Patents

Literature

134results about How to "Positioning is safe and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

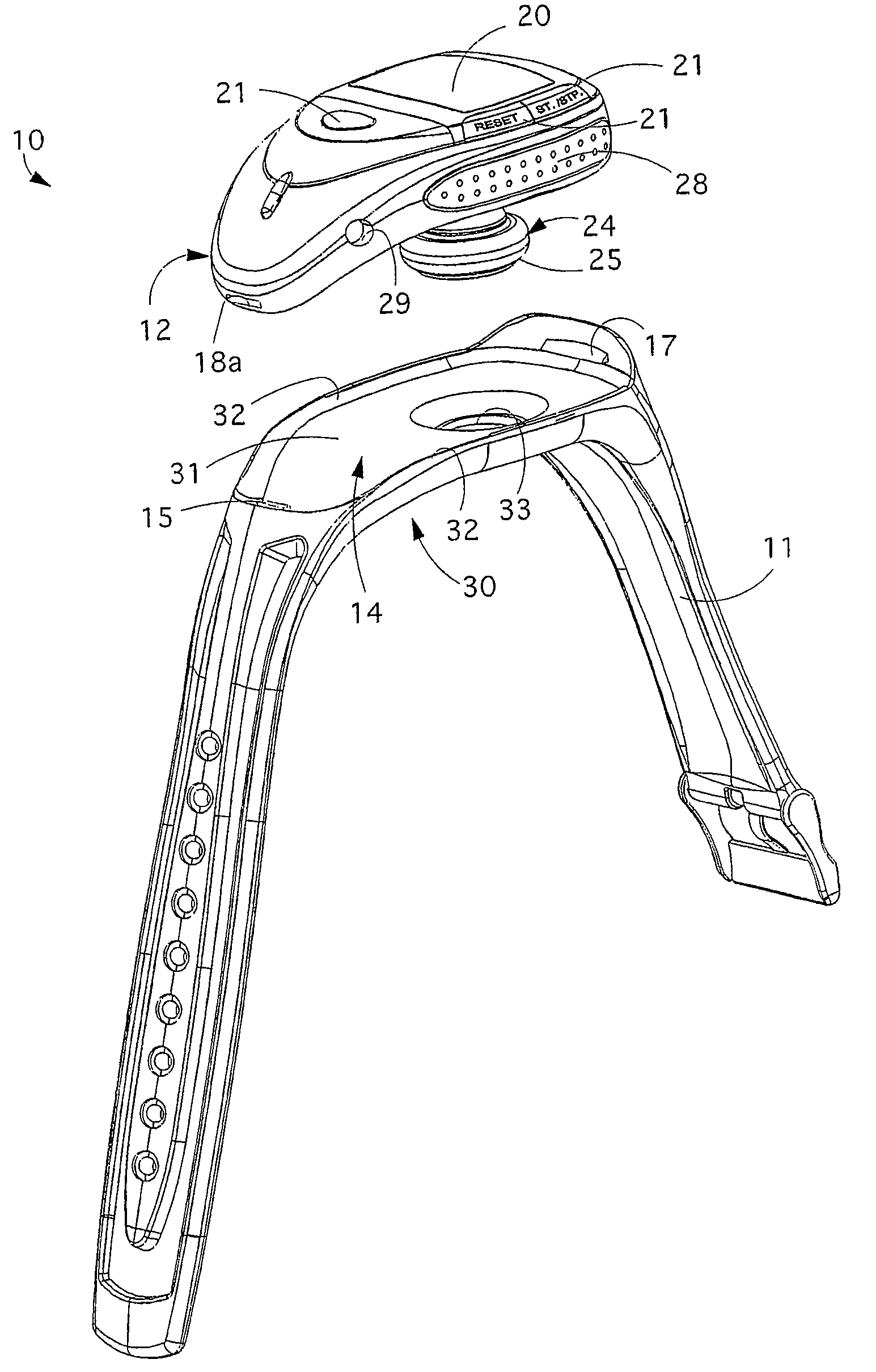

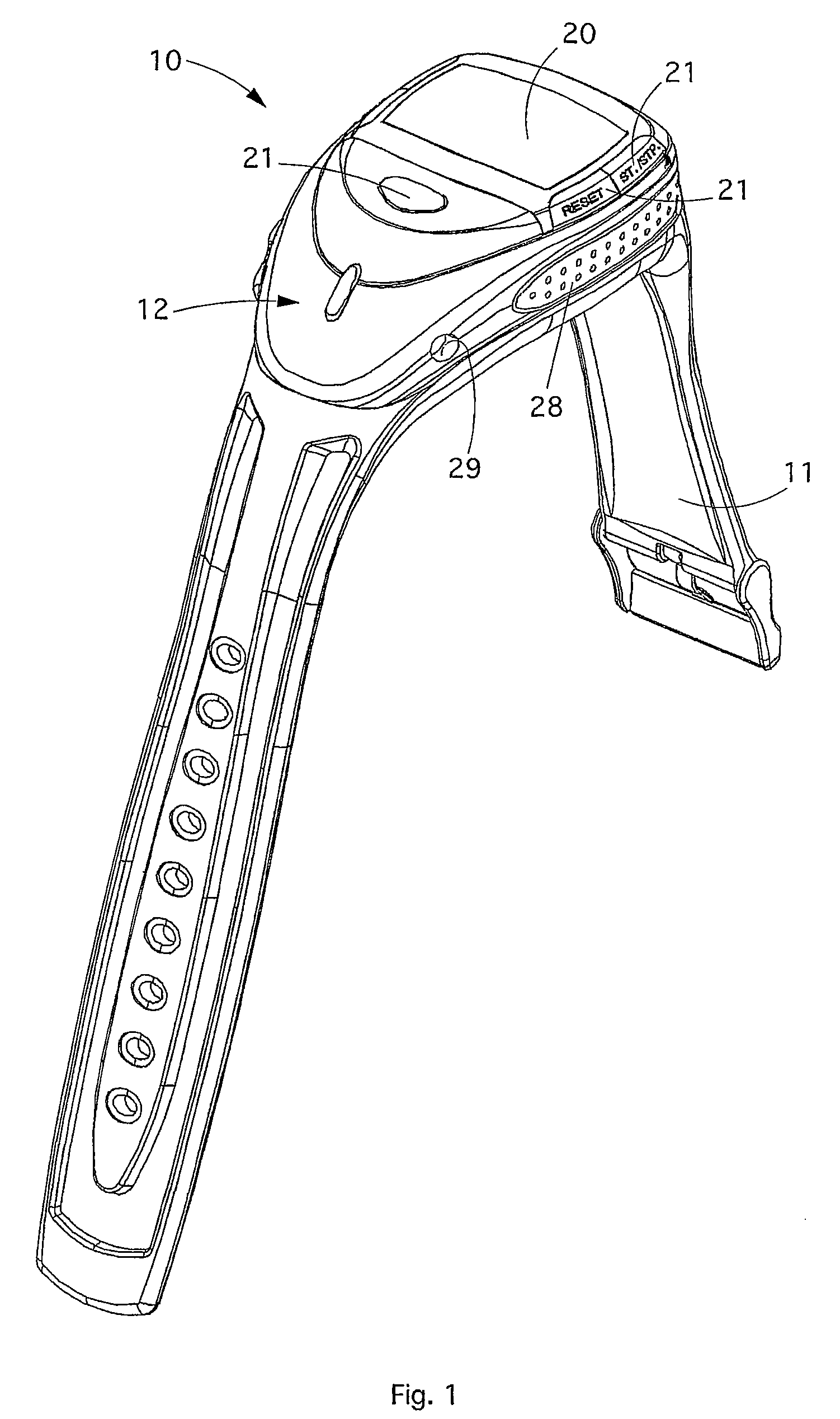

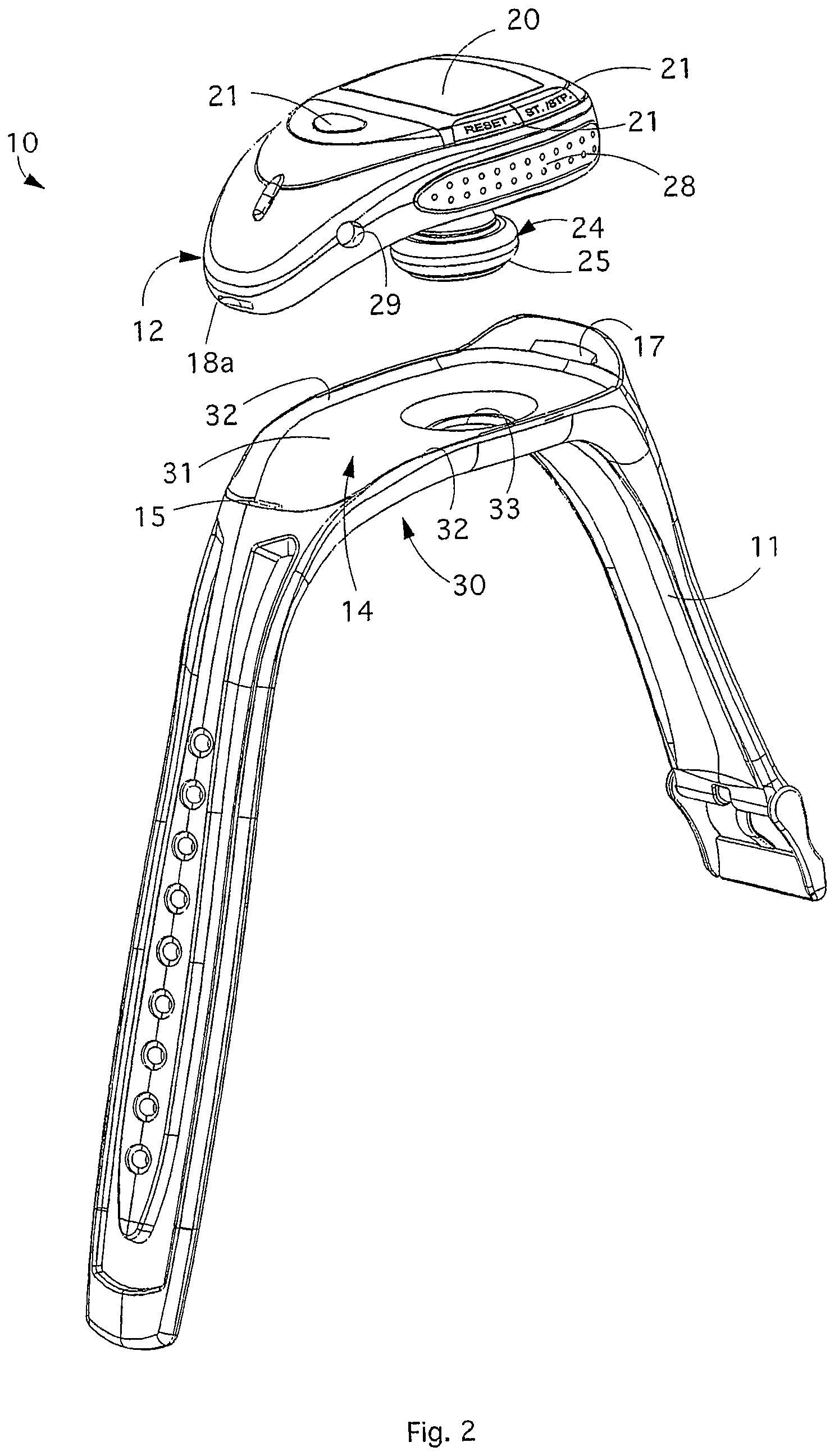

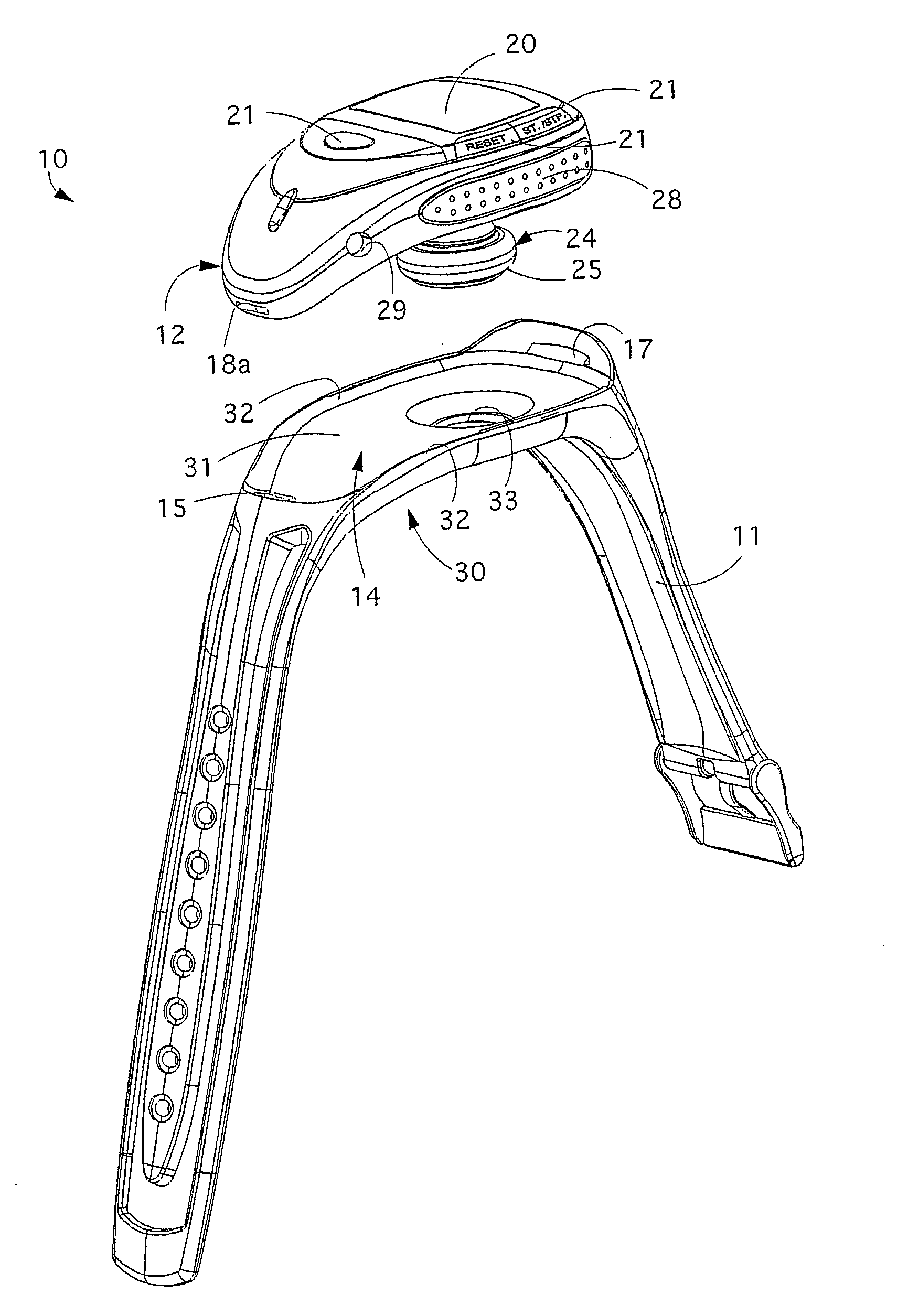

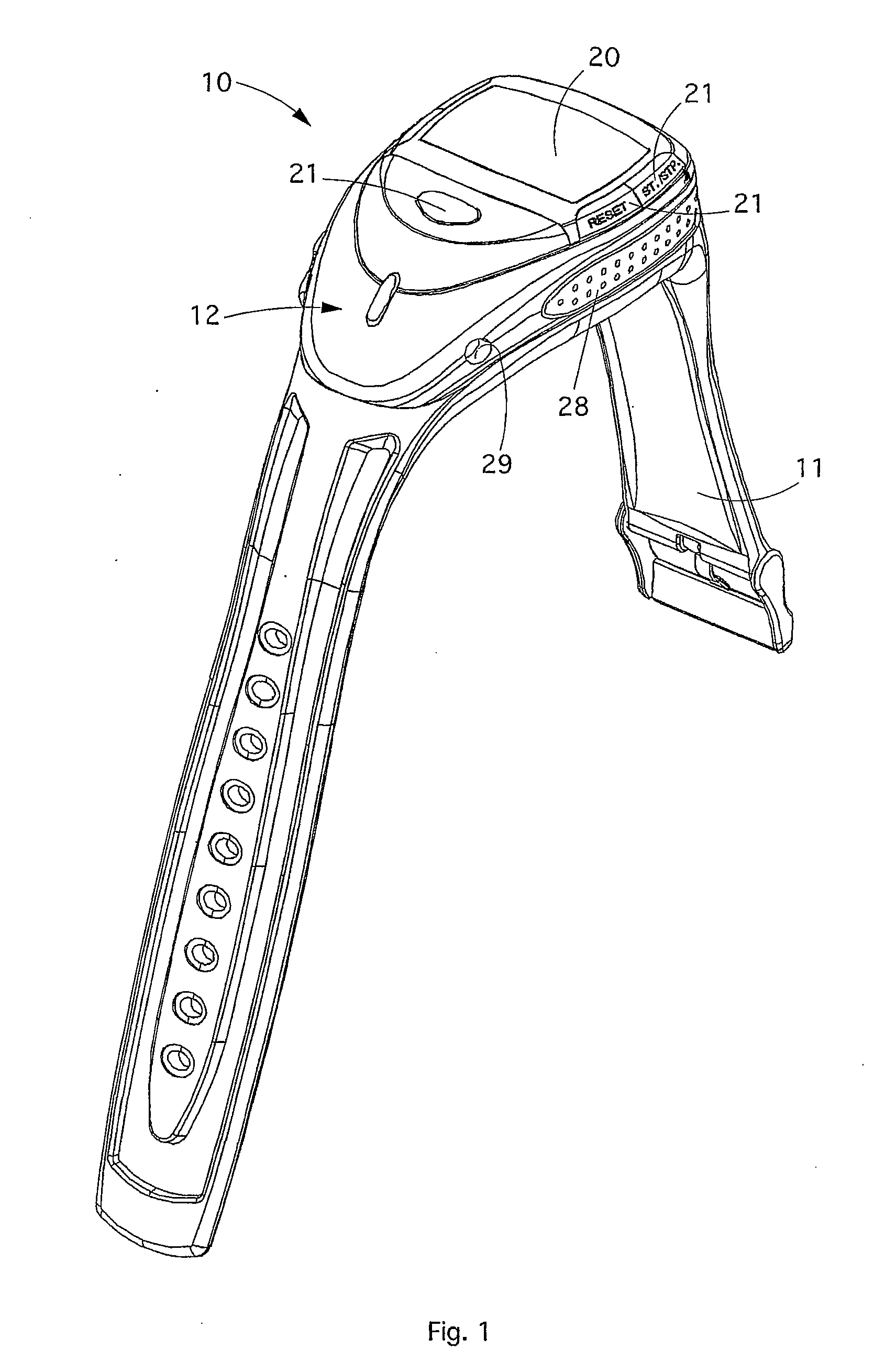

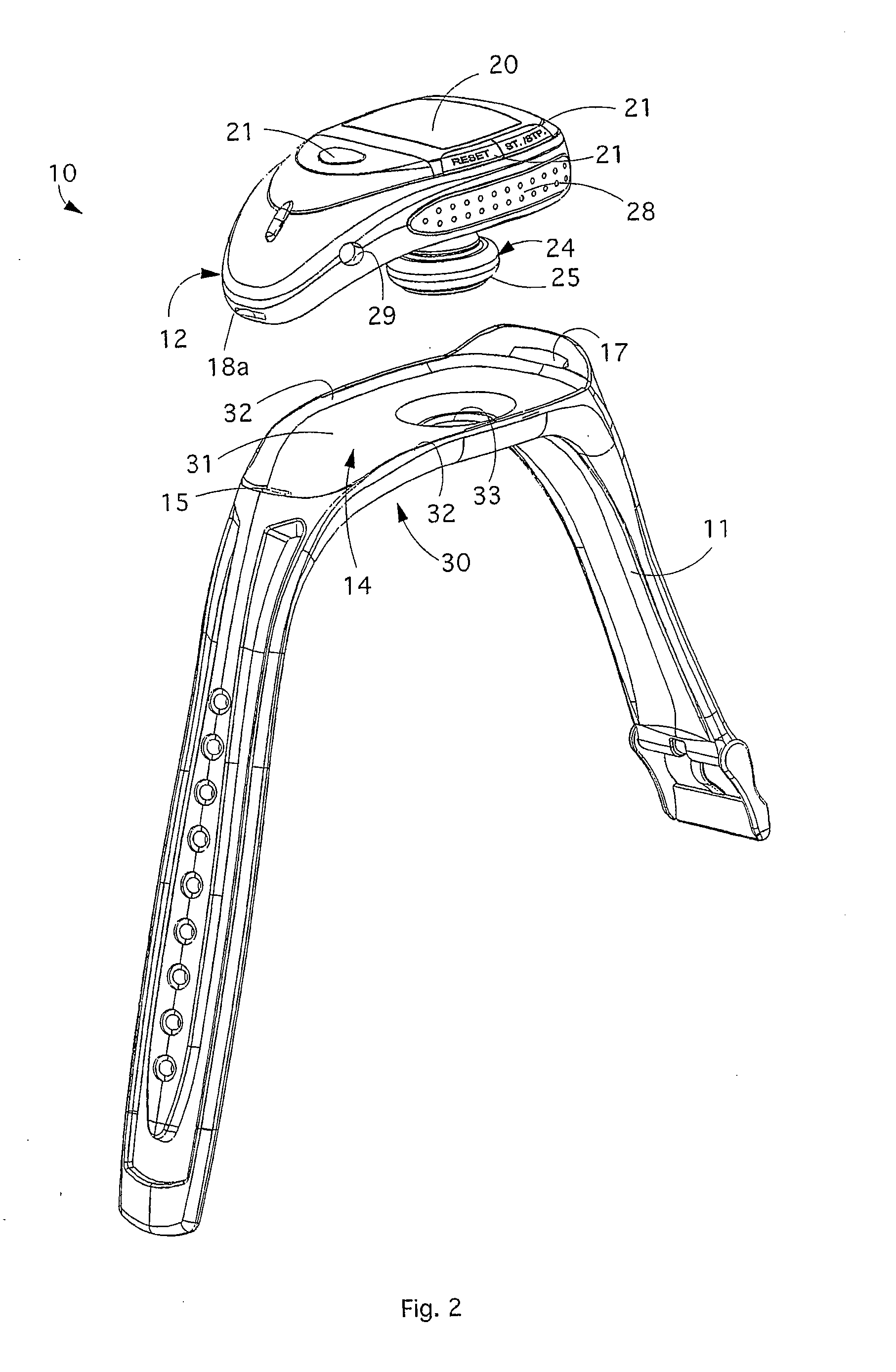

Wristwatch with earphone function

InactiveUS7529155B2Optimum portability and appearanceAvailable for useMicrophonesVisual indicationsEngineeringHeadphones

A wristwatch comprising a main unit associated in removable manner with a seating prepared on a support and / or positioning element, which is in turn associated with an attachment element to attach it to the user's wrist. The main unit incorporates both the normal functions of a watch and also the function of an earphone.

Owner:GLOBAL WATCH INDS

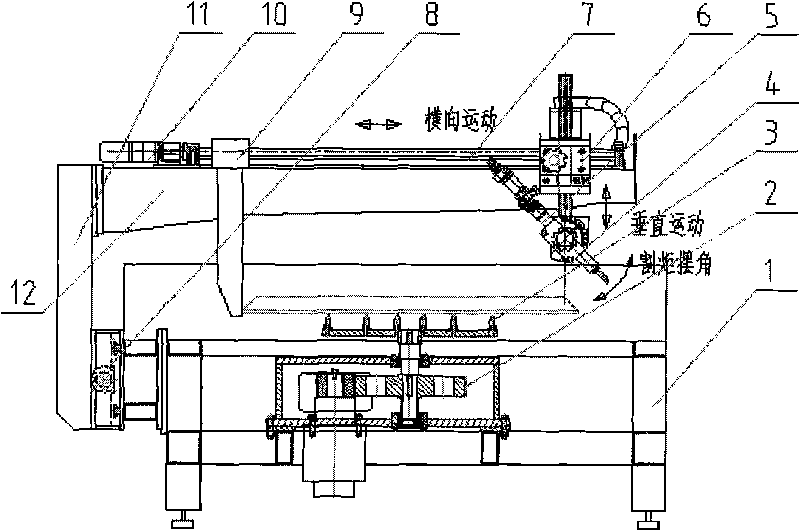

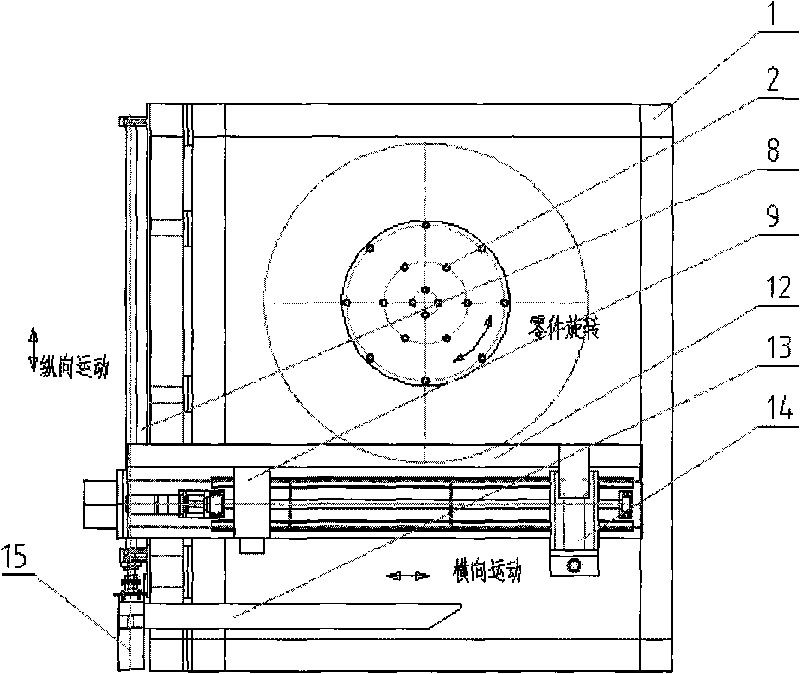

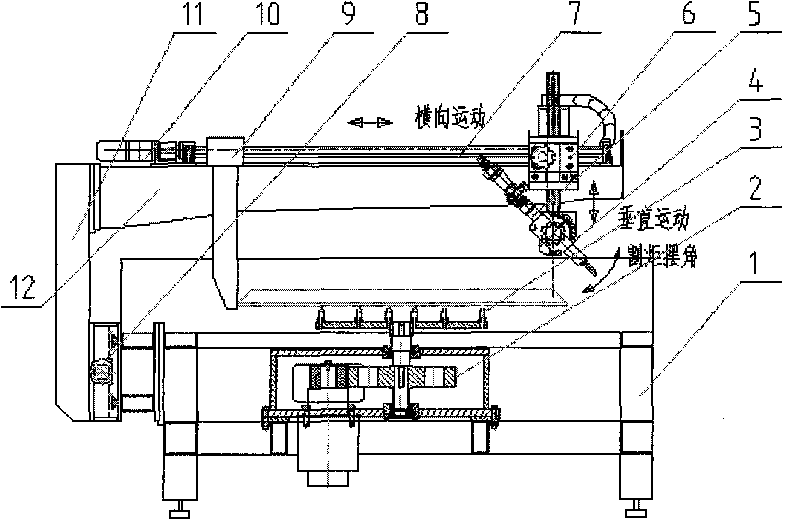

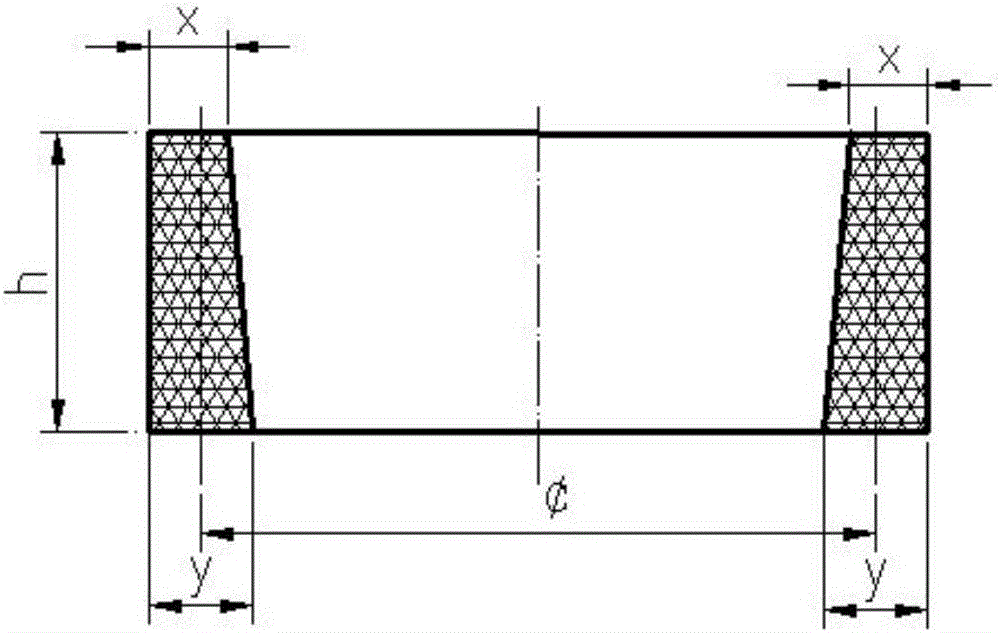

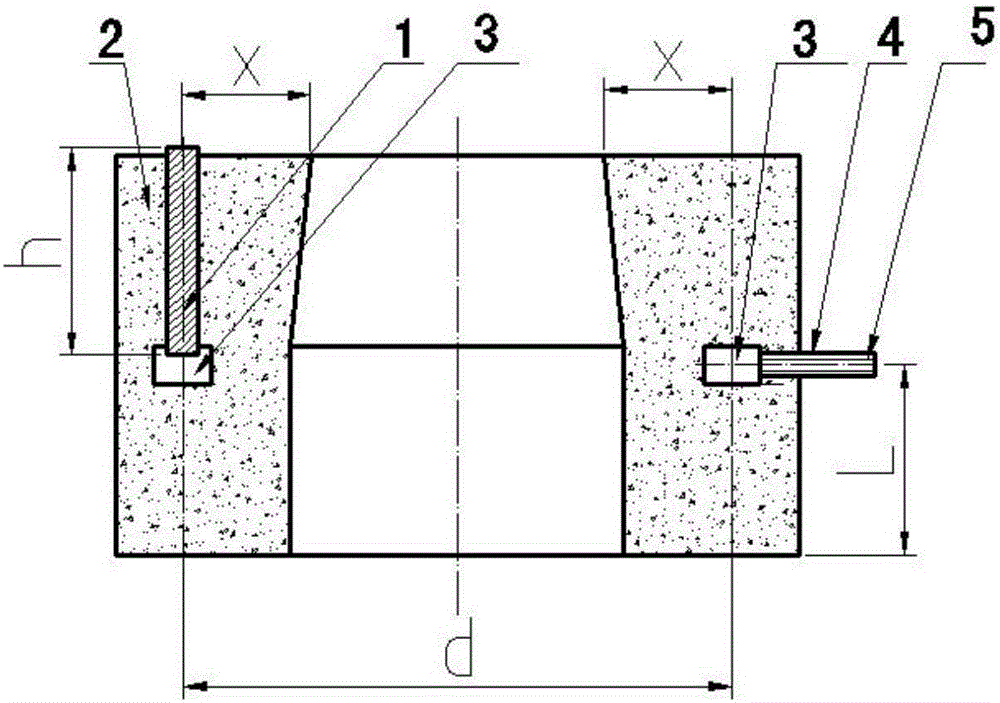

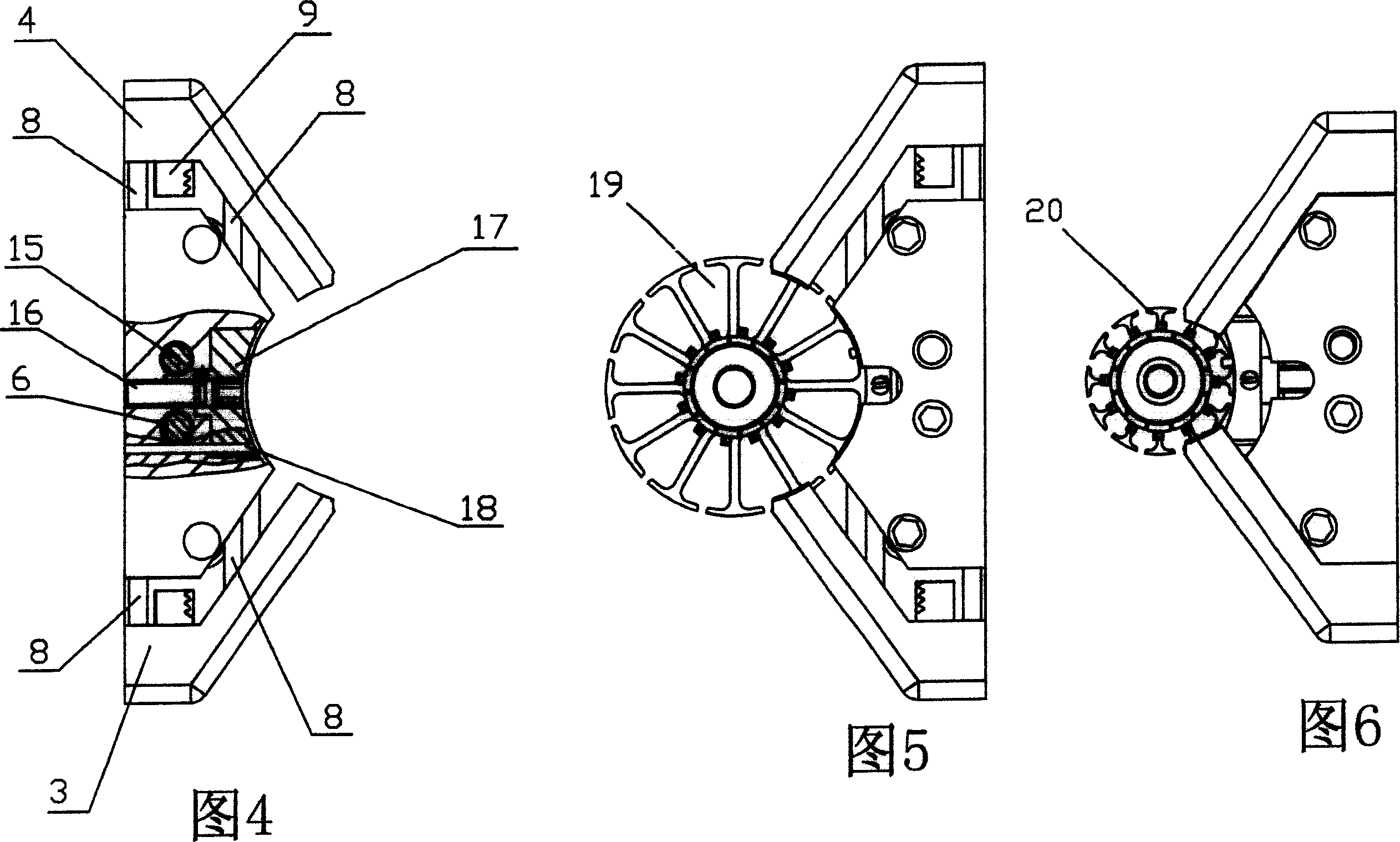

Machining method of workpiece welding groove-workpiece rotary type numerical control cutting machine

InactiveCN101716709ANovel structureLow manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesGas pipelineEngineering

The patent of the invention relates to an innovative numerical control cutting machining method aiming at (sheet metal) workpiece welding grooves, which is a cutting application method combining blaze, plasma and flying optics laser and belongs to the field of industrial welding and cutting technology. The invention adopts a machining mode that workpiece actively rotates, the workpiece can be freely clamped, the invention is suitable for numerical control cutting machining of the welding groove with any curved profiles, the cutting quality, the production efficiency and the material utilization are obviously enhanced, and the device cost is low. The invention adopts the mode that the workpiece revolves around tools (cutting torch) to rotate, thoroughly solves the technology bottlenecks of complex structure (winding and restrictions of connecting cables, gas pipelines, and the like of the cutting torch caused by the rotation of the workpiece) of traditional numerical control cutting method, and the like. The technical implementation scheme is that a workpiece active (unlimited) rotary disk arranged on a substrate loads the workpiece; each axis (A, X, Y, W and Z) of the numerical control procedure control system moves the edge of the workpiece groove to a cutting zone, and cutting torch (Z) axis automatically falls downwards to a working height and completes initial cutting gesture according to groove angle and thickness of the programming workpiece; and the workpiece (W) placed on the unlimited rotary disk is continuously matched with the cutting torch to swing (A) to do transverse (X) and longitudinal associated movement after a numerical control cutting processing program is operated, and the cutting torch is placed in a normal section of a cut workpiece all along and completes processing molding of the welding groove of the workpiece. The invention can be widely applied and popularized in industrial welding and cutting field.

