Detachable internals maintaining support

An internal component, split technology, applied in the direction of reactor fuel elements, reactor, climate sustainability, etc., to achieve the effect of light weight, simple overall structure, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

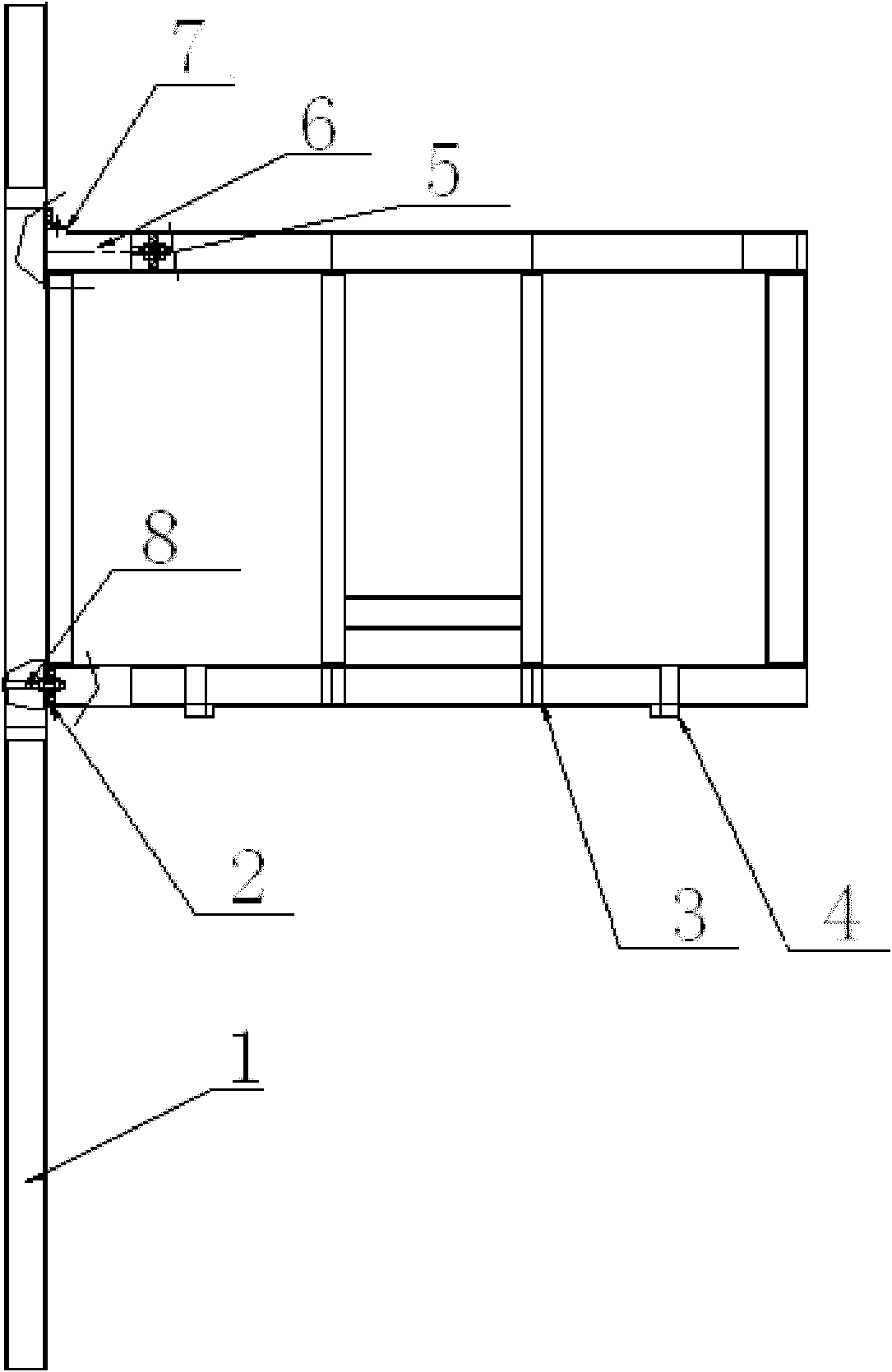

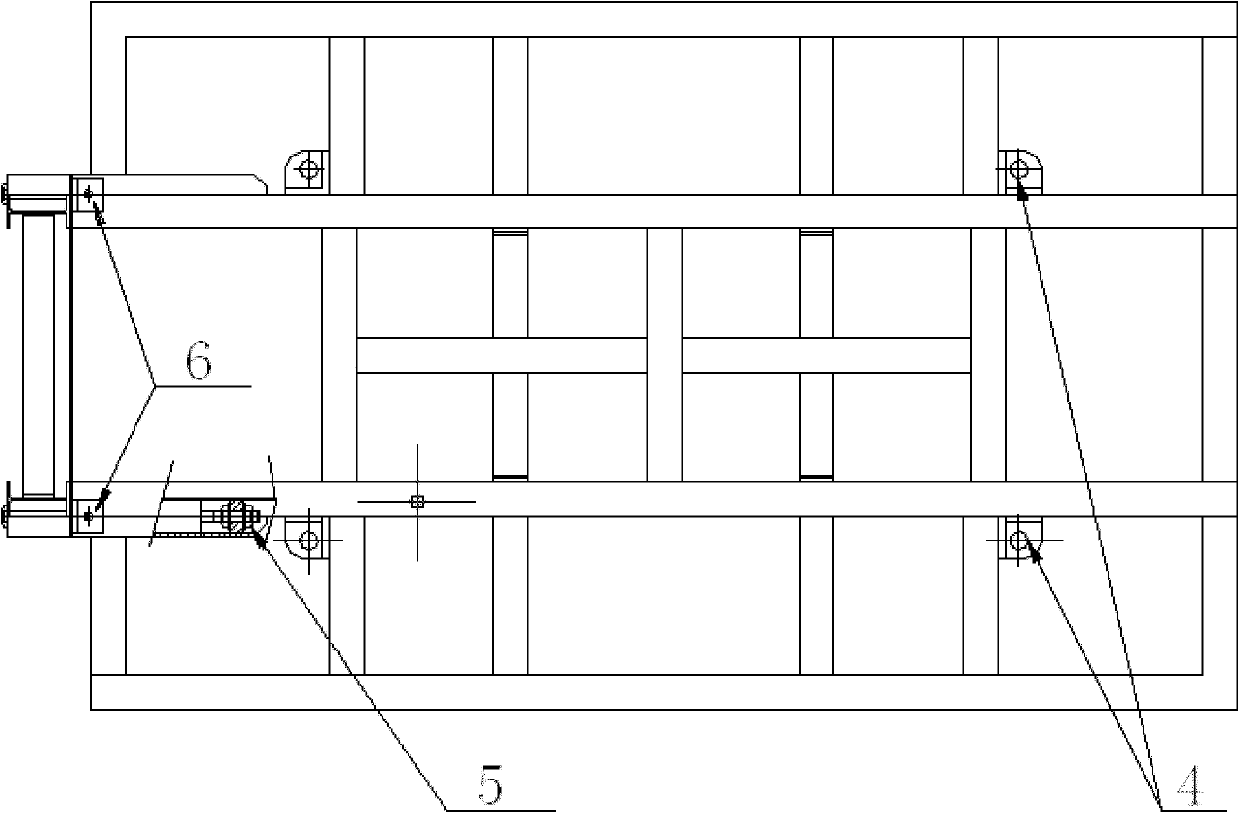

[0021] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0022] The structure of a detachable internal component maintenance and repair bracket and its installation and debugging method will be described in detail below in conjunction with the accompanying drawings.

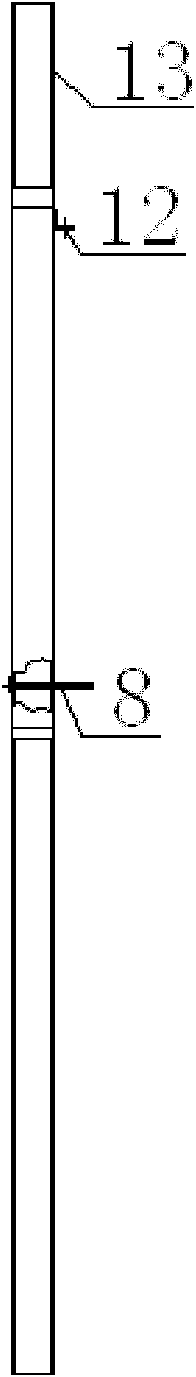

[0023] Such as Figure 1-5 As shown, the present invention is a working bracket used during the maintenance and repair of nuclear power plant reactor internals. It mainly includes: a stand 1, a lower adjustment pad 2, a platform frame 3, a positioning assembly I4, an upper adjustment nut 5, a positioning assembly II6, Upper adjustment pad 7, lower adjustment nut 8.

[0024] Wherein, the stand 1 includes a crossbeam 9, an I-beam 10, an auxiliary support 11, a positioning piece 12, and a flat plate 13. The I-beam 10 is located on both sides of the flat plate 13. 10 is vertical, the positioning planes 22 of the two positioning members 12 are equal in heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com