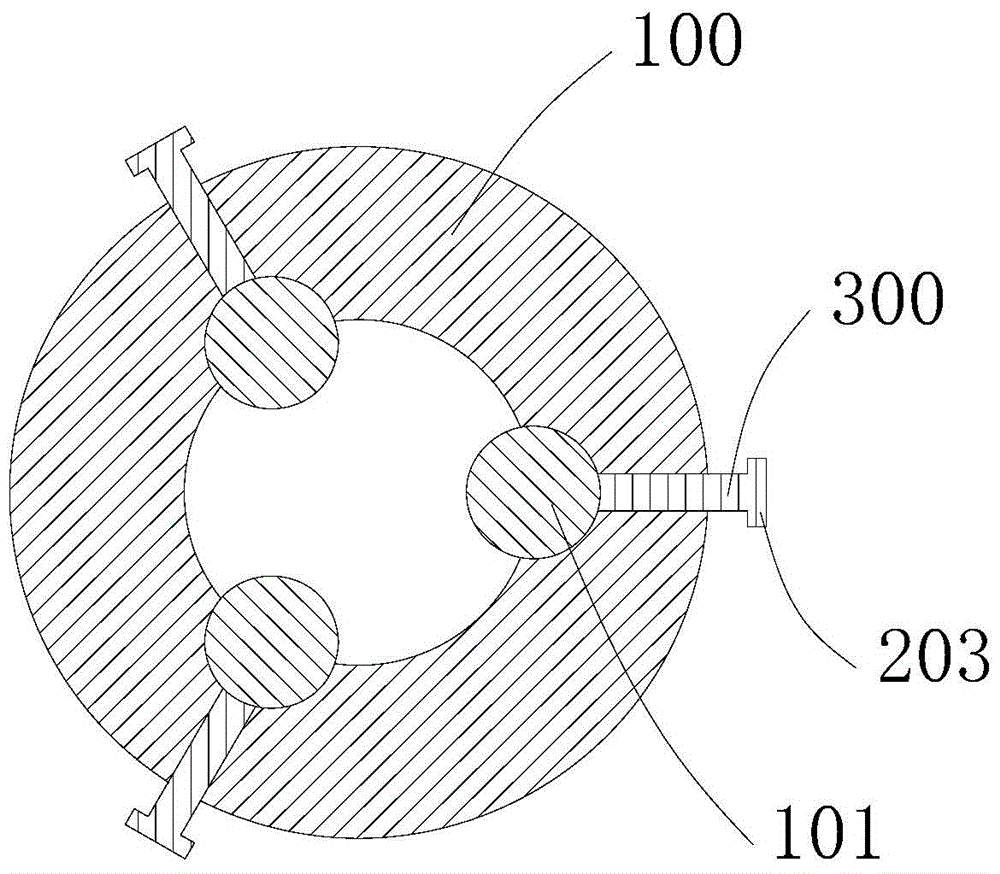

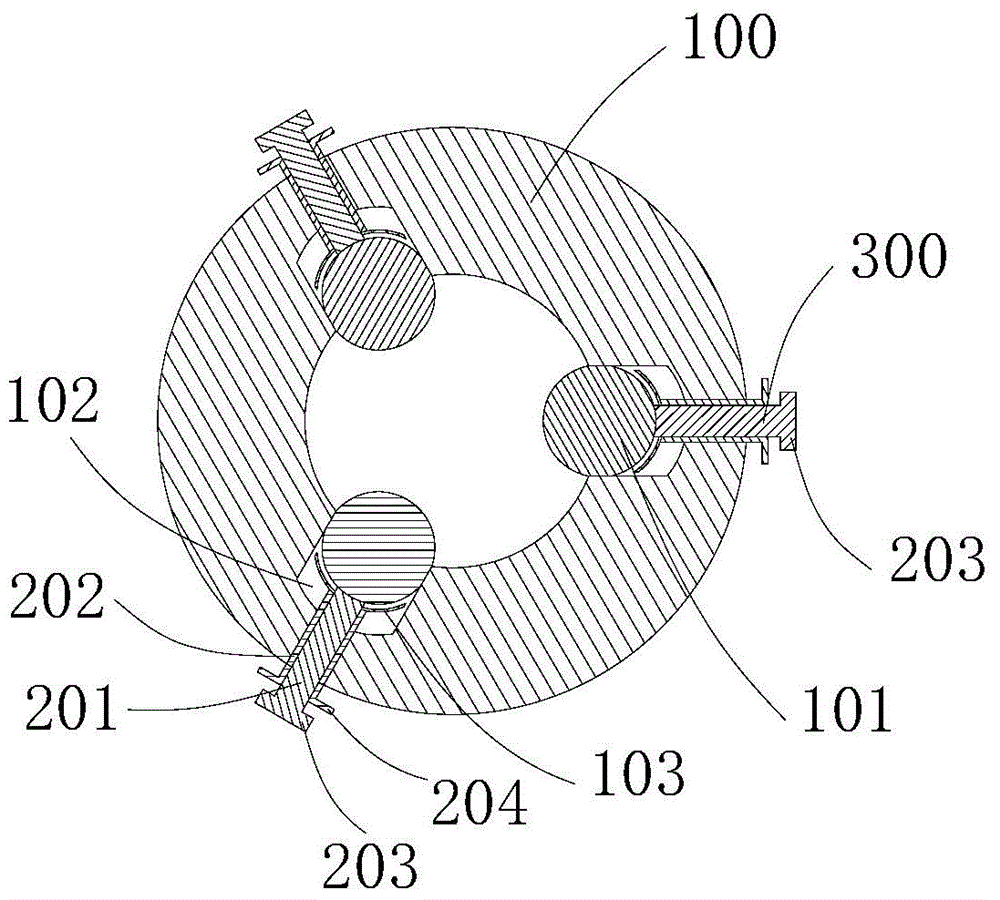

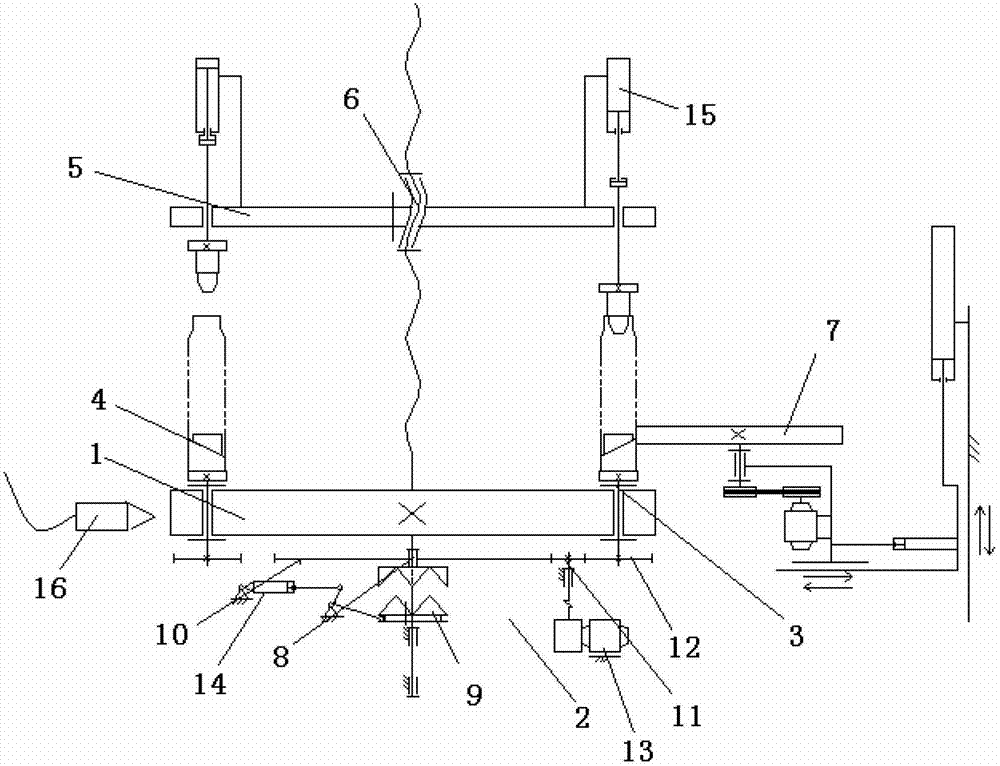

Device for evaluating and testing interrupted cutting performance of tools at high speed

InactiveCN102490084ARealize online measurementHigh speedMeasurement/indication equipmentsAudio power amplifierData acquisition

The invention provides a device for evaluating and testing interrupted cutting performance of tools at a high speed. The device comprises a rotary disk body, a tool bar, a tool rest, a piezoelectric type dynamometer, an infrared temperature detector, an electric charge amplifier and a computer, wherein the tool bar is arranged on the tool rest, the piezoelectric type dynamometer and the infrared temperature detector are fixed on the tool test, the piezoelectric type dynamometer is connected with the electric charge amplifier through a connecting wire, the electric charge amplifier is connected with a data acquisition card in the computer; a clamping part is arranged above the rotary disk body, and an even number of workpiece block installation locations symmetrically distributed at intervals on the same circumference by taking the center of rotation of the rotary disk body as a center, are arranged on the rotary disk body. The testing device can realize the interrupted cutting on the circumference and the cylindrical end face, can be used for the test evaluation of the interrupted cutting performance of the tools, and can realize the tool cutting performance evaluation test at different interrupted degrees and the on-line measurement of the cutting force, the cutting temperature and the service life of indexable blades to be evaluated, thus realization process and method are simple and convenient.

Owner:SHANDONG UNIV

Tensile fixture of round bar tensile sample

The invention discloses a tensile fixture of a round bar tensile sample. The fixture comprises an upper connector and a lower connector, which are respectively connected with a tester, wherein the fixture also comprises an upper clamp connected with the upper connector; the upper clamp comprises an upper chuck; the clamp also comprises a lower clamp connected with the lower connector; the lower clamp comprises a lower chuck; the fixture also comprises lower bolts which are arranged inside the upper chuck and the lower chuck. By adopting the tensile fixture, the defects of large noise, high power consumption, incapability of mounting an extensometer and the like of the traditional fixture are overcome; meanwhile, the tensile fixture is convenient and fast to replace, and is an accurate, fast and economic clamp system.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

