Lining plate device for impact plate of impact crusher

An impact crusher and impact plate technology, applied in grain processing and other directions, can solve the problems of insufficient connection strength between the lining plate and the impact plate, the impact plate liner falling off, and the damage of connecting bolts, etc., so as to reduce maintenance time and prolong use. The effect of life, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

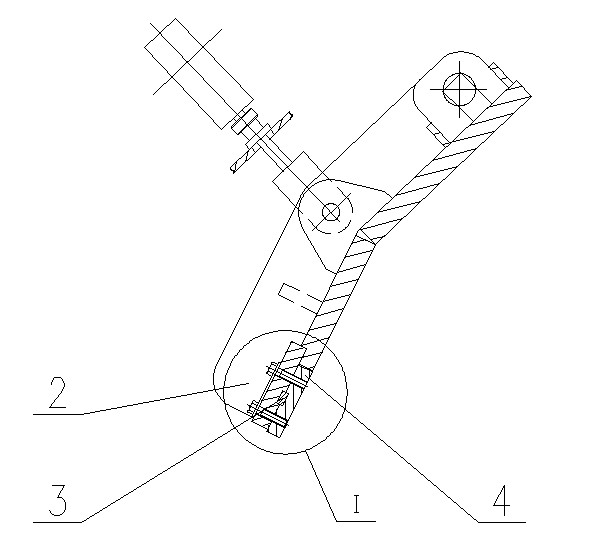

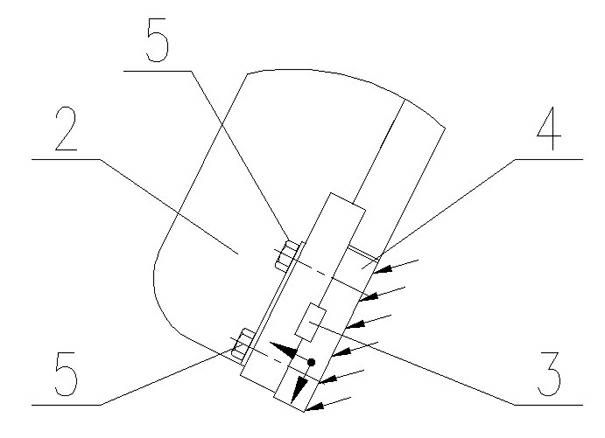

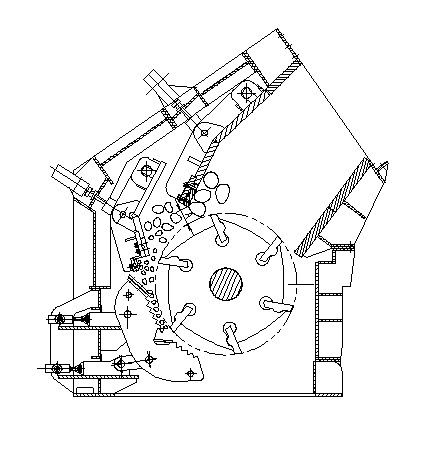

[0012] Refer below figure 1 , 2 , 3, 4 further explain the patent.

[0013] Such as figure 1 , 2 As shown, the liner device of the impact plate of the impact crusher includes the impact plate body 2 and the liner plate 4, and the liner plate is fastened on the impact plate body by connecting bolts 5. A horizontal pin key mechanism is arranged between the contact surface of the liner plate and the impact plate body. The pin key mechanism is to open a transverse square groove at the corresponding position on the contact surface of the impact plate body and the lining plate, and key the square key pin 3 into the square hole formed by the fastening of the two square grooves.

[0014] Such as Figure 4 As shown, the pin key mechanism can also be such that a transverse square groove is opened on the contact surface of the counterattack plate body and the lining plate, corresponding to the position, and a transverse square convex groove is arranged on the contact surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com