Flexible supporting method of large-aperture lens

A support method and large aperture technology, applied in installation, optics, instruments, etc., can solve problems such as field curvature and astigmatism, and achieve the effects of light weight, good vibration reduction performance, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

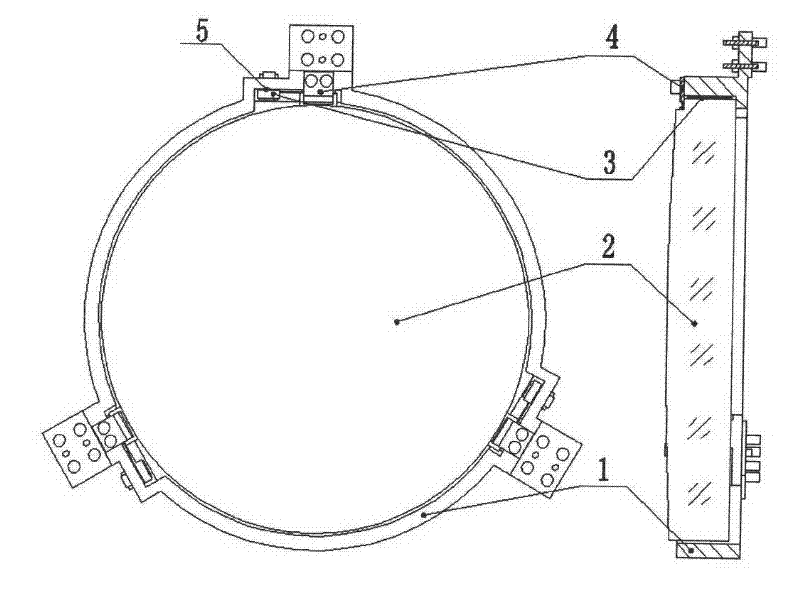

[0027] Such as figure 1 As shown, it is a schematic diagram of the supporting structure of the lens supported by the method of the present invention. In the figure, 1 is a mirror holder, 2 is a large-aperture lens, 3 is a flexible element, 4 is an axial pressure plate, and 5 is an adjusting gasket. The main steps of the lens flexible support method of the present invention are as follows:

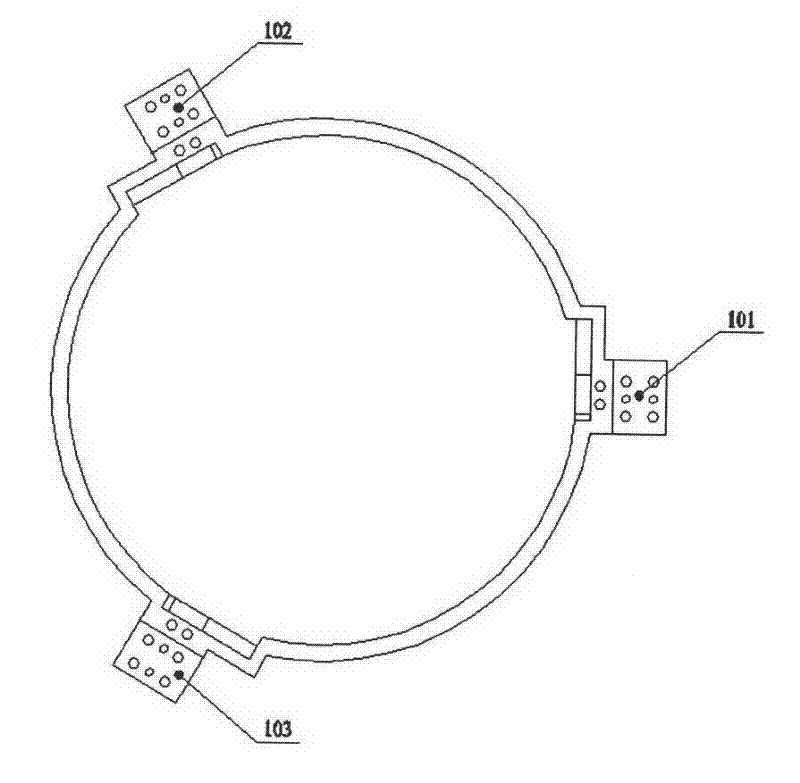

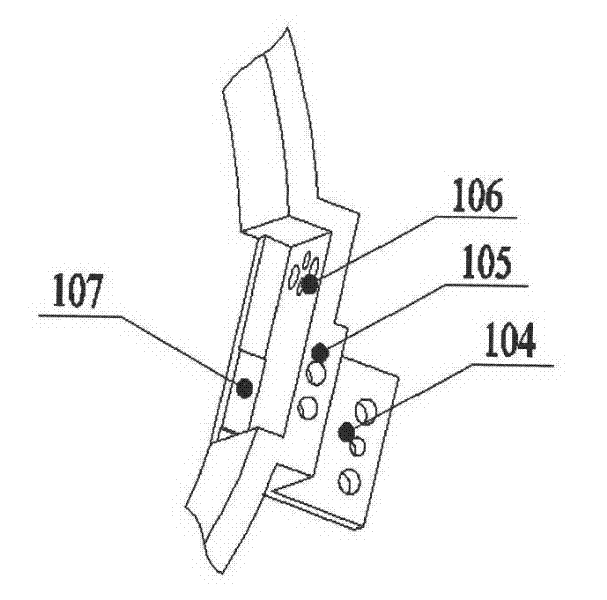

[0028] (1) if figure 2 and image 3 As shown, three bosses 101-103 are processed at intervals of 120 degrees on the outer side of a circular mirror base 1 with a certain thickness, and a connection part 104 with a cuboid structure is processed on the outside of each boss. The connection part 104 The width of the connection with the boss is half of the outer width of the boss, the mounting hole 105 and the pin hole 106 are machined along the radial direction of the mirror base 1 on the other half of the width of the outer side of the boss, and the connecting part 104 is machined and insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com