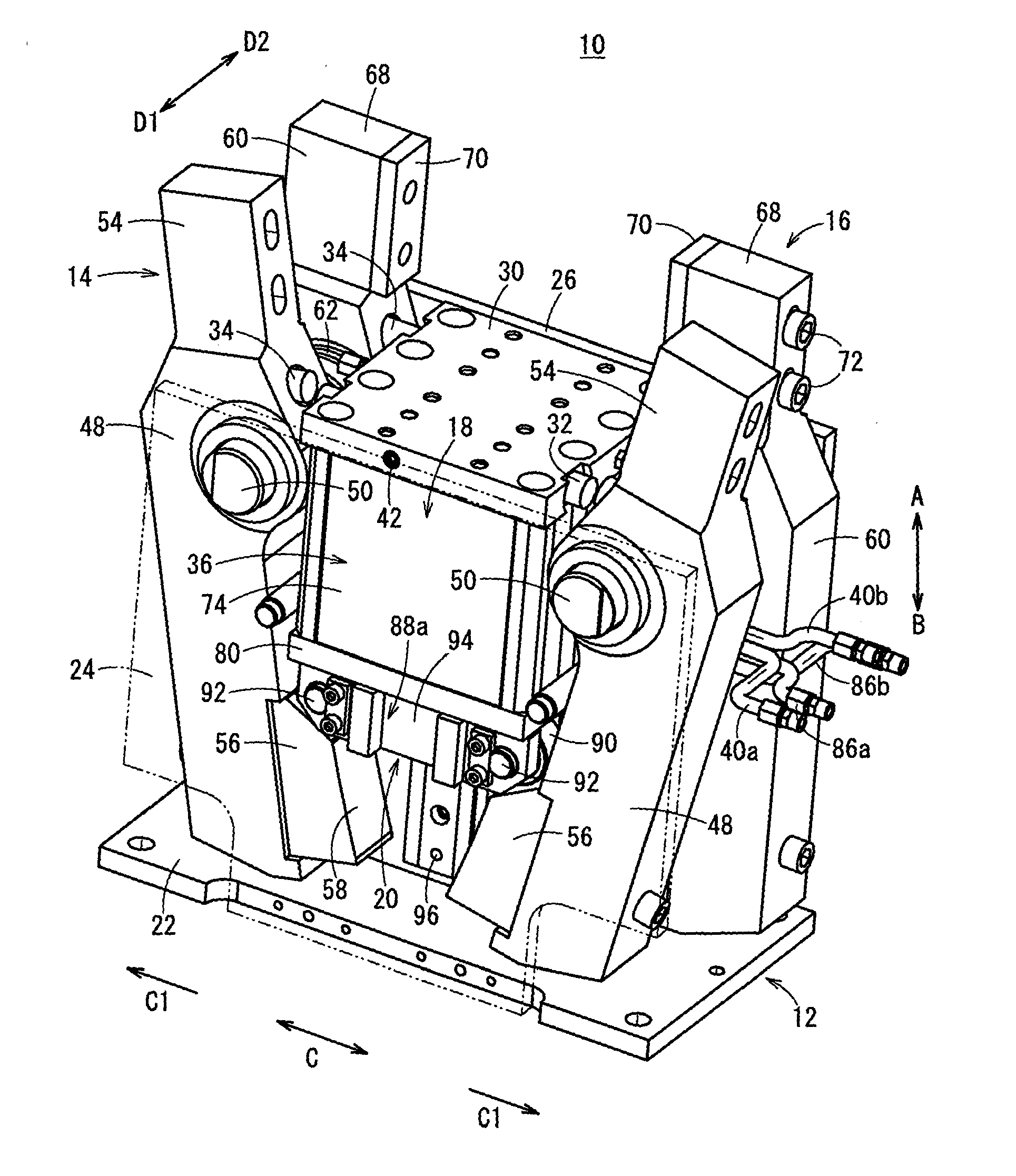

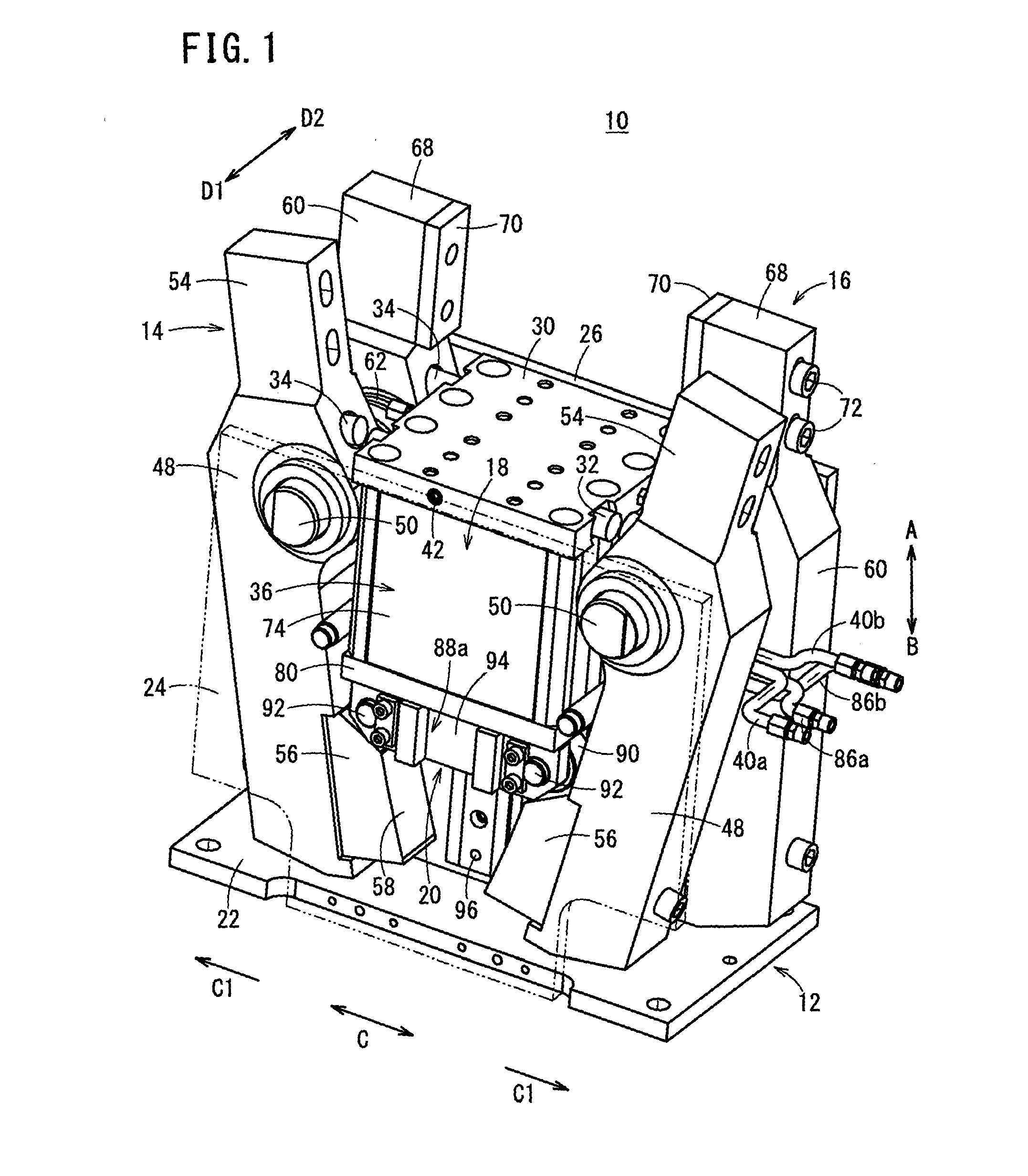

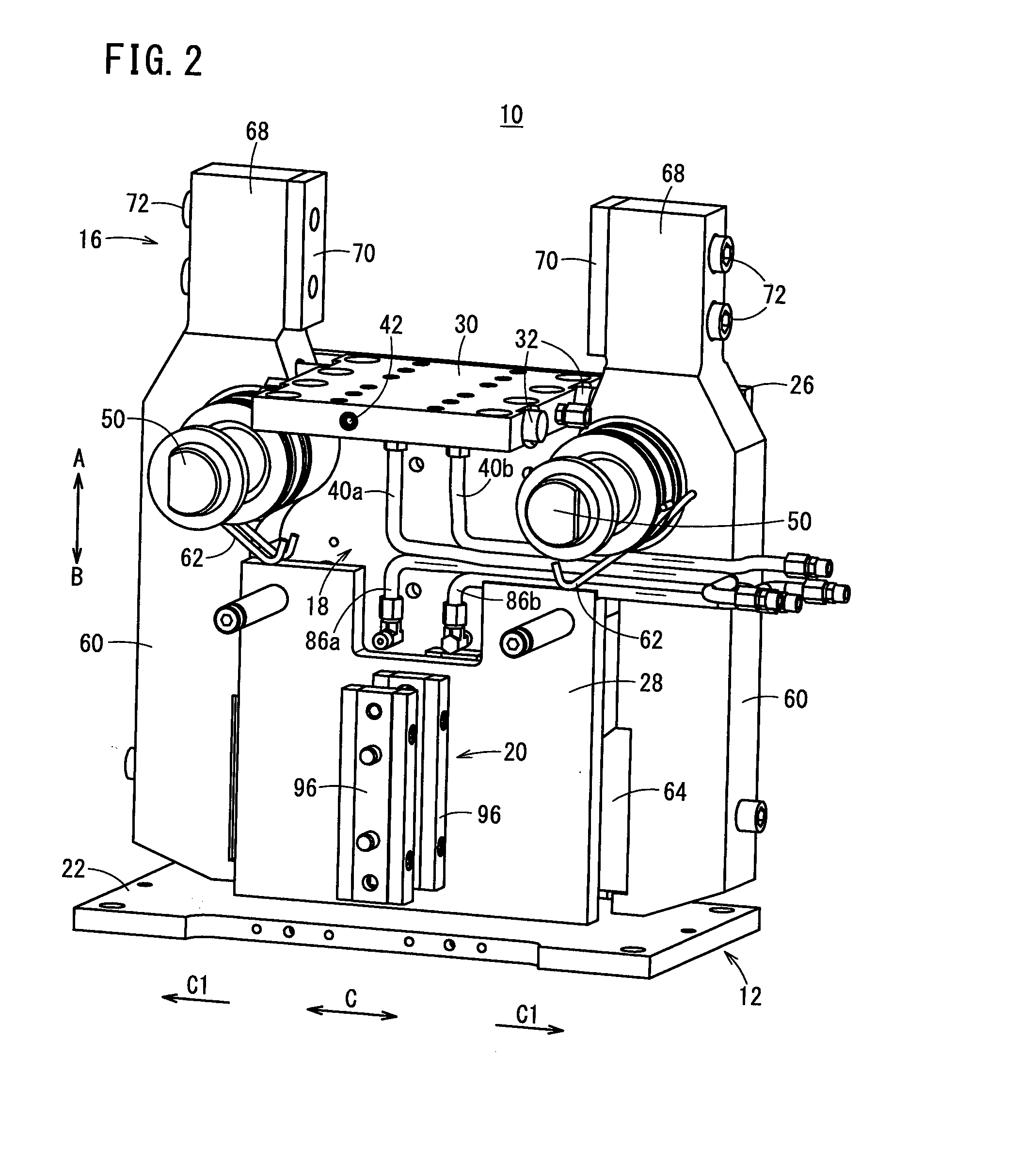

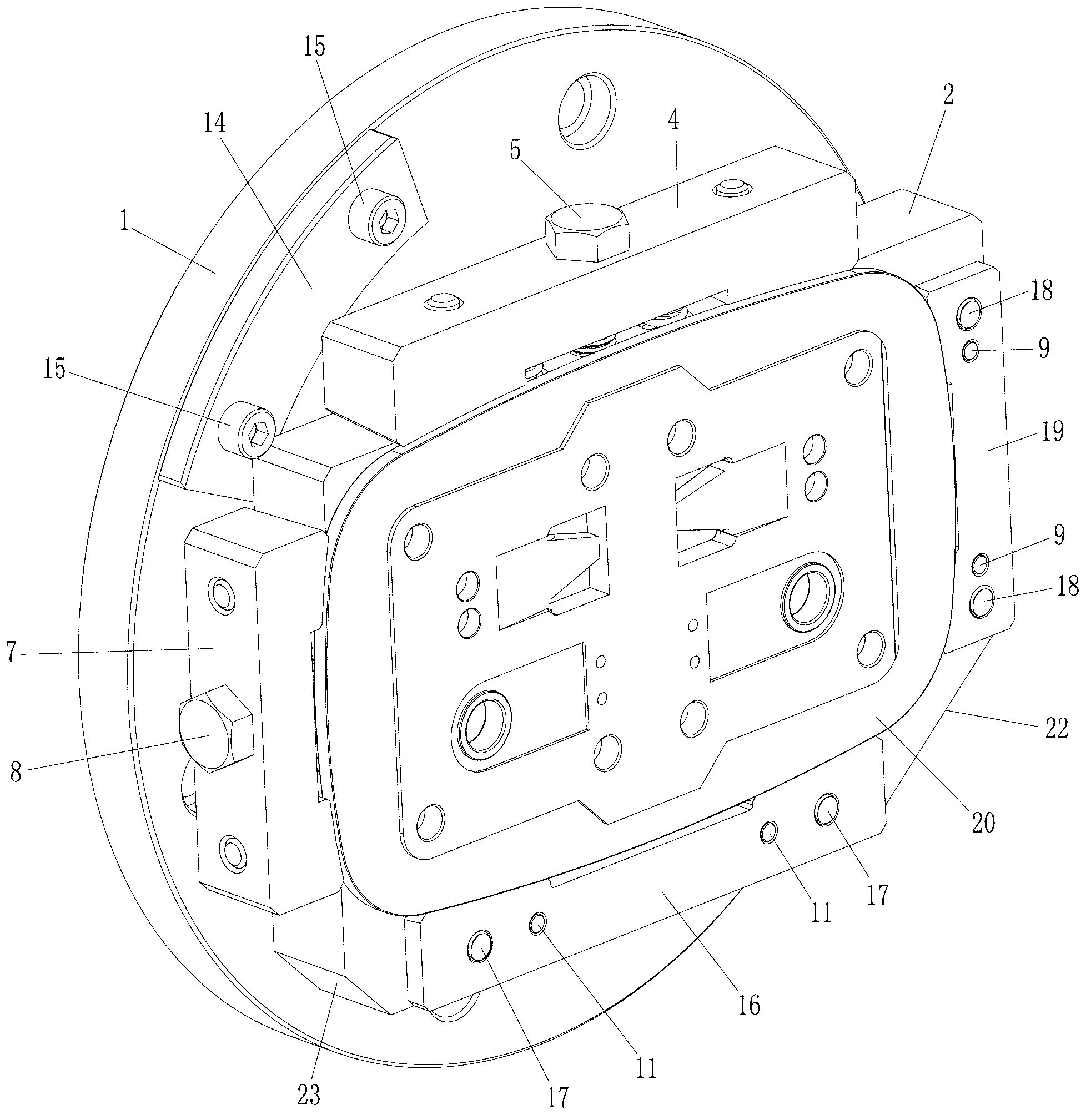

Clamp apparatus

ActiveUS20160136789A1Contribute to space savingStable and reliable clampingPositioning apparatusVicesEngineeringCam

A clamp apparatus including two pairs of first and second clamp arms, which are supported rotatably with respect to a body and are disposed mutually in parallel. First and second cam members including respective cam surfaces are provided on ends of the first and second clamp arms. The first cam members are pressed by rollers upon lowering of a block body under a driving action of a first cylinder that makes up a drive unit. The first clamp arms are rotated to assume a clamped state. The second cam members are pressed by rollers upon lowering of a block body under a driving action of a second cylinder of the drive unit, whereby the second clamp arms are rotated to assume a clamped state.

Owner:SMC CORP

Fixture for detecting errors of transmission wave surface of large-sized neodymium glass plate

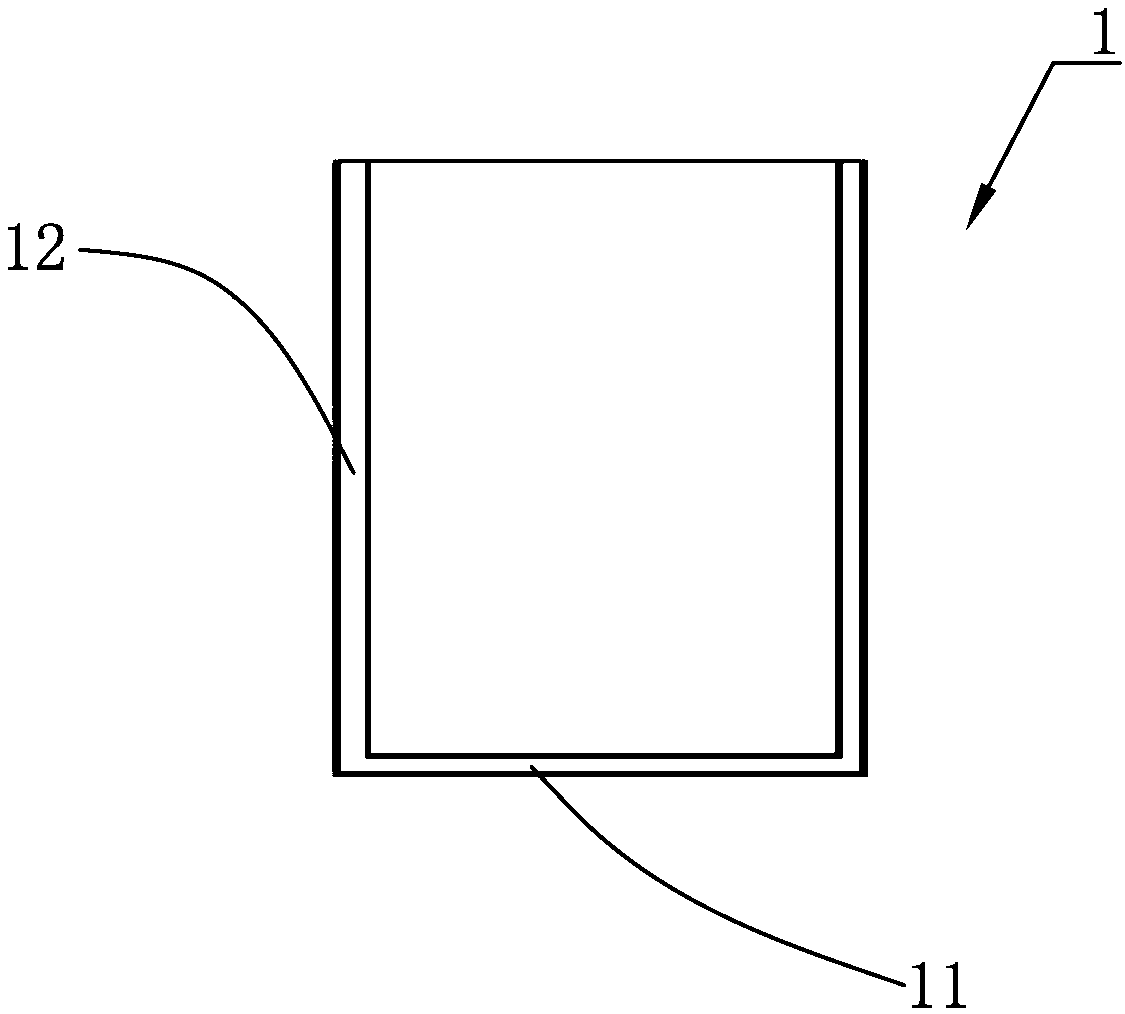

InactiveCN104608075AAdjust the placement angle at willSafe and reliable clampingWork holdersOptical apparatus testingNeodymiumGlass chip

The invention discloses a fixture for detecting errors of a transmission wave surface of a large-sized neodymium glass plate, and relates to a clamping device for detecting errors of transmission wave surfaces of large-sized neodymium glass plates in the technical field of special-purpose fixtures. By the fixture for detecting the errors of the transmission wave surface of the large-sized neodymium glass plate, the large-sized neodymium glass plate can be clamped safely, and a placing angle can be adjusted conveniently and quickly. The fixture comprises a base, wherein two sides of the base are connected with travelling mechanisms; the top of the base is connected with a base rotating plate; the top of the base rotating plate is connected with a support frame; the support frame can rotate around the axis of the base along with the base rotating plate; an H-shaped left sliding track, a bottom concave clamping block and an H-shaped right sliding track are sequentially arranged on the top of the support frame from left to right; the H-shaped left sliding track is provided with a left supporting arm capable of moving along the length direction of the H-shaped left sliding track; a left concave clamping block is arranged on the left supporting arm; a right supporting arm capable of moving along the length direction of the H-shaped right sliding track is arranged on the H-shaped right sliding track; and a right concave clamping block is arranged on the right supporting arm.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