Owner:北京林克曼数控技术股份有限公司

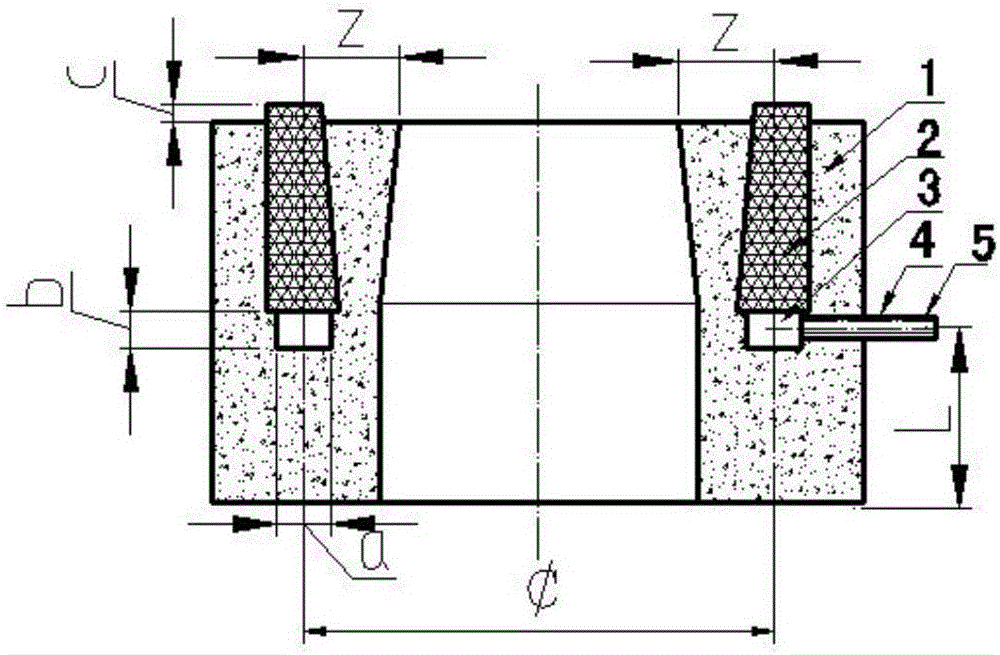

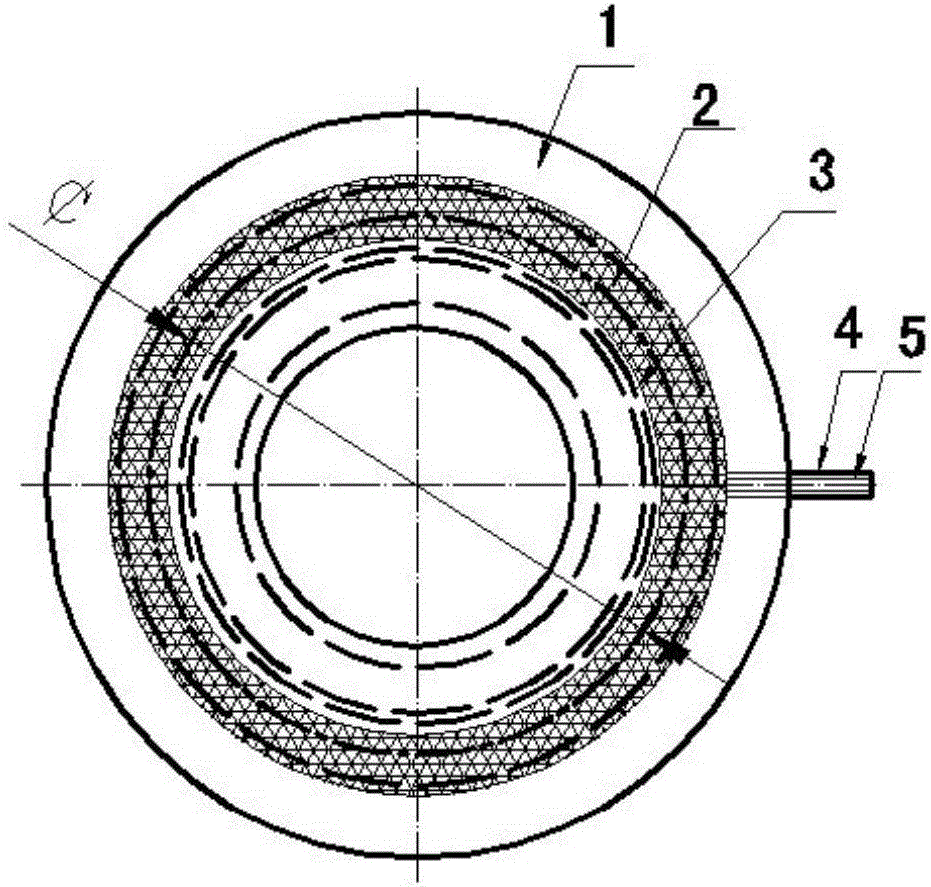

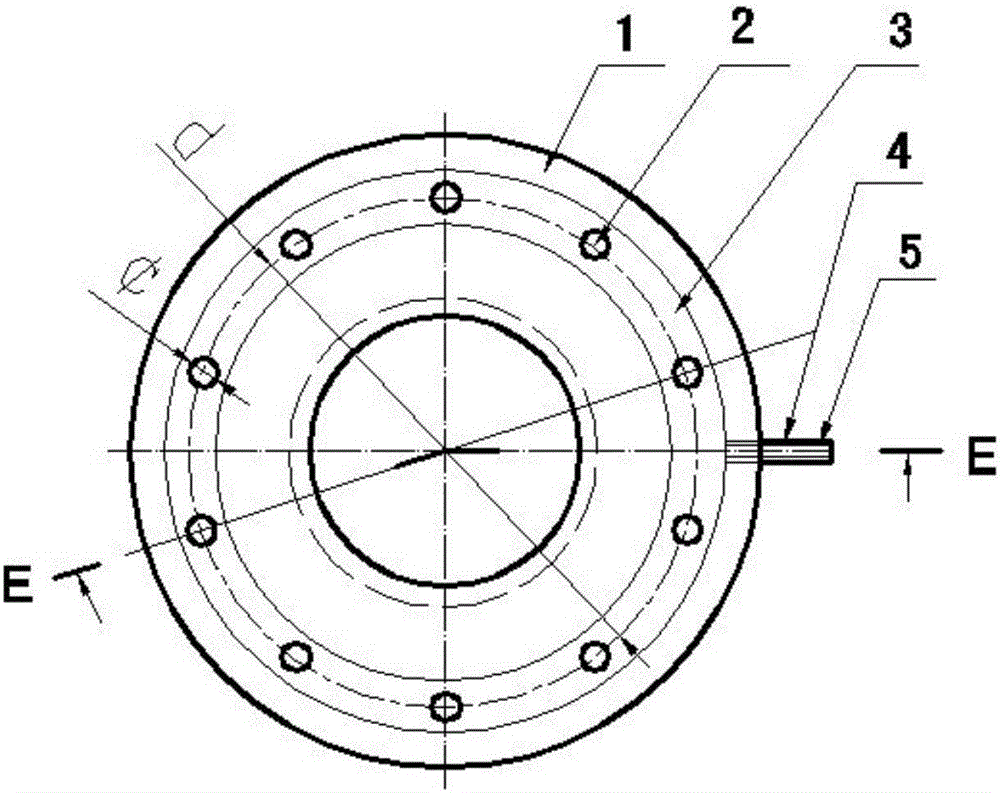

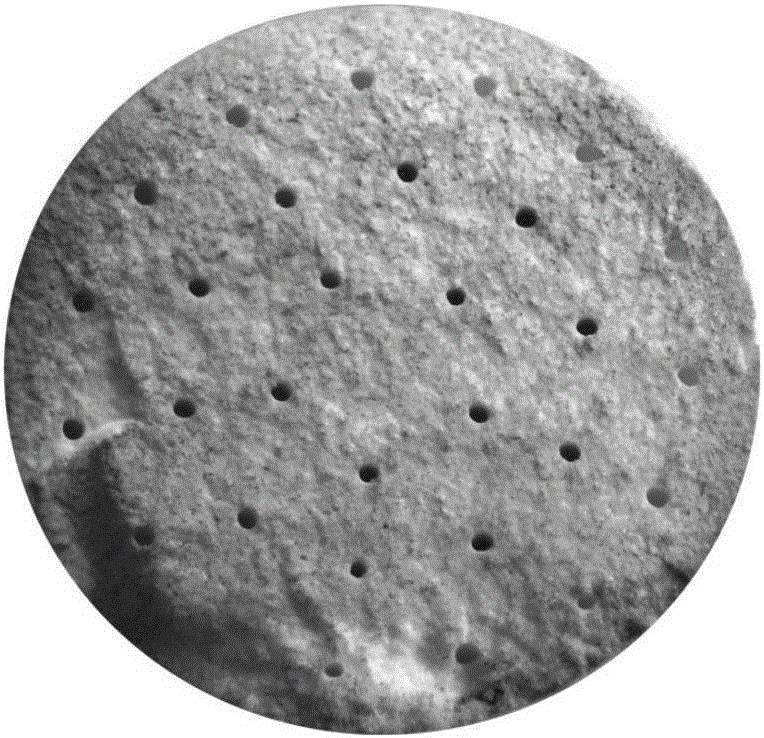

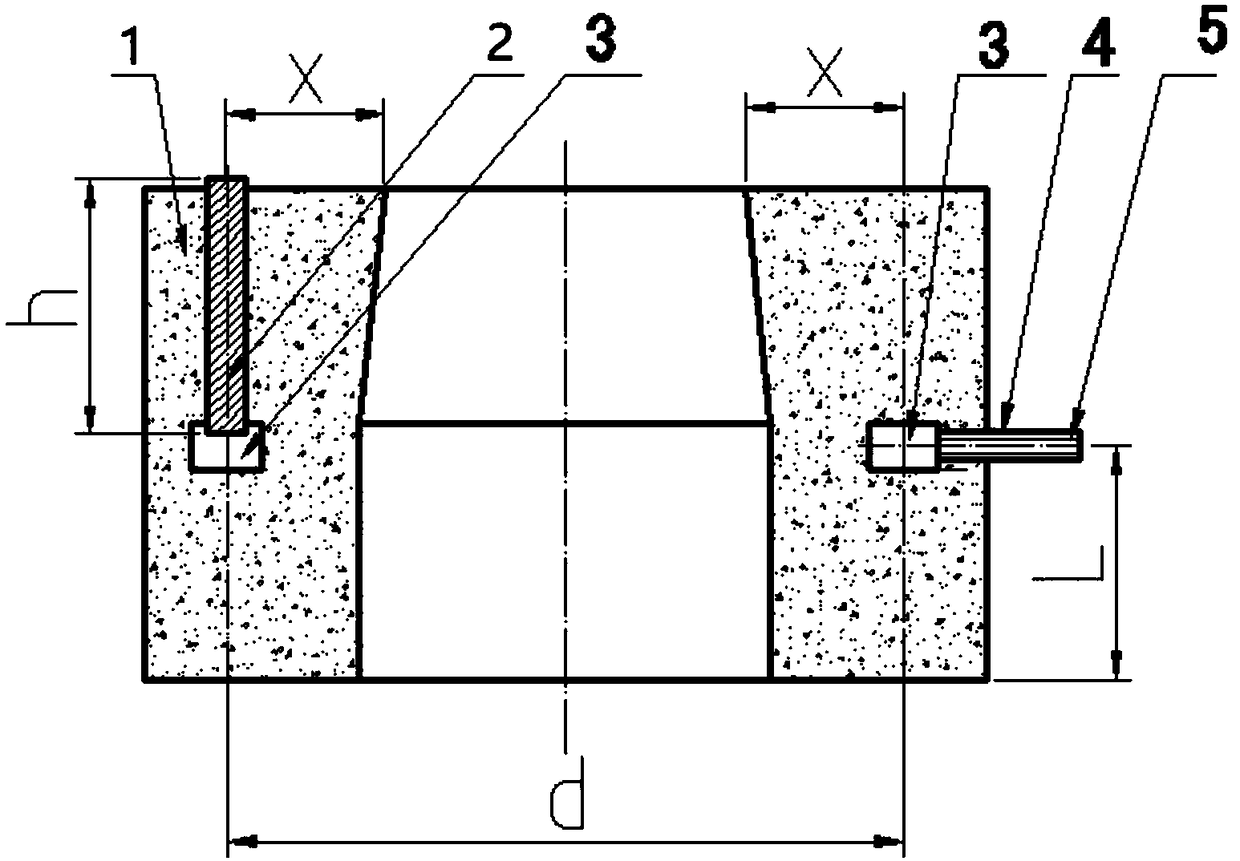

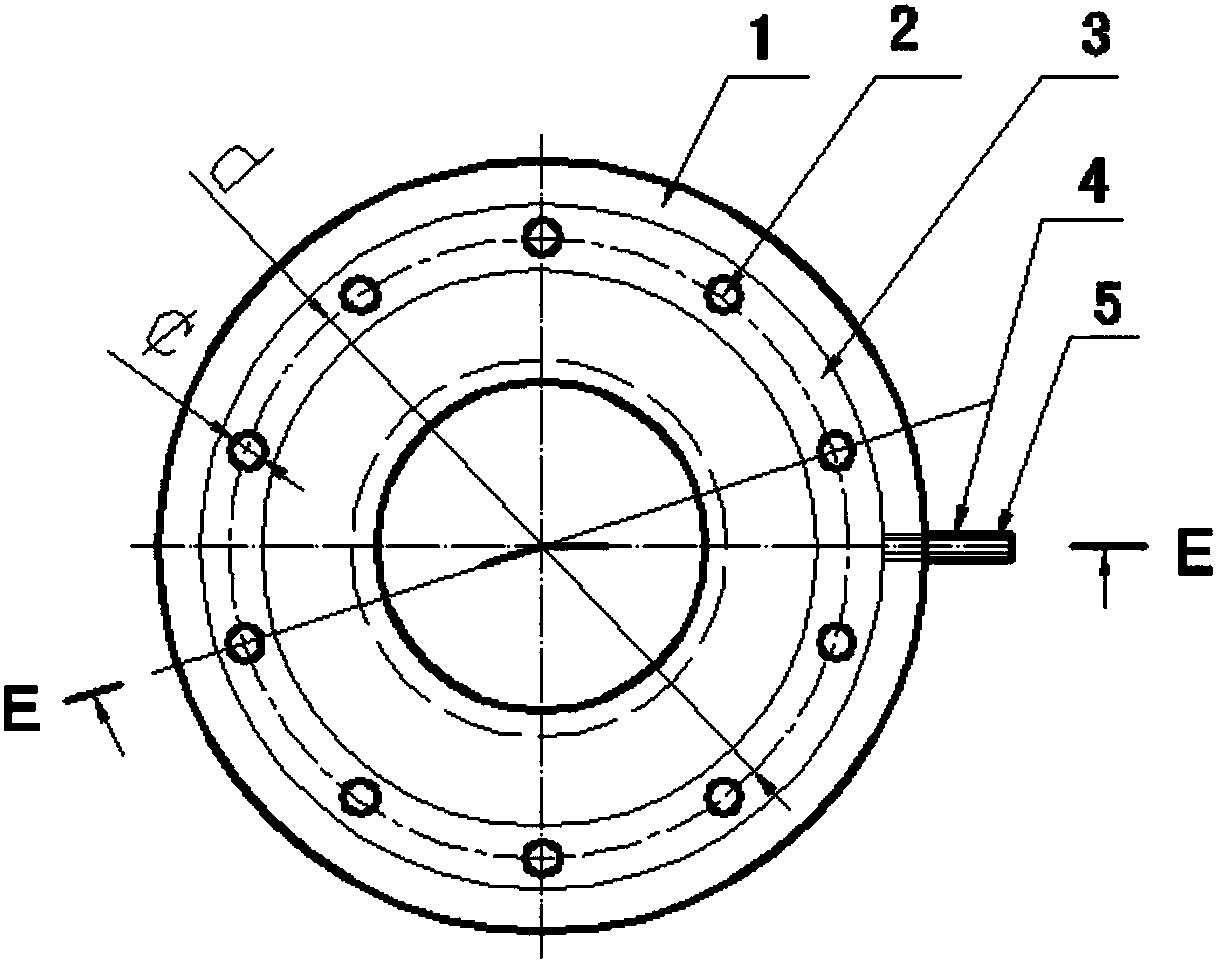

Continuous casting tundish diffuse-type gas-permeable ring upper nozzle brick cup and argon blowing refining method thereof

The invention relates to a continuous casting tundish diffuse-type gas-permeable ring upper nozzle brick cup and an argon blowing refining method thereof. The upper nozzle brick cup comprises an upper nozzle brick cup body, diffuse-type gas-permeable rings, a gas chamber and a gas inlet pipe, wherein the gas-permeable rings are uniformly arranged in a circle; the gas-permeable rings and the circular gas chamber are arranged in the upper nozzle brick cup body; the air chamber is arranged at the bottoms of the diffuse-type gas-permeable rings and communicate with the diffuse-type gas-permeable rings; the upper parts of the gas-permeable rings extend out of the upper surface of the upper nozzle brick cup body by 5 to 10 mm; the gas inlet pipe is connected to one side part of the gas chamber; one end of the gas inlet pipe communicates with the air chamber; the other end of the gas inlet pipe extends out of one side part of the upper nozzle brick cup body, is connected with a metal pipe fitting and communicates with an external argon gas source; an upward circular air curtain barrier is formed after argon gas is blown into the gas inlet pipe, so that gas washing of molten steel entering an upper nozzle is realized, and floating and removing of inclusions are promoted; and a certain quantity of argon bubbles enter the upper nozzle along with a steel flow, so that a stable and continuous circular gas flow is formed, which not only solves the problem of nozzle clogging, but also solves the technical problem that protective argon bubbles enter steel to cause sub-surface bubbles of a casting blank.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Wristwatch with Earphone Function

InactiveUS20080043575A1Easy to handleAttractive external appearanceMicrophonesVisual indicationsEngineeringHeadphones

A wristwatch comprising a main unit associated in removable manner with a seating prepared on a support and / or positioning element, which is in turn associated with an attachment element to attach it to the user's wrist. The main unit incorporates both the normal functions of a watch and also the function of an earphone.

Owner:GLOBAL WATCH INDS

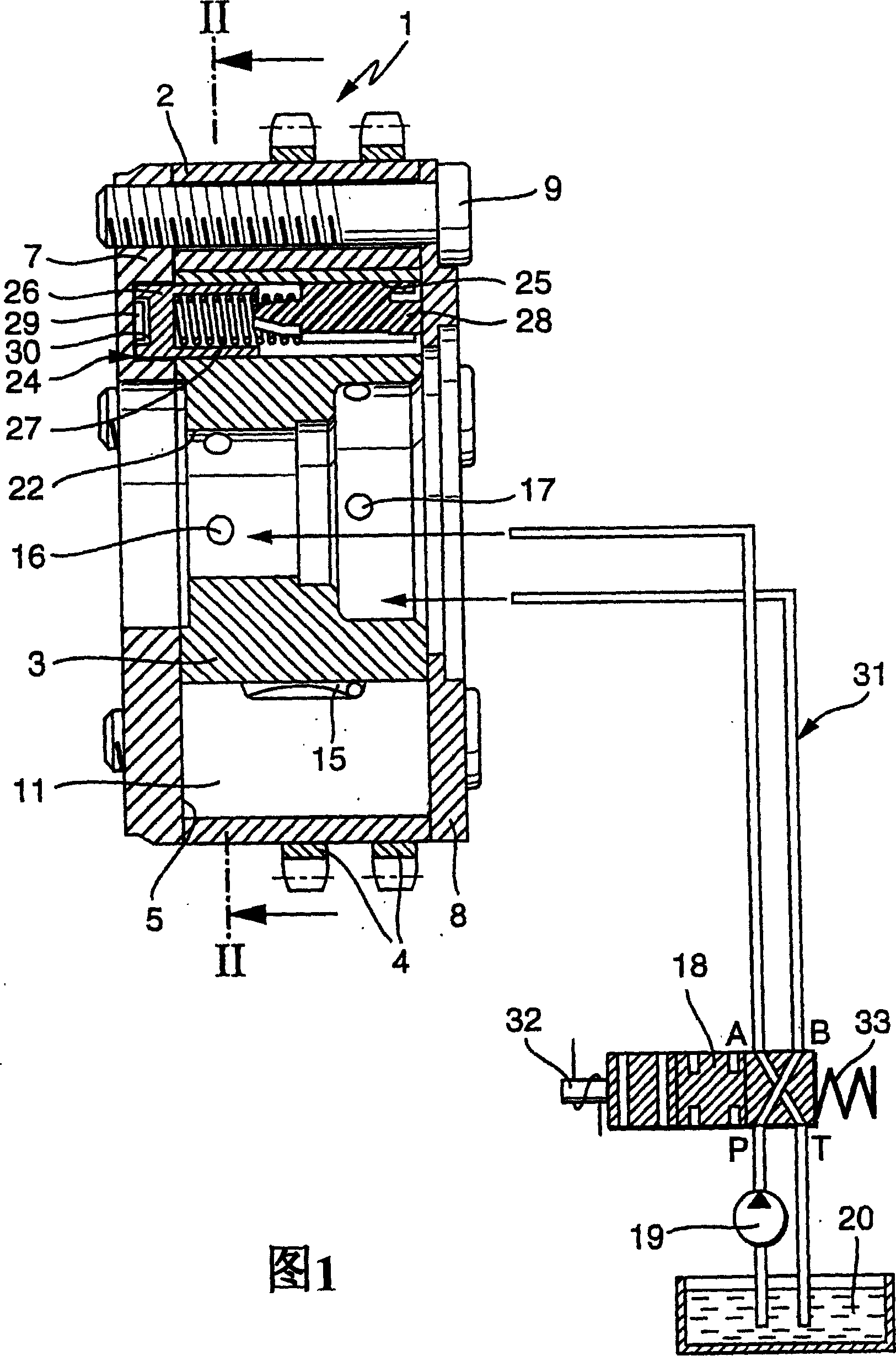

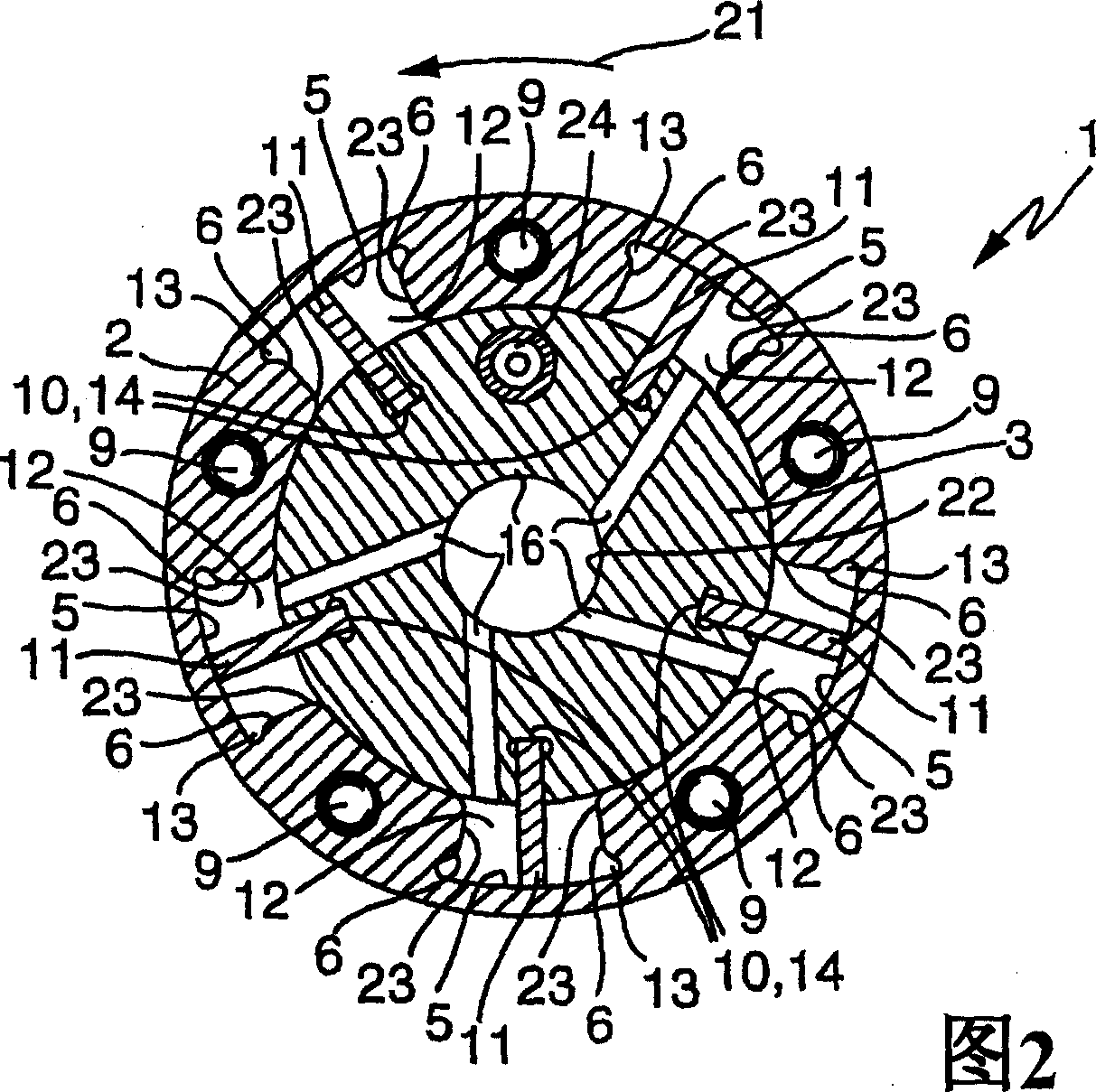

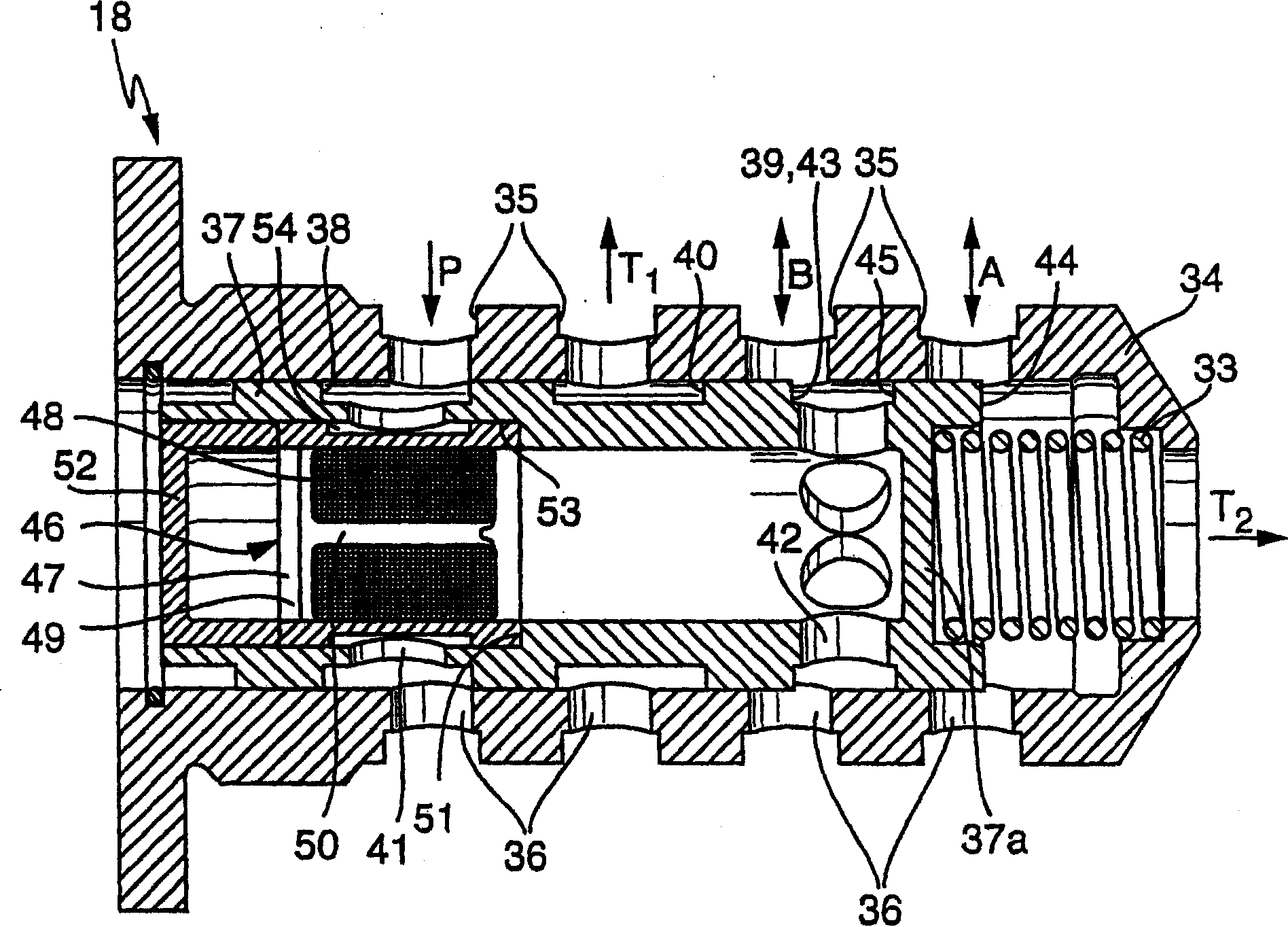

Control valve for a device to modify the timing of an internal combustion engine

InactiveCN1724852APrevent mobilityBlocker openOperating means/releasing devices for valvesServomotor componentsExternal combustion engineFuel tank

The invention relates to a control valve (18) of a device (1) for varying the control time of an internal combustion engine. In this case, a targeted rotation of the camshaft relative to the crankshaft can be achieved by means of a hydraulic actuator. A control valve (18) with a working connection (A, B), a pressure oil connection (P) and at least one tank connection (T, T1, T2) controls the pressure oil supply or pressure oil discharge of the hydraulic actuator. The invention proposes to arrange a filter (46) between the pressure oil connection (P) and the working connections (A, B).

