Semiautomatic disk type polishing machine

A disc type, polishing machine technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of unfavorable polishing of long-axis workpieces, single roughness, easy surface damage, etc. The effect of reduced requirements and labor intensity, better consistency, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

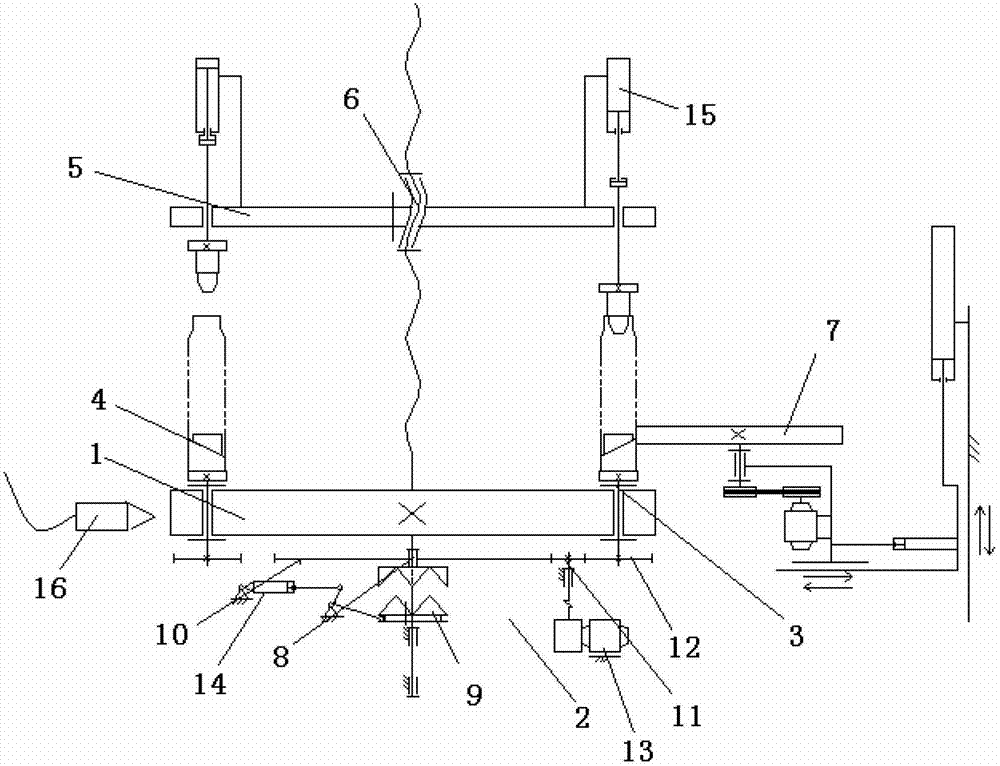

[0012] Referring to the accompanying drawings, a semi-automatic disc polishing machine includes an indexing disc 1, and the indexing disc 1 is rotatably installed on the lower part of the self-rotation synthetic power system 2, and the surface of the indexing disc 1 is spaced from A plurality of workpiece rotation gears 3 are distributed, and a clamping station 4 is provided above each of the rotation gears 3, and a vertical cylinder bracket workpiece positioning 5 is provided above the indexing disc 1, and the indexing disc 1 The center of 1 is provided with a workpiece length adjusting screw 6 and a vertical cylinder support workpiece positioning 5 above, and one side of the indexing disk 1 is provided with a plurality of axially reciprocating scanning polishing heads 7 .

[0013] The autorotation synthetic power system below the indexing disc 1 includes a rotating shaft 8 fixedly installed in the center of the lower surface of the indexing disc, the rotating shaft 8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com