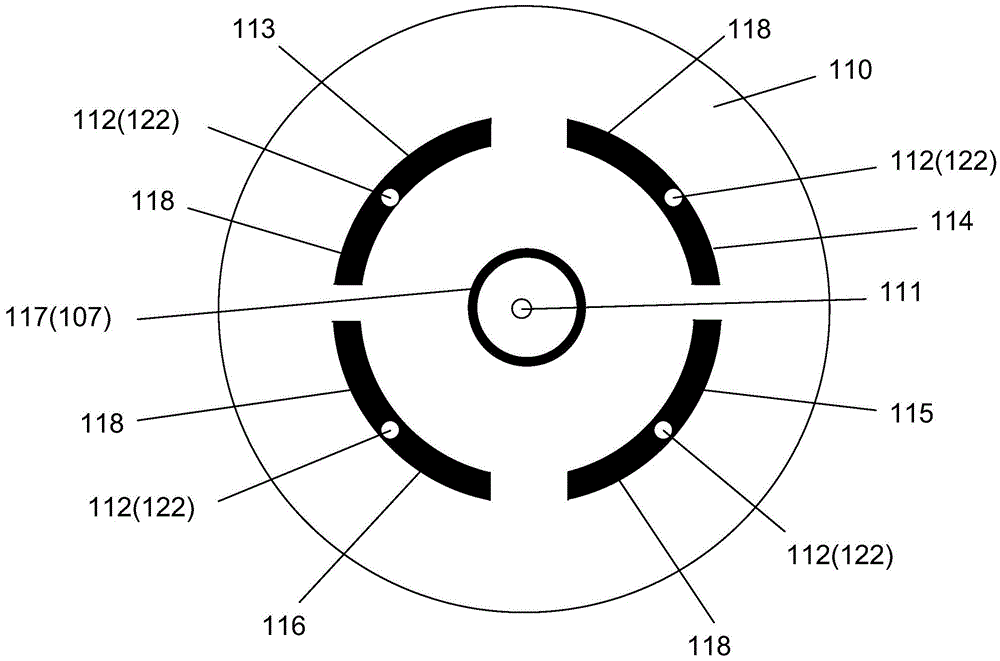

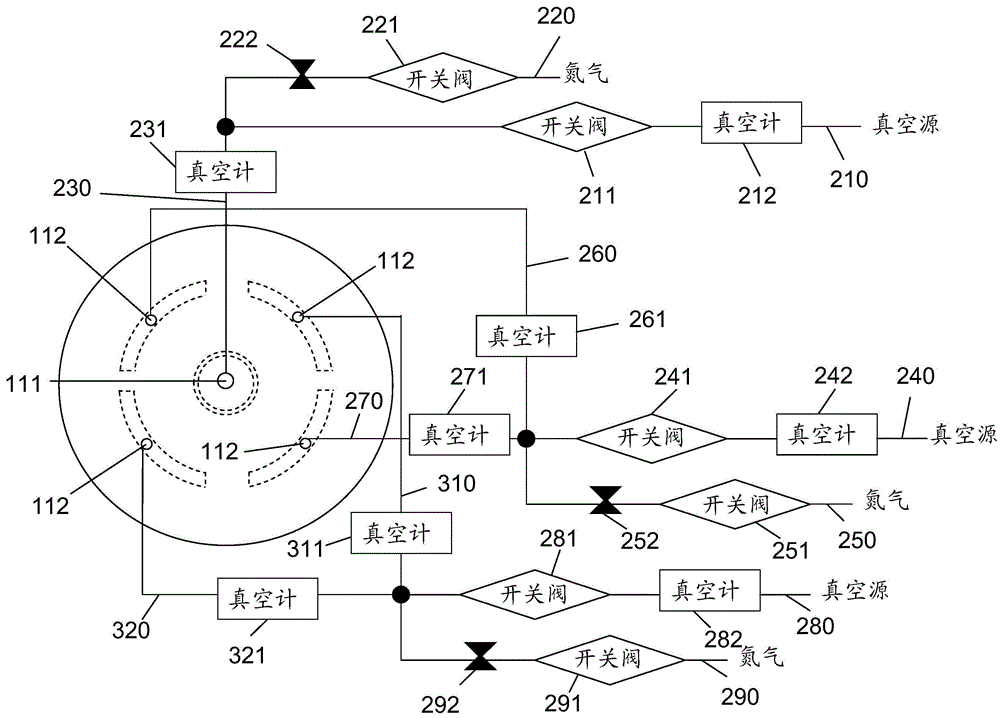

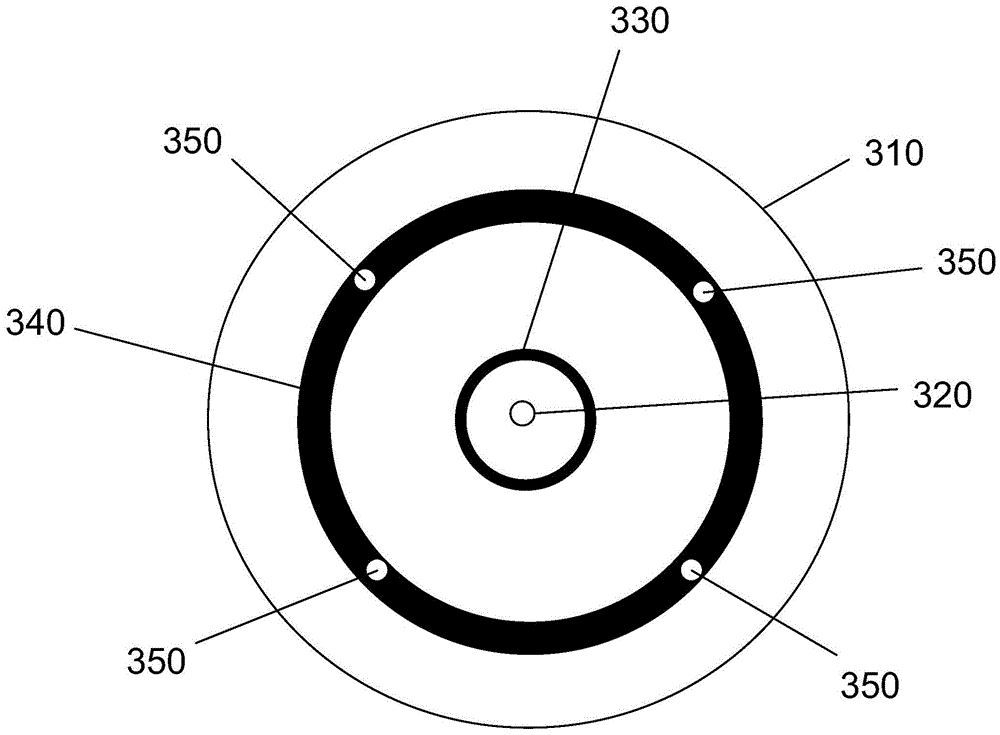

Vacuum clamp

The invention discloses a vacuum clamp. The vacuum clamp comprises a clamp body, wherein multiple grooves are formed in the clamp body, each groove is an independent groove area, a first vacuum hole penetrating through the clamp body is formed in each groove, a sealing part is arranged in each groove, a second vacuum hole is formed in each sealing part and communicated with the first vacuum hole of the corresponding groove, each first vacuum hole is connected with a pipeline structure, and each pipeline structure comprises an exhaust pipeline and a gas inlet pipeline. The mutually independent grooves are formed, so that even if vacuum leakage happens to one of the grooves, the vacuum clamp cannot be influenced when used for clamping a silicon wafer. Besides, the gas inlet pipelines are arranged, accordingly, the gas pressure difference between an upper plane and a lower plane of the silicon wafer can be adjusted, and the vacuum clamp can clamp an ultrathin silicon wafer stably and safely.

Owner:ACM RES SHANGHAI

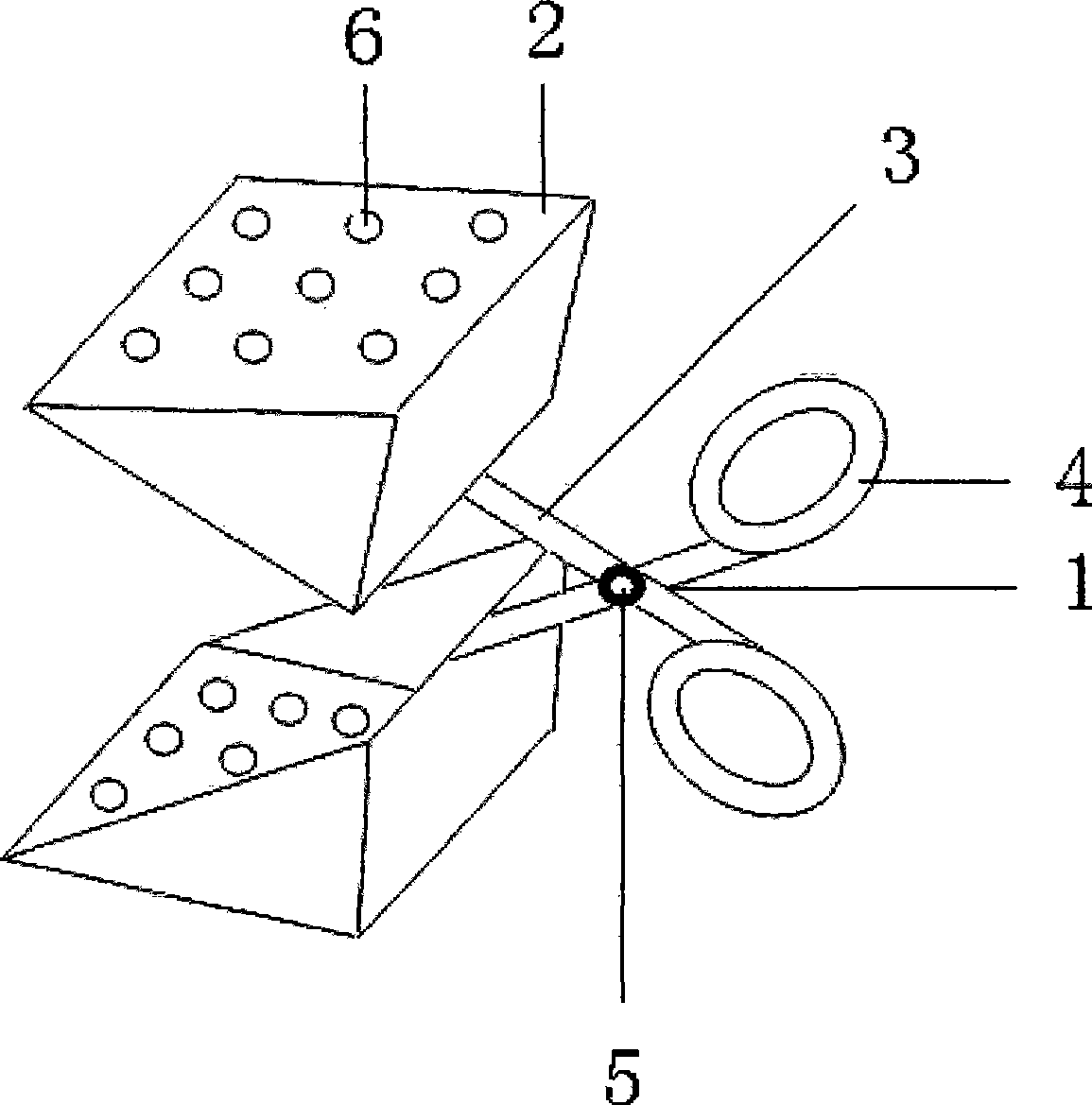

Crab gripper

InactiveCN101507445ASafe and reliable clampingSimple and fast operationSlaughtering animals fettering apparatusPisciculture and aquariaWater filterEngineering

The invention discloses a crab clamper, and aims to provide a tool suitable for clamping crabs. The technical proposal adopted by the invention comprises a water-filtering dust pan is arranged on a pair of pliers. The crab clamper comprises the pliers and the dust pan, wherein the water-filtering dust pan is arranged on the pliers, and the pliers and the dust pan are made of rust-proof materials. The technical proposal is simple and convenient to operate, and the crab clamp is safe to clamp the crabs, does not damage the crabs, and is convenient to use.