Owner:SCHAEFFLER TECH AG & CO KG

Flexible supporting method of large-aperture lens

InactiveCN102243359ANo destructive deformationAvoid curvature of fieldMountingsOptical aberrationMechanical engineering

The invention discloses a flexible supporting method of a large-aperture lens, which comprises the steps of; firstly, machining three bosses on the excircle of a circular lens base with a certain thickness at intervals of 120 DEG , machining a connecting part with a cuboid structure on the outer side of each boss, machining an installing hole and a pin hole on the outer side of each boss along the radial direction of the lens base, machining an installing hole and a pin hole on the connecting part along the axial direction of the lens base, machining an installing hole on each boss along the axial direction of the lens base, and machining a small boss with a step on the inner side of each boss; secondly, machining three corresponding installing surfaces on the excircle of the lens at intervals of 120 DEG, and machining radial flexible elements and axial press plates; thirdly, bonding the radial flexible elements with the lens, and fixing the bonded assembly in the lens base through the installing holes and the pin holes; and finally, tightly pressing the lens through the axial press plates, and fixing the axial press plates through the installing holes. According to the supporting method disclosed by the invention, positioning precision of the lens is integrally improved, stress environment of the lens under an assembling condition is improved, and optical aberration such as field curvature, astigmatism and the like can be eliminated.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

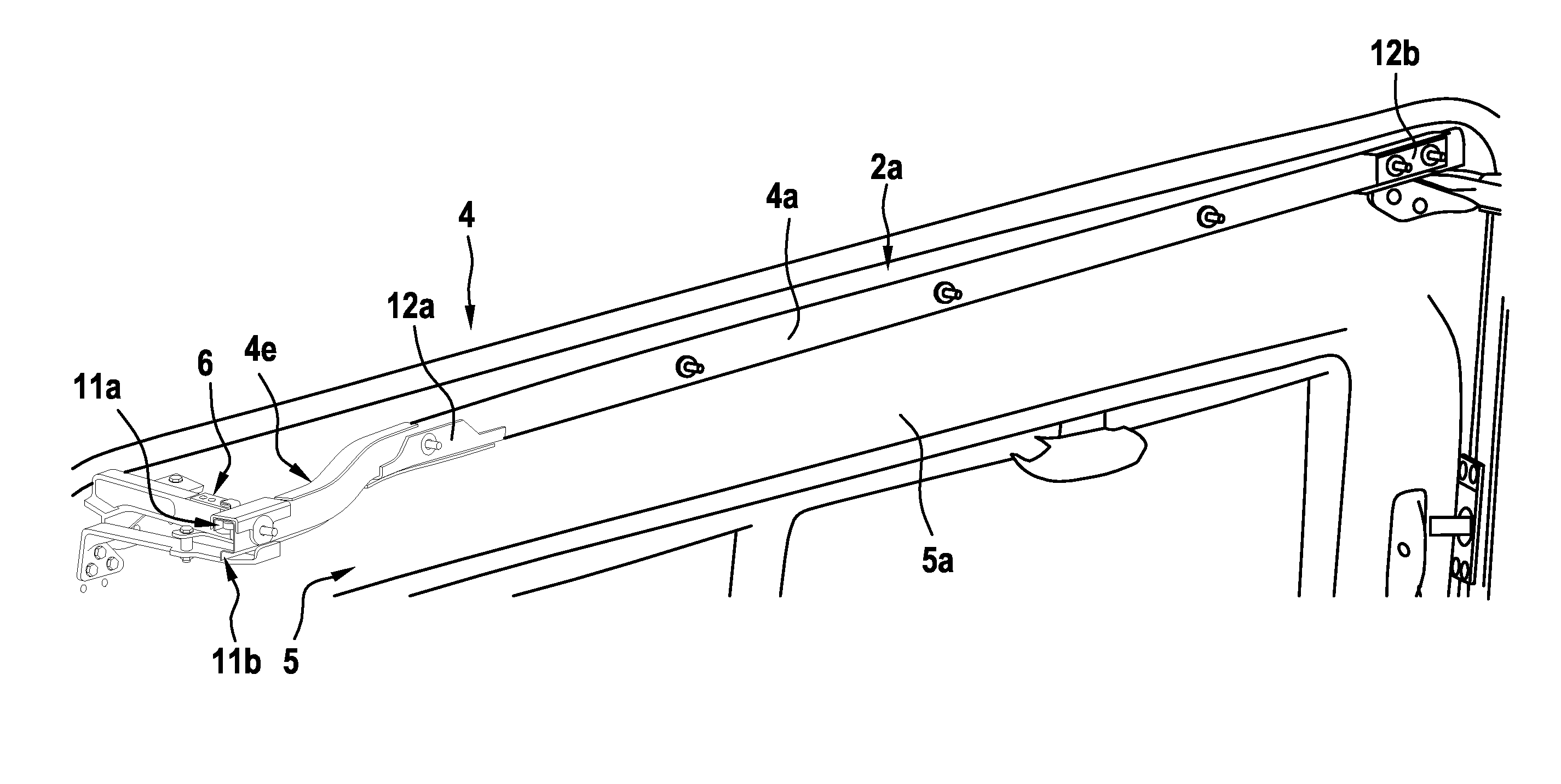

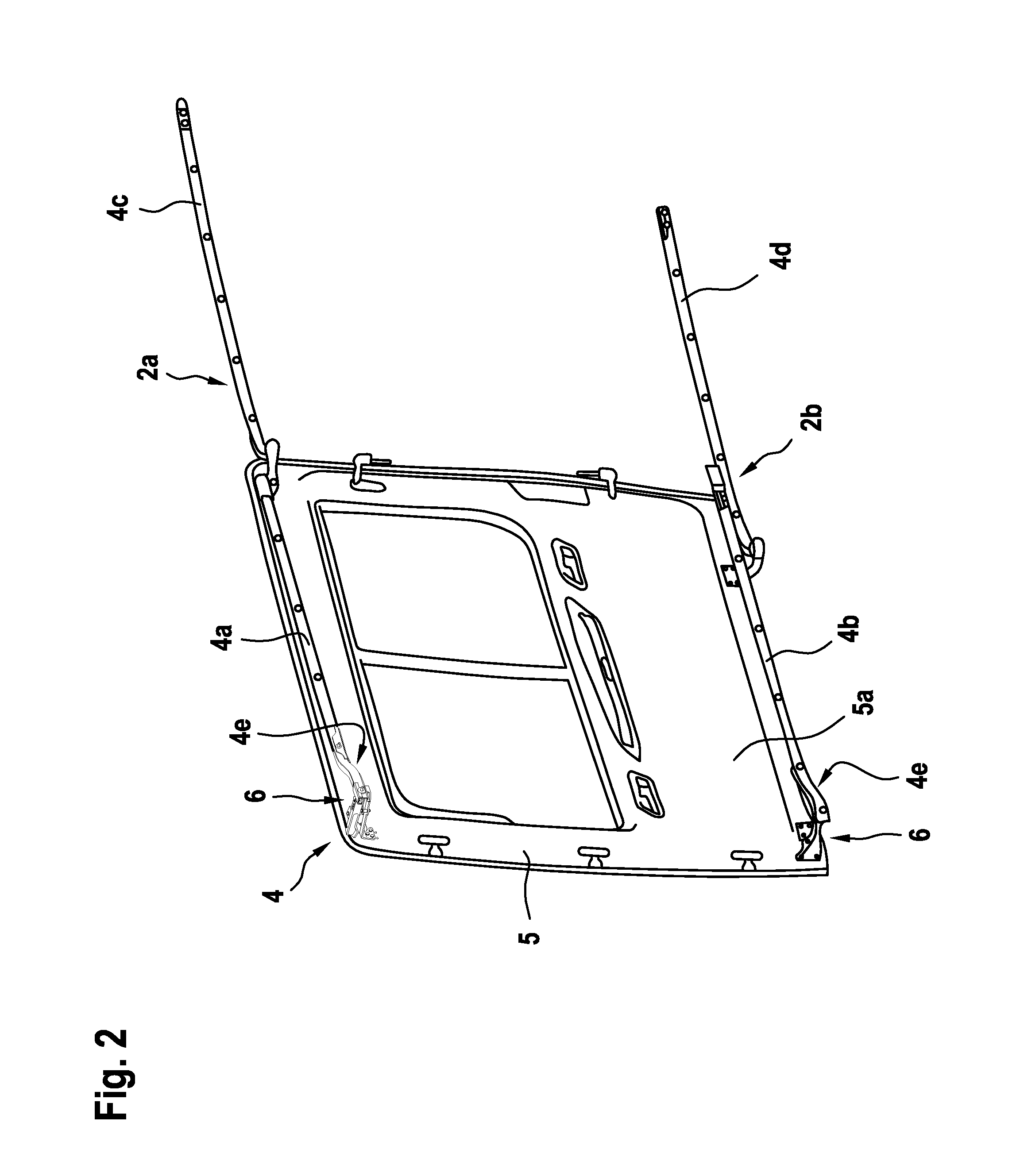

Sliding closing element, in particular a sliding door or a sliding window, for a sliding closing element arrangement of a vehicle, in particular of an aircraft

ActiveUS20160245006A1Reduce weightReduce manufacturing costAircraft doorsWing arrangementsBogieSlide window

A sliding closing element for a sliding closing element arrangement of a vehicle, the sliding closing element arrangement comprising at least one rail that is adapted for slidably supporting the sliding closing element, the sliding closing element comprising at least one fail safe sliding arm assembly with at least one bogie support arm and at least one safety arm, the at least one bogie support arm comprising at least one bogie assembly with at least one guide roller that is adapted for rolling along the at least one rail in operation, and the at least one safety arm being adapted for retaining the at least one fail safe sliding arm assembly on the at least one rail in case of a failure of the at least one bogie support arm.

Owner:AIRBUS HELICOPTERS DEUT GMBH

Continuous casting tundish breathable ceramic tube upper nozzle brick cup and argon blowing refining method thereof

The invention relates to a continuous casting tundish breathable ceramic tube upper nozzle brick cup and an argon blowing refining method thereof. The upper nozzle brick cup comprises an upper nozzle brick cup body, a plurality of ceramic tubes, a gas chamber and a gas inlet pipe, wherein the ceramic tubes are uniformly arranged in a circle; the ceramic tubes and the circular gas chamber are arranged in the upper nozzle brick cup body; a plurality of sockets are uniformly arranged on the gas chamber in a circle; the top ends of the ceramic tubes extend out of the upper surface of the upper nozzle brick cup body by 5 to 10 mm; the lower ends of the ceramic tubes are fixed in the sockets on the gas chamber, and communicate with the gas chamber; the gas inlet pipe is connected to one side part of the gas chamber, and communicates with an external argon gas source by being connected with a metal pipe fitting; an upward circular air curtain barrier is formed after argon gas is blown into the gas inlet pipe, so that gas washing of molten steel entering an upper nozzle is realized; and a certain quantity of argon bubbles enter the upper nozzle along with a steel flow, so that a stable and continuous circular gas flow is formed, which not only solves the problem of nozzle clogging, but also solves the technical problem that protective argon bubbles enter steel to cause sub-surface bubbles of a casting blank.

Owner:SHANDONG IRON & STEEL CO LTD

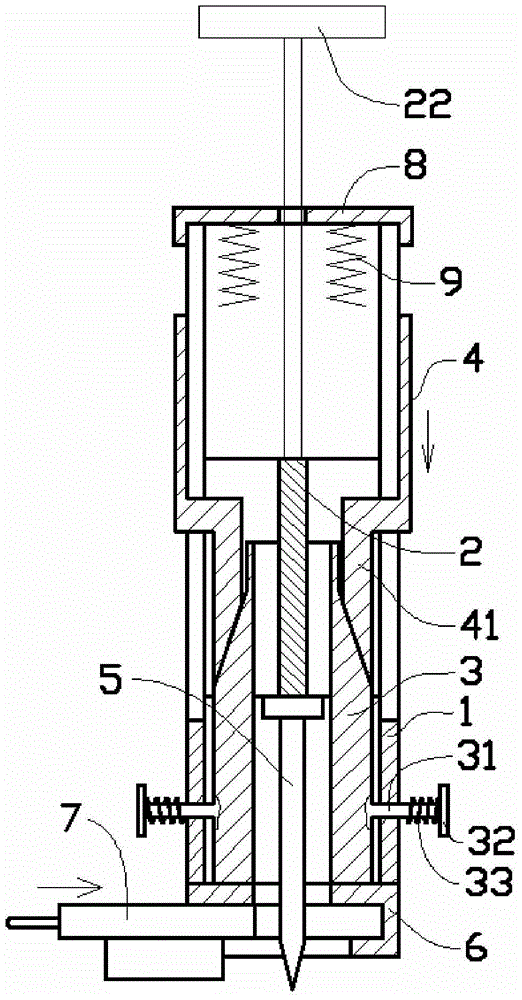

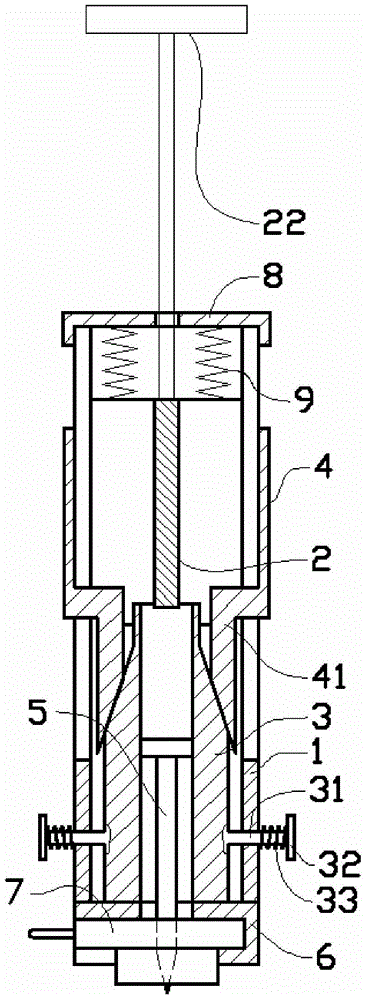

Easily oriented manual nail knocking device

ActiveCN104908009AOperational securityPrecise positioningDispensing apparatusNailing toolsEngineeringMechanical engineering

Owner:张承澍

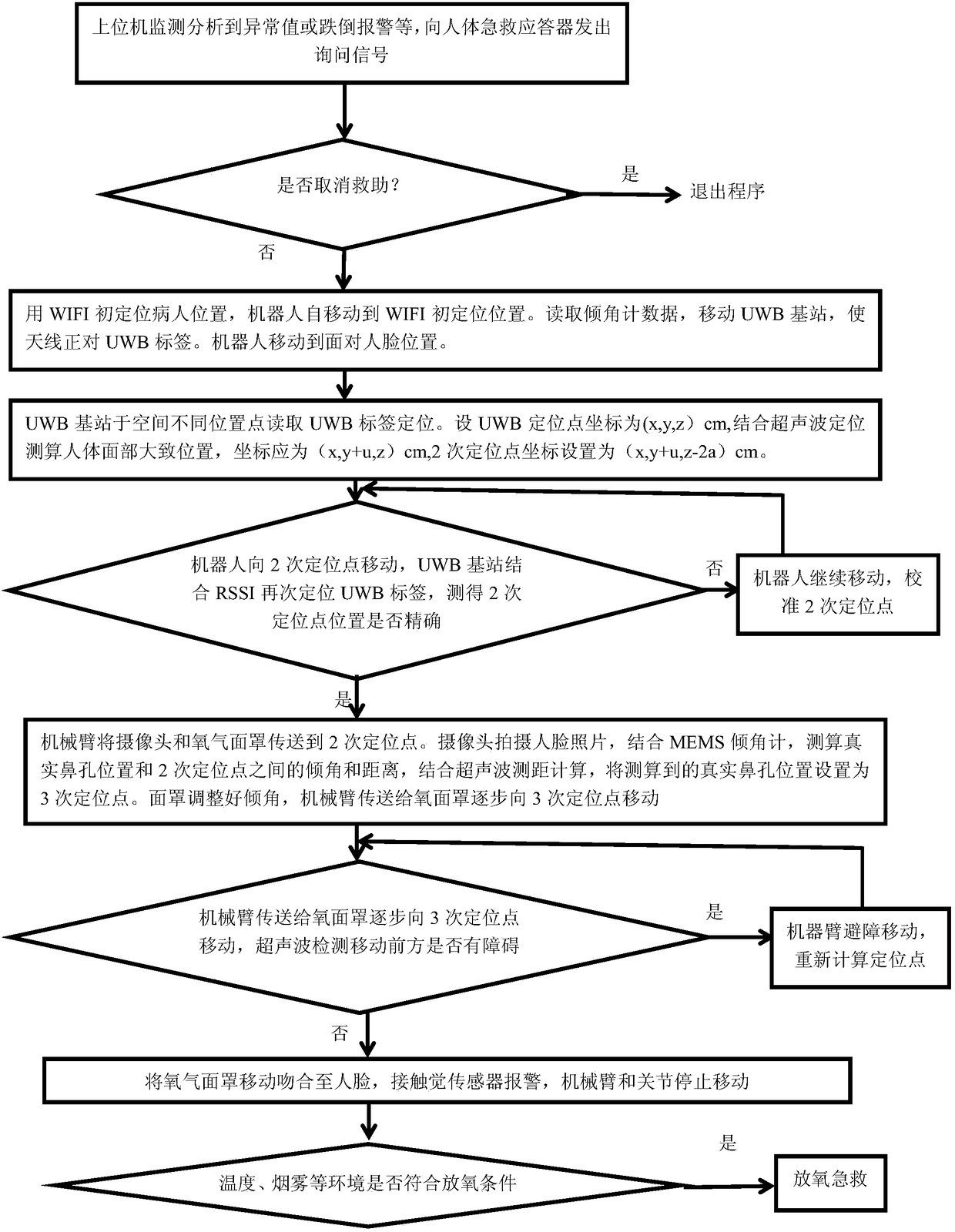

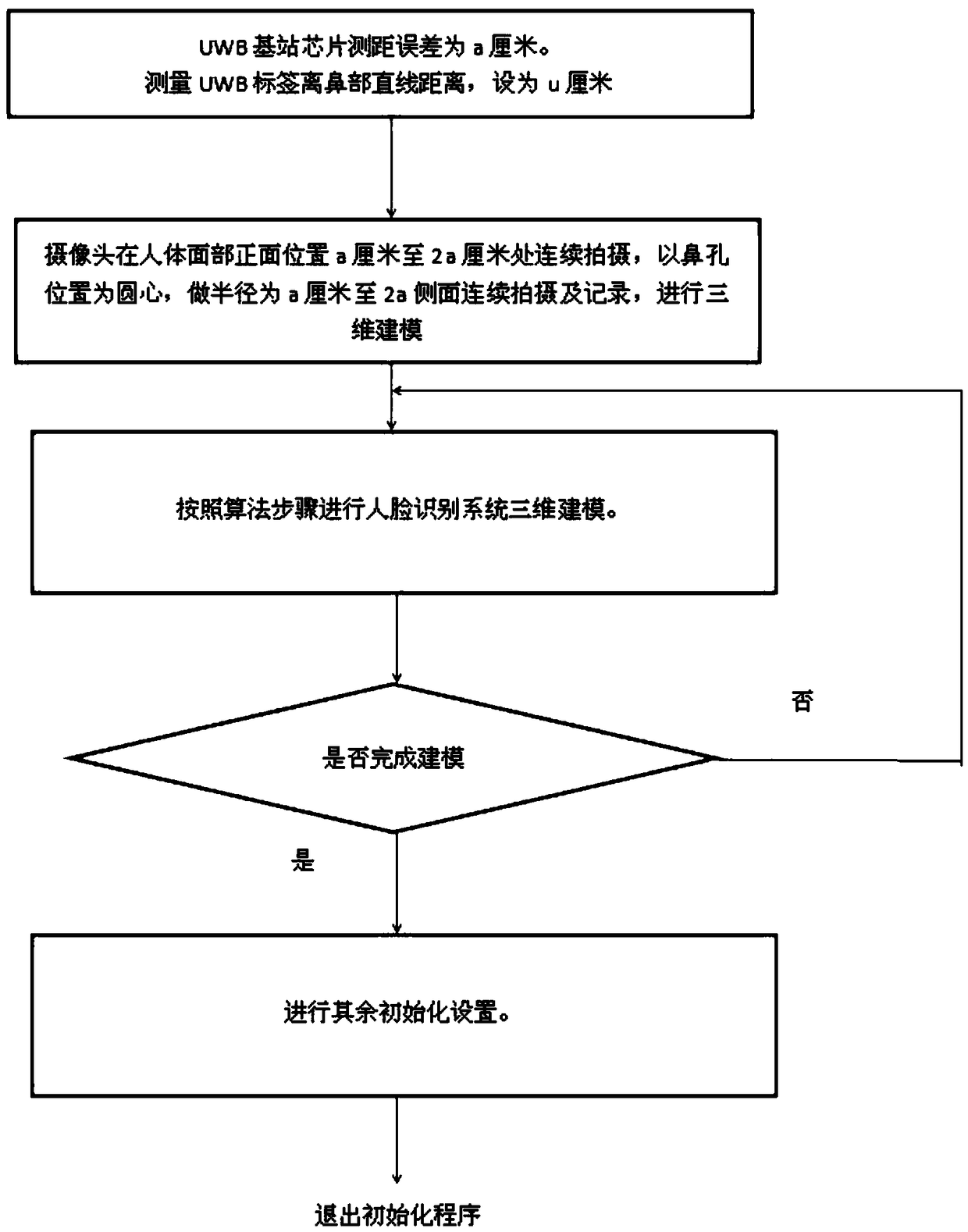

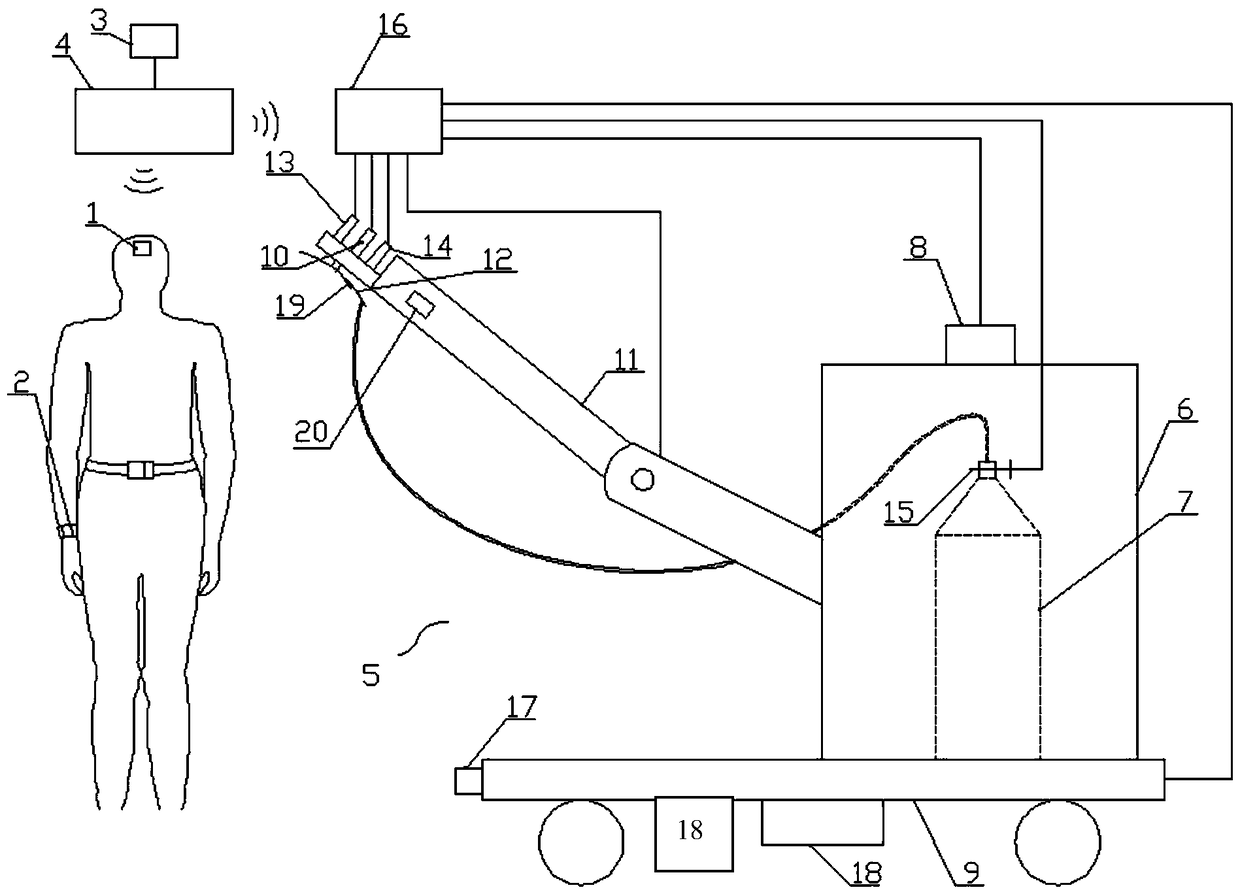

Oxygen feeding method and system of full-automatic oxygen feeding robot

The invention discloses an oxygen feeding method and system of a full-automatic oxygen feeding robot. The method includes: a patient wears wearable monitoring equipment so as to monitor the physiological features such as heartrate and blood pressure of the patient in real time, the monitoring data is transmitted to an upper computer for real-time analysis, the upper computer preliminarily positions a human body through a WIFI network when data abnormality is found after the analysis, and a moving wheel type traveling mechanism moves a WIFI positioning point according to the preliminary positioning information; a UWB base station is used to perform UWB positioning, and then ultrasonic sensor positioning is performed to obtain the approximate position of the human face; a mechanical arm delivers a camera and an oxygen mask to a position right in front of the approximate position of the human face, and a machine vision algorithm is utilized to identify real nostril positions; the distanceand dip angle between the oxygen mask and the real nostrils are calculated, the oxygen mask is accurately attached to the face through ultrasonic ranging, and then oxygen supply is performed. The oxygen feeding method and system has the advantages that human health conditions can be monitored in real time, and automatic oxygen feeding under emergency can be achieved.