Owner:谭建

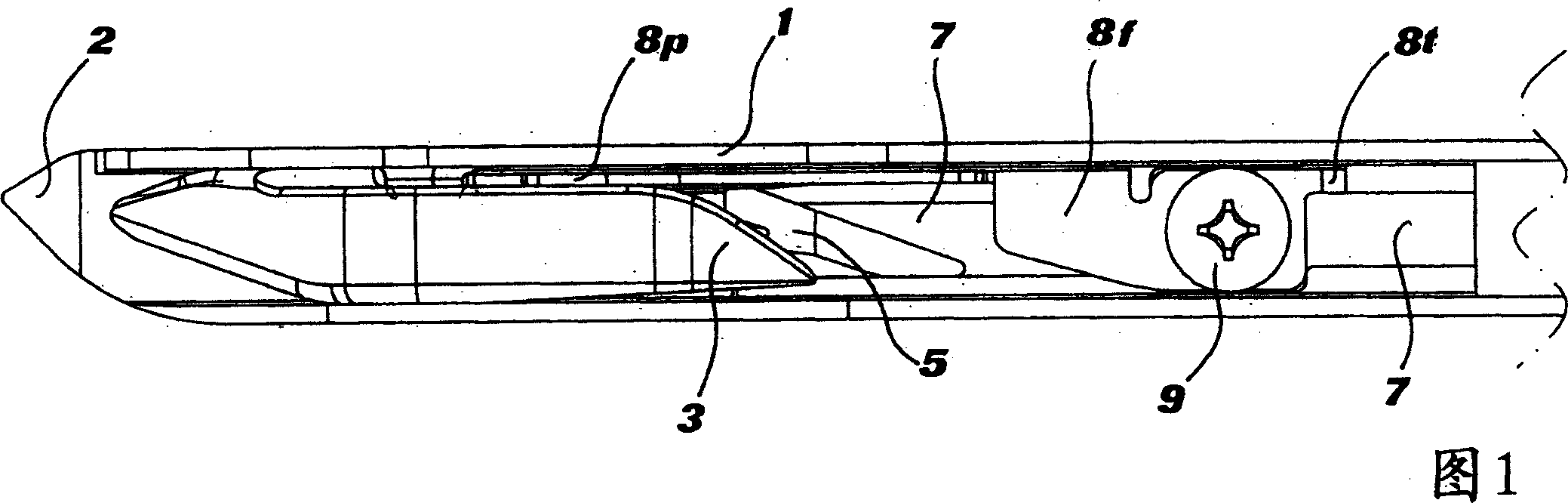

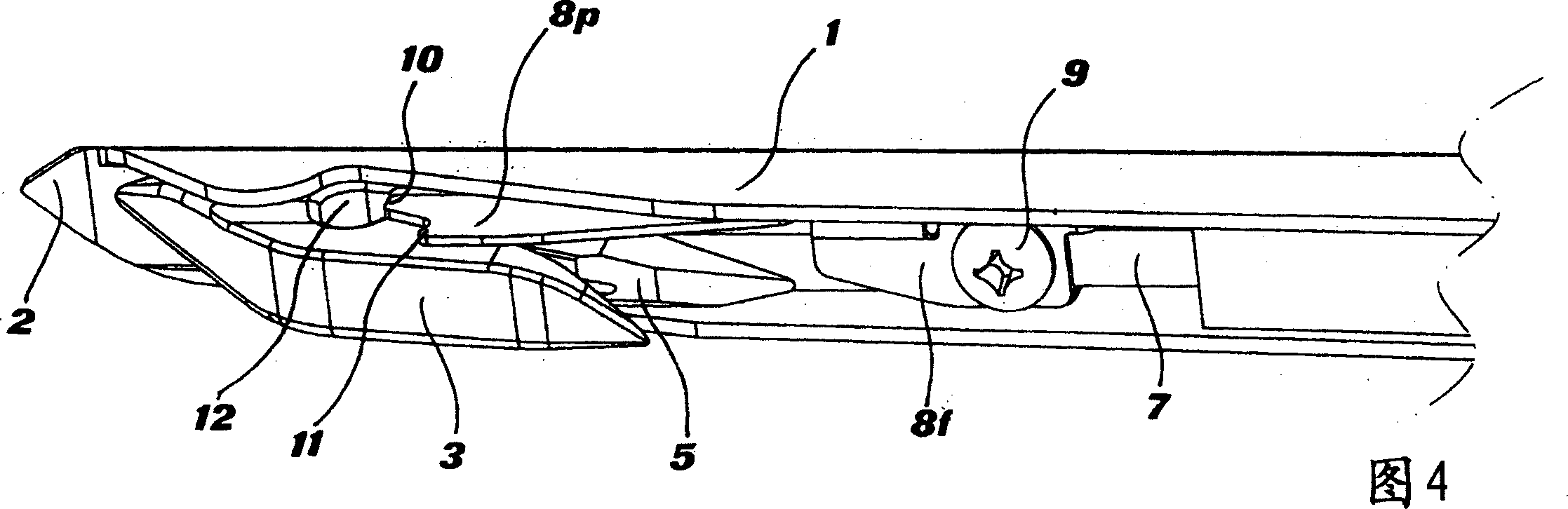

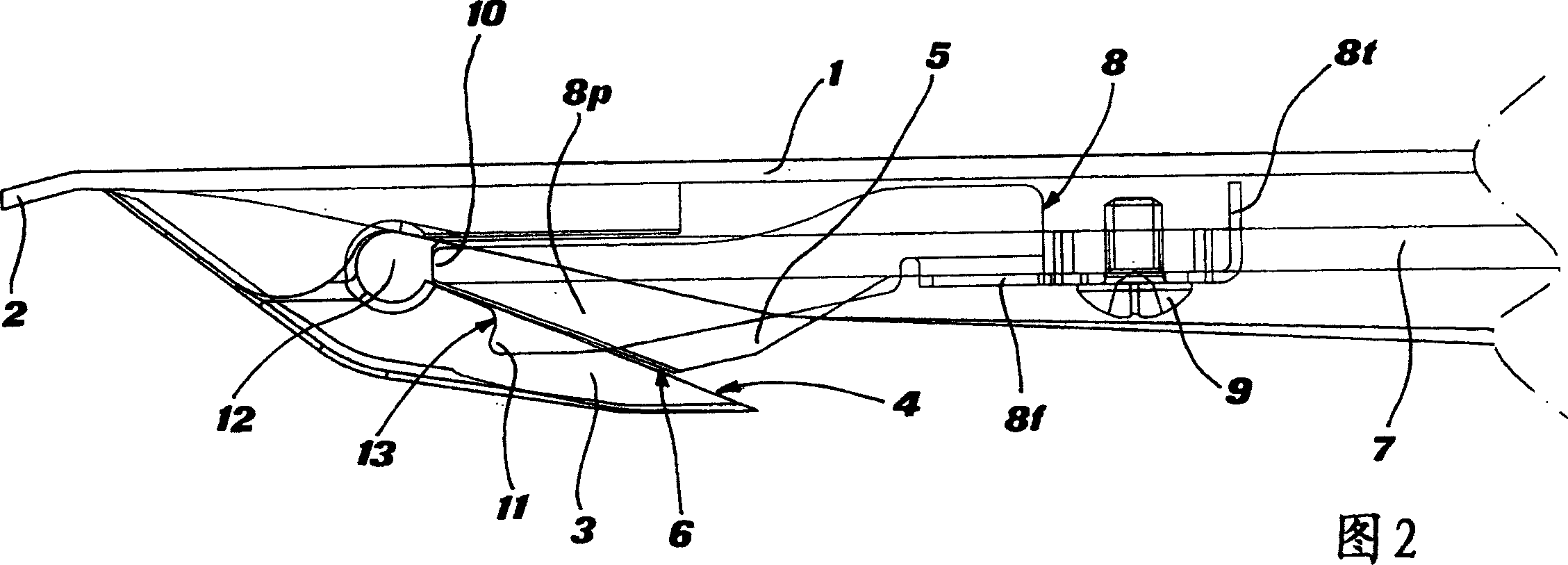

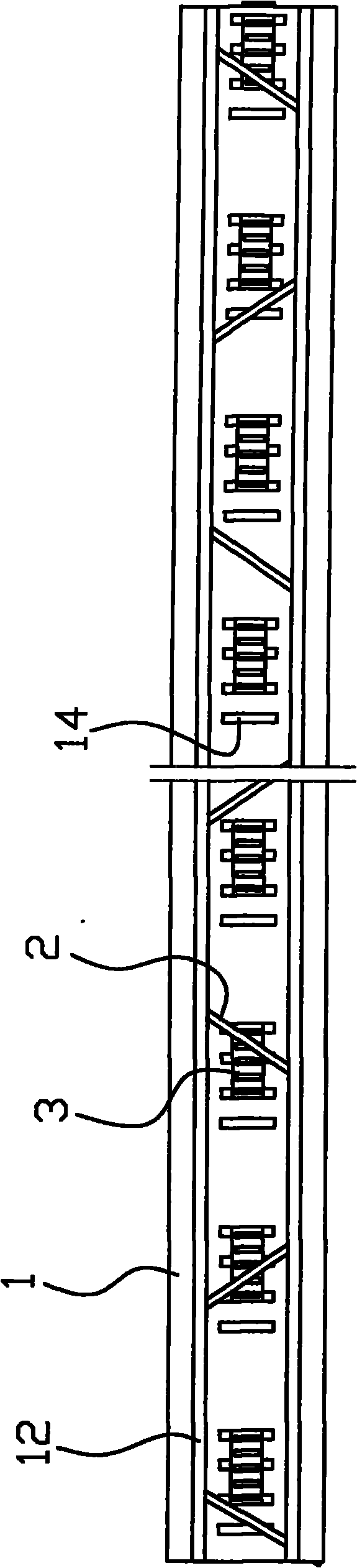

Drawing gripper for weaving looms with improved performance for the transport of double weft yarns

Drawing gripper for weaving looms comprising a gripping device of the weft thread consisting of the coupling between a fixed surface formed in the inner part of the gripper hook and inclined with respect to the shifting direction of the gripper, and the mobile surface of a wedge carried on the front end of a longitudinal rod housed in the gripper and movable in an axial direction with respect thereto. The movable rod is driven in an open position of the gripping device, in contrast with spring means provided on the gripper, by lever means cooperating with fixed outer abutments arranged on the loom, and on the same rod the rear portion of a flexible metal plate is attached, the free front portion whereof imparts an elastic pressure force to the upper edge of at least one of the cooperating surfaces of said gripping device.

Owner:PROMATECH

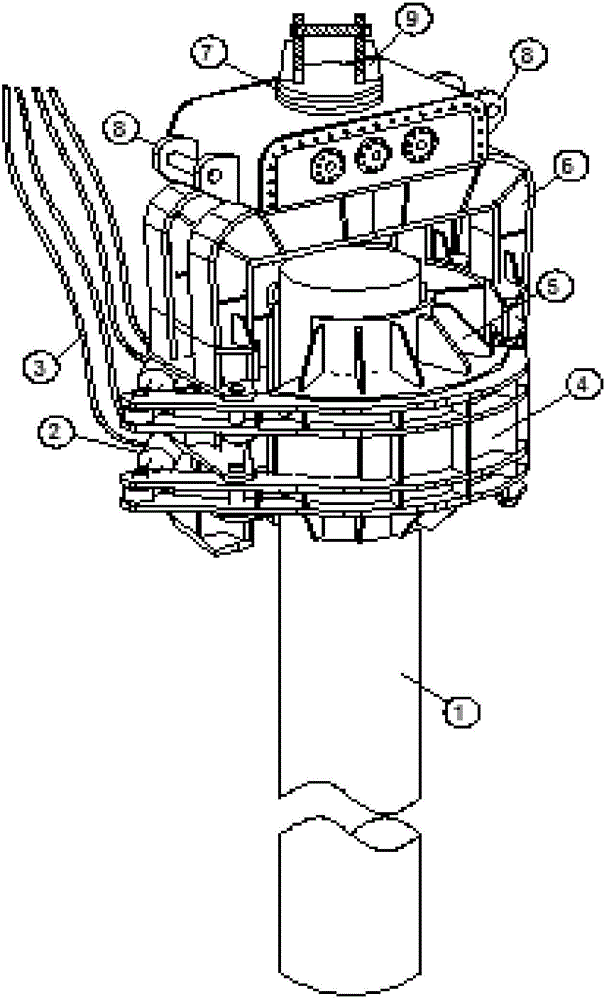

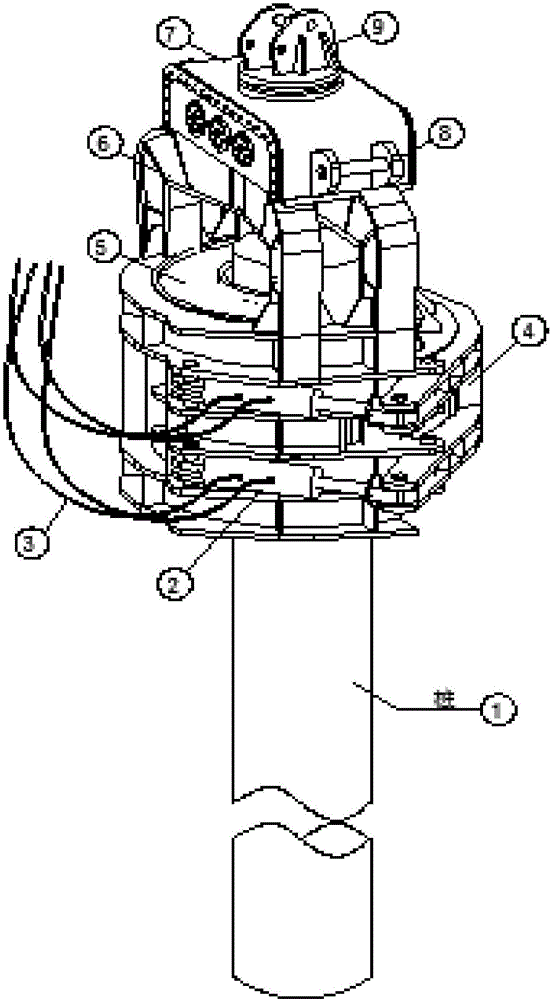

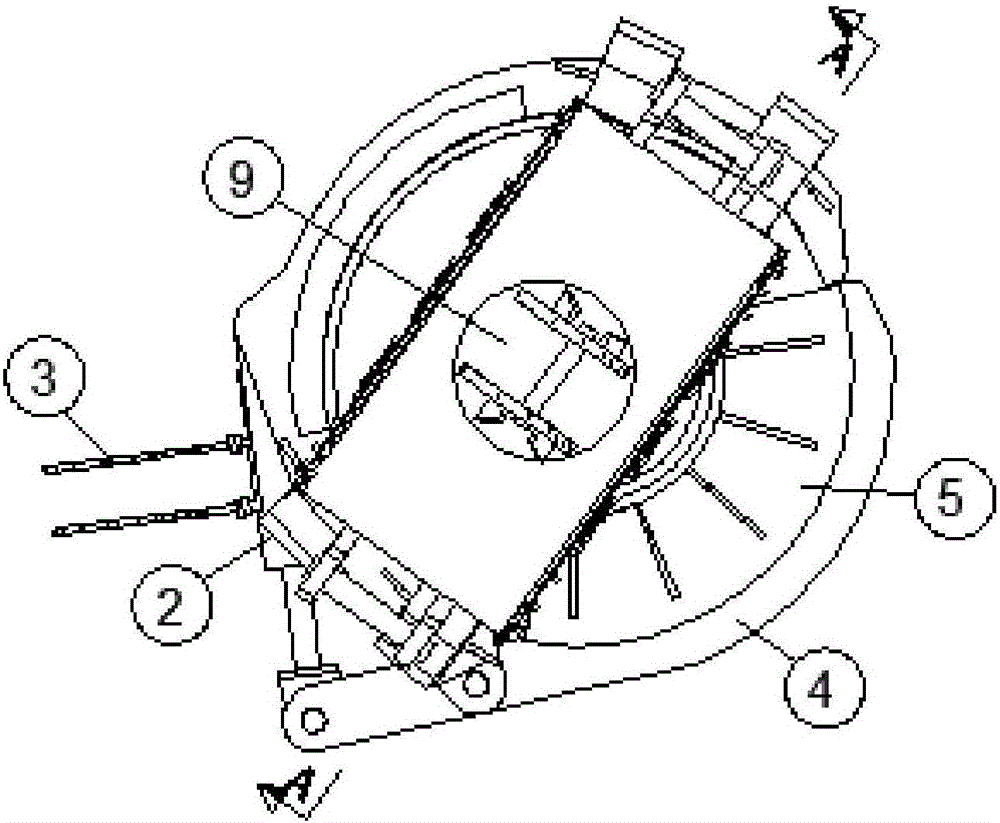

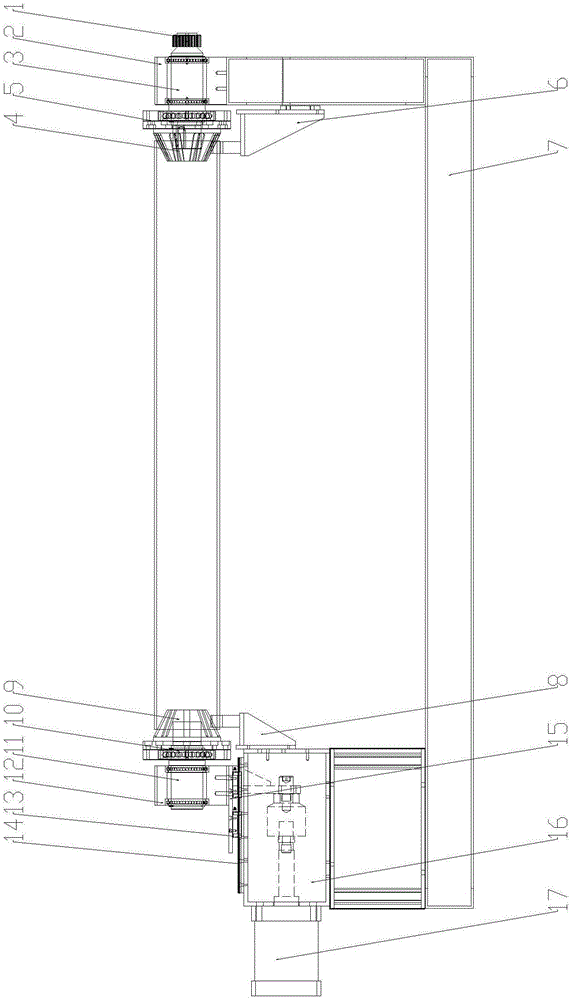

Hydraulic tong type pile pulling machine and pile pulling method

ActiveCN106759341ASo as not to damageIncrease frictionBulkheads/pilesControl theoryBuilding construction

The invention discloses a hydraulic tong type pile pulling machine and a pile pulling method. The hydraulic tong type pile pulling machine comprises a hydraulic tong type clamping device and a vibration machine. The vibration machine is arranged on the hydraulic tong type clamping device and provided with lifting lugs. The hydraulic tong type clamping device comprises an inner movable clamp and an outer clamp. The inner movable clamp comprises multiple movable blocks, and the multiple movable blocks form a clamp ring. The outer clamp comprises two tong arms. One end of one of the tong arms is connected with one end of the other tong arm through bolts, and electric hydraulic jacks are connected between the other ends of the tong arms. The outer clamp is arranged on the outer circle of the inner movable clamp in a sleeving manner, and the inner movable clamp is arranged on the outer circle of a to-be-pulled pile in a sleeving manner. The outer clamp locks the inner movable clamp through the electric hydraulic jacks, so that the inner movable clamp is closely attached to the to-be-pulled pile for clamping. The hydraulic tong type pile pulling machine is simple in sleeving assembly, large in clamping force, safe and reliable and attached to the pile more; the slipping-off situation generated in the pile pulling process is avoided; the pile can be pulled out more easily; efficiency is improved; a pile body is prevented from being damaged; and the hydraulic tong type pile pulling machine is simple in structure, easy to operate, small in size and free of limitation of geographic positions and facilitates construction.

Owner:CHINA FIRST METALLURGICAL GROUP

Speed-recognition-based automatic fixture for robot

PendingCN109397319ASafe and reliable clampingHigh degree of automationGripping headsEngineeringPressure sensor

The invention relates to the field of automatic equipment and particularly discloses a speed-recognition-based fixture for a robot. The fixture comprises a base, side supports, cylinder seats, clamping cylinders, reinforcing ribs and clamping plates. Identical clamping blocks are fixedly mounted on the clamping plates on the two sides. A vertical lifting cylinder is fixedly arranged in the centerpoint of the base. A horizontal carrying plate is fixed to the output end of the lifting cylinder. The two sides of the lower side of the carrying plate are both provided with vertical height adjusting mechanisms. The clamping cylinders, first pressure sensors, the lifting cylinder, second pressure sensors and speed recognition modules are all connected to a controller. The fixture is manually controlled to start. The fixture is started by manually pressing and providing speed input. Moreover, after the fixture is started, there is no need to manually and continuously hold a workpiece until the workpiece is clamped, so that occurrence of some safety accidents are avoided. Thus, the fixture is safer in workpiece clamping, high in automation degree, convenient to operate and capable of saving time and labor.

Owner:宁波帮手机器人有限公司

Thin-wall blind hole part honing clamp

PendingCN107914209ASimple structureFast clamping speedHoning machinesGrinding work supportsThin walledBlind hole

The invention relates to a thin-wall blind hole part honing clamp. The clamp is used for clamping a thin-wall blind hole part; the thin-wall blind hole part is provided with a compaction part and a hollow part, the honing clamp comprises a supporting frame and a clamp body arranged on the supporting frame, the clamp body is connected to the supporting frame, the clamp body comprises a containing space used for containing a thin-wall blind hole part, a first clamping part which is arranged in the circumferential direction of the containing space, located at the bottom of the containing space and correspondingly collides with the compaction part of the thin-wall blind hole part, and a second clamping part which is arranged in the circumferential direction of the containing space, located above the first clamping part and correspondingly collides with the hollow part of the thin-wall blind hole part, the first clamping part is in rigid contact with the compaction part, and the second clamping part collides with the hollow part flexibly. The thin-wall blind hole part honing clamp has the beneficial effects of being simple in structure, high in clamping speed and safe and reliable in clamping; compared with the traditional clamping technology, the thin-wall blind hole part honing clamp has the beneficial effect that the effect can be improved by three to five times.

Owner:SUZHOU XINNENG PRECISE MACHINERY

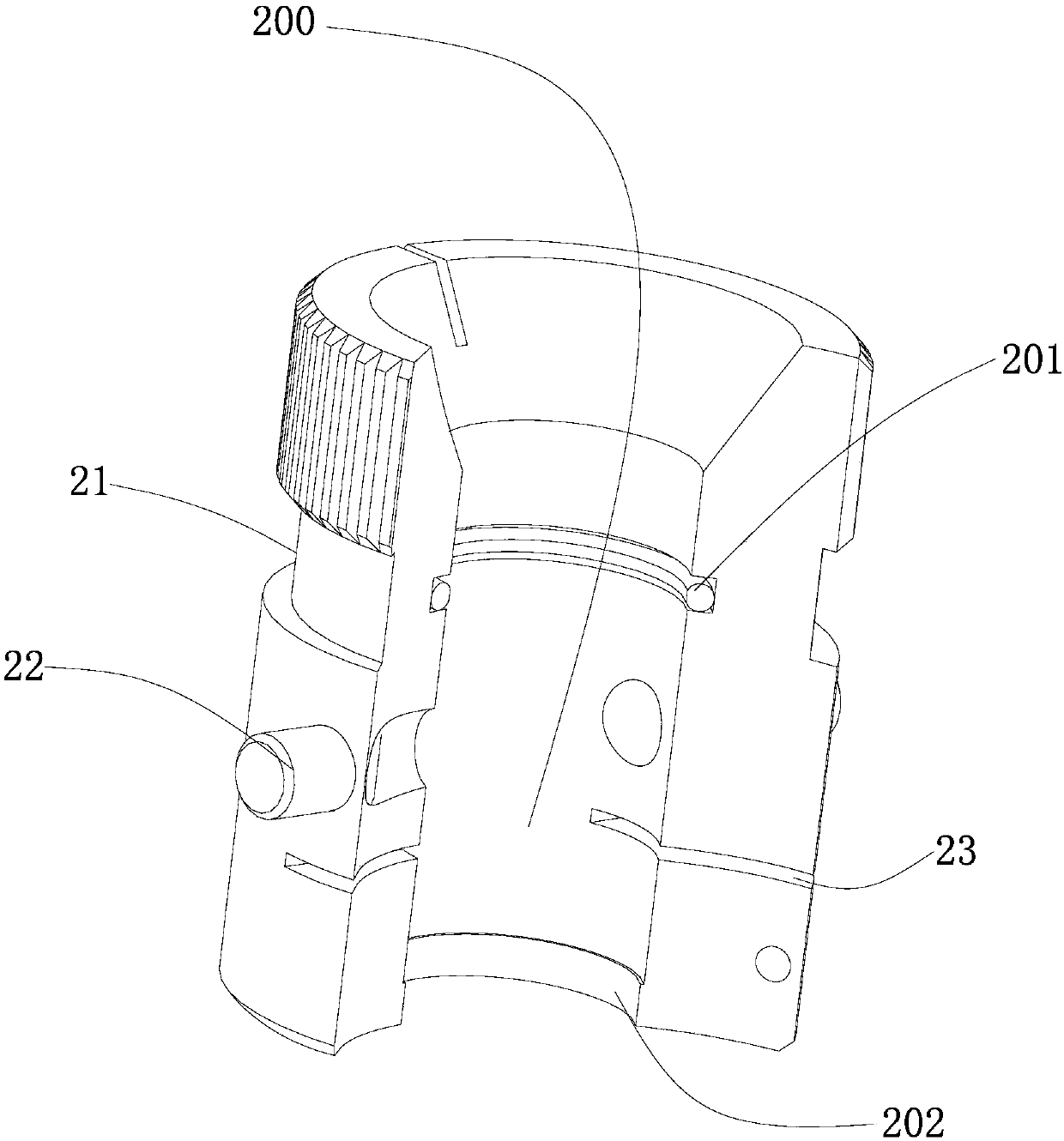

Clamping head device of winding machine

InactiveCN106364983ASafe and reliable clampingFlexible disassemblyFilament handlingWebs handlingWinding machineEngineering

The invention relates to a clamping head device, particularly relates to a clamping head device, capable of transversely moving and clamping a tube core, of a winding machine and belongs to the technical field of clamping heads of winding machines. The clamping head device comprises a power end clamping head component, a cylinder end clamping head component, a driving cylinder and an underframe, wherein two ends of the underframe are respectively a power end and a cylinder end; the cylinder end of the underframe is fixedly provided with a cylinder seat; the cylinder seat is fixedly provided with the driving cylinder; the upper end of the cylinder seat is provided with a guide rail which is slidably connected with a guide rail sliding block; the guide rail sliding block is fixedly connected with a pedestal base; the pedestal base is fixedly provided with the cylinder end clamping head component; the front end of a piston rod of the driving cylinder is fixedly connected with the pedestal base. The clamping head device is practical in function, is safe and convenient in clamping, and can be used for greatly improving the working efficiency and lowering the production cost; the power end clamping head component and the cylinder end clamping head component can be flexibly disassembled and assembled, so that the clamping head device can be assembled onto and used in different devices; during disassembly and assembly of the tube core, a supporting rack achieves an effect of supporting the tube core, so that the clamping head can realize convenient and safe clamping.

Owner:WUXI CHUANGHENG MACHINERY

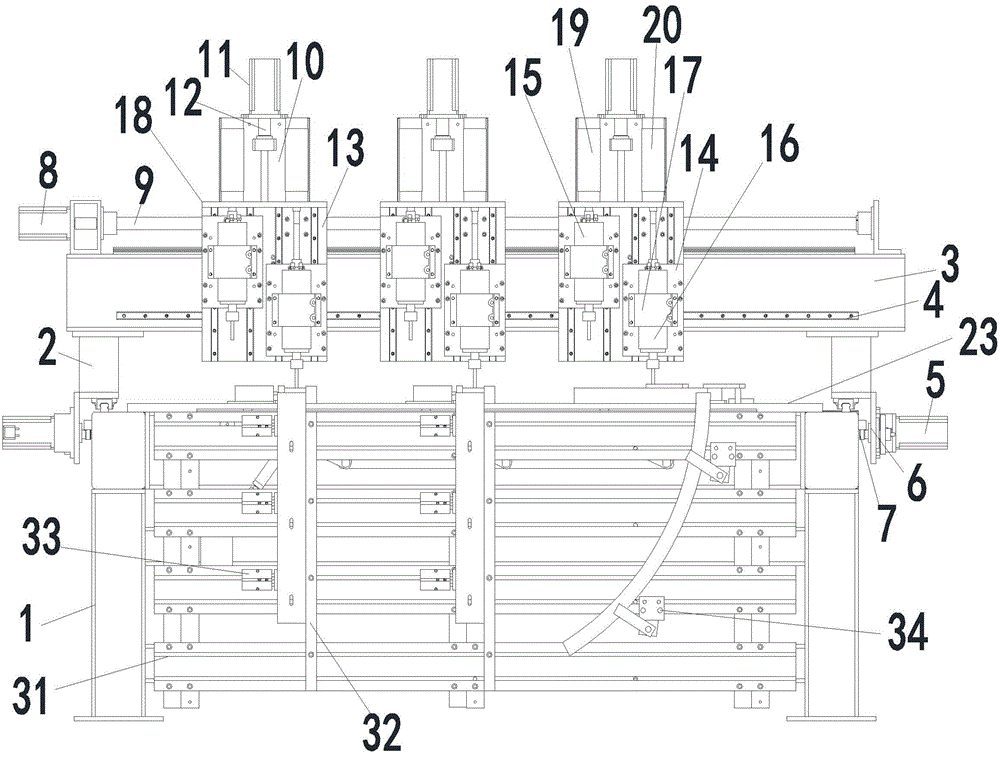

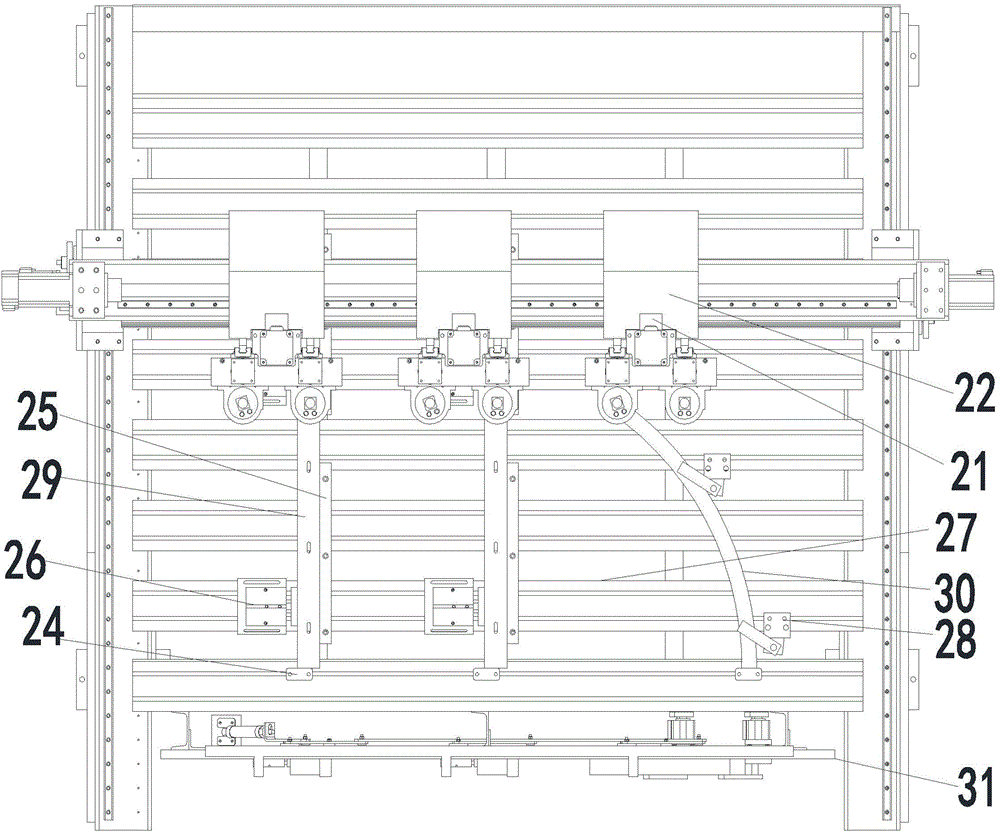

Multifunctional mortise and tenon machine and implementing method thereof

ActiveCN104972527ASimple structureLow costTongue/grooves making apparatusMortise and tenonEngineering

The invention discloses a multifunctional mortise and tenon machine. The multifunctional mortise and tenon machine comprises a rack, and front-back moving devices are arranged at the left end and the right end of the rack. The front-back moving devices are connected with the bottom end of a cross beam support. A left-right moving device is arranged at the top end of the cross beam support. A cross beam is arranged on the cross beam support. A left-right guide rail is arranged on the cross beam, and a plurality of exchange type tool sets are arranged on the left-right guide rail. A transverse table board is arranged below the exchange type tool sets. A plurality of transverse locating plates are arranged at the end of the transverse table board, and a plurality of transverse workpiece backers and transverse compressing air cylinders are arranged on the transverse table board in the longitudinal direction. A longitudinal fixed device is vertically arranged at the front end of the transverse table board. The invention further discloses an implementing method of the multifunctional mortise and tenon machine. The multifunctional mortise and tenon machine is characterized by being simple in structure, low in cost, convenient to use, high in speed, good in quality, high in precision and good in safety, facilitating workpiece clamping and the like.

Owner:DONGYANG XINHE ELECTRONICS MACHINERY

Air clamper in use for principal axis of lathe

InactiveCN1915565AImprove sealingReduced service lifeTurning machine accessoriesPositioning apparatusSteel ballMachine tool

A pneumatic fixture for the mainshaft of machine-tool is composed of a mainshaft with bearings, a central pull rod in said mainshaft and with front end connected to clamping spring and back end with clamp releasing mechanism, a steel ball sleeve on said pull rod and with radial through holes, pull rod sleeve in said steel ball sleeve and with a ring slot, steel balls in said ring slot and matched with external sleeve via said radial through holes, a piston module with bevel bearing, and a cylinder module.