Owner:贵州中医药大学

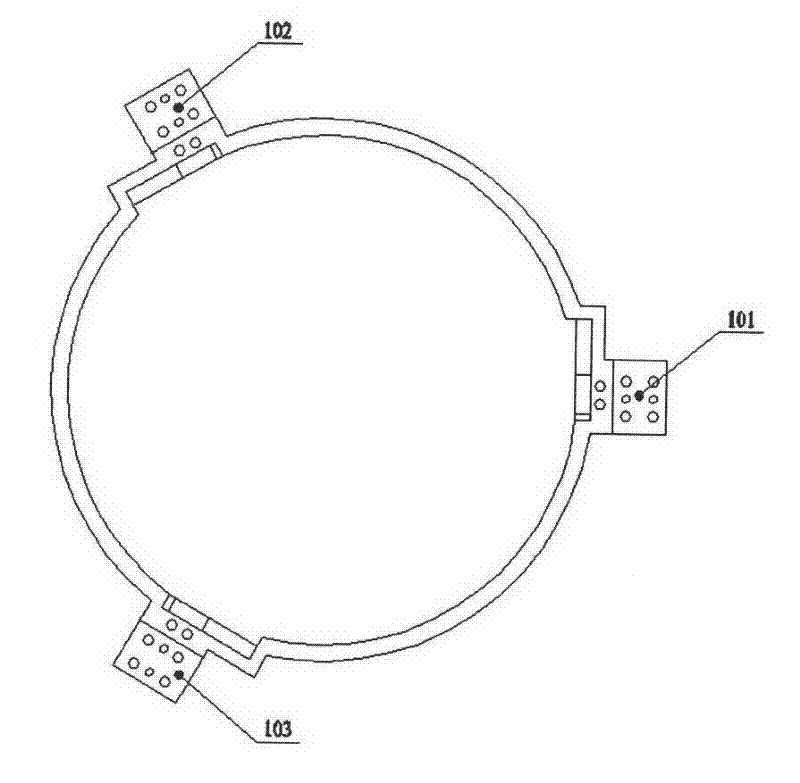

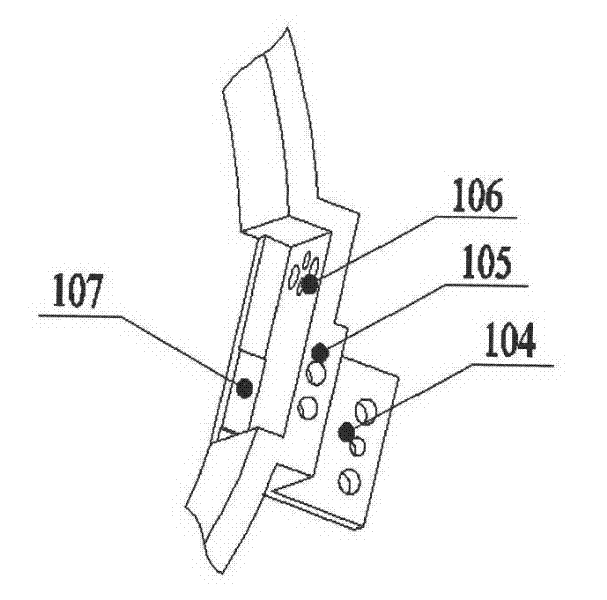

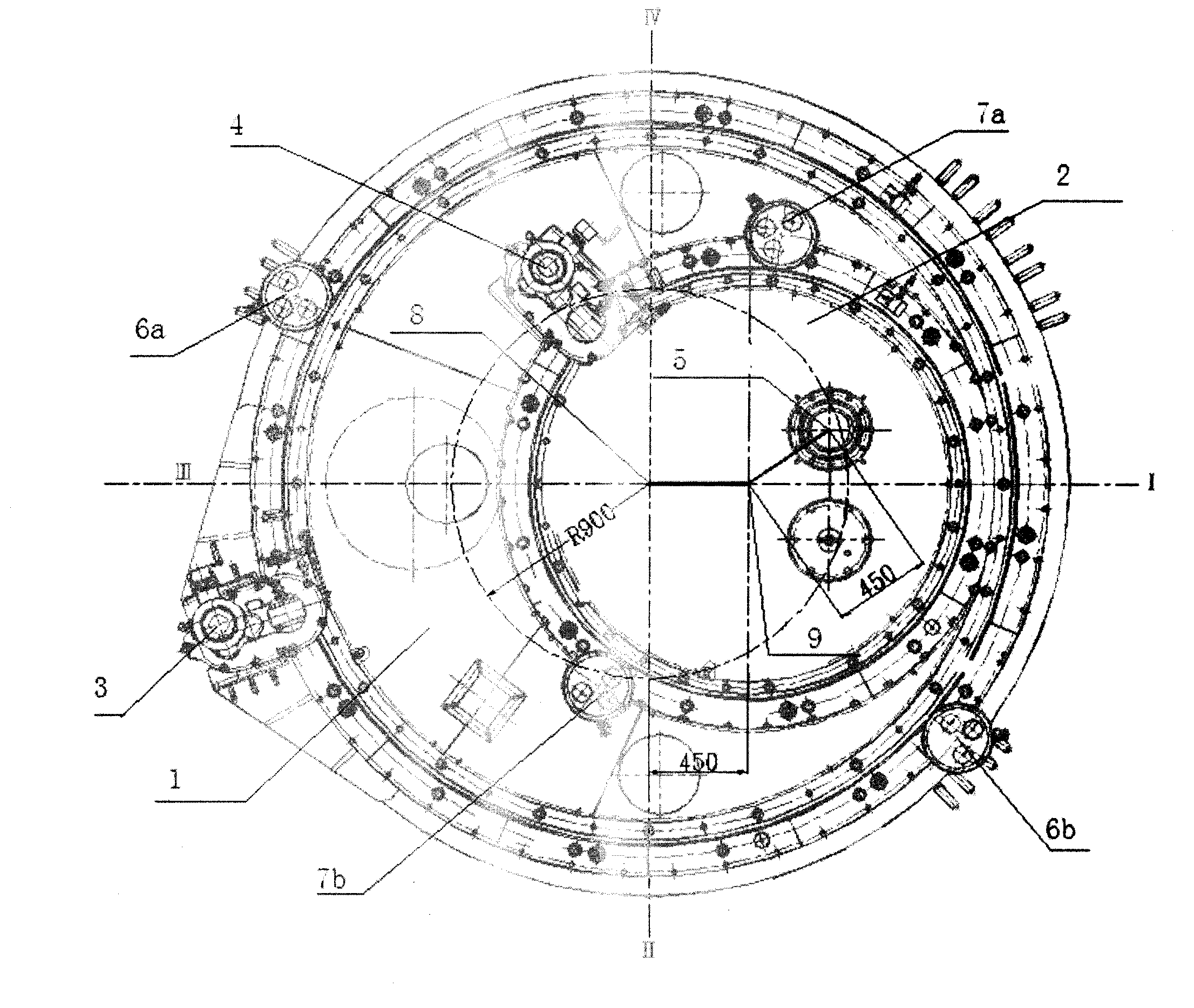

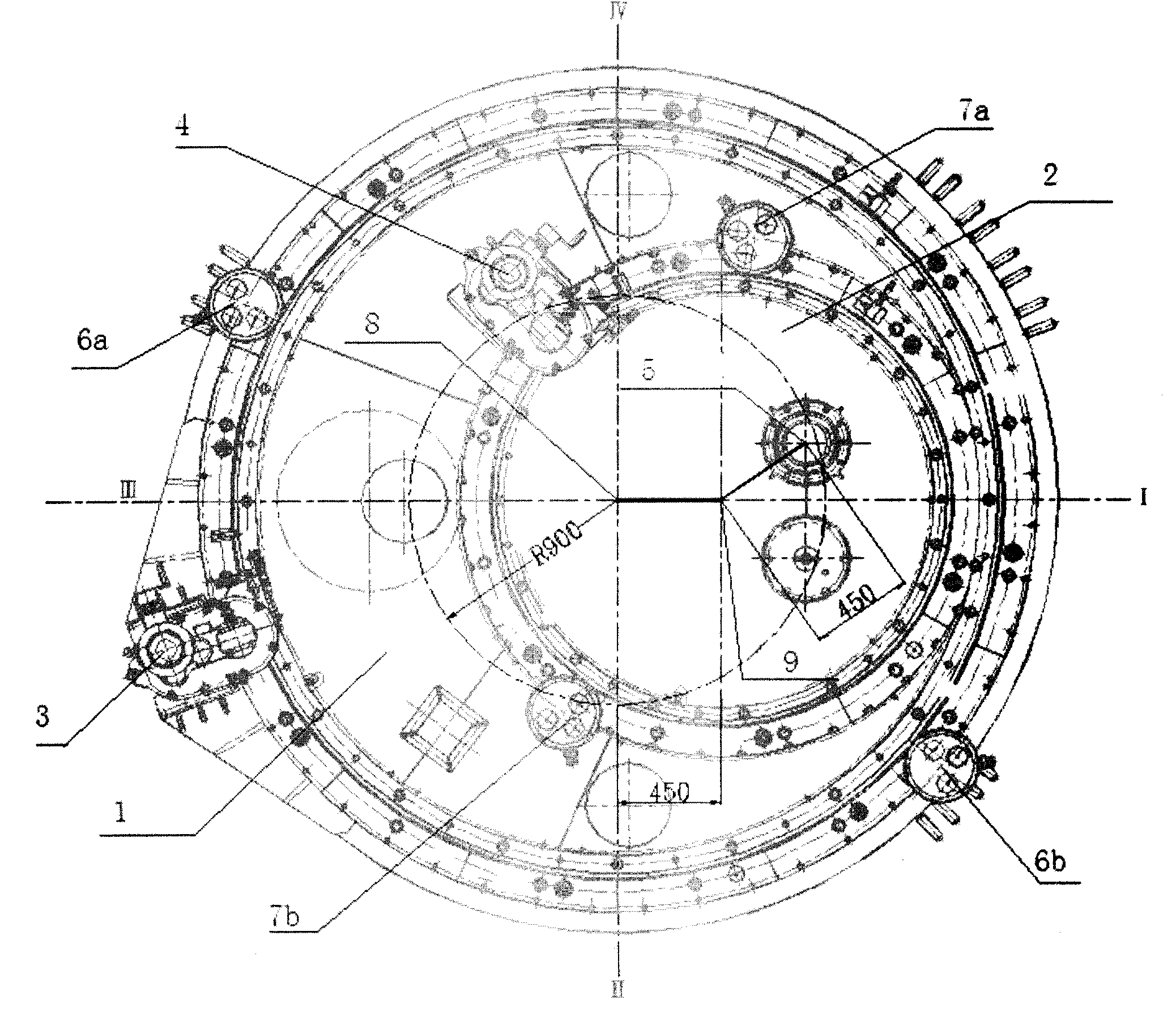

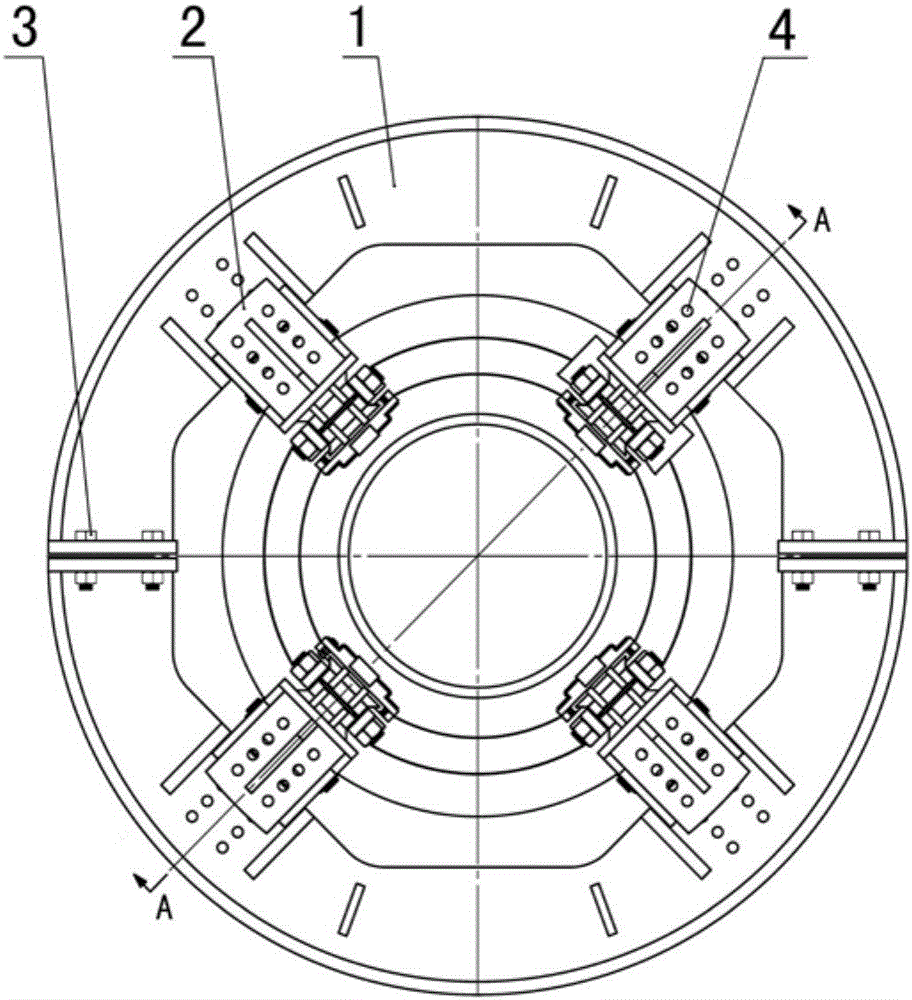

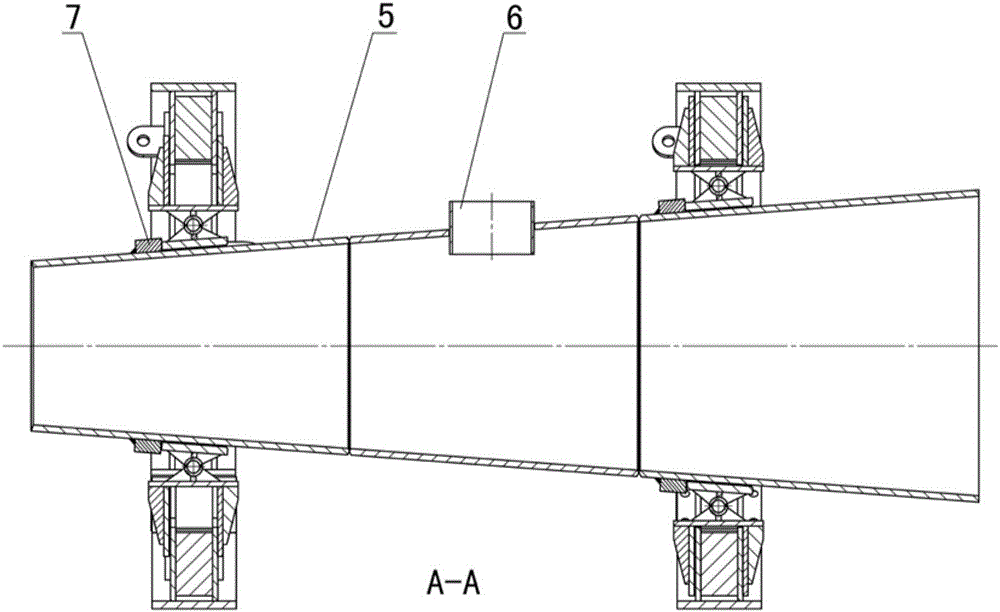

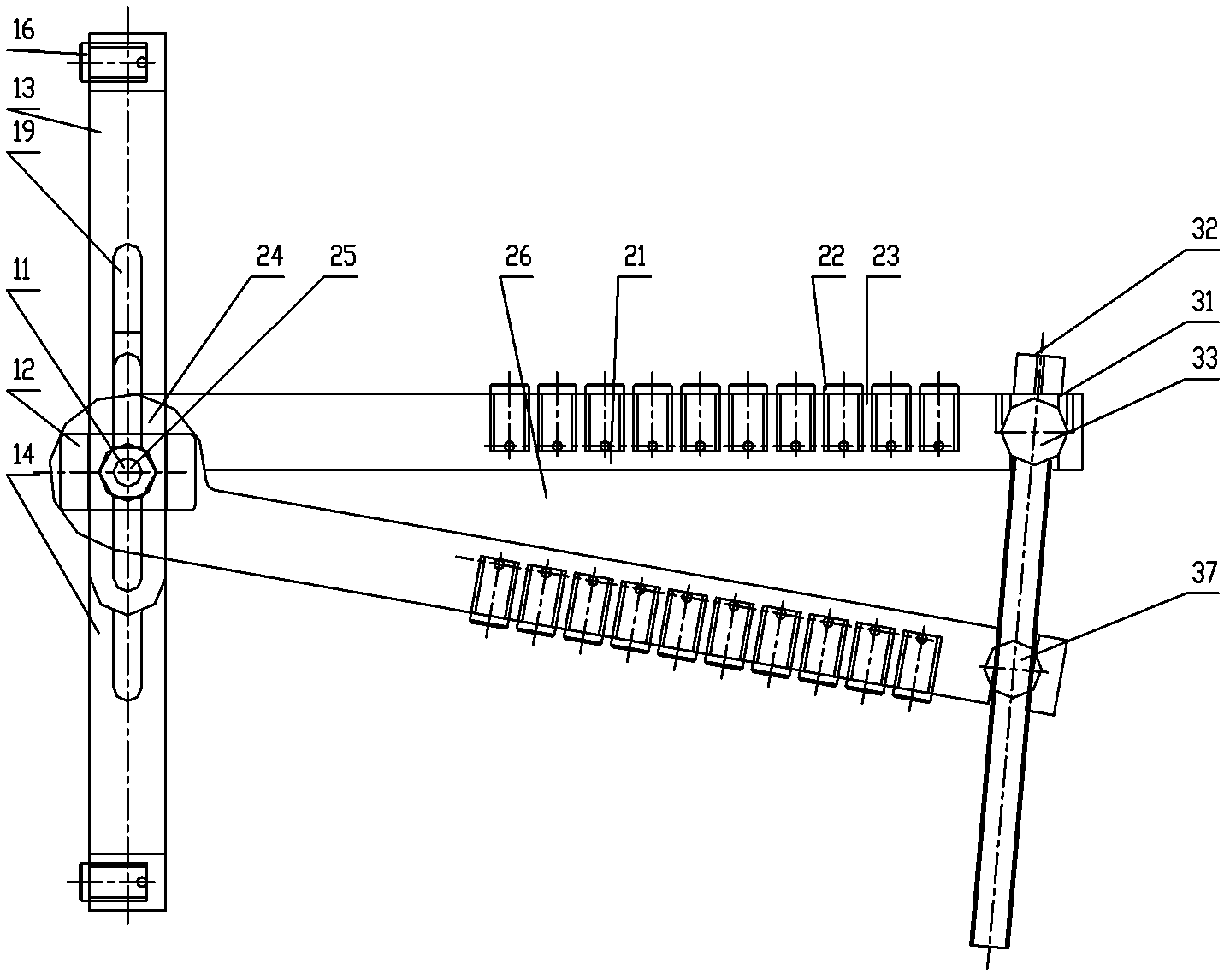

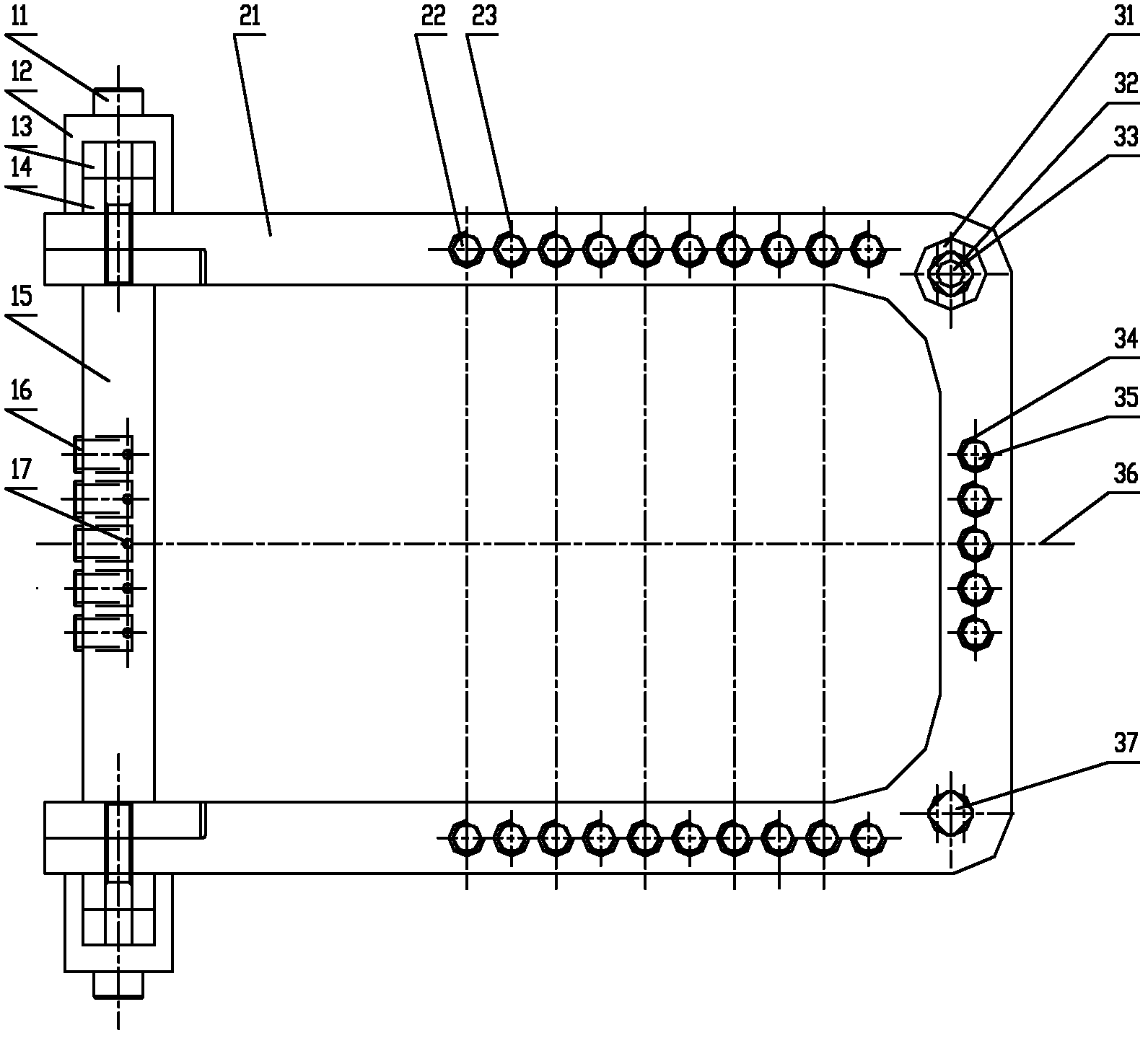

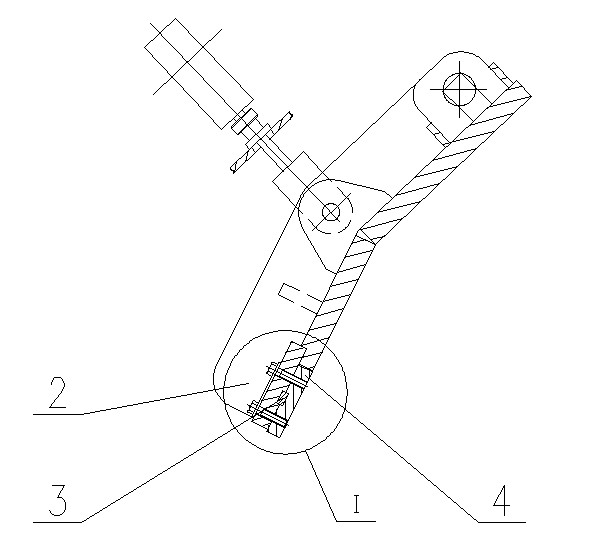

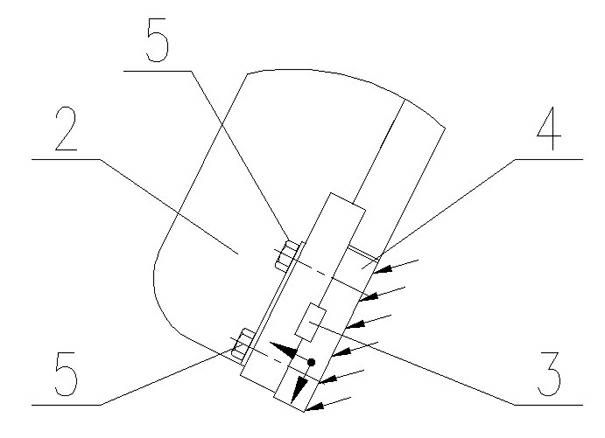

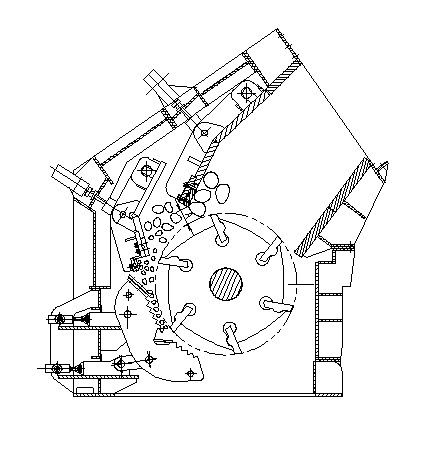

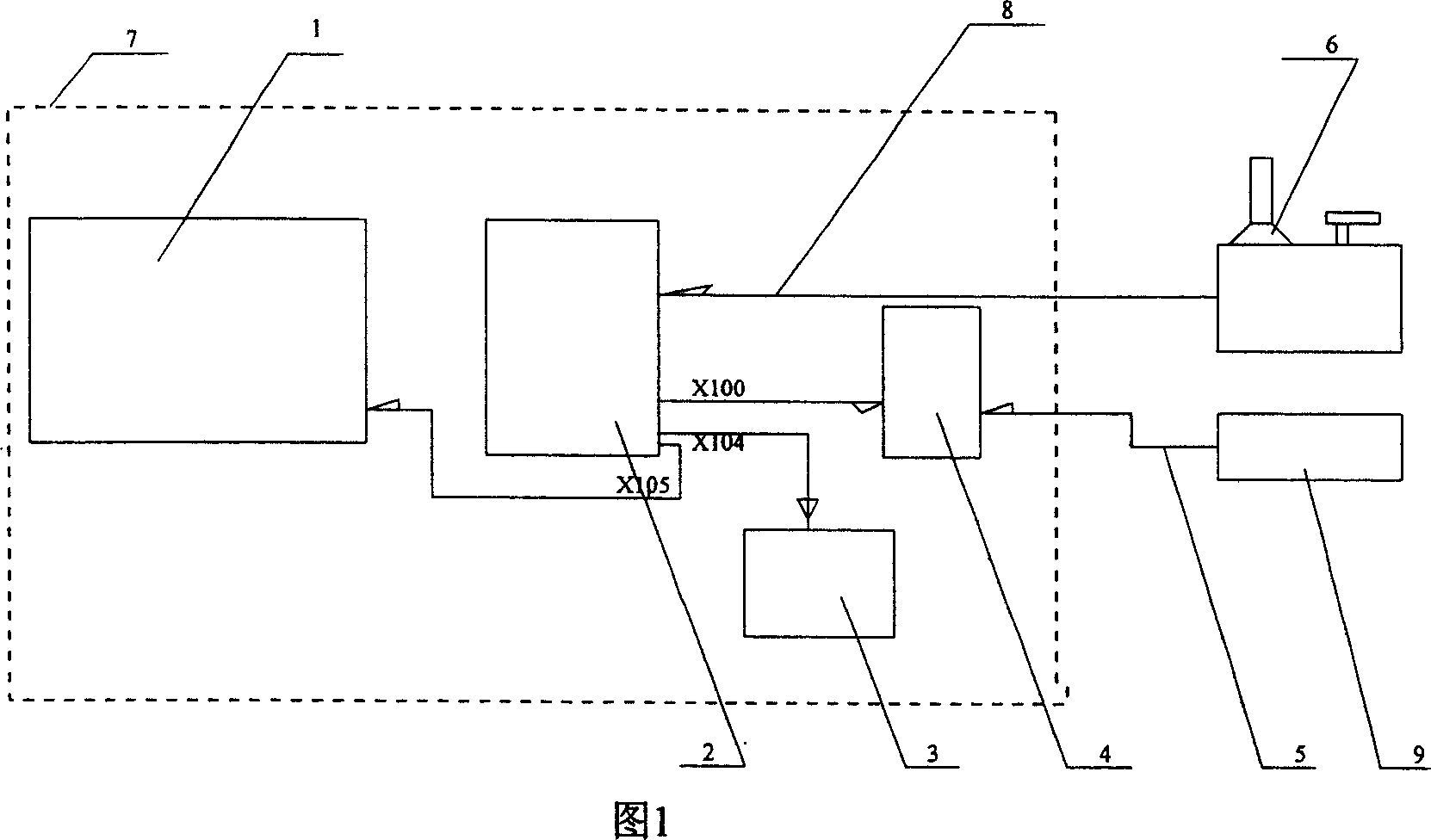

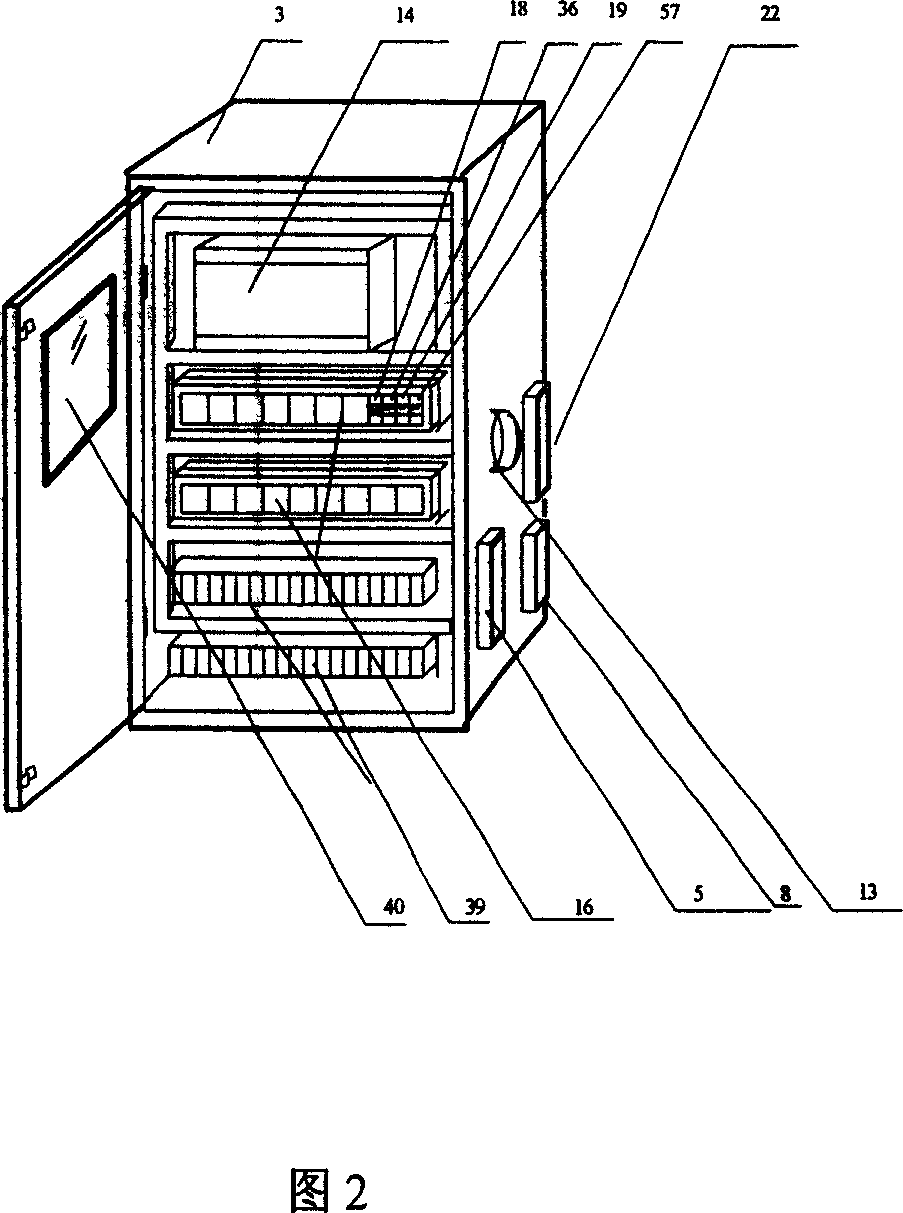

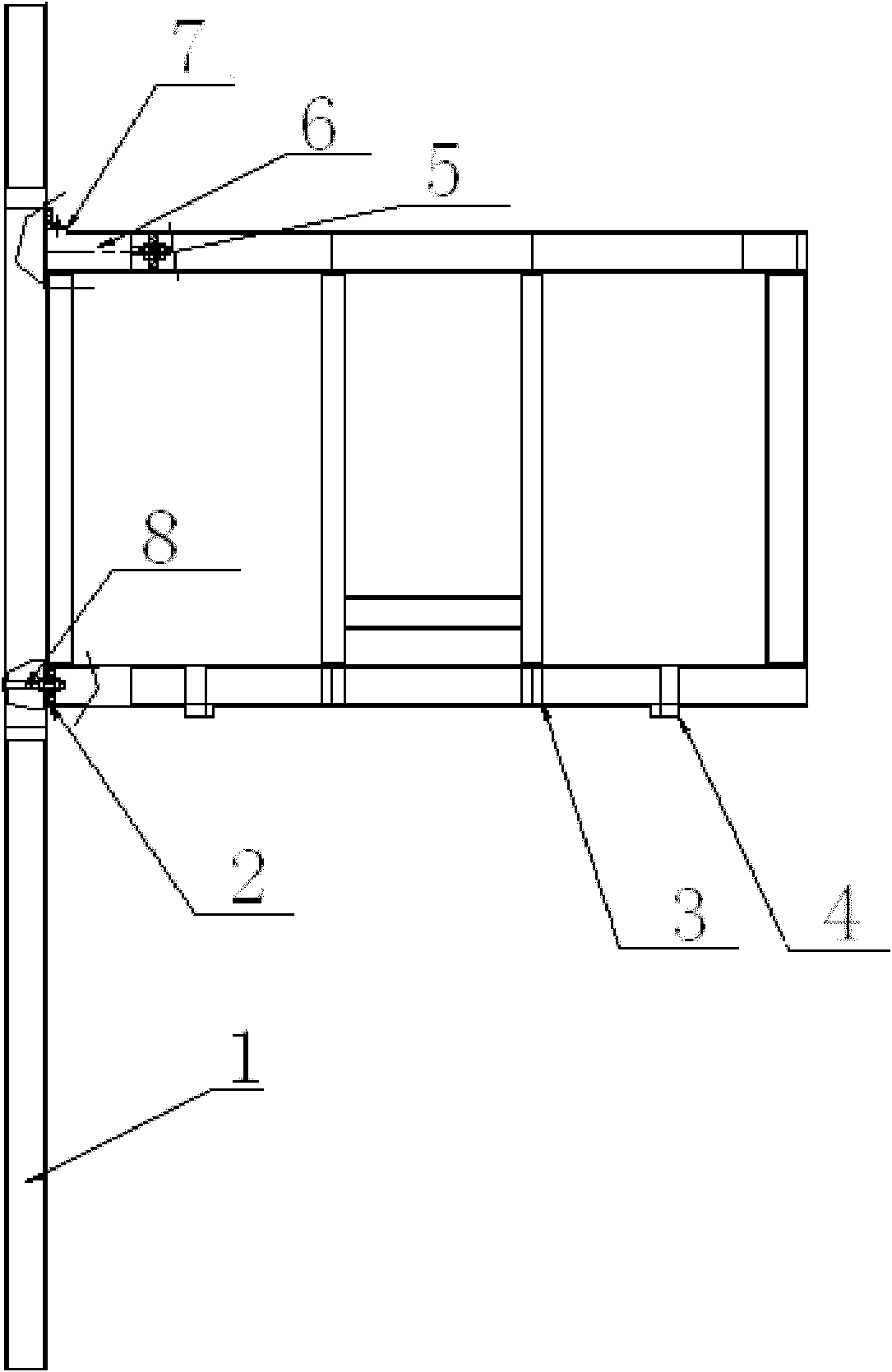

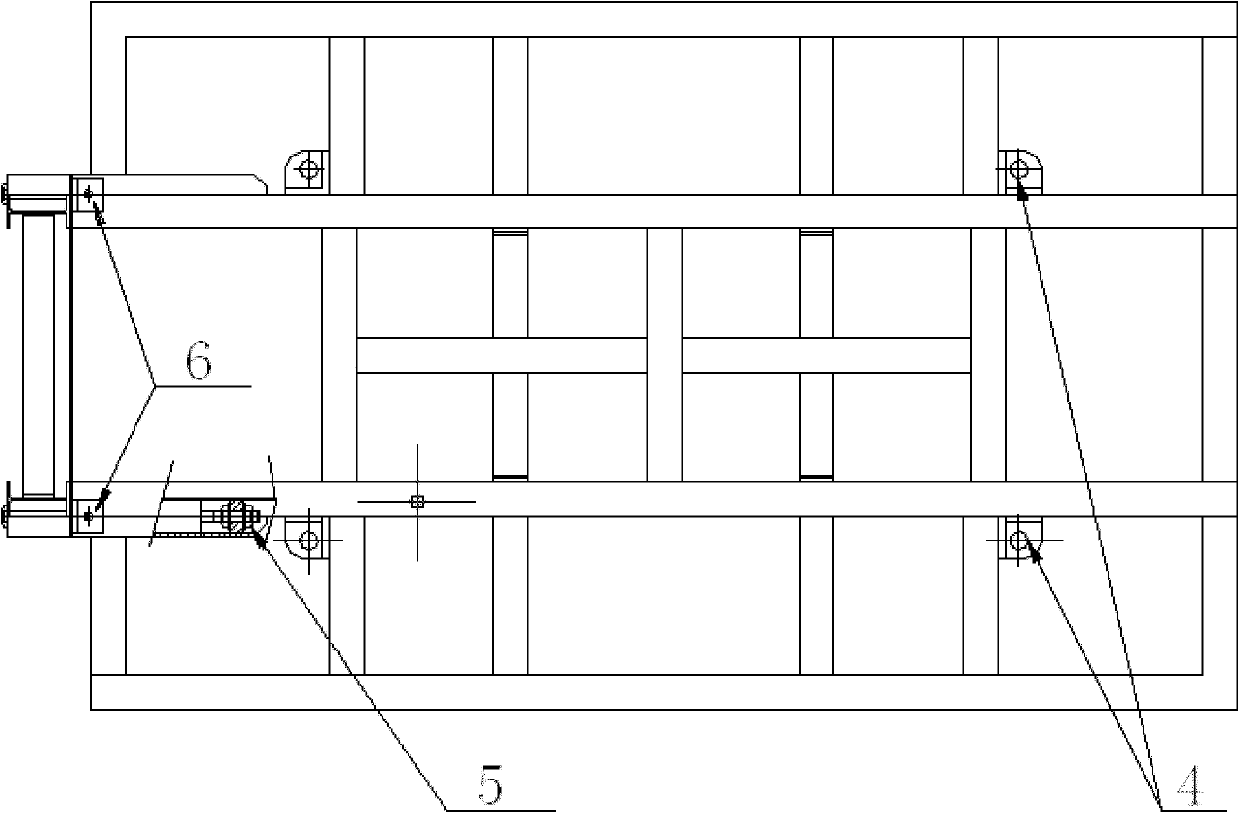

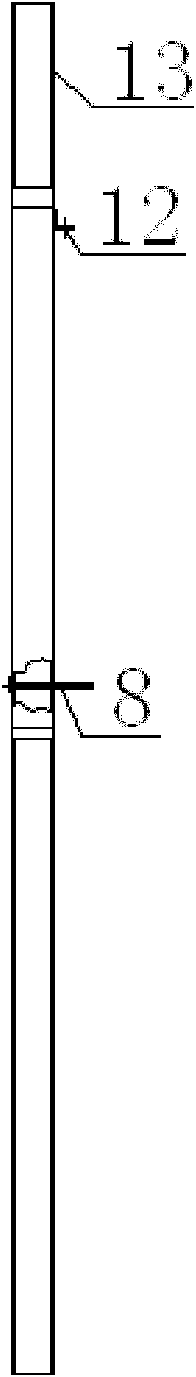

Rotary positioning device for sodium-cooled fast-reactor reloading

InactiveCN101783190APositioning is safe and reliablePrecise positioningNuclear energy generationReactor fuel elementsBreeder reactorStopcock

The invention belongs to the technical field of fast breeder reactors, and particularly relates to a rotary positioning device for sodium-cooled fast-reactor reloading, which consists of a large cock and a pet cock. The large cock is arranged at the top of a reactor vessel; the pet cock is arranged on the large cock; the large cock and the pet cock can do rotary motion around respective axis; the large cock is driven by a large cock driving mechanism arranged at the top of the reactor vessel; and the pet cock is driven by a pet cock driving mechanism arranged on the large cock. The rotary positioning device is characterized in that: the pet cock is eccentrically arranged on the large cock; a reloading machine is eccentrically arranged on the pet cock; and the reloading machine can be guided to be aligned with any reactor core component through the rotary motion of the large cock and the pet cock by adjusting the eccentricity of the pet cock and the large cock and the eccentricity of the reloading machine and the pet cock. The rotary positioning device for the sodium-cooled fast-reactor reloading can safely, conveniently, and precisely realize the positioning mode that the reloading machine is aligned with the reactor core component in a totally closed state.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

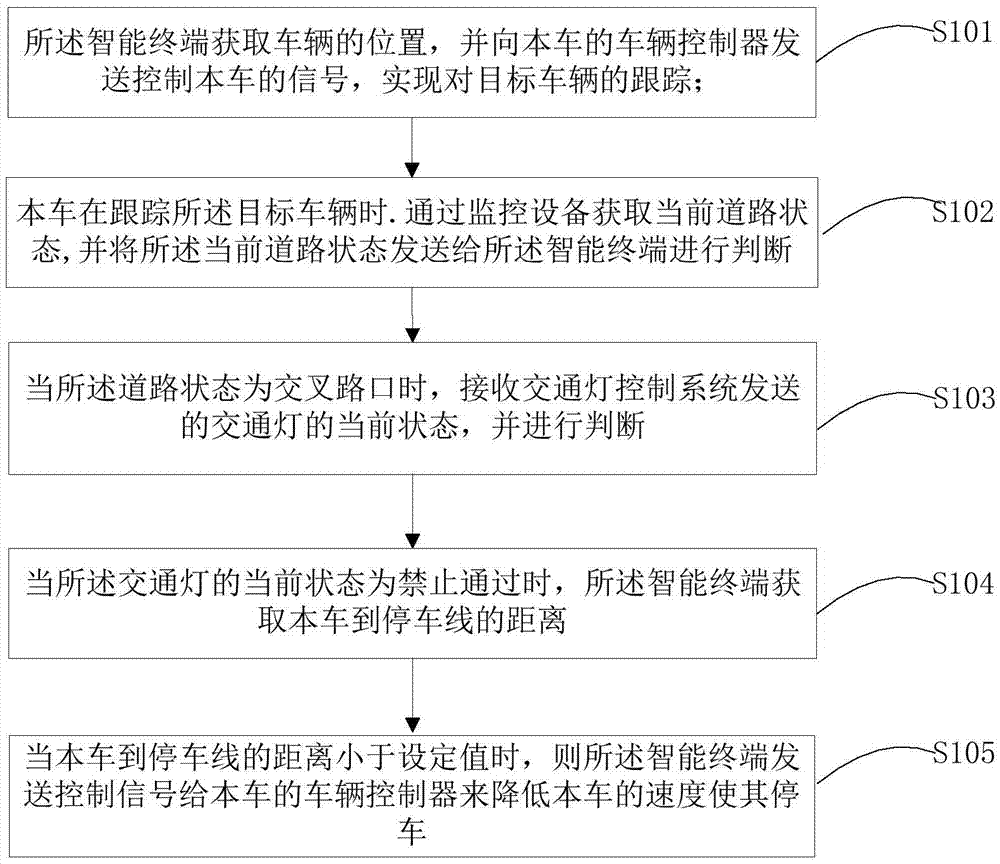

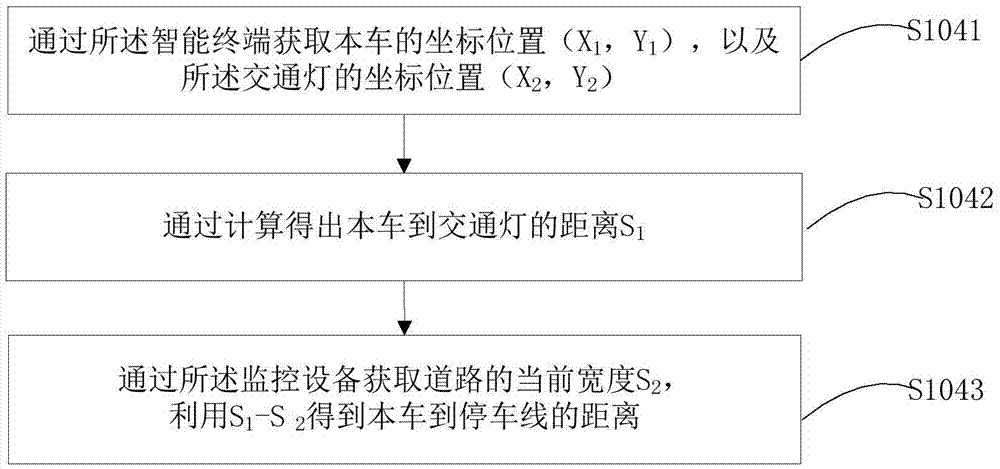

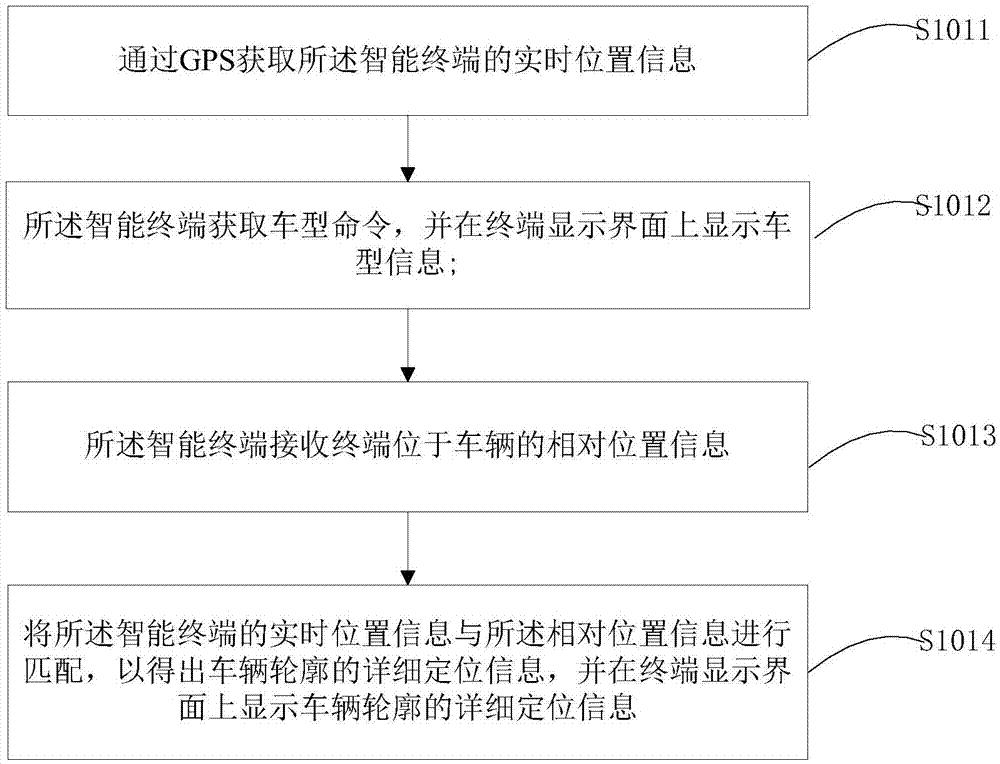

Intersection passing method and device in automatic vehicle following process

InactiveCN106920411ARelieve stressAvoid lossRoad vehicles traffic controlExternal condition input parametersControl signalEngineering

The invention discloses an intersection passing method and device in the automatic vehicle following process. The method comprises the following steps: obtaining positions of vehicles and sending a local vehicle control signal to a vehicle controller of a local vehicle to realize target vehicle tracking, wherein the positions of the vehicles comprise position of a target vehicle and position of the local vehicle; when the local vehicle tracks the target vehicle, obtaining a current road state through a monitoring device, and sending the current road state to an intelligent terminal for judgment; when the road state is an intersection, receiving a current state of traffic light sent by a traffic light control system and carrying out judgment; when the current state of the traffic light is no passage, obtaining the distance between the local vehicle to a stop line by the intelligent terminal; and when the distance between the local vehicle to the stop line is smaller than a preset value, sending by the intelligent terminal the control signal to the vehicle controller of the local vehicle to reduce the speed of the local vehicle and stop the local vehicle.

Owner:BEIJING QIHOO TECH CO LTD +1

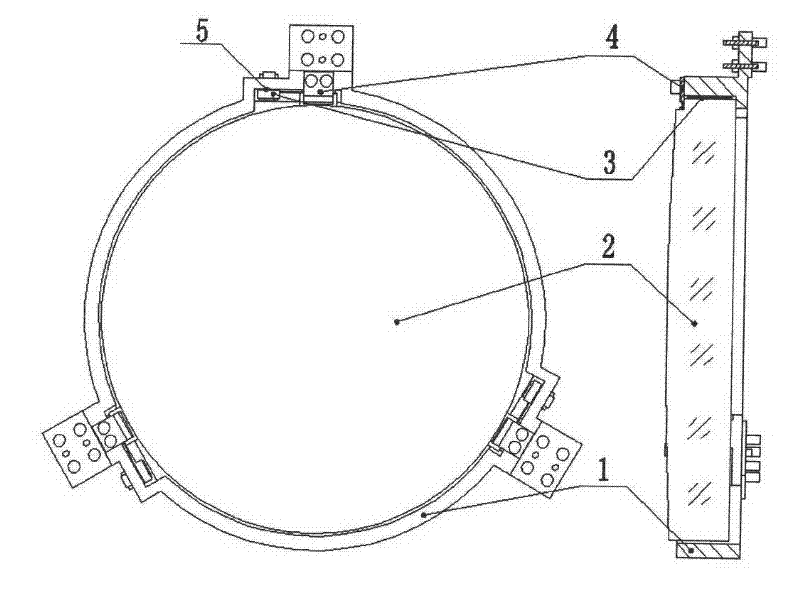

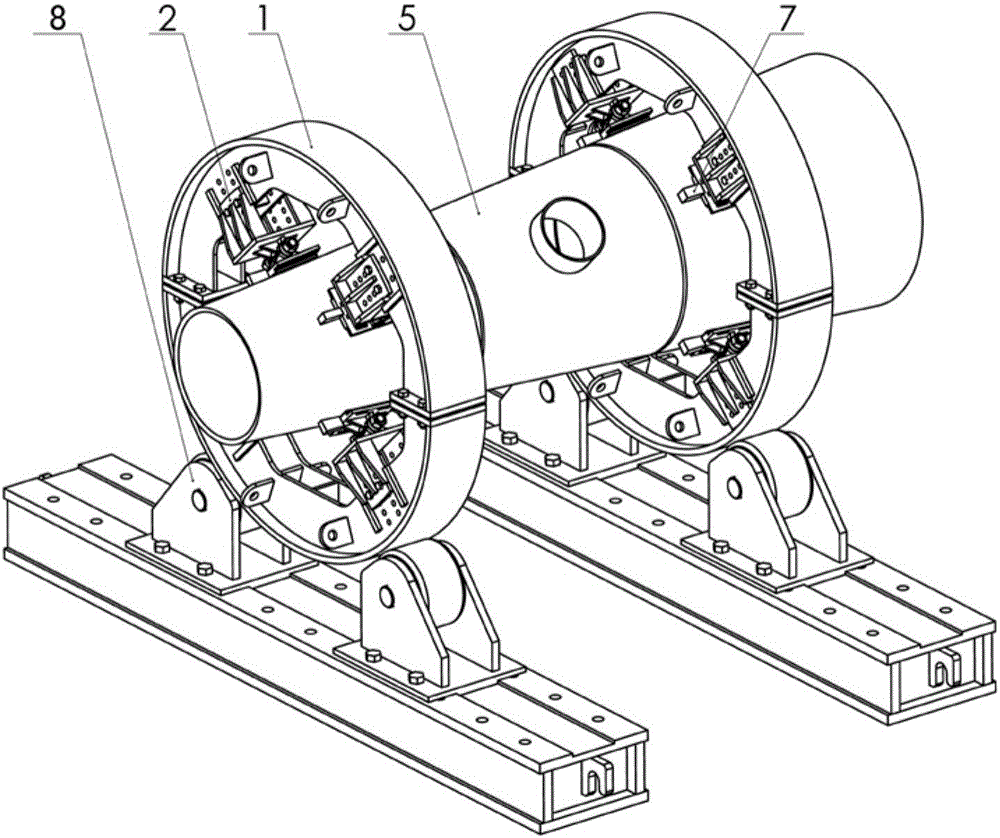

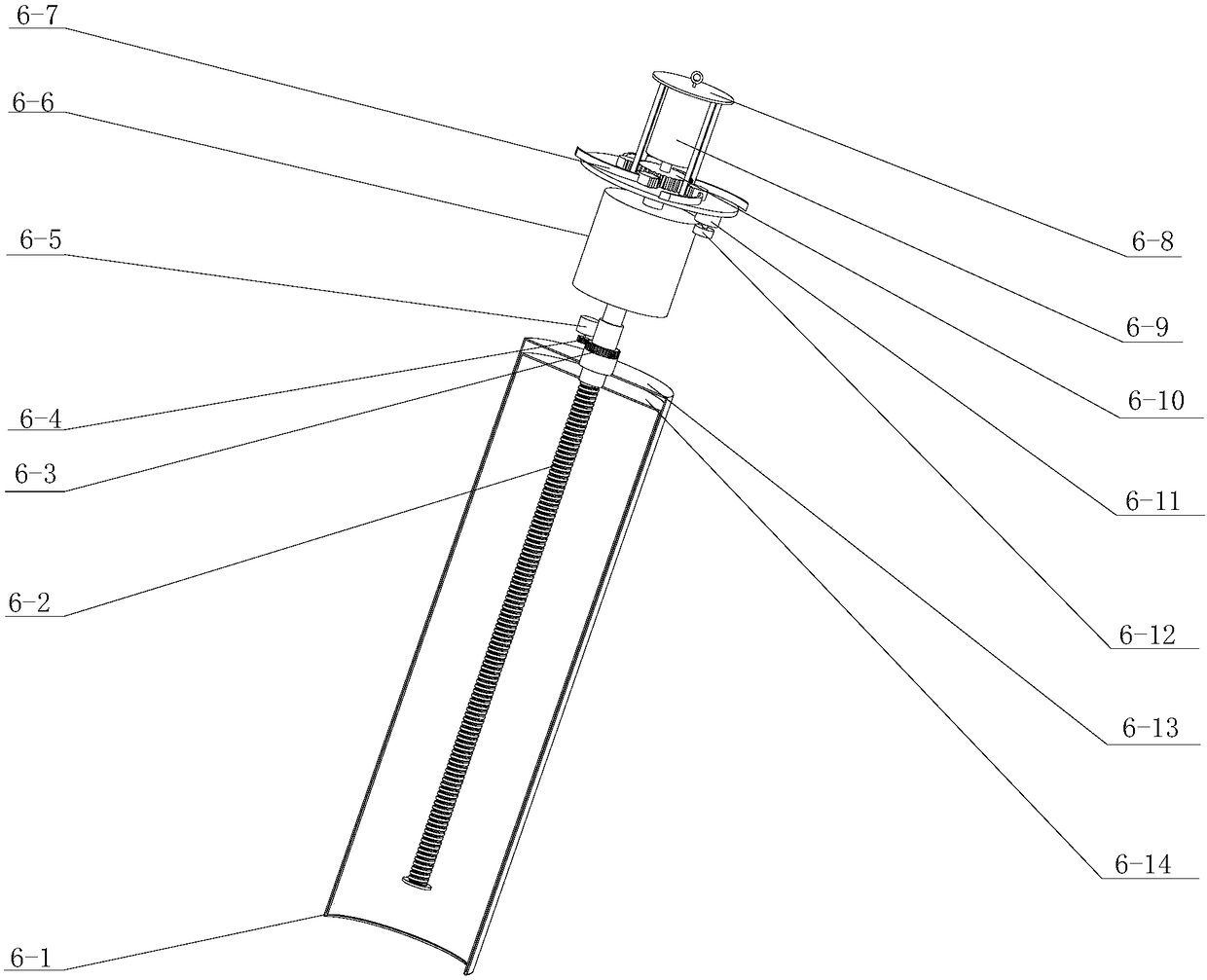

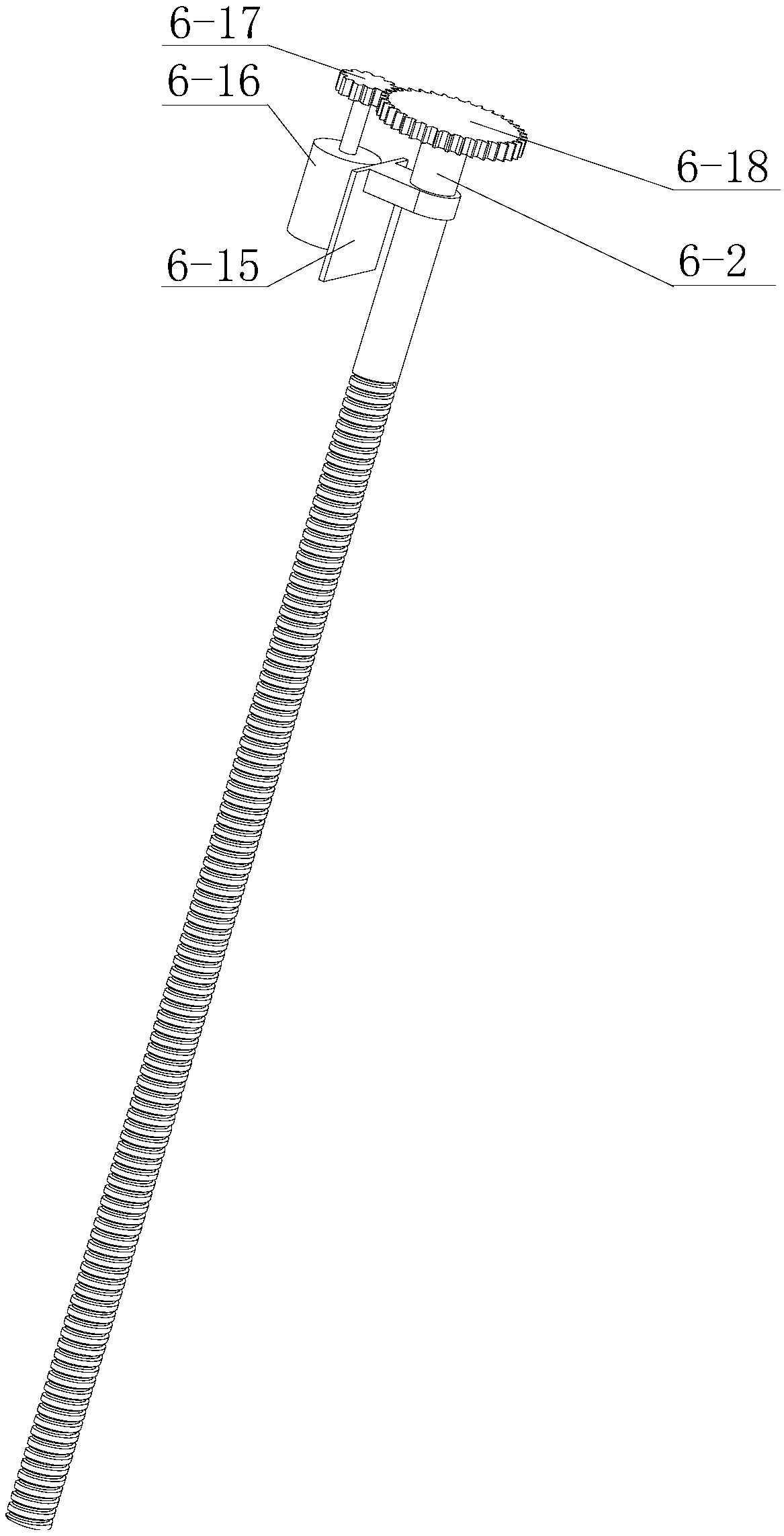

Horizontal rotating device for conical barrel body

ActiveCN106624576ASmooth horizontal rotationReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesCircular coneEngineering

The invention discloses a horizontal rotating device for a conical barrel body. The horizontal rotating device comprises support rings and hinged supports installed on the support rings, each support ring is a disc-shaped member, through holes are evenly distributed at the periphery of each support ring, and each group of through holes comprises a plurality of pairs of equidistant through holes distributed radially along the support ring. The support surfaces of lower hinged supports are uniformly in contact with the periphery of the outer circular conical surface of the conical barrel body at the same time, the horizontal rotating device is guaranteed to clamp the conical barrel body coaxially, the connection positions of upper hinged supports and the radial through holes of the support rings are adjusted, and then the distances from the lower hinged supports to the axes of the support rings are changed to adapt to clamping of the conical barrel bodies of different diameters. The horizontal rotating device is novel and simple in structure, and when the rotating device clamps the conical barrel body to roll on an idler wheel, the various operations like automatic welding for the butted joint of the long conical barrel body, multi-directional mounting on a cone body, and welding parts inside and outside the cone body are completed.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

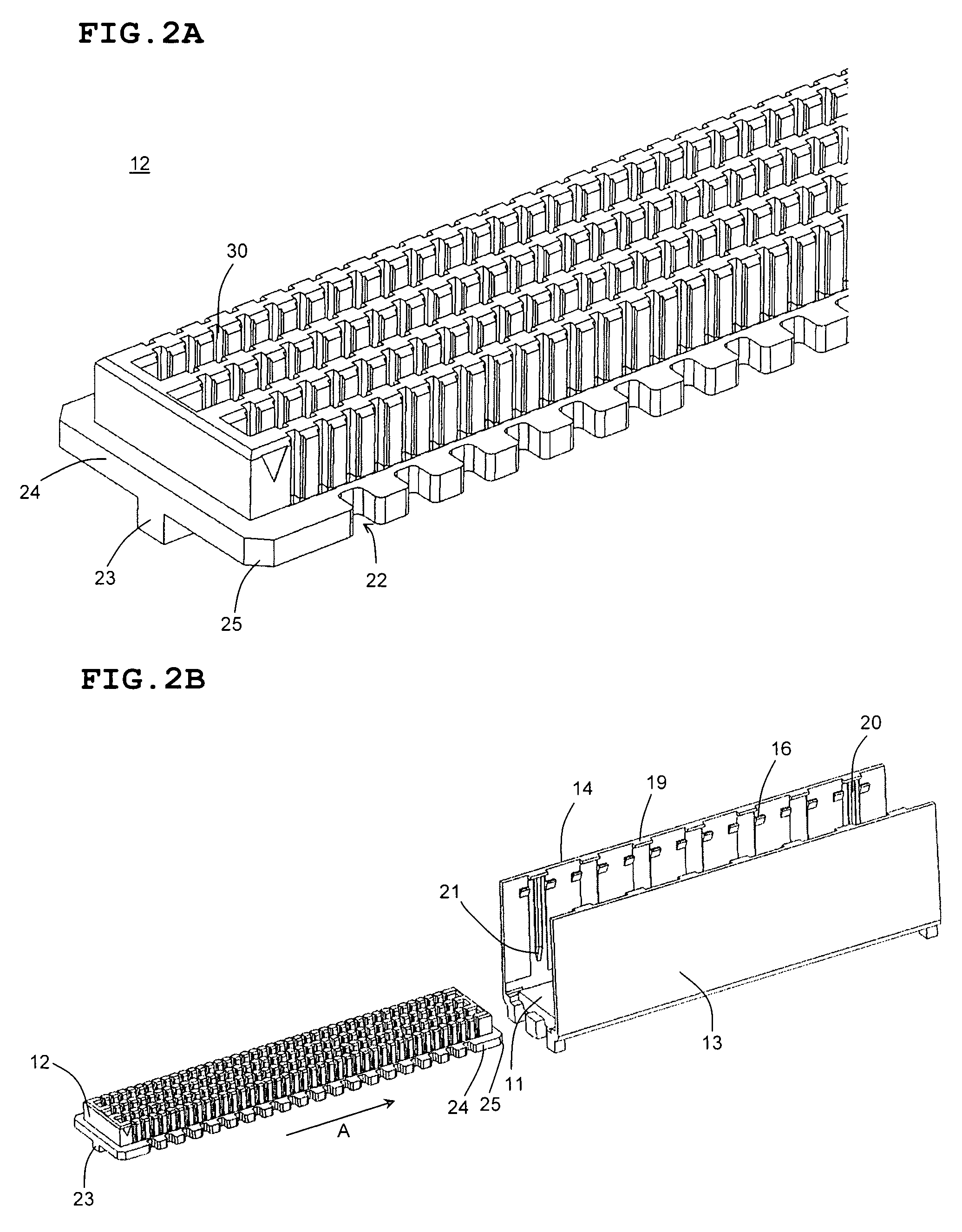

Elevated height electrical connector

ActiveUS20060246785A1Increase heightEasy to assembleContact member assembly/disassemblySecuring/insulating coupling contact membersEngineeringElectrical connector

An electrical connector includes first and second connector bodies which are arranged to first be positioned together, and then separated once electrical contacts have been inserted in at least one of the first and second connector bodies. During, after, or both during and after the separating of the two connector bodies, portions of the first and second connector bodies are in direct contact with each other. The first connector body has first and second walls extending therefrom. At least one ramp and at least one stop are arranged on at least one of the first wall, the second wall, and the second connector body. At least one protrusion is arranged on at least one of the first wall, the second wall, and the second connector body. The at least one ramp, the at least one stop, and the at least one protrusion are arranged such that, when the at least one ramp and the at least one stop engage the at least one protrusion, a distance between the first and second connector bodies is fixed.