Owner:宾焕南

Welding fixture of vehicle rear composition device

InactiveCN102962622AConvenient one-time weldingReasonable structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a welding fixture of a vehicle rear composition device, and belongs to a positioning and clamping device for combining and welding vehicle rear decks of an all-terrain double-section track carrier vehicle. A mandrel clamping mechanism is arranged on a bracket; a rear support clamping mechanism is fixedly connected with the bracket by a fixed base; an inserted board is fixedly connected with the bracket; an inducer clamping mechanism is fixedly connected with the bracket by an oil cylinder connection base 1; a pull arm and pull lug clamping mechanism is fixedly connected with the bracket by a frame; and a rear support ring clamping mechanism is fixedly connected with the bracket by an oil cylinder connection base 2. The welding fixture of the vehicle rear composition device, disclosed by the invention, has the advantages of reasonable structure, convenience for loading and unloading, positioning and regulation, preciseness in positioning and safety and reliability in clamping.

Owner:中国兵器工业集团第五五研究所

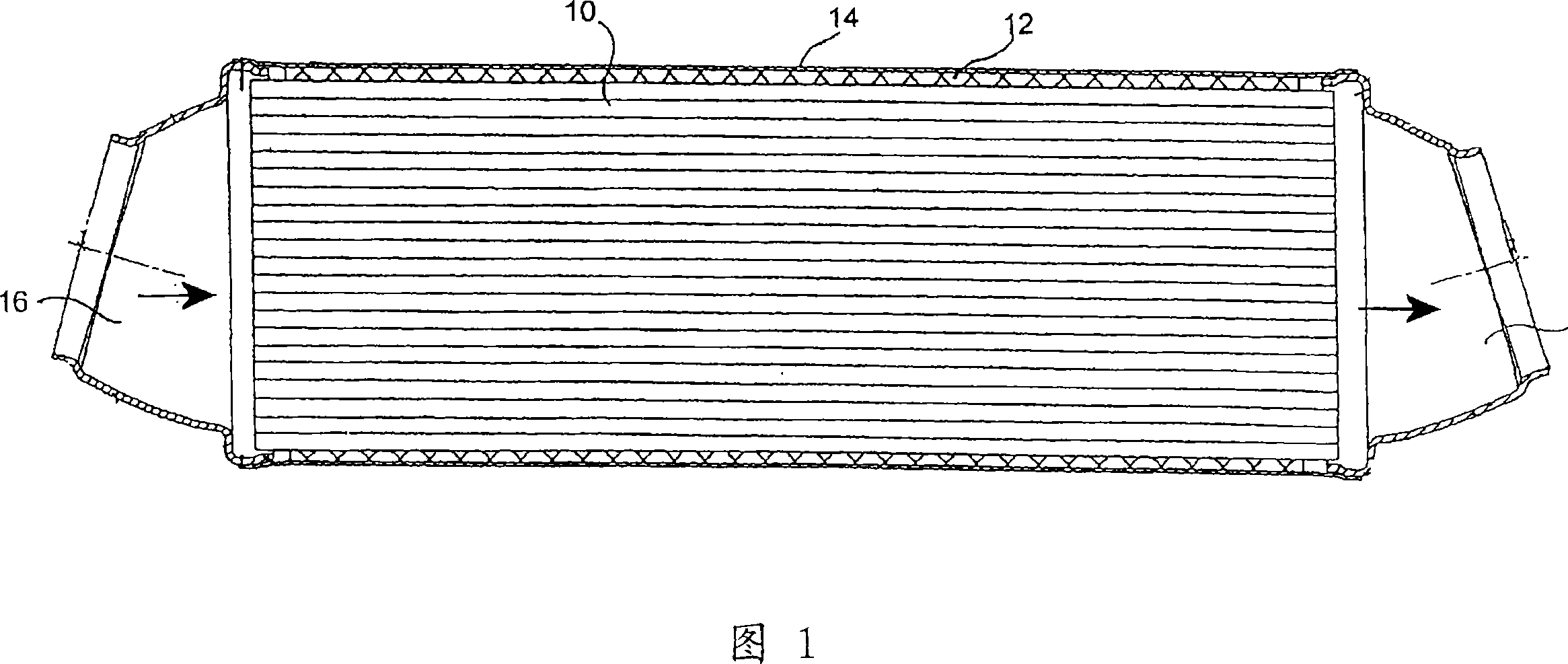

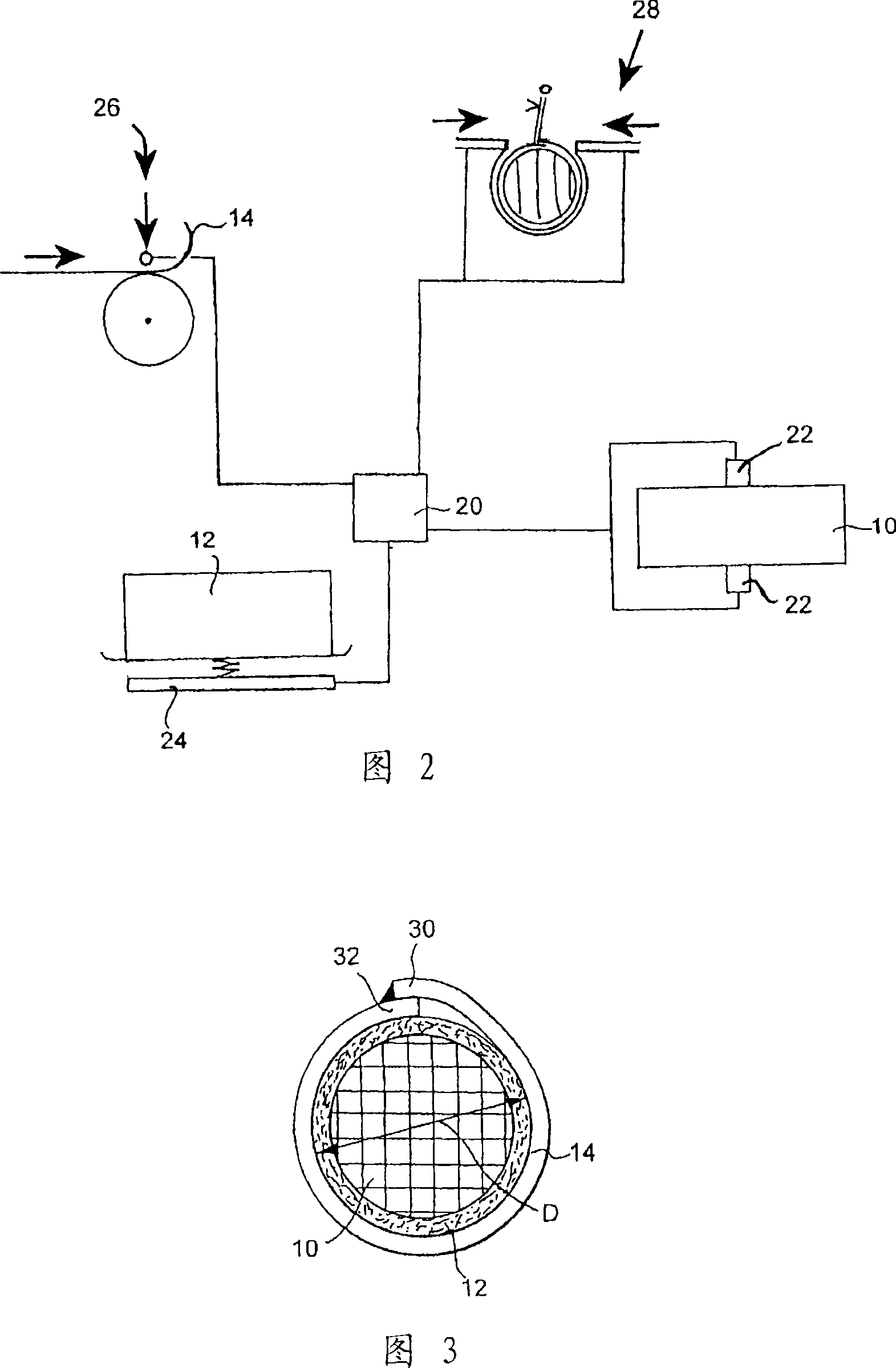

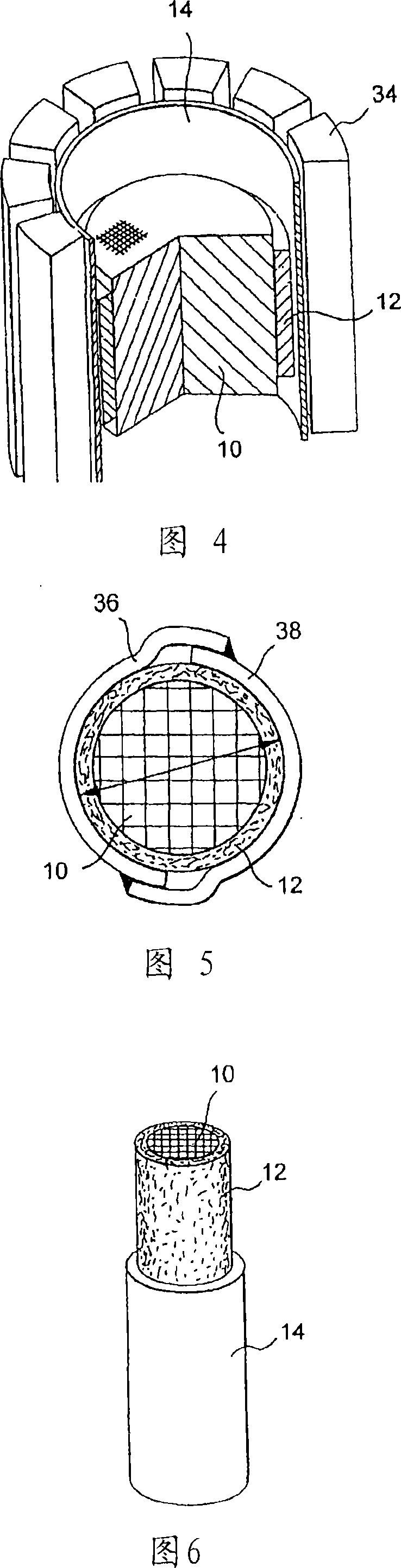

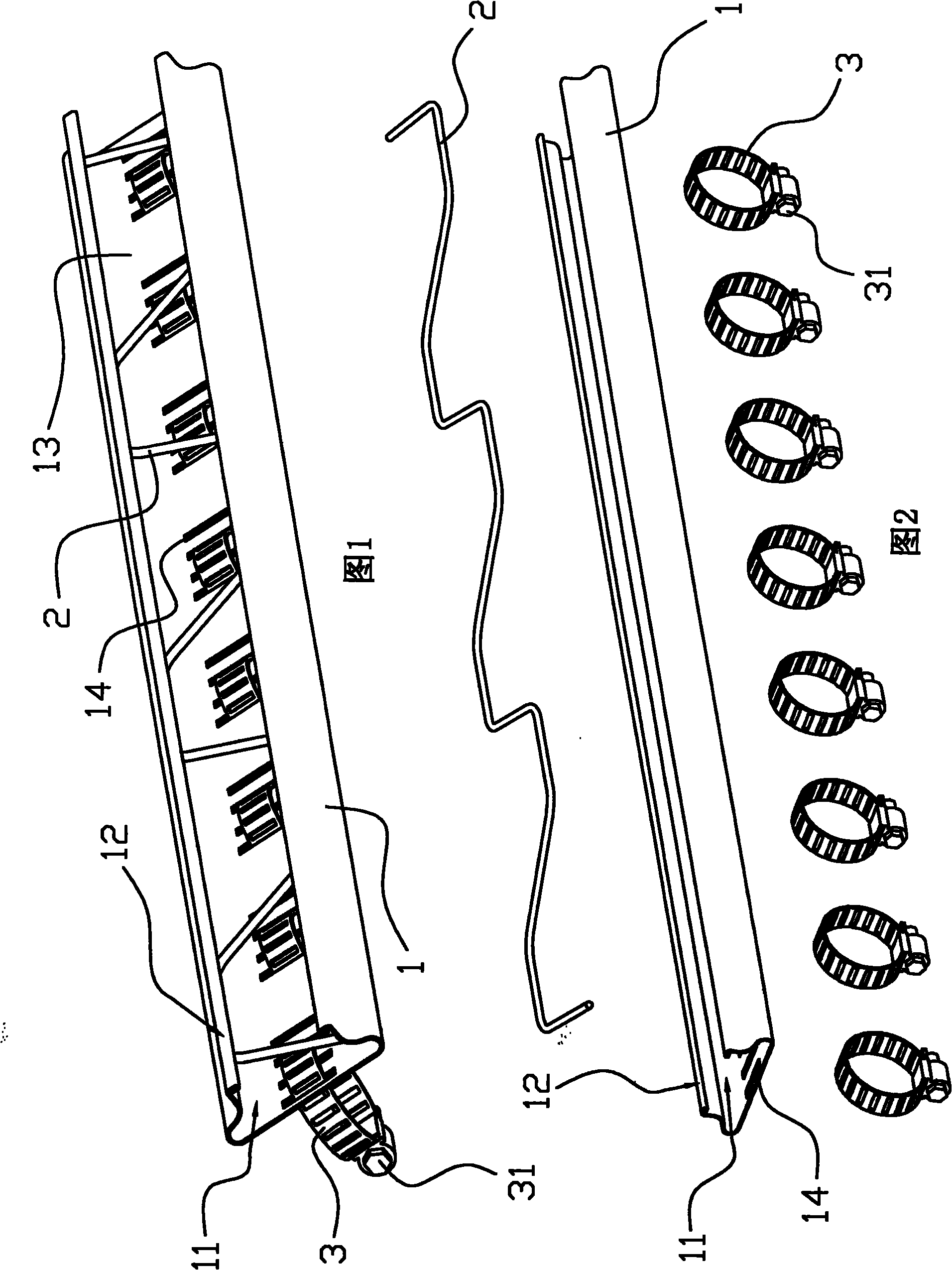

Method of producing exhaust-gas carrying devices, in particular exhaust-gas cleaning devices

ActiveCN101248259ASafe and reliable clampingInternal combustion piston enginesDispersed particle separationEngineeringMechanical engineering

Owner:ARVINMERITOR EMISSIONS TECH GMBH

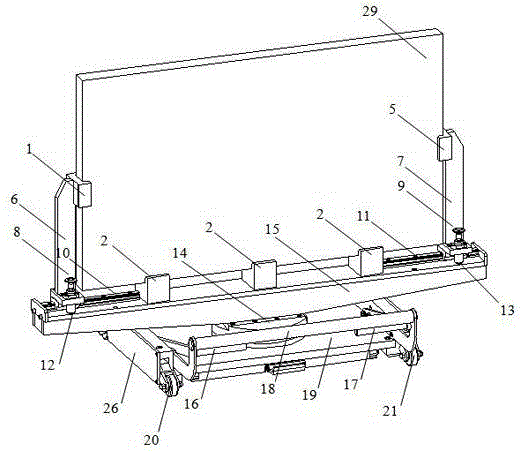

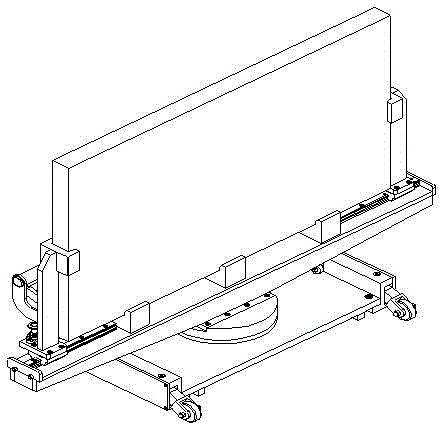

A full degree of freedom restraint fixture for impact fatigue testing machine

ActiveCN105571808BClamp firmlySafe and reliable clampingShock testingStrength propertiesEngineeringMachine

The invention discloses a fixture constrained by full degrees of freedom for an impact fatigue testing machine. Under the reciprocating impact of the impact fatigue testing machine, the general fixture cannot guarantee reliable clamping, and may even cause damage to the fixture itself. The present invention is composed of a distance adjusting mechanism, an X-direction clamping mechanism, a Y-direction clamping mechanism, a Z-direction clamping mechanism and a Z-direction clamping self-locking mechanism; The length of the sample; the X-direction clamping mechanism, the Y-direction clamping mechanism and the Z-direction clamping mechanism are used to clamp the sample and constrain all the degrees of freedom of the sample; the Z-direction clamping self-locking mechanism is used to prevent The Z-direction clamping mechanism is loose. The invention can be used for clamping a rectangular cross-section sample used in an impact fatigue testing machine, can restrain all degrees of freedom of the sample, and is provided with a self-locking device in the impact direction, thereby ensuring the reliability and safety of sample clamping.

Owner:ZHEJIANG SCI-TECH UNIV

Lathe clamp and lathe

ActiveCN105215757ASimple structureEasy to process and manufactureWork clamping meansPositioning apparatusBiomedical engineeringMachining

The invention provides a lathe clamp and a lathe, and belongs to the field of mechanical processing equipment. The lathe clamp comprises a clamp housing and a clamp main body, wherein the clamp main body comprises a plurality of cylindrical chucks which are uniformly arranged in a peripheral direction of the clamp housing; central lines of the cylindrical chucks extend in an axial direction of the clamp housing; a plurality of threaded holes are respectively formed in positions, corresponding to the cylindrical chucks, on the clamp housing; the threaded holes are arranged at intervals in an axial direction of the clamp housing; bolts are in corresponding threaded connection in the threaded holes; the clamp main body is provided with a connecting part and a clamping part which are coaxially arranged, and the connecting part is inserted into the clamp housing; the connecting part is movably connected with a mounting part; the clamp housing and the clamping part are connected though a bolt, and the clamp housing and the connecting part are connected though a bolt; and the bolts are screwed up, so that the cylindrical chucks move in the radial direction of the clamp housing. The lathe comprises the lathe clamp. The clamp is convenient and quick in operation and good in clamping effect; and the lathe is high in processing precision, and safe and reliable to process.

Owner:CHONGQING RUIJIA MACHINERY CO LTD

Semiautomatic disk type polishing machine

ActiveCN102756322AIncrease the lengthSimplify the drivetrainPolishing machinesEngineeringUltimate tensile strength

The invention discloses a semiautomatic disk type polishing machine which comprises an index plate. The index plate is rotatably mounted below a rotation combining power system; a plurality of work piece rotation gears are distributed on the surface of the index plate at intervals; a clamping station is arranged above each work piece rotation gear; a vertical cylinder bracket work piece is arranged above the index plate for positioning; a work piece length adjusting screw rod arranged at the center of the index plate is positioned with the above vertical cylinder bracket work piece; and a plurality of axial reciprocating scanning type polishing heads are arranged at one side of the index plate. According to the semiautomatic disk type polishing machine provided by the invention, the skill requirements of workers and the labor intensity can be greatly reduced, the machine structure is simple, the manufacture cost is lower, and the reliability is high.

Owner:BAOLONG ANHUI AUTO PARTS

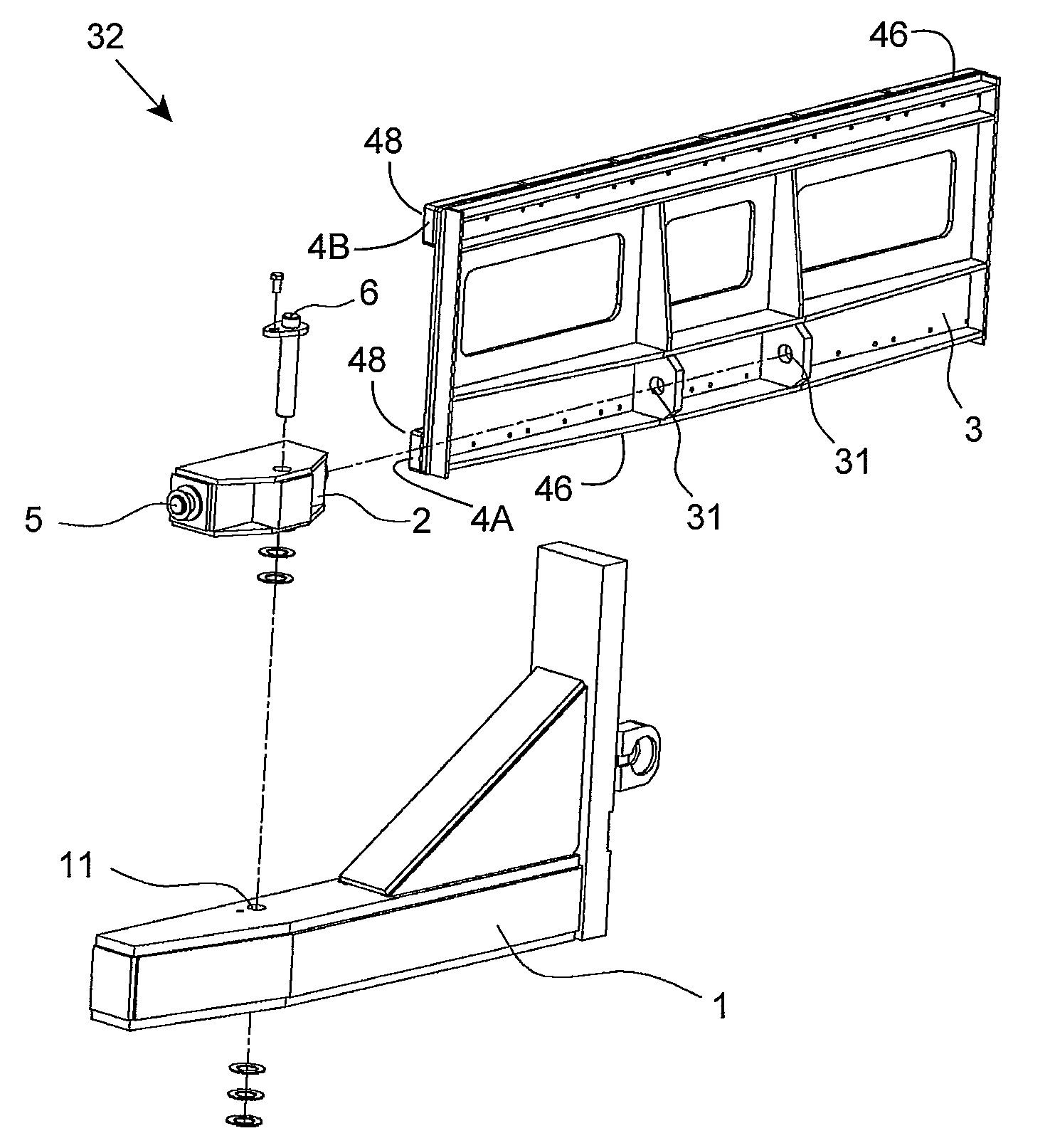

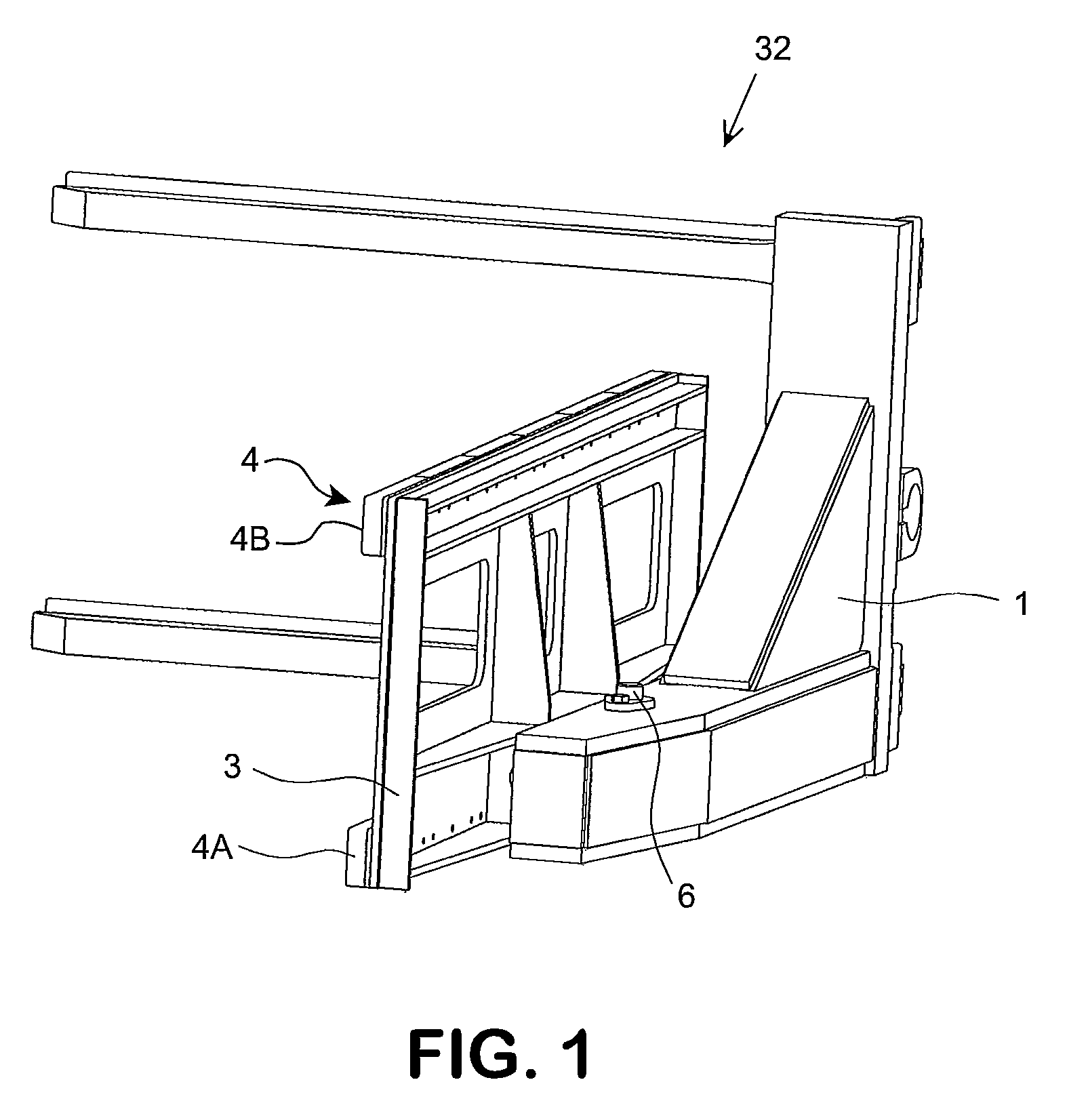

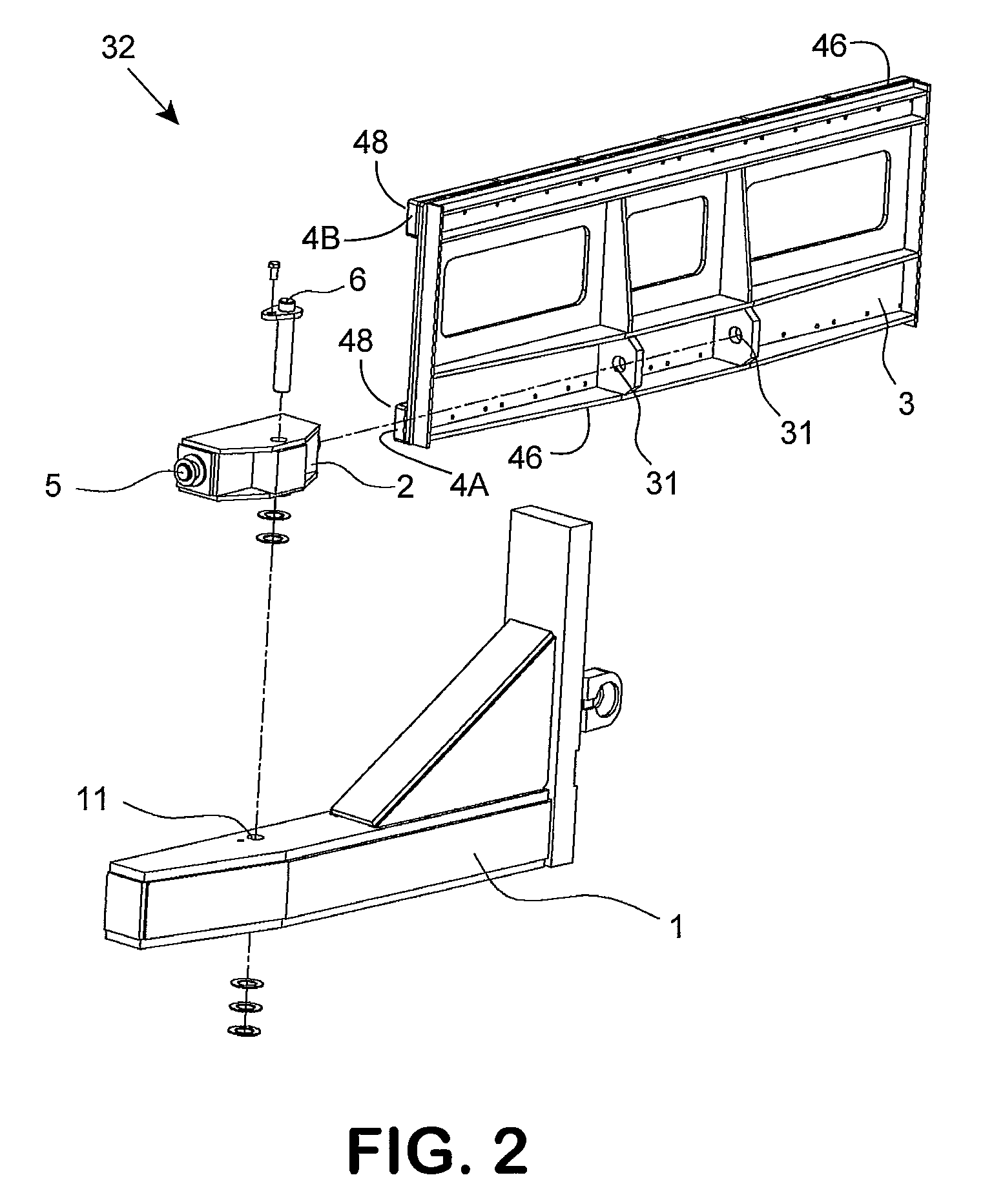

Multi-axis load gripping arm

Owner:CASCADE CORP

Fixture for turning thin aluminum valve plate

InactiveCN103286603ACompact designReduce overhang lengthPositioning apparatusMetal-working holdersEngineeringDigital control

A fixture for turning a thin aluminum valve plate comprises a flange bottom connected with a spindle of a digital controlled lathe. A rectangular main positioning plate of the valve plate is fixedly connected to a positioning spigot tire of the flange bottom, and is arranged deviating the center of the flange bottom right-off and downwards. The left lower corner of the main positioning plate of the valve plate is provided with a small chamfer, and the right lower corner of the main positioning plate of the valve plate is provided with a large chamfer. A longitude fixed clamping plate is arranged on the upper right edge of the outer side of the main positioning plate of the valve plate, and a transverse fixed clamping plate is arranged on the upper lower edge of the outer side of the main positioning plate of the valve plate. A longitude movable clamping plate is arranged on the left end face of the main positioning plate of the valve plate, and a transverse movable clamping plate is arranged on the upper side end face of the main positioning plate of the valve plate. The outer side faces of the longitude movable clamping plate and the transverse movable clamping plate are flush and are slightly lower than the plane to be machined of the thin aluminum valve plate. The thin aluminum valve plate is clamped radially, the fixture is safe and reliable, products have well flatness after machining, and the requirement of processing technology of the products can be guaranteed.