Owner:SAMTEC

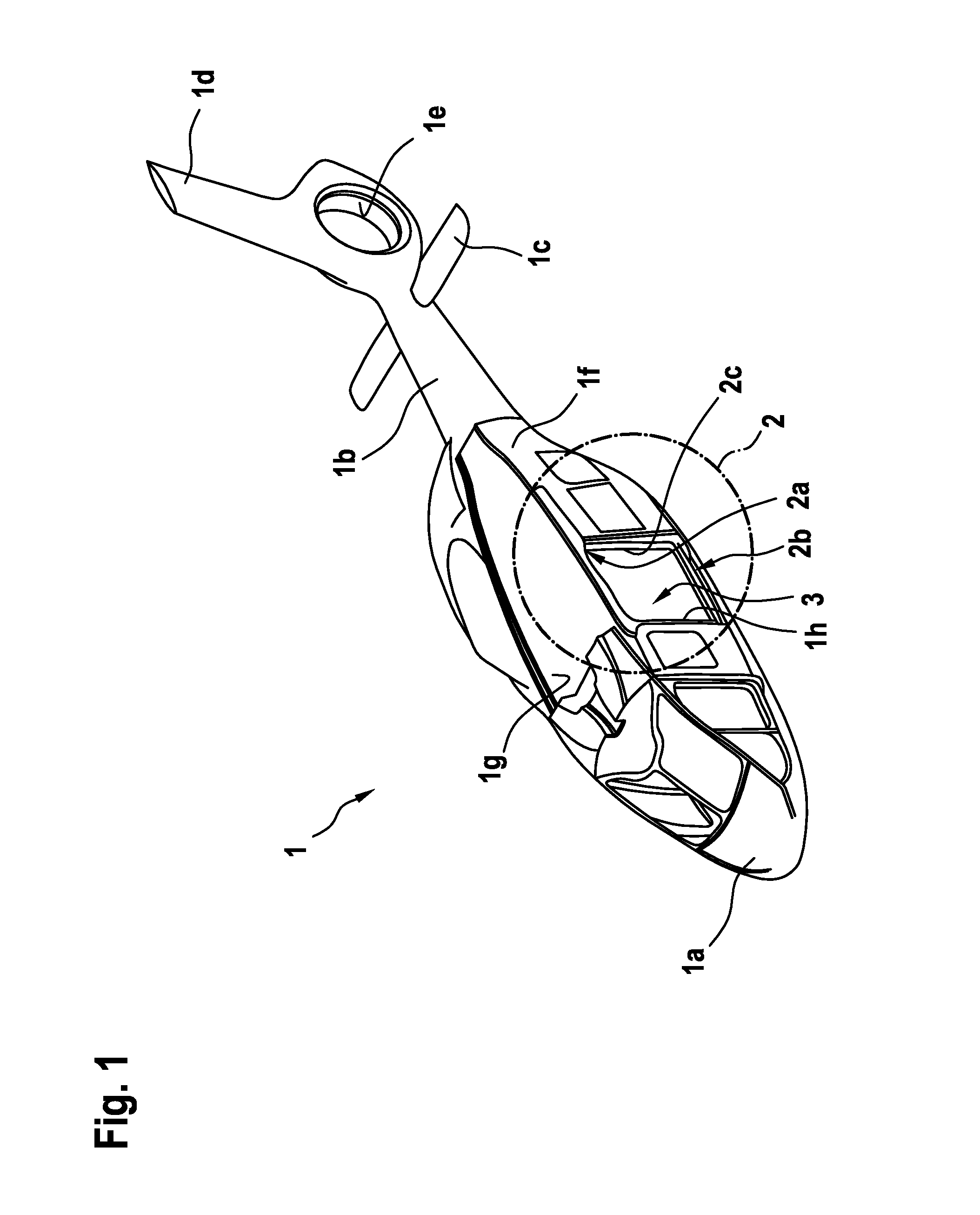

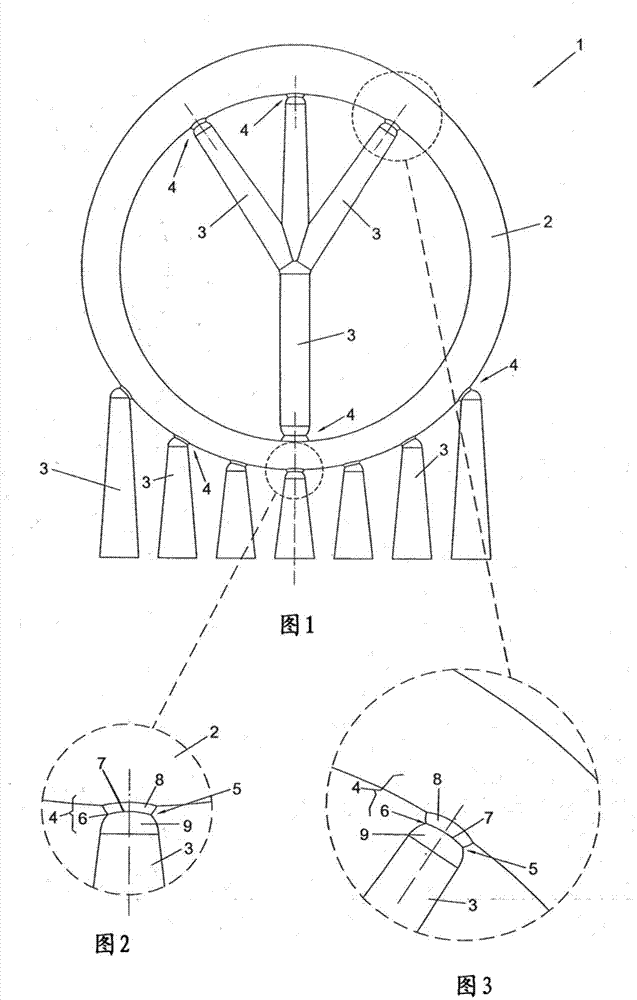

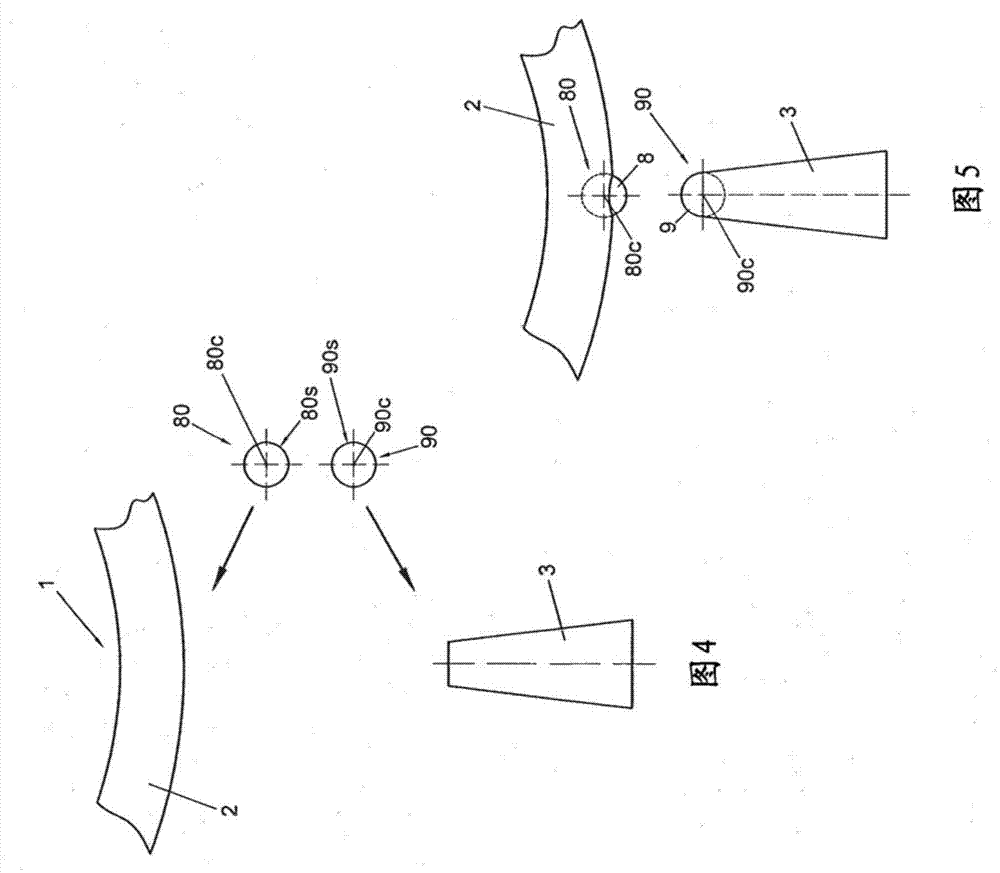

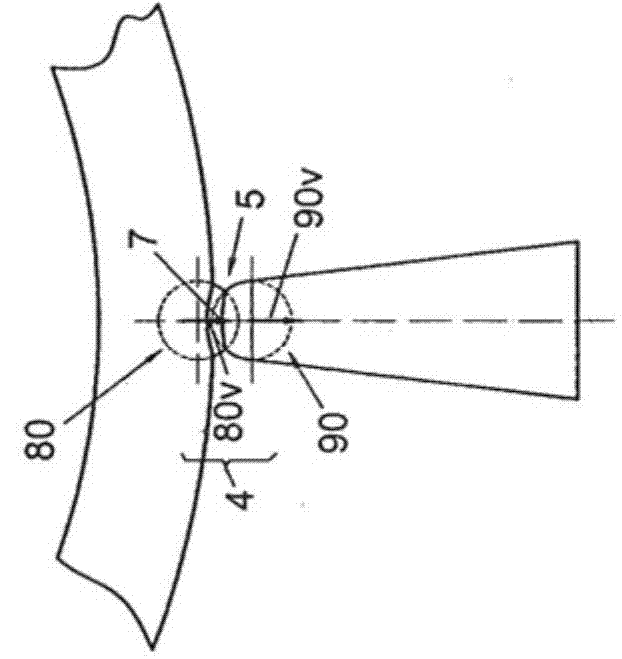

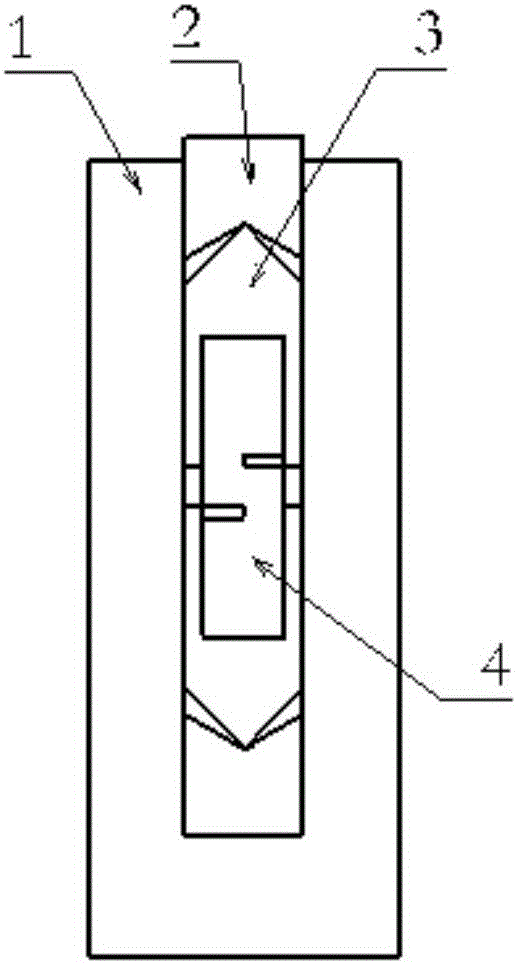

Improved three-dimensional object obtained by means of a stereolithography process and method for the computer graphic design of said object

InactiveCN103946008AEasy to removeQuick and cheap removal3D object support structuresManufacturing data aquisition/processingGraphicsComputer science

The invention is a three-dimensional object (1) made by means of a stereolithography process, comprising a plurality of supports (3) that are connected to the body (2) of the object through joining elements (4) in each one of which it is possible to identify a shaped area (5), recessed with respect to the external surface of the joining element (4) and having the bottom corner (6) that delimits a pre-established fracture area (7) for the detachment of the support (3). Each one of the joining elements (4) comprises a first body (8) projecting from the external surface that delimits the body (2) of the object and a second body (9) projecting from the support (3), the bodies (8) and (9) being connected to each other so as to define the shaped area (5) whose bottom corner (6) delimits the pre-established fracture area (7). Each one of the bodies (8, 9) has its convex curved external surface that constitutes part of the external surface of a sphere or an ellipsoid.

Owner:DWS SRL

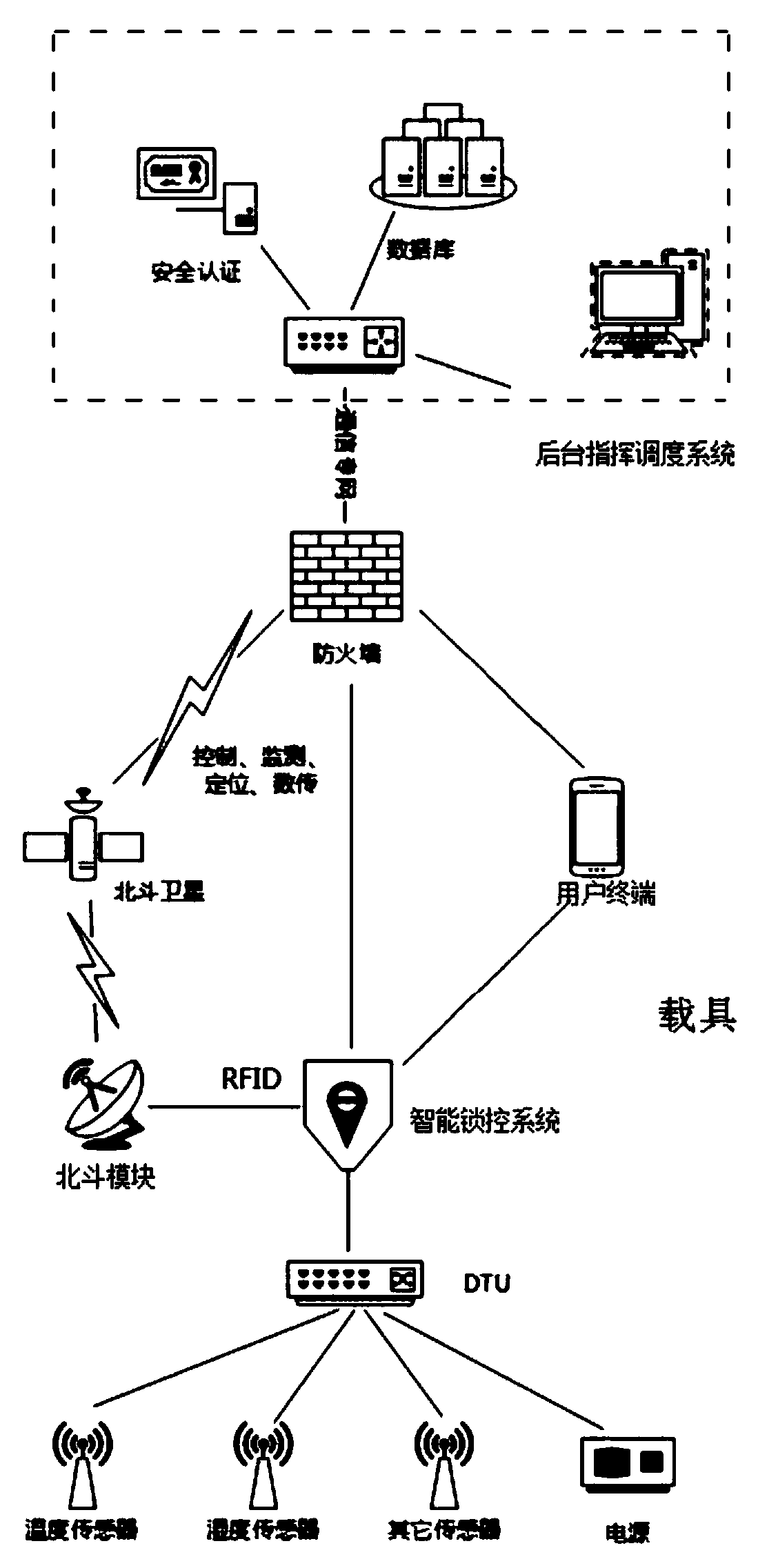

Intelligent logistics platform of dangerous-goods transportation

InactiveCN108389016AGood effectEnsure safetyCo-operative working arrangementsLogisticsTime informationLogistics management

The invention provides an intelligent logistics platform of dangerous-goods transportation. The platform includes a Beidou ground-based augmentation system, a user terminal, a carrier, an RFID module,sensors, an intelligent lock control system and a background commanding and dispatching system. The intelligent lock control system is located on the carrier. The Beidou ground-based augmentation system includes a Beidou module and a Beidou satellite. The Beidou ground-based augmentation system sends identity information collected by the RFID module and real-time information, which is of temperature, humidity, vibration and light sources and is collected by sensor modules, to the background commanding and dispatching system through a manner of Beidou short messages. According to the platform,safety of dangerous-goods transportation is guaranteed through real-time interaction of information of three parts of the Beidou ground-based augmentation system, the intelligent lock control systemand the background commanding and dispatching system, and safety thereof is usually considered to be at a level of deciphering impossibility through user identity authentication of the intelligent lock control system. Therefore, the platform is characterized by security, accuracy and real-time positioning.

Owner:王珏

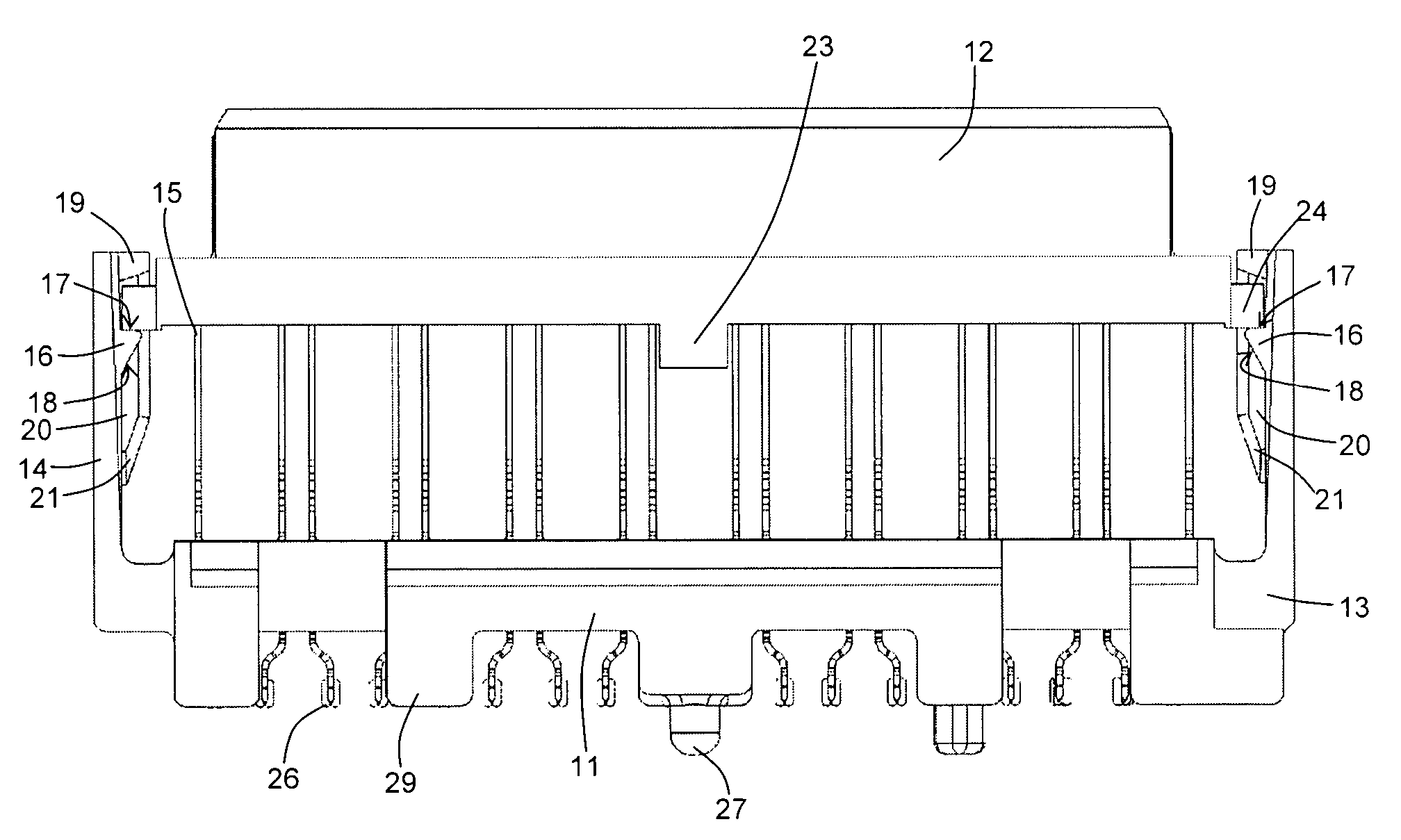

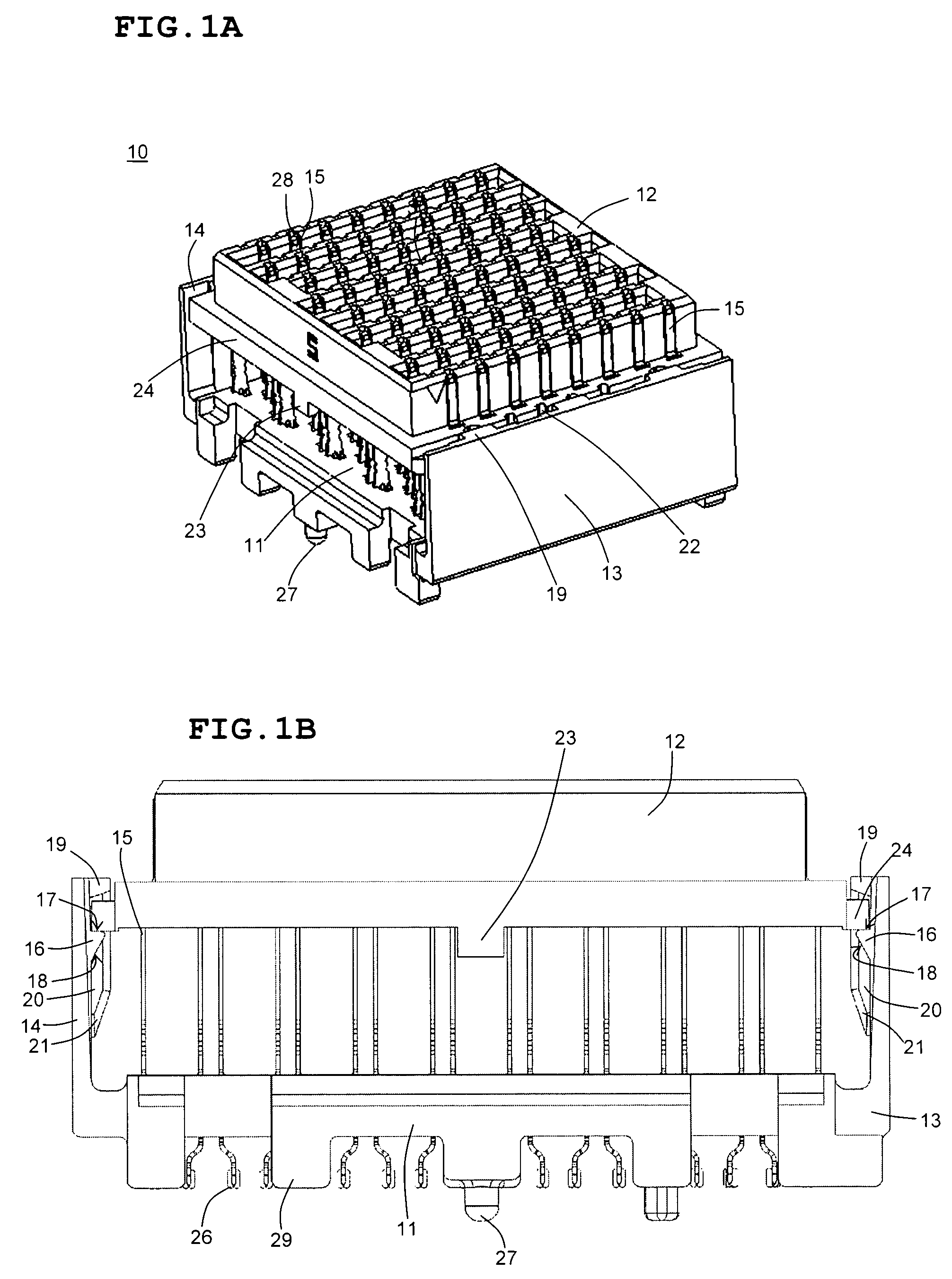

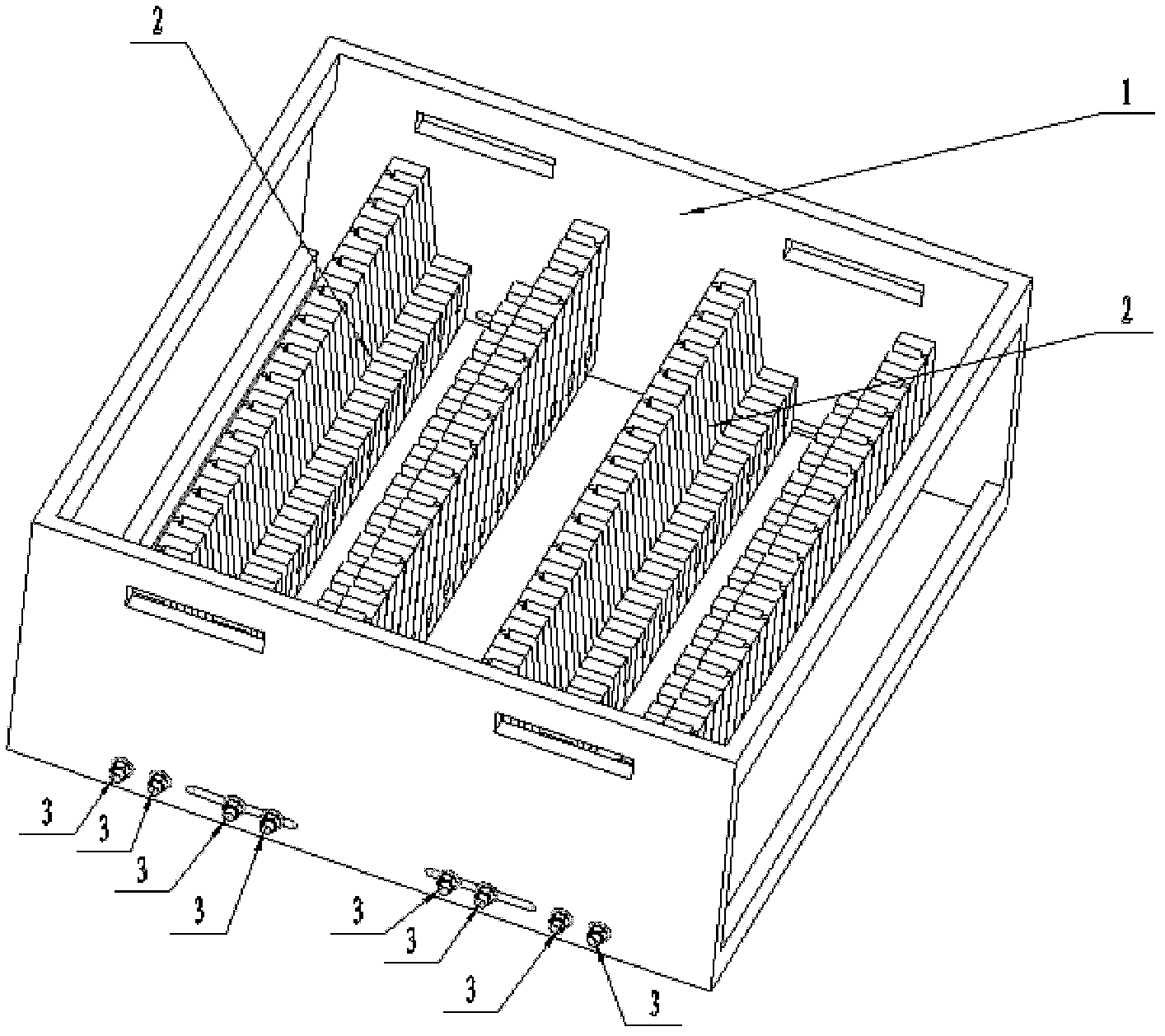

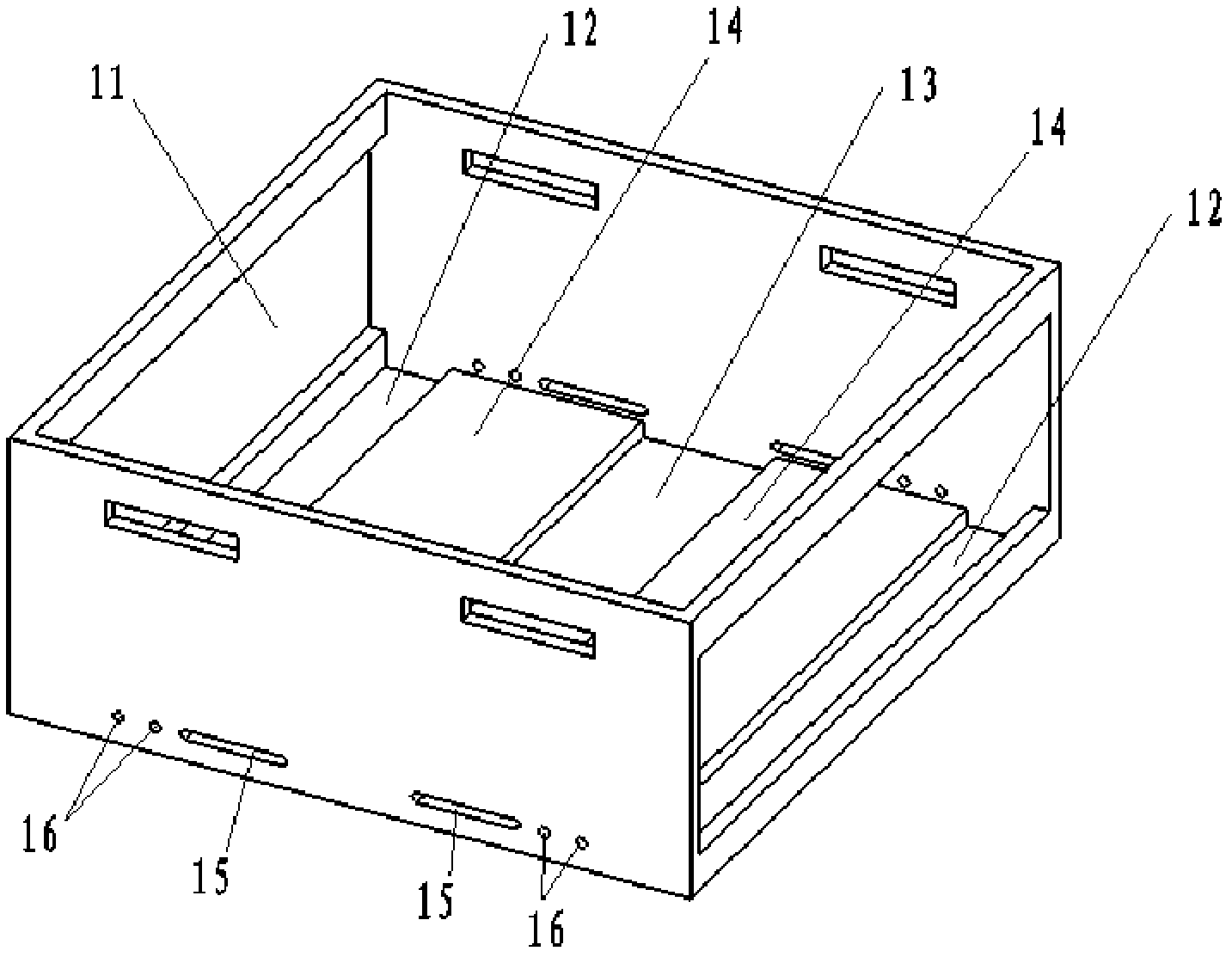

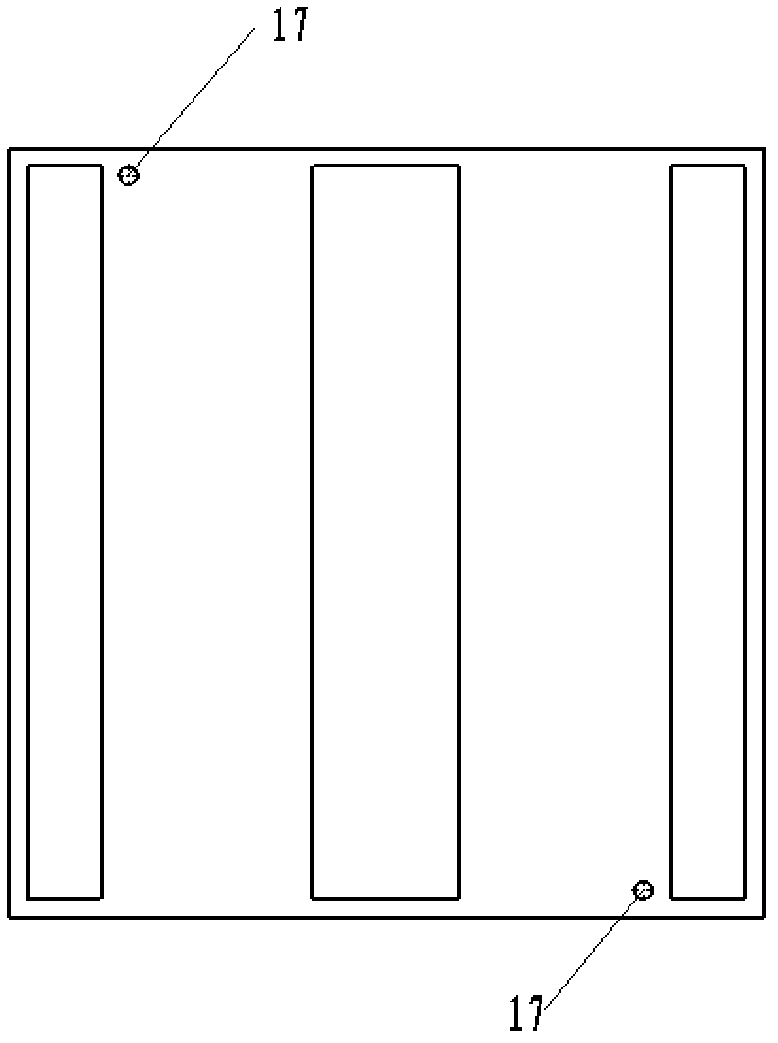

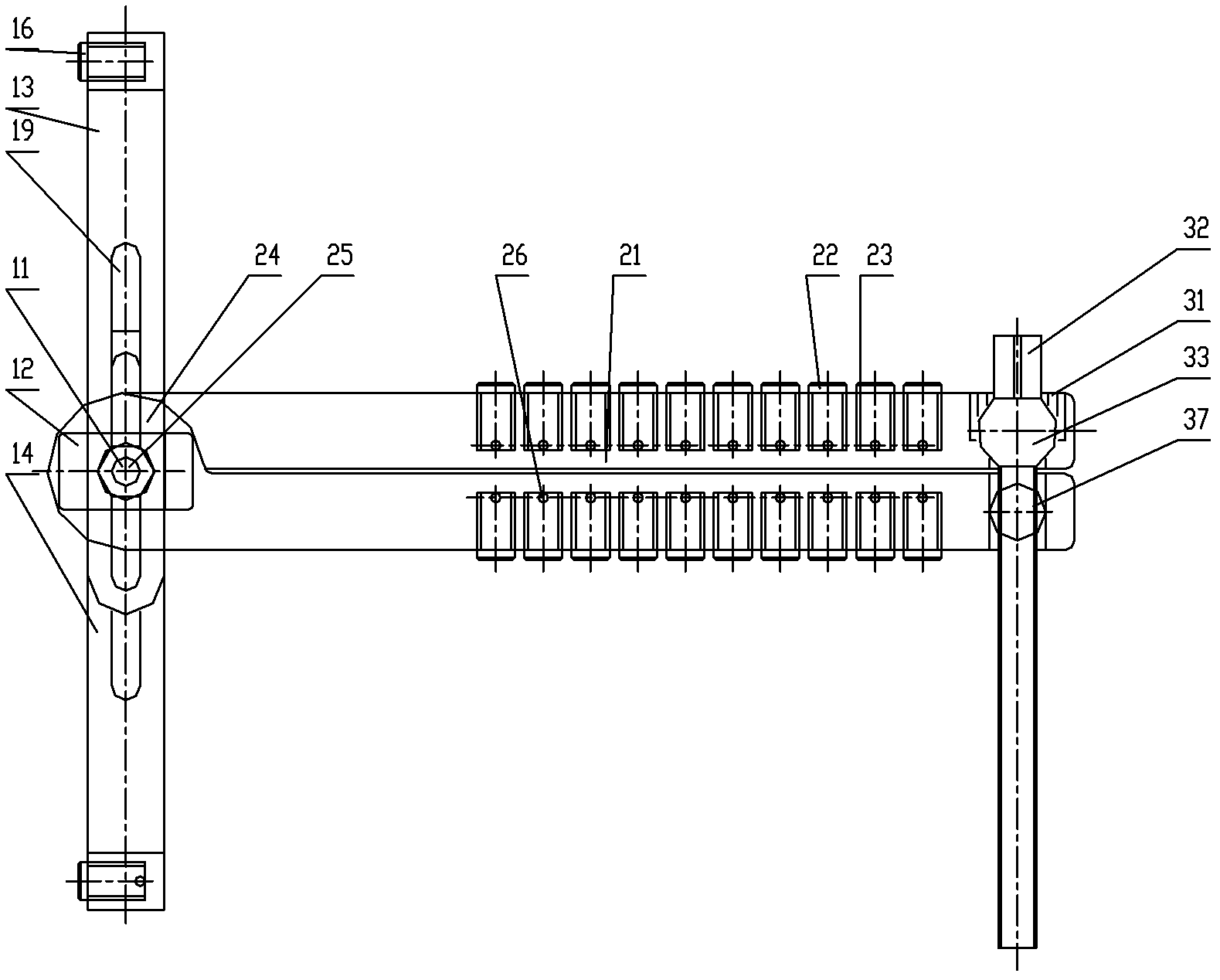

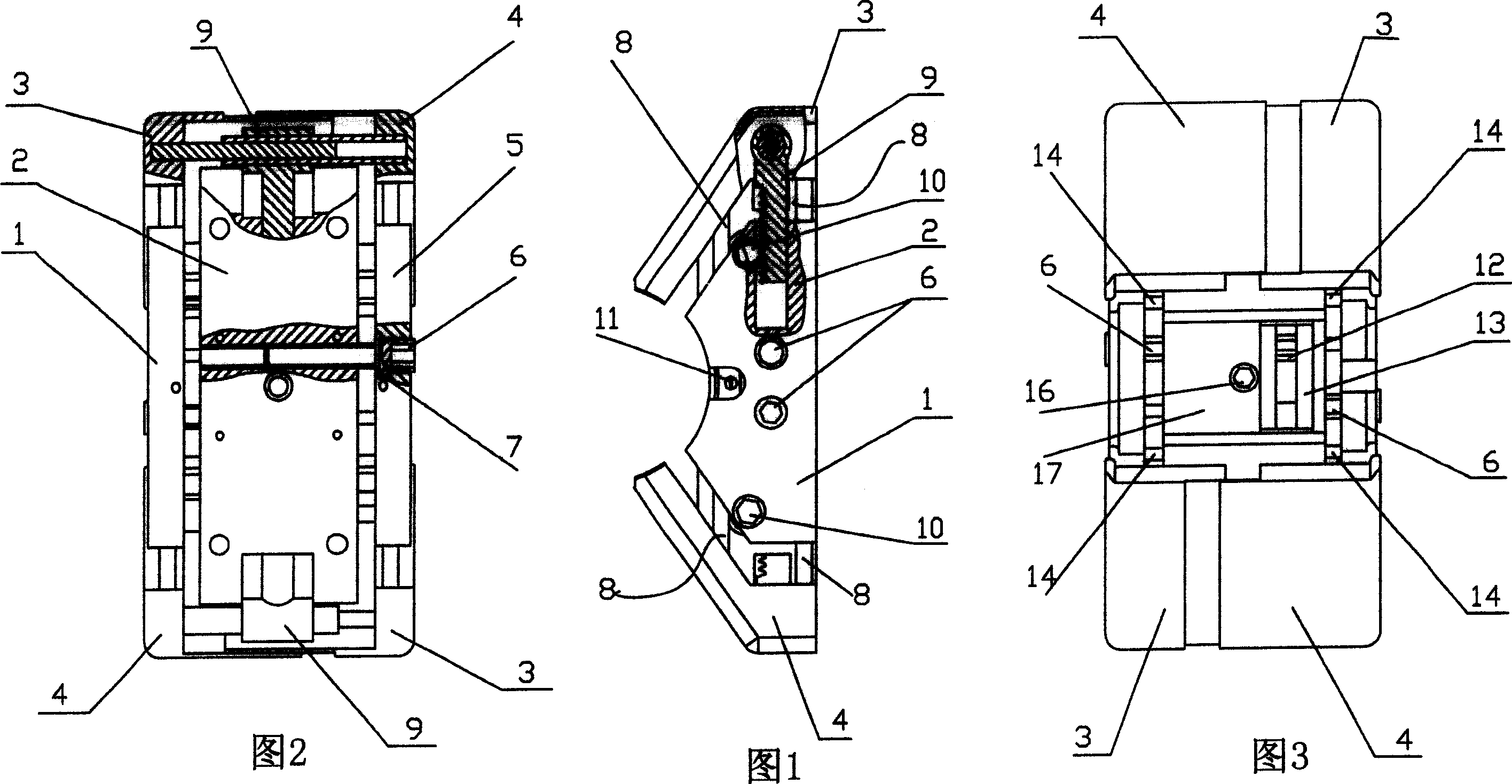

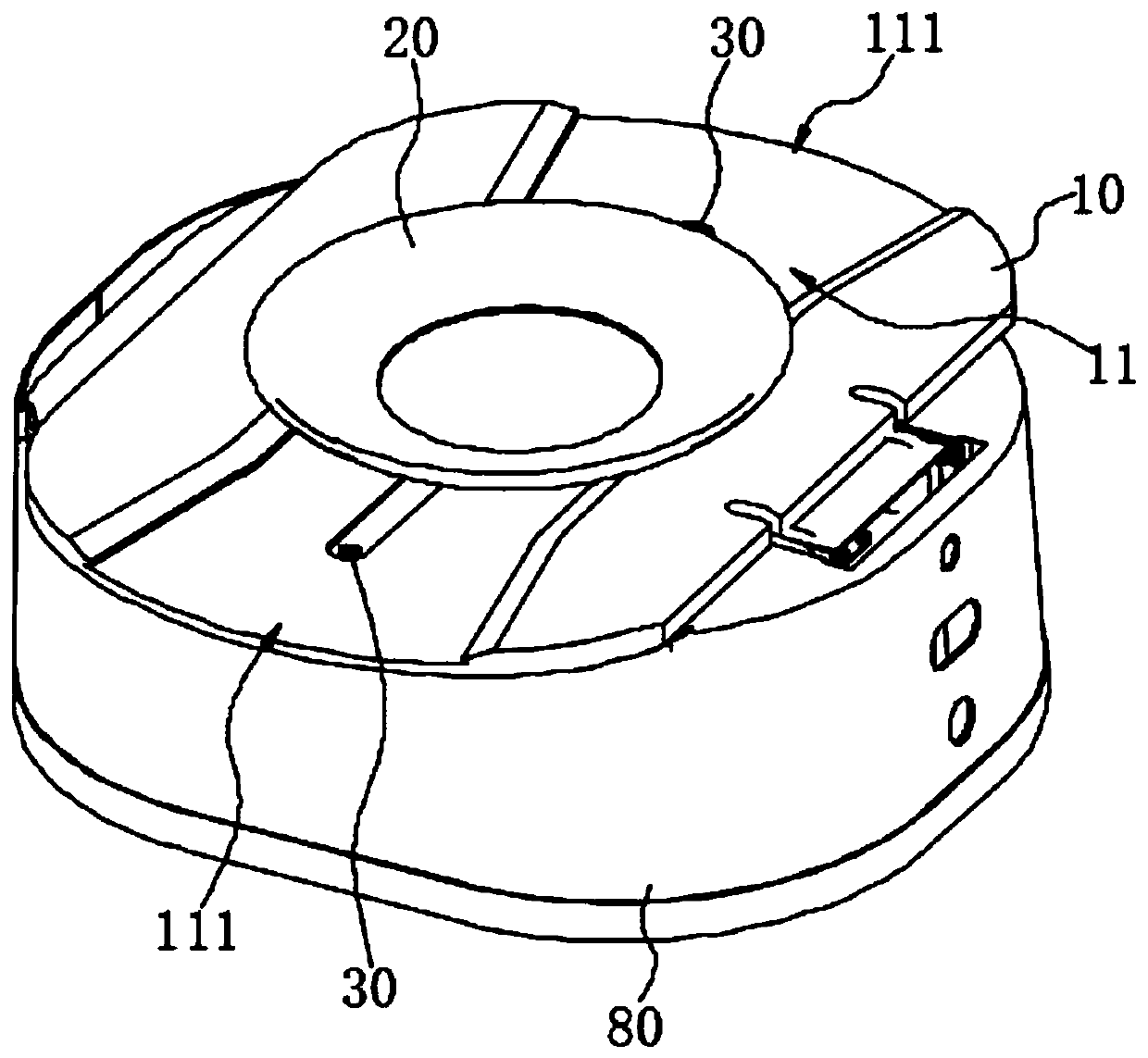

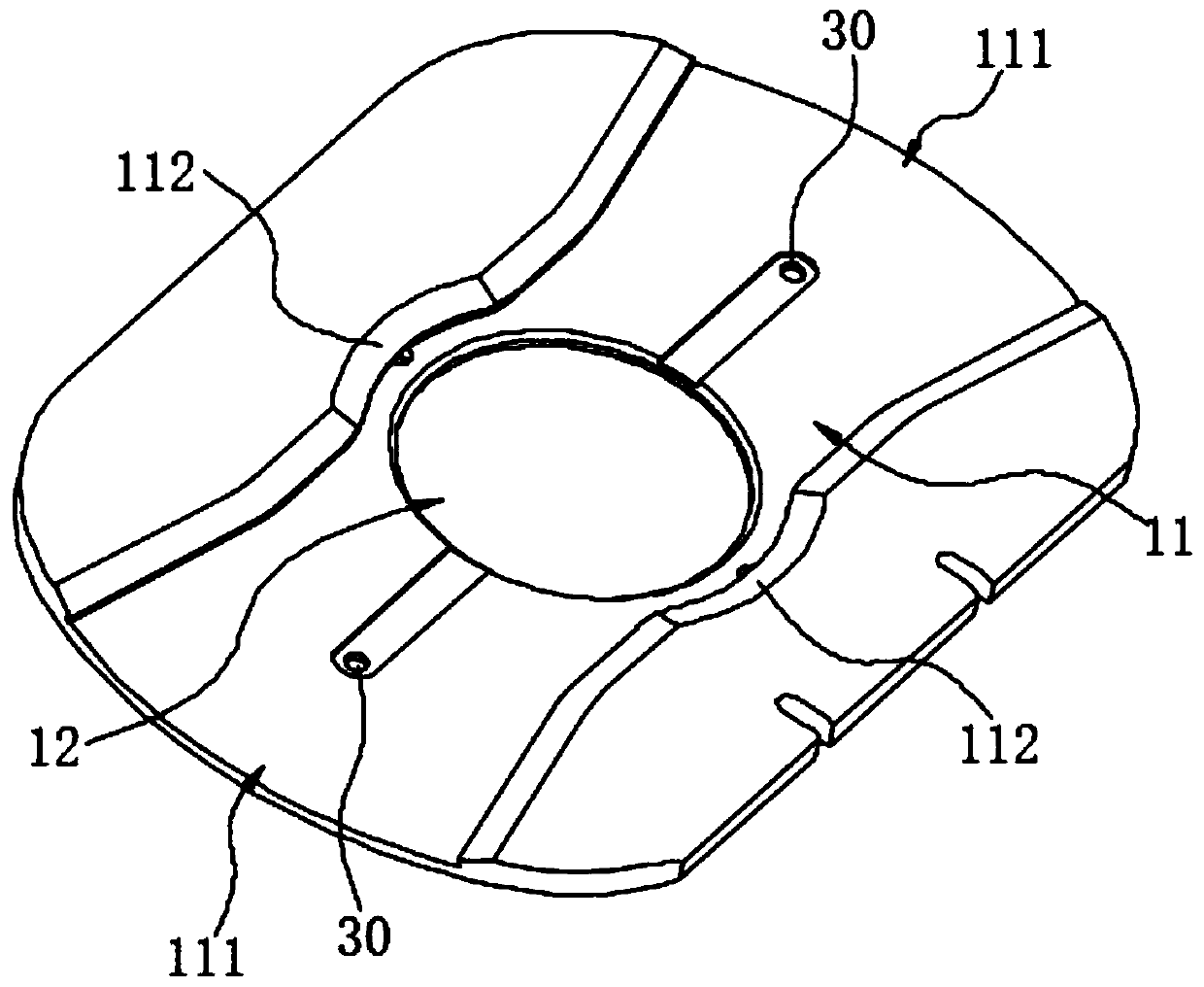

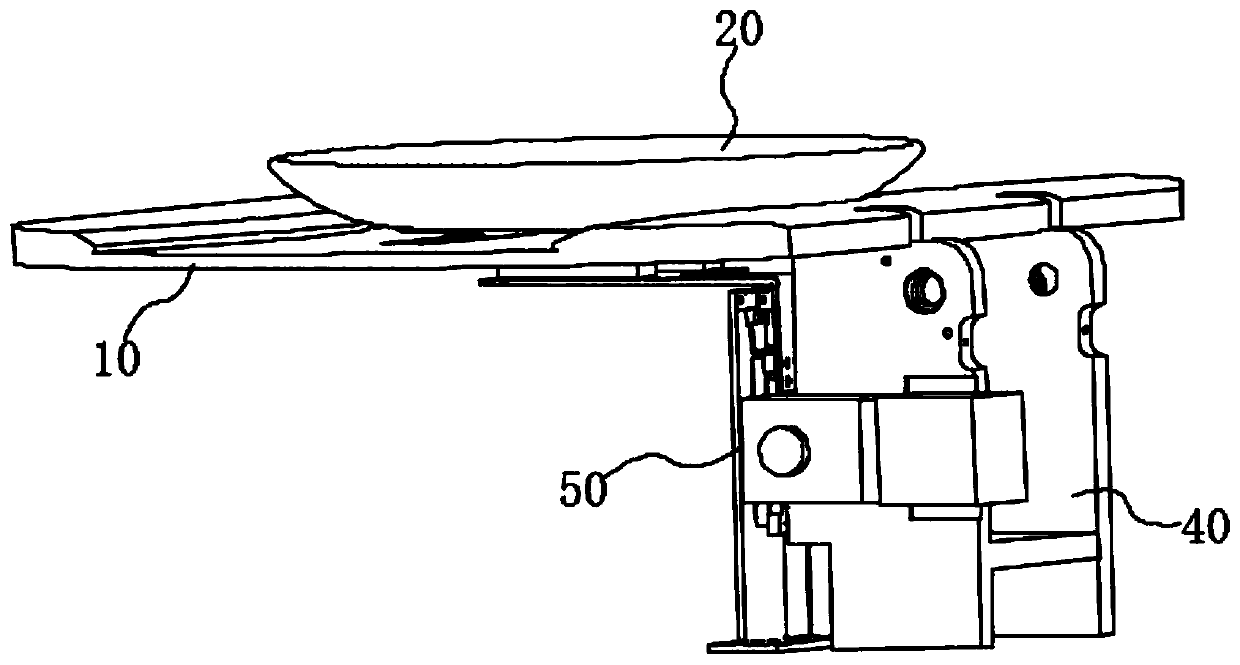

Battery tray applicable to automatic lithium battery formation production line

InactiveCN102324569APositioning is safe and reliablePrecise positioningFinal product manufactureCell component detailsProduction lineEngineering

The invention relates to a battery tray applicable to an automatic lithium battery formation production line. The battery tray comprises a tray frame body (1), battery brackets (2) and a mandril (3), wherein a plurality of battery brackets (2) are arranged in sequence and connected in series by the mandril (3) to form a bracket group, and is vertically laid on a bottom board (14) of the tray frame body (1); two ends of the mandril (3) are axially and fixedly arranged on two opposite surfaces of the tray frame body (1), and the mandril (3) can do tangential movement along waist holes (15) of the tray frame body (1). In the invention, the battery tray can be applicable to laying, delivery and charging and discharging process operations of lithium batteries of different types and different regular dimensions for both single-side electrode outlet and two-side electrode outlet, without the need of changing the tray or the bracket, and solves the problems of universality and compatibility of the battery trays in automatic production line of the lithium batteries of different types and different regular dimensions.

Owner:DONGHUA UNIV

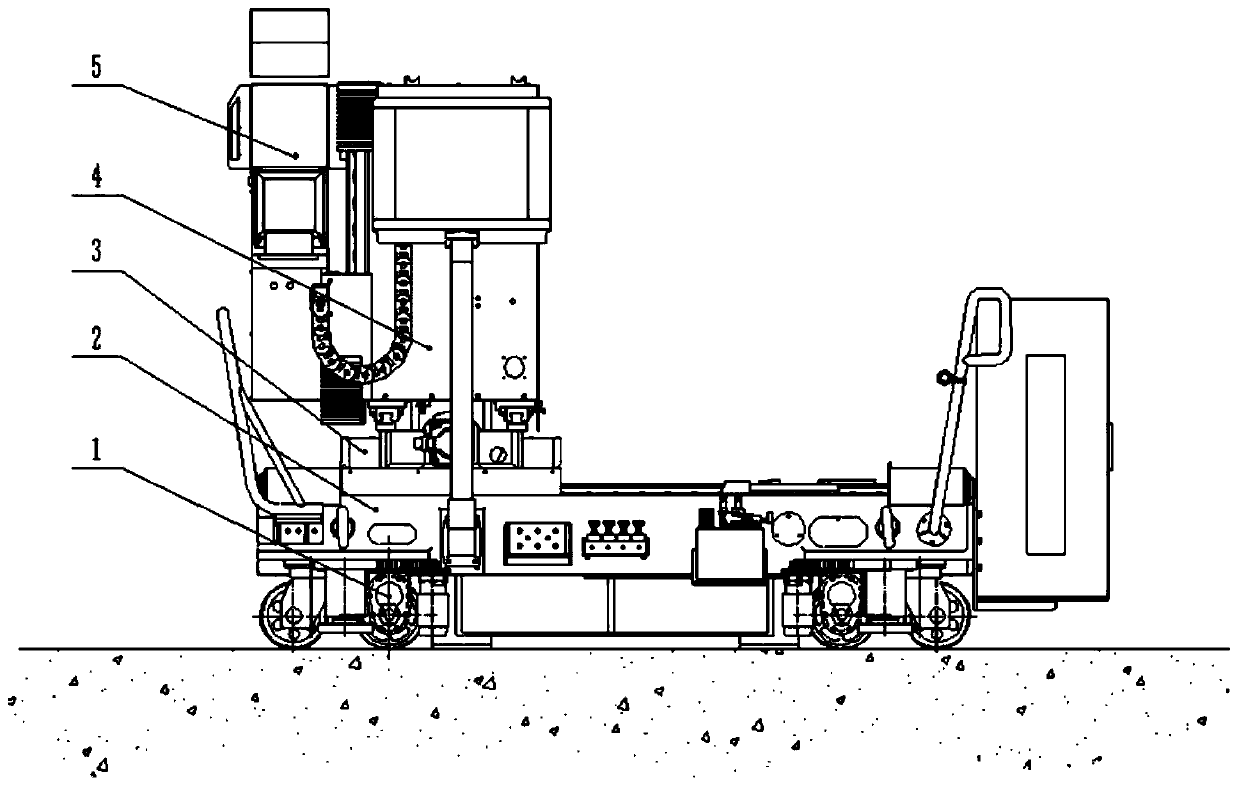

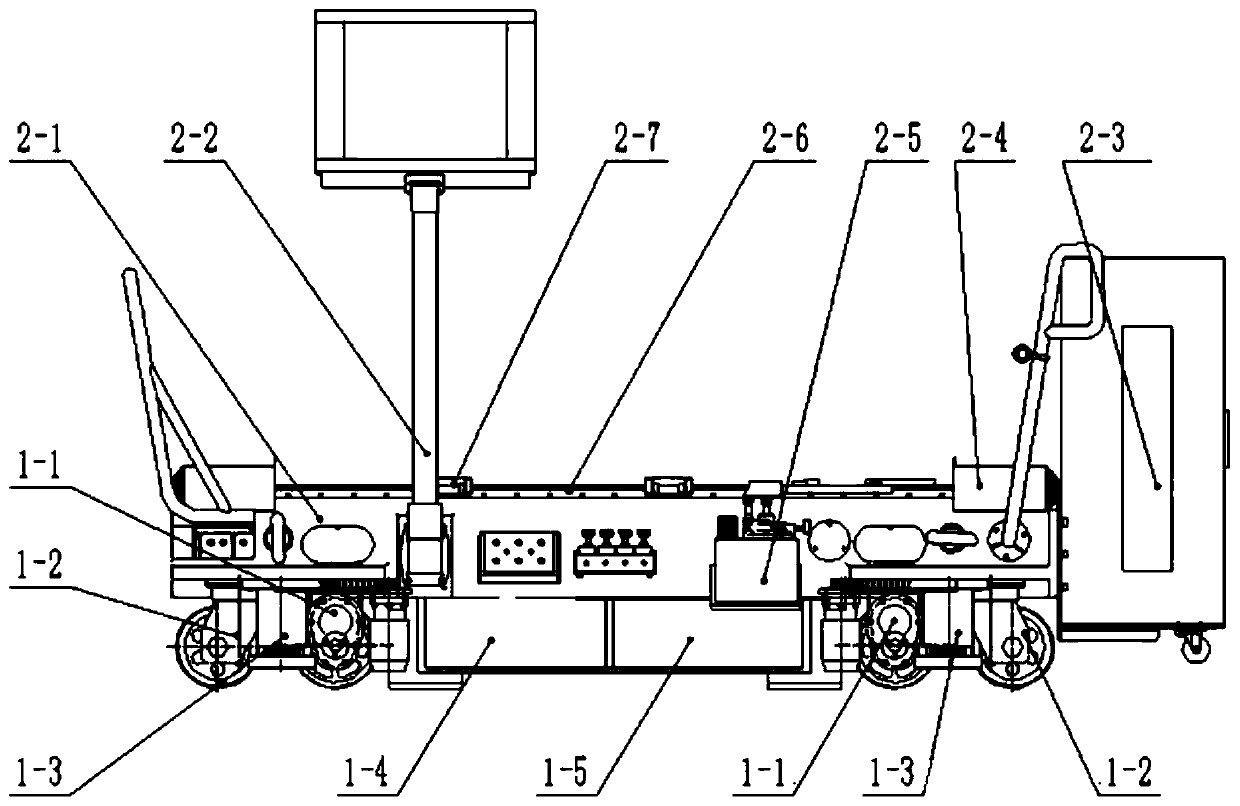

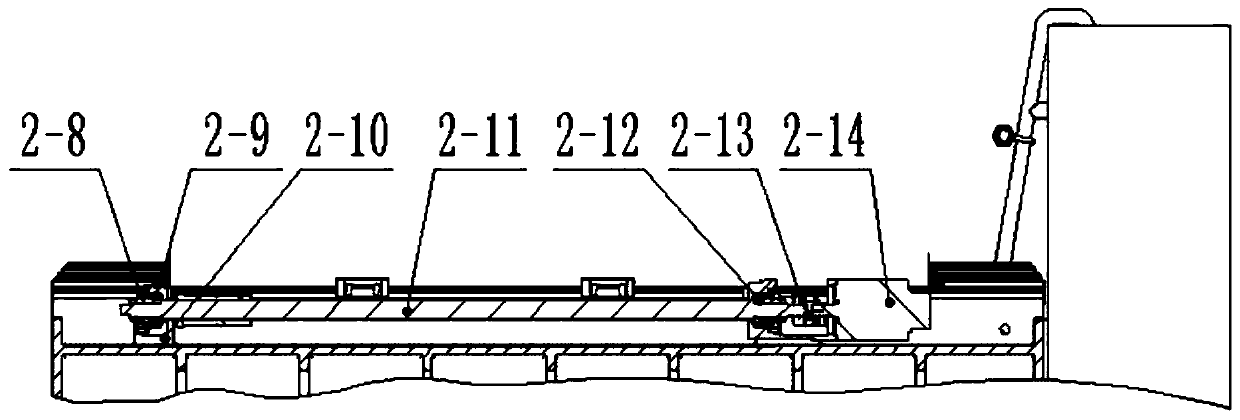

All-round self-moving type flexible multi-functional special numerical control milling machine

InactiveCN111069669ASimple structureReasonable designEdge grinding machinesGrinding wheel securing apparatusNumerical controlSteering wheel

The invention discloses an all-round self-moving type flexible multi-functional special numerical control milling machine, and belongs to the technical field of vehicle body milling. An all-round AGVchassis, an X-axis subassembly, a Y-axis subassembly, a Z-axis subassembly and a main axis subassembly are arranged from bottom to top in sequence; the all-round AGV chassis comprises two horizontal steering wheels, four universal wheels, lifting oil cylinders, an electronic control module and a storage battery. The horizontal steering wheels, the universal wheels and lifting oil cylinders are symmetrically arranged at the two ends of the all-round AGV chassis, the horizontal steering wheels and the universal wheels are installed on the bottom of the all-round AGV chassis, and the electronic control module and the storage battery are arranged in the middle of the all-round AGV chassis. The all-round self-moving type flexible multi-functional special numerical control milling machine is simple in structure and reasonable in design, a milling vehicle body can be quickly, conveniently, safely and accurately positioned, moreover, the manual work intensity can be greatly reduced, the production efficiency is improved, and the milling quality is ensured.

Owner:无锡恒久安泰智能制造有限公司

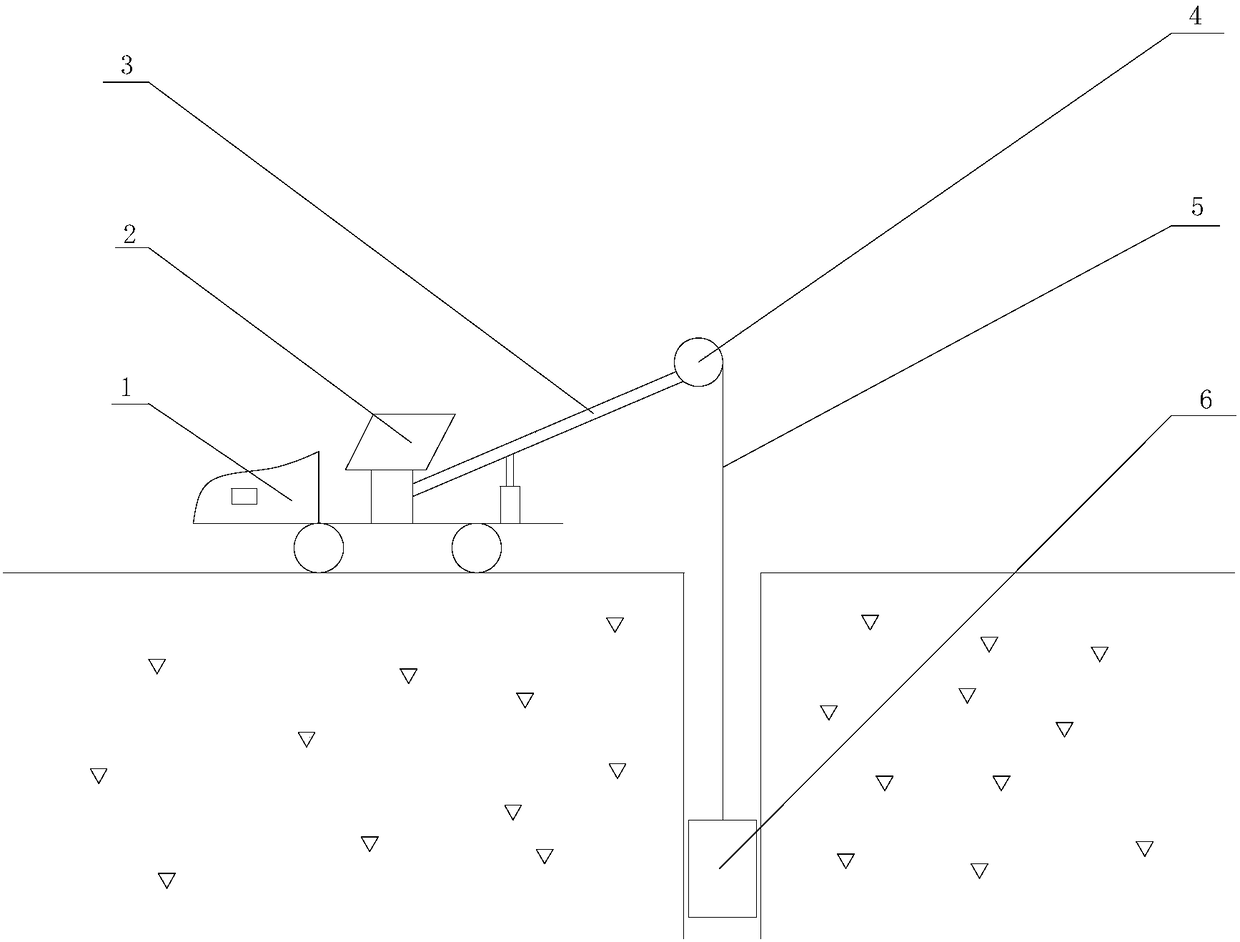

Vehicular deep-well rescue device for wellheads of different diameters

PendingCN108079465AConvenient and fast mobile rescuePositioning is safe and reliableBreathing protectionWellheadRescue vehicle

A vehicular deep-well rescue device for wellheads of different diameters is characterized in that a rescue vehicle is fitted with a control device, the control device is connected with a winch througha support, and the winch is connected with a rescue device to enter an accident well through a wire rope. The vehicular deep-well rescue device for wellheads of different diameters has the advantagesthat, for instance, the design is reasonable, the structure is simple, rescue effect is good, power provision is convenient, protection is provided for trapped staff, the device is suitable for popularization and application in the technical field of accident well rescue devices or apparatus in order to increase rescue speed and ensure good safety and high efficiency of rescuing.