Owner:ZHEJIANG SHANHAI MACHINERY

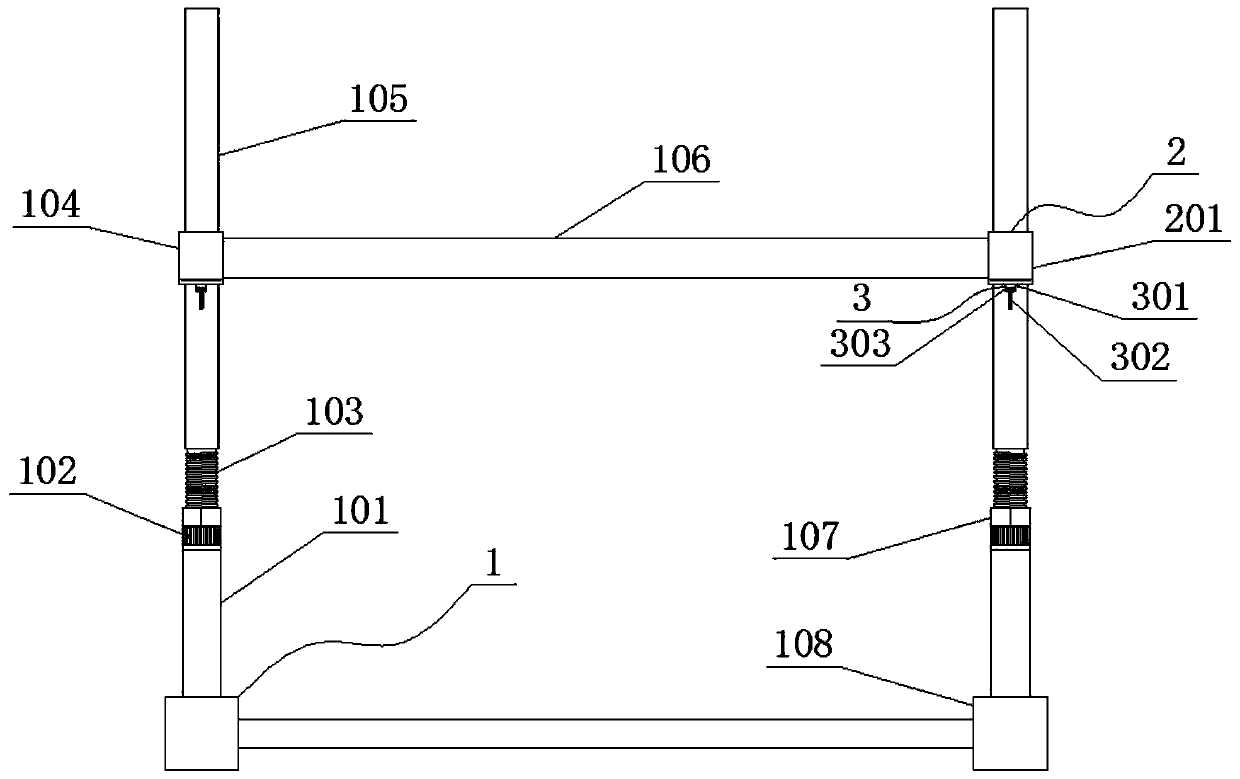

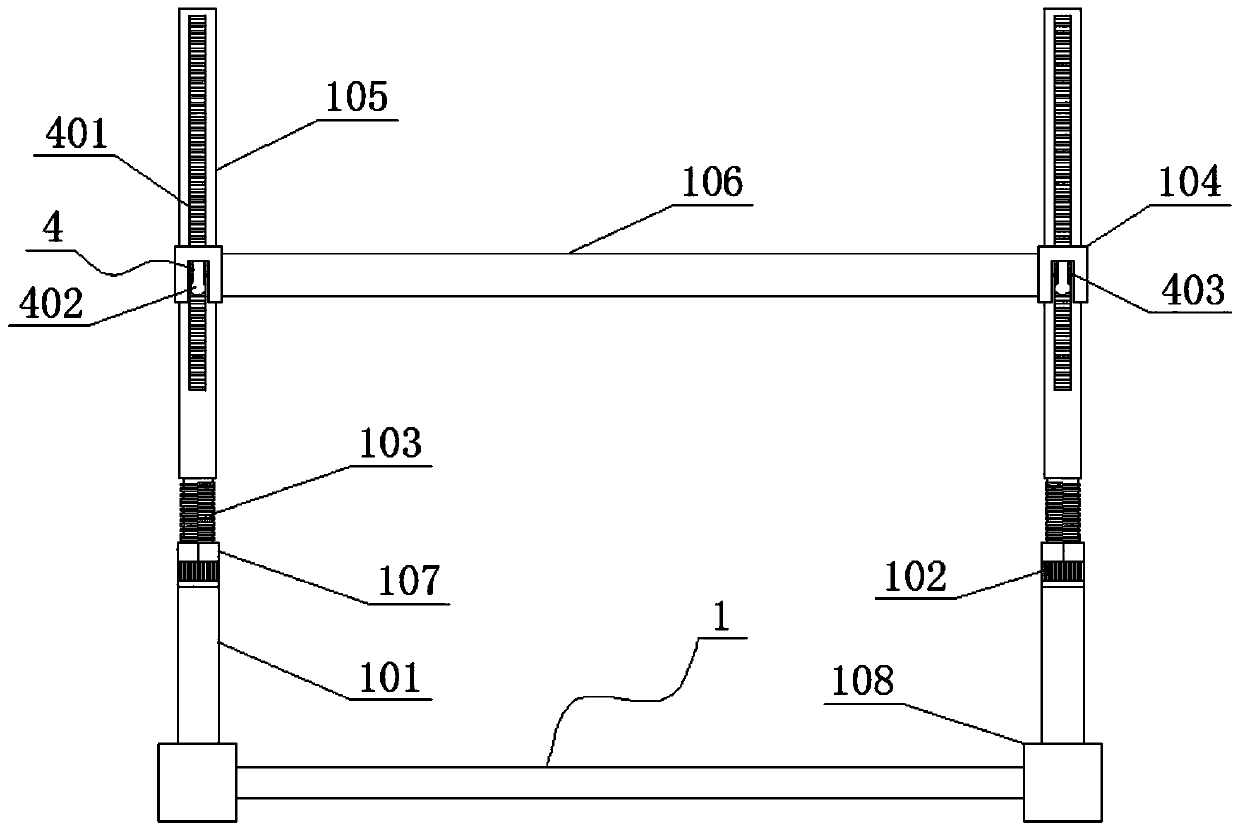

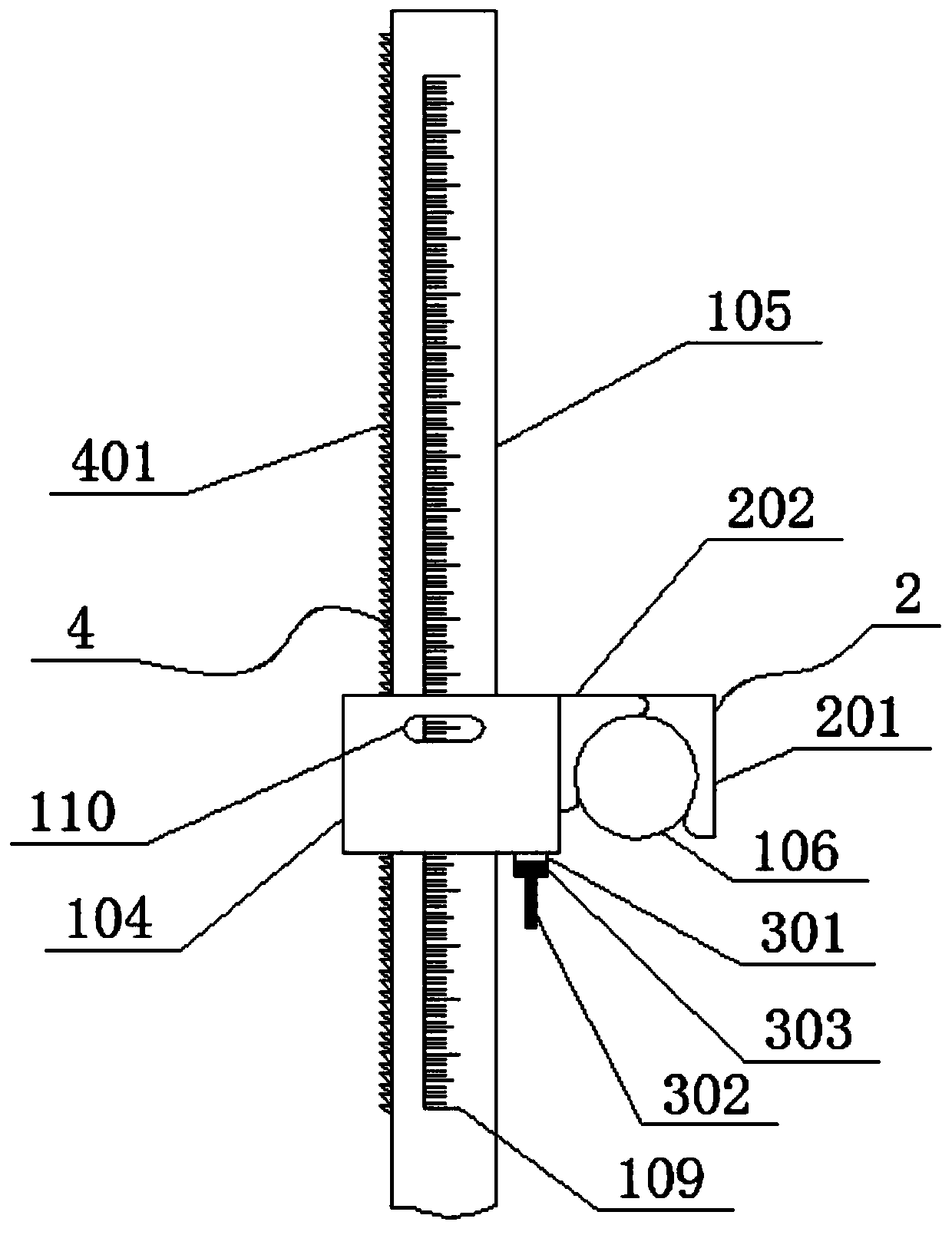

Hurdle frame for physical education

ActiveCN111151017AHeight adjustableSafe and reliable clampingRace-coursesRidingPhysical educationClassical mechanics

The invention discloses a hurdle frame for physical education. The hurdle frame comprises a hurdle structure, a cross rod clamping structure, a cross rod height fine adjustment structure and a heightquick adjustment structure, the hurdle structure comprises a bottom supporting frame and a hurdle vertical rod, a vertical rod fixing cylinder is fixed to one end of the bottom supporting frame, a hurdle vertical rod is fixed at the top end of the vertical rod fixing cylinder; a cross rod placing frame is clamped on the outer side of the hurdle vertical rod; a cross rod clamping structure is arranged at one end of the cross rod placing frame; a height quick adjustment structure, a cross rod clamping structure and a cross rod height fine adjustment structure are arranged at one end of the crossrod placing frame; the height of the hurdle cross rod can be quickly adjusted; the hurdle structure is simple in structure and quite safe in clamping of the hurdle cross rod, when a user jumps to belower than the hurdle cross rod and touches the hurdle cross rod, the hurdle cross rod falls off immediately, accidental injury is avoided, and when the hurdle structure is used for a long time and deforms to cause inaccurate height of the cross rod placement frame, calibration can be conducted by adjusting the cross rod height fine adjustment structure.

Owner:皖北卫生职业学院

Quick clamping flat tongs

PendingCN110281052AImprove machining accuracyGuaranteed level tightPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses high-quality quick clamping flat tongs. The high-quality quick clamping flat tongs are specially developed and designed for machinery manufacturing users and have the advantages that time and labor are saved in the operation process, and the safety is extremely high. The high-quality quick clamping flat tongs are quick clamping flat tongs of a brand new structure, and the quick clamping flat tongs of a brand new structure are researched and developed through many years after comprehensive retrieval and analysis processing is conducted on the whole market of existing flat tongs at home and abroad. The horizontal bottom face of a movable jaw is closely attached to the upper end face of a sliding rail under the action of a clamping nut and a screw reset device, the front end of a clamping screw abuts against the upper portion of the front clamping face of the movable jaw, the defect that a workpiece is warped on the movable jaw side is avoided, and then precise positioning and the machining high precision of the workpiece are guaranteed. The problem that existing quick clamping flat tongs have very serious potential safety hazards is thoroughly solved through the unique structure. The high-quality quick clamping flat tongs achieve a leading level in the world on the aspects of safely using and efficiently, quickly and conveniently clamping the workpiece.

Owner:杜洪波

Clamping device for clamping films

InactiveCN101779580AEasy to fixThe clamping is firm and stableClimate change adaptationGreenhouse cultivationEngineeringMechanical engineering

Owner:楼冬子

Feedback device for detecting descending position of workpiecepretargeting tray

ActiveCN103111913ASimple structureEasy to manufacture and installMeasurement/indication equipmentsClosed loop feedbackPlunger

The invention discloses a feedback device for detecting a descending position of a workpiecepretargeting tray. The feedback device comprises a main body, an action rod, a straight pin, a spring plunger and a gas sensitive element. Interior air passage is communicated and closed through reciprocation from top to bottom of the action rod, an oil cylinder is clamped and then a workpiece is clamped after the result detected by the gas sensitive element is fed back to a numerical control system. According to the feedback device, closed loop feedback of the pretargeting tray is achieved, accident damage of clamps is avoided, and potential safety hazard is eliminated.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Air clamper in use for principal axis of lathe

InactiveCN100421847CImprove sealingReduced service lifeTurning machine accessoriesPositioning apparatusEngineeringSteel ball

Owner:宾焕南

Driver plate for clamping crank shaft

InactiveCN103551897AReasonable structureEasy to manufactureTailstocks/centresPositioning apparatusMechanical engineeringEngineering

The invention relates to a driver plate for clamping a crank shaft, which comprises a lathe main shaft provided with a finial in the center, an upper tilting fillet, a lower tilting fillet, an upper clamping tile and a lower clamping tile, wherein a lug is arranged on the upper tilting fillet; a pin hole is formed in the lug; a lug groove and a pin hole are formed in the outer edge of the end face of the lathe main shaft; the upper tilting fillet and the lower tilting fillet take the finial as the centers, and are mounted on the end face of the lathe main shaft in an up-and-down symmetrical manner; the upper tilting fillet lug is correspondingly mounted in the lug groove of the lathe main shaft, and is connected and fixed through a pin; the upper tilting fillet and the lower tilting fillet are connected through connecting bolts; the upper clamping tile and the lower clamping tile are mounted in the upper tilting fillet and the lower tilting fillet respectively; the large end of the crank shaft is mounted between the upper clamping tile and the lower clamping tile, and the crank shaft can be clamped by tightening the connecting bolts between the upper tilting fillet and the lower tilting fillet; when the lathe main shaft rotates, a feeding device of a lathe can be operated to process a workpiece. The driver plate has a reasonable structure, is convenient to operate, safe and reliable to clamp, and applicable to the assembly of different shaft diameter size, therefore, the driver plate is an ideal driver plate for clamping the crank shaft.

Owner:TIANRUN IND TECH CO LTD

Moving device for large flower pots

Owner:来安县永阳知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com