Owner:XIAN UNIV OF SCI & TECH

A continuous casting tundish breathable ceramic tube upper nozzle seat brick and argon blowing refining method thereof

Owner:SHANDONG IRON & STEEL CO LTD

Clamp for assembling and expanding conducting bar of motor rotor

InactiveCN105656257AImprove tightening effectHigh positioning accuracyManufacturing stator/rotor bodiesElectric machineSmall footprint

The invention relates to a clamp for assembling and expanding a conducting bar of a motor rotor, especially to a clamp for assembling and expanding the conducting bar of the copper bar rotor of a motor, and aims at solving the problems that the length of the rotor bar stretching out of two ends of a rotor core is determined through marking lines when a present electric machine copper rotor bar is assembled and expanded, operation is complex, the rotor bar cannot be accurately positioned, lengths, stretching out of two ends of a rotor core, of the rotor bar are different, two ends of the rotor bar are not fixed when the rotor bar is expanded, and the rotor bar is easy to slip off a rotor core groove when the expanding force is over large or the direction is inclined. A circular-ring-shaped non-driving end pressure plate is connected to a driving end pressure plate through four screws, the inner circle of the non-driving end pressure plate is provided with a circular-ring-shaped stage, and four bolts are uniformly connected to the periphery of the ring stage. By adopting the clamp, the labor intensity is reduced, positioning precision of the rotor bar and the expanding effect are improved, the size is small, the weight is low, the floor space is small, and the clamp is suitable for assembling and expanding a batch of copper rotor bars at the same time.

Owner:襄阳中车电机技术有限公司

Dactylion separating and spreading device

The invention discloses a dactylion separating and spreading device. The device comprises a first U-shaped frame (13), a second U-shaped frame (14), wherein the first U-shaped frame (13) and the second U-shaped frame (14) are buckled together mutually to form an enclosed ring capable of regulating width; the opening ends of a first finger bone U-shaped frame (21) and a second finger bone U-shapedframe (27) are provided with hinges (24); the hinges are provided with hinge holes (25); and a locking screw (11) penetrates through guide grooves (19) on a guide positioning sleeve (12), the first U-shaped frame (13) and the second U-shaped frame (14). According to the invention, the defect that the additional pain caused by the cutting of the conglutination part by the existing operation methodis overcome; and by elastically regulating the spreading force of a bolt, the finger web can be separated apart naturally, the finger web can also be prolonged naturally, and natural physiological skin can be formed.

Owner:WUHAN CONSTANT SCI & TECH

Adjustable rotor coiling mould

InactiveCN101009447AIncrease profitRealize multi-purposeManufacturing dynamo-electric machinesEngineeringConductor Coil

An adjustable rotor winding former is disclosed, the upper end surface and the lower end surface matches with a group of the first model surface and the second surface which can linkage up and down, fore and back; four guiding columns of the first, the second, the third are assorted; the gear shaft set on the mould joggles with linked T type rack; a adjustable bolt is separately mounted on the first end plate and the second end plate; the relative adjustable bolt axial position is limited at the first end plate and the second end plate via the first spacer pin, the screw thread part of the adjustable bolt is connected with the tap of mould; the arc locating plate component which embeds locking screw, tongue element, arc locating plate, the third guiding column, the adjustable bolt is whorled with the mould and is assembled to the arc locating plate via spacer pin. It can realize the clamping and winding of rotor with multiple specifications, without changing mould; the structure is compact, the adjustment is easy, and the location is safe and reliable.

Owner:安明科

Weftless bandage tape compression cutting method

ActiveCN105784469ASafe installationEasy loading and unloadingMaterial strength using steady shearing forcesAirplaneBandage

The invention belongs to detection technology and relates to a weftless bandage tape compression cutting method. The method includes that a split positioning structure which can effectively contact with a product sample is adopted; a special clamp is designed, a tensile machine is utilized for a compression experiment of a weftless bandage tape, namely a glass fiber product after being cured and formed, the problem that inside tissue cannot be detected after rotors of airplane products are manufactured well is solved, and the rotors after being formed are ensured to meet quality requirements on the products. The clamp is safe and reliable to mount, simple to demount and convenient to assemble, angles of parts in the clamp are set to enable stressed direction to accurately ensure fiber direction of a testing sample. The clamp has a rigid connection function and meets the quality requirements on the rotors of the airplane products. The objectives of safety and reliability of the glass fiber product in the rotors are achieved, and requirements on integral quality of rotor products are met. The structure is reliable in positioning, firm in clamping and simple and convenient to operate.

Owner:HARBIN

Lining plate device for impact plate of impact crusher

InactiveCN102145311AEasy to install and maintainPositioning is safe and reliableGrain treatmentsEngineeringShear force

The invention discloses a lining plate device for an impact plate of an impact crusher, which comprises an impact plate body and a lining plate, wherein the lining plate is fastened on the impact plate body through a connecting bolt; the contact surfaces of the impact plate body and the lining plate are respectively provided with a transverse square groove at corresponding positions; a square key pin is keyed in a square hole formed by closing the two square grooves; or, the surface of the impact plate body in contact with the lining plate is provided with a transverse square groove, the surface of the lining plate in contact with the impact plate body is provided with a transverse square convex key corresponding to the transverse square groove, and the square convex key and the square groove are closed together. The lining plate device disclosed by the invention can transfer the transverse impact force applied to the lining plate to the impact plate body so that the shear force and the transverse impact force borne by the bolt used for connecting the lining plate with the impact plate body are greatly reduced, and the accident of falloff of the lining plate, caused by cracking and loosening of the bolt, is prevented effectively. Meanwhile, the used impact plate lining plate with a thrust structure is convenient to install and maintain, the lining plate is positioned safely and reliably, and the service life of the impact plate is prolonged effectively.

Owner:NANJING KISEN INT ENG

Self-positioning device and intelligent serving trolley

ActiveCN111358180AAddress reliabilityHigh working reliabilityFurniture partsServing tablesEngineeringMechanical engineering

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

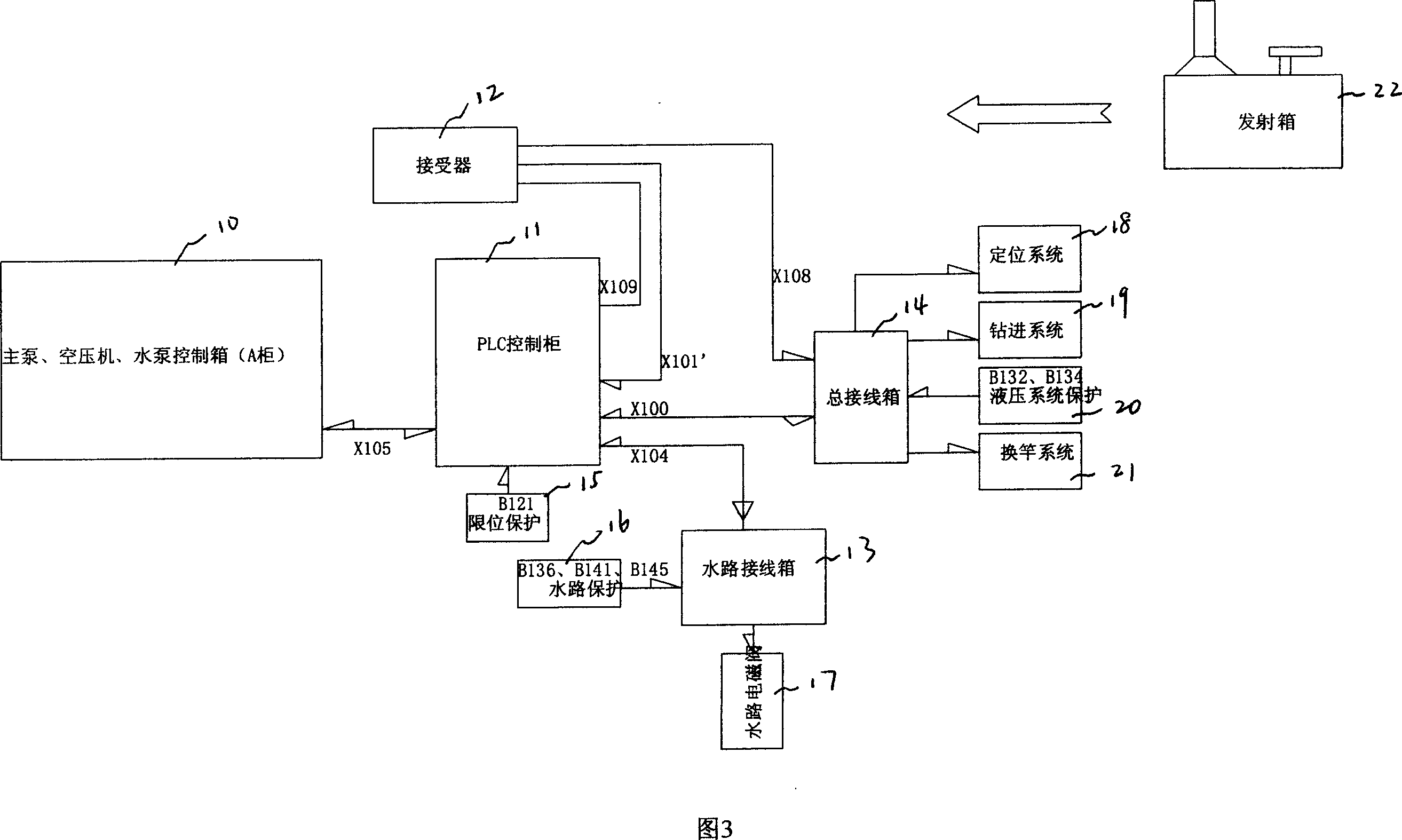

Medium sized or large sized hole drilling flat car wireless remote controller

InactiveCN101042050AEasy conversionPrecise positioningSlitting machinesAir compressorPosition control

It relates to a ore radio control device, especially for drilling, robot, positioning control and so on. It can reach any hostile conditions with convenience. The big and medium drilling hole truck radio control device comprises the receiving and emitting devices with main pump, air compressor, water pump control case connected to the PLC control cupboard that connects to the receiver and the limit protecting device, water path connecting box and the bus connecting bus, the receiver connecting with the bus connecting box, water path connecting box connecting water path protector and electromagnetic valve, output of the bus connecting box connecting to the linking positioning system, drilling system, hydraulic protection system and the pole change system. The emitting device is ERCULESA2-P2S type. PLC sends out instructions through internal programs, controls the operation of the main pump, water pump, drilling oil path and water path through the relay at the output with LED. It can controls the operation of the robot directly.

Owner:宝钢集团上海梅山有限公司

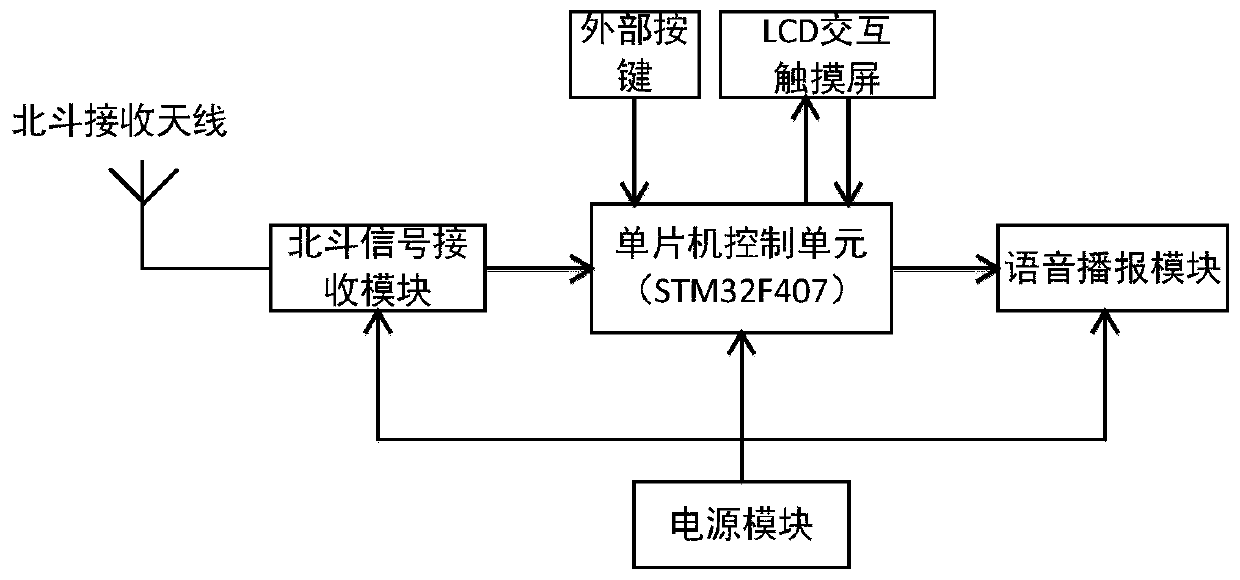

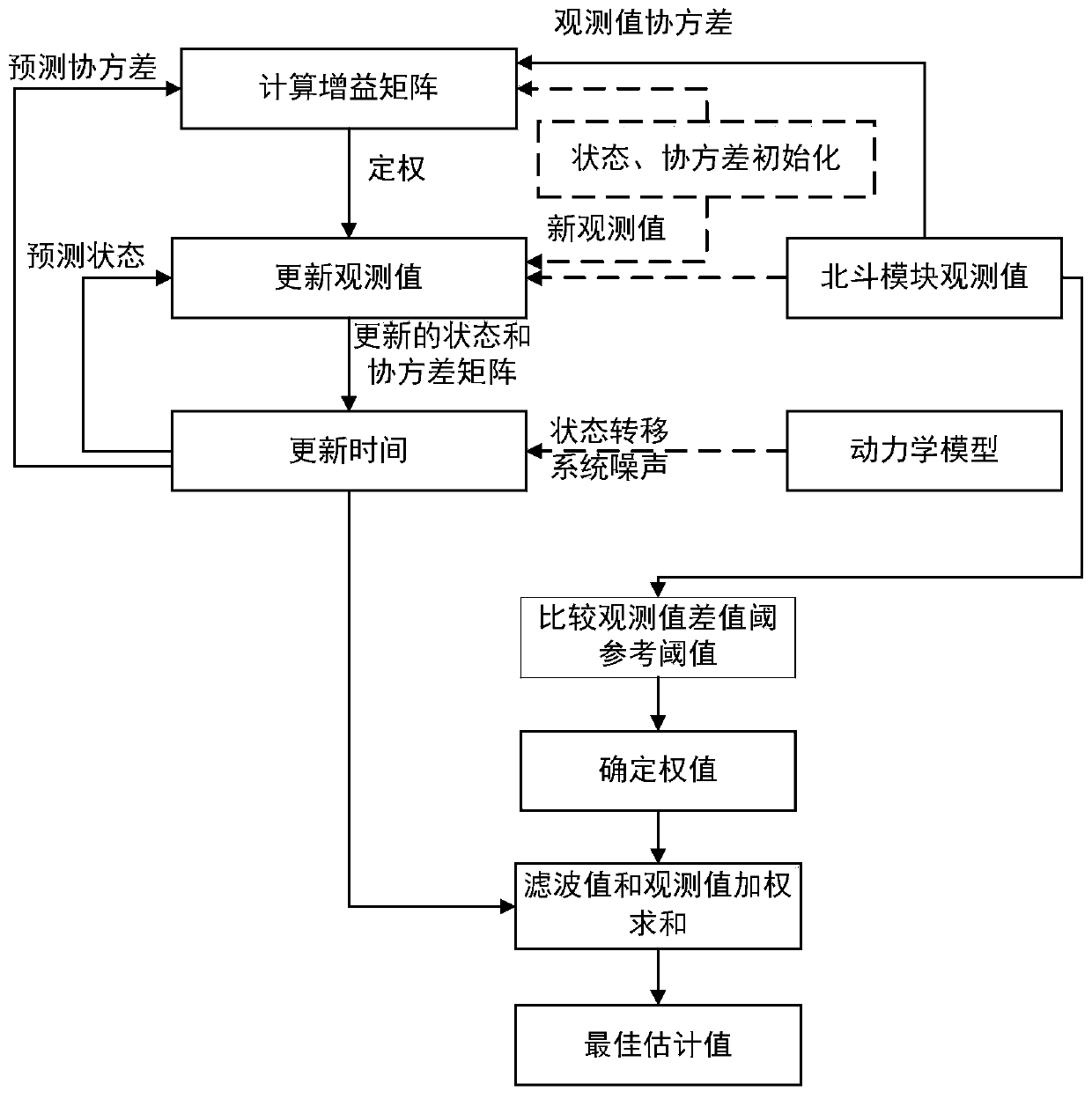

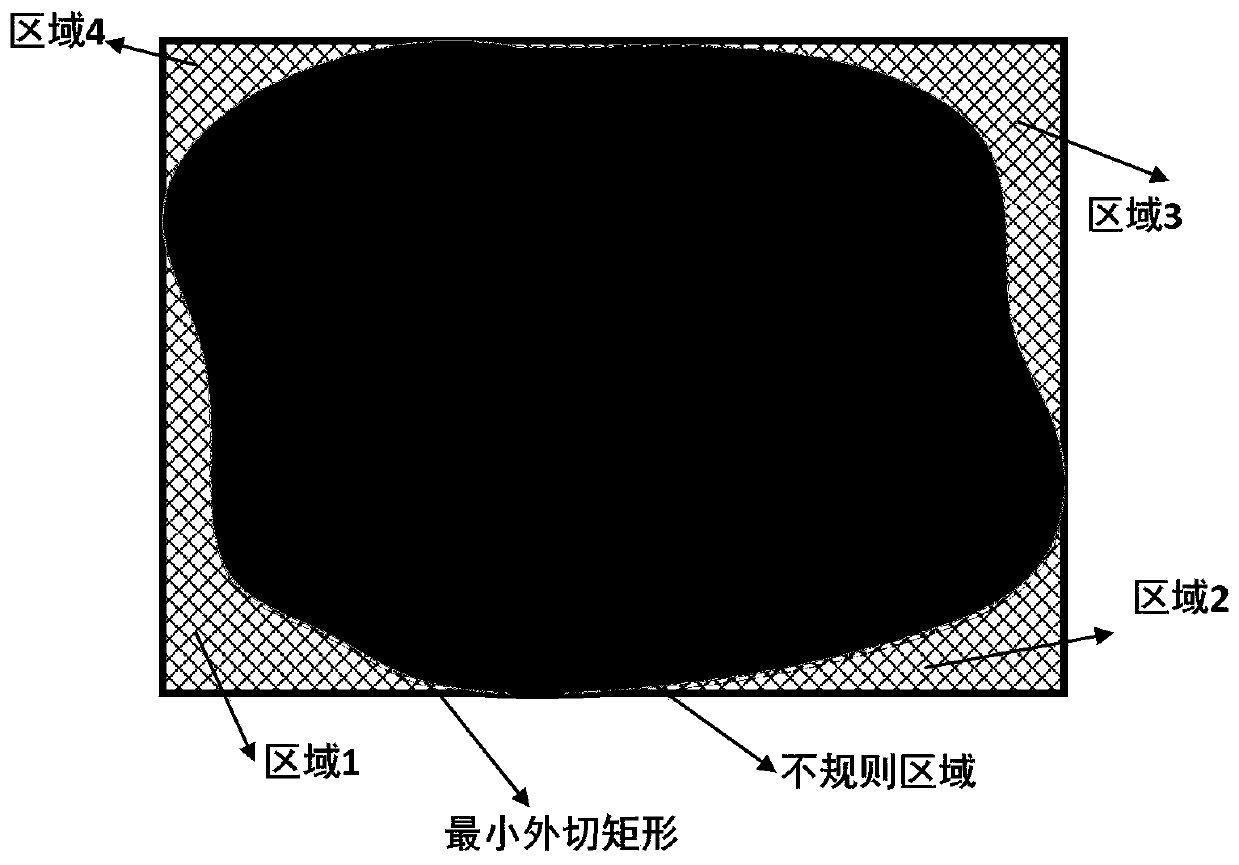

Parcel area measuring device and method based on Beidou positioning

PendingCN109883321AHigh degree of fitHigh precisionElectric/magnetic area measurementsMicrocontrollerLongitude

The invention discloses a parcel area measuring device and method based on Beidou positioning. The parcel area measuring device comprises a Beidou signal receiving module, a singlechip module, an interactive touch screen module and a power supply module. The Beidou signal receiving module is used for receiving information sent by Beidou satellites, the power supply module provides stable voltagesfor power supply interfaces of the Beidou signal receiving module, a singlechip and a voice broadcasting module through voltage conversion modules, an interactive touch screen displays current coordinate points in real time, the coordinate points with obvious errors can be corrected through the screen, and the unit price of the operation can be input through the interactive touch screen for pricing in a pricing mode. The singlechip receives the longitude and latitude data sent by the Beidou signal receiving module in real time and filters the data to obtain more accurate longitude and latitudedata. When an area is measured, the singlechip directly outputs a result to the interactive touch screen for display. In the pricing mode, in addition to displaying the measured area, the unit priceinformation input by the screen is received, and the unit price multiplies the area and then the pricing result is displayed on the screen.

Owner:JIANGSU UNIV

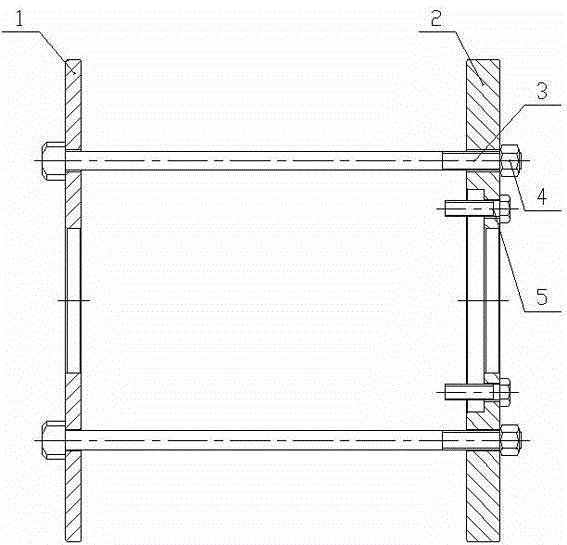

Detachable internals maintaining support

ActiveCN102568630AEasy to installEasy to disassembleNuclear energy generationReactor fuel elementsNuclear powerEngineering

The invention relates to a reactor internals maintaining tool for a nuclear power station, in particular to a working support for maintaining reactor internals of the nuclear power station. The support comprises a vertical frame and a platform frame, wherein the vertical frame and the platform frame are fixedly connected by a positioning assembly II, and a positioning assembly I is fixedly connected on the platform frame. The support has the advantages that (1) the whole support can be installed and dismantled conveniently and is convenient for remote transportation; (2) as all components of the whole frame are positioned by positioning pins and locked by bolts, and the position precisions are adjusted by gaskets during connection, the support has high positioning and adjustment precision and reliable and safe positioning; and (3) as the support is mainly in an I-steel frame structure, the support has good rigidity in the forced direction, simple overall structure and light weight.

Owner:QINSHAN NUCLEAR POWER

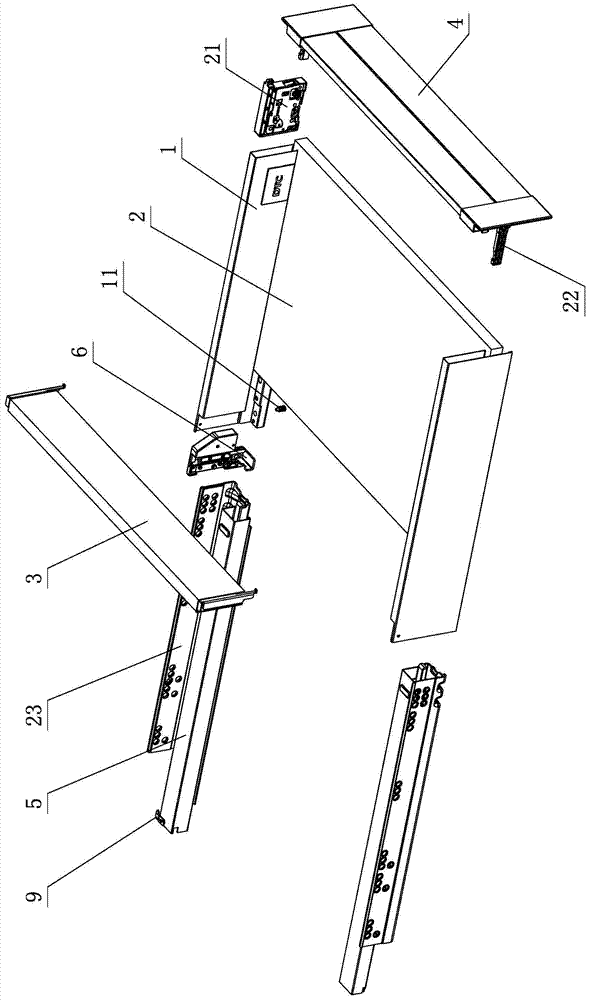

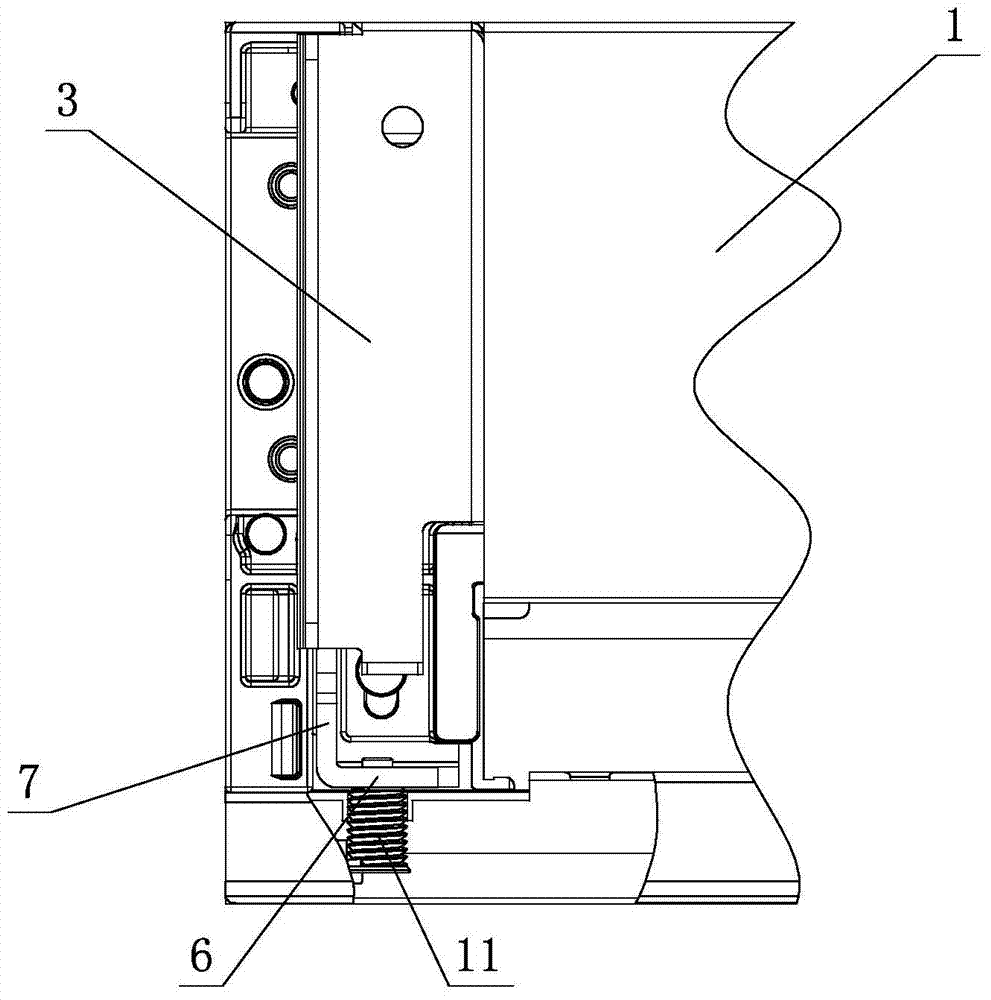

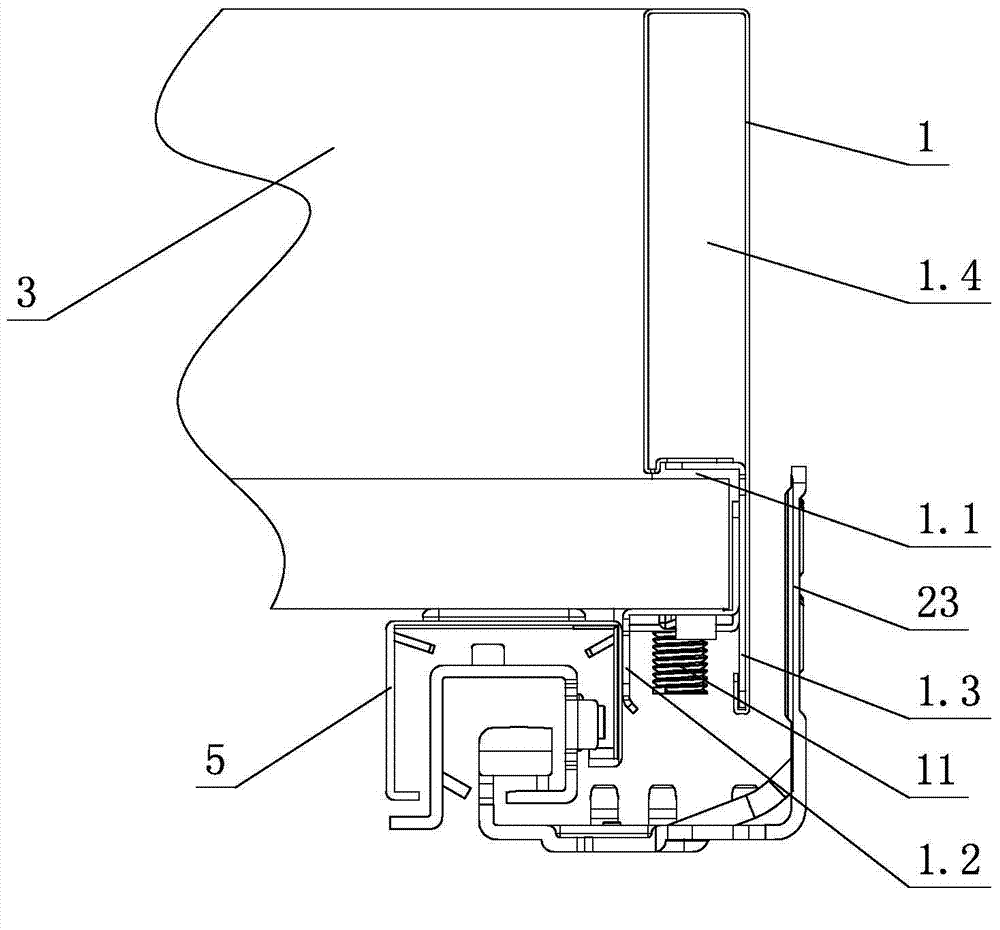

Furniture drawer hidden adjusting device

A furniture drawer hidden adjusting device comprises a frame, a base plate, a rear plate, a front panel and a sliding rail assembly. The adjusting device is arranged on the frame and used for adjusting rising and lowering of the frame relative to the sliding rail assembly. A bearing portion connected with a pulling rail of the sliding rail assembly in a matching mode is arranged on the adjusting device, and an operation part is arranged on a bottom area of the adjusting device facing the frame. The bearing part achieves vertical movement of the frame relative to the pulling rail by rotating or wrenching the operation part. By means of structure improvement, the operation part of the adjusting device is arranged in a U-shaped area of the frame in a hidden mode, and the hiding performance of the adjusting device is effectively improved. Meanwhile, a user can adjust the operation part of the adjusting device on the U-shaped area of the frame through a tool or manually to enable the guide portion of the adjusting device to move vertically and linearly relative to the guide matching portion of a rear connection device, finally adjustment of inclination position of the frame relative to the sliding rail assembly is achieved, and the practicability is high.

Owner:伍志